Company details for:

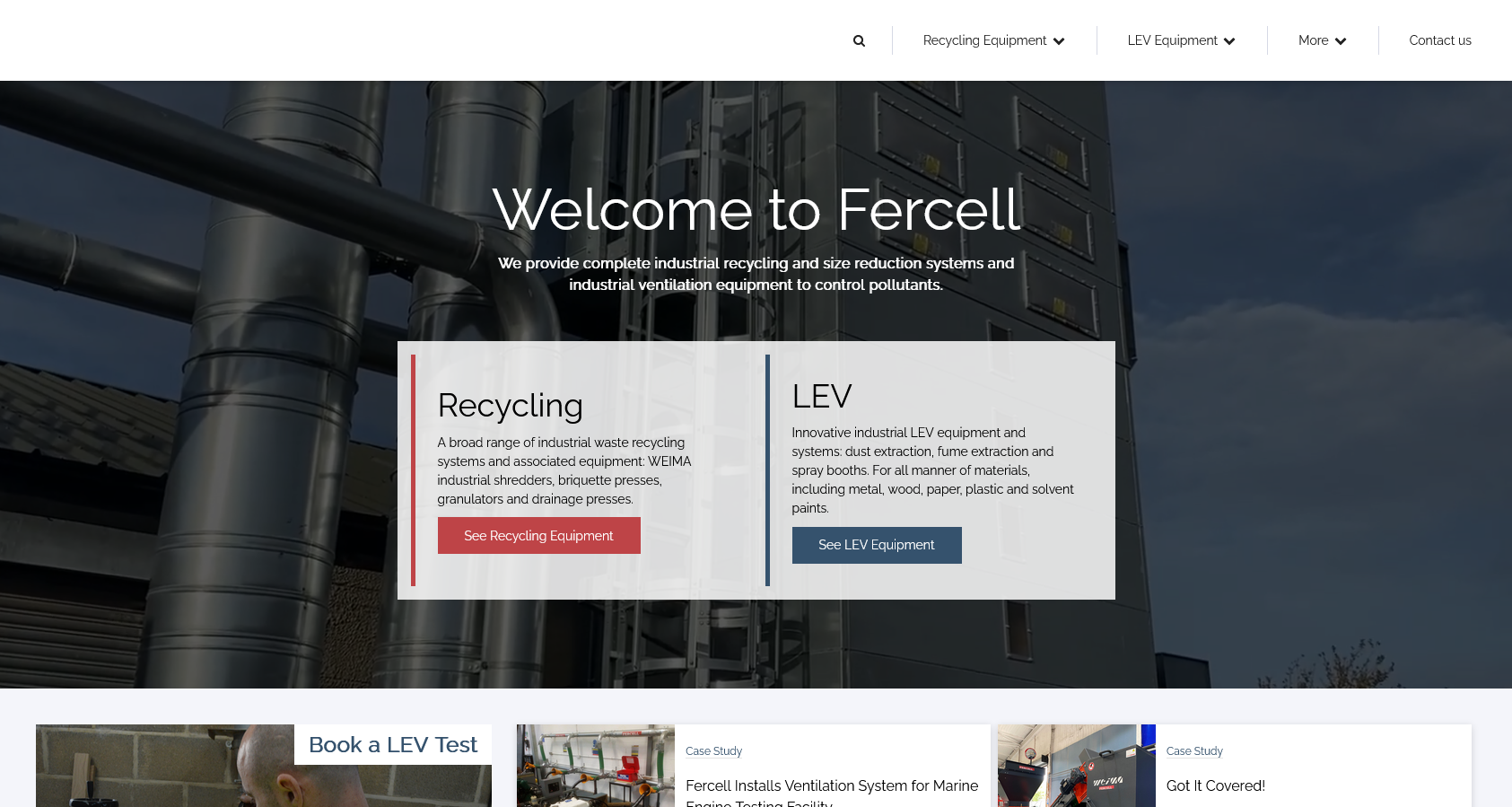

Fercell Engineering Ltd

Unit 1,

Old Mill Lane,

Aylesford,

Kent,

ME20 7DT,

United Kingdom

Quick Links:

Products / Services

WL600 Industrial Wood Shredder

WL4 − WL8 Industrial Timber Shredders

WL10 − WL20 Industrial Shredders

Capable of shredding large quantities of both linear and lump wood off-cut timber waste, due to the rotor widths which range from 1,000 mm to 2,000 mm, depending on design configuration. It’s driven by electric motors with power outputs from 28 kW to 110 kW.

WLK4 − WLK20 Industrial Shredders

The WEIMA WLK Series of universal single shaft industrial shredders are economical, powerful, robust and reliable. Designed for high throughput size reduction of the broadest range of plastic production waste, fibres, textiles, carpets, pipes, automotive parts, blow-moulded plastic based materials such as PET bottles, PE/PP bottles, containers and buckets.

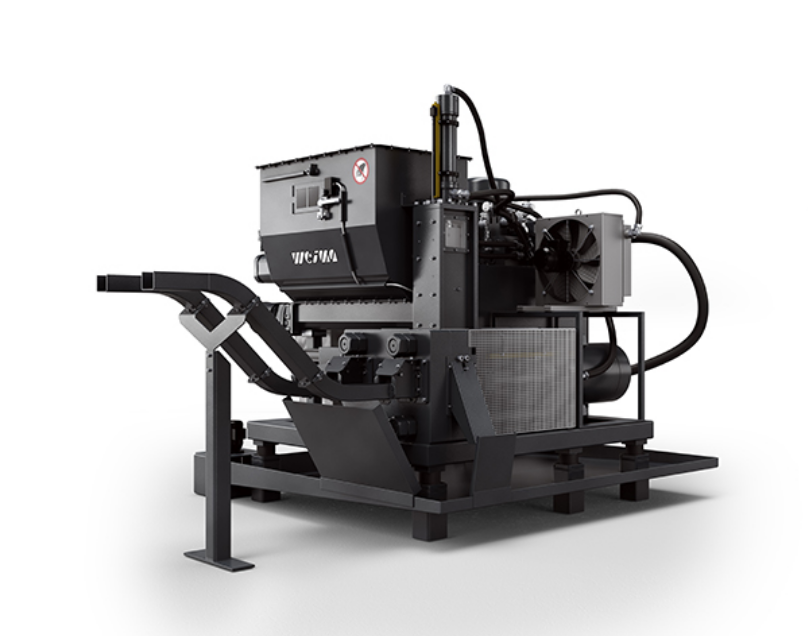

W5 Series Industrial Shredder

What makes this W5 industrial shredder series stand out is the newly-designed material feeding system. Instead of the typical horizontal ram, this industrial shredder operates a “swing-ram,” which is guided on rolls. This makes the W5 shredder compact and easy to maintain, while also allowing for an aggressive material in feed.

TH514 − TH820 Briquette Press Series

Using innovative cylinder technology, enhanced hydraulics and progressive sensor technology to provide the power to produce stable, round briquettes, the TH Series can be equipped with hydraulic cooling and automatic packaging systems for continuous operation.

C Briquette Press Series

Their sturdy design, low energy consumption and small footprint make them a favourite amongst small to medium operations demanding a low maintenance briquette solution with self diagnostic technology.

TH800 − TH900 VARIO+ Briquette Press Series

Using innovative cylinder technology, enhanced hydraulics and progressive sensor technology to provide the power to produce high density, round briquettes, the TH-VARIO+ Series can be equipped with hydraulic cooling and automatic packaging systems for continuous operation.

TH-VARIO+ presses operate with two integrated cylinders equipped with suction valves enabling a faster press-stroke to create denser briquettes with higher calorific values, ideal for biomass burners.

TH1500 Briquette Press Series

Capable of processing voluminous materials such as wood, paper, metal and plastic (up to 6,000 kgs/hr) into extremely dense rectangular briquettes, achieving significant volume reduction, liberating valuable storage space and simplifying transportation.

Equipped with a powerful axial piston pump hydraulic system, powered by an energy-efficient electric motor, operating two integrated cylinders equipped with suction valves enabling a faster press-stroke to create denser briquettes with higher calorific values, ideal for biomass burners.

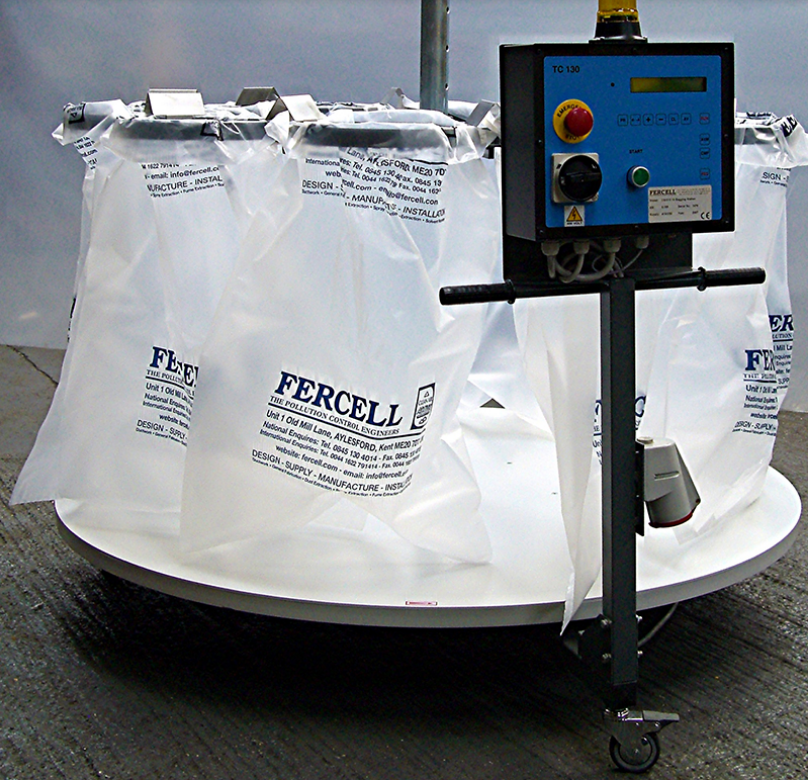

Briquette Bagging Solutions

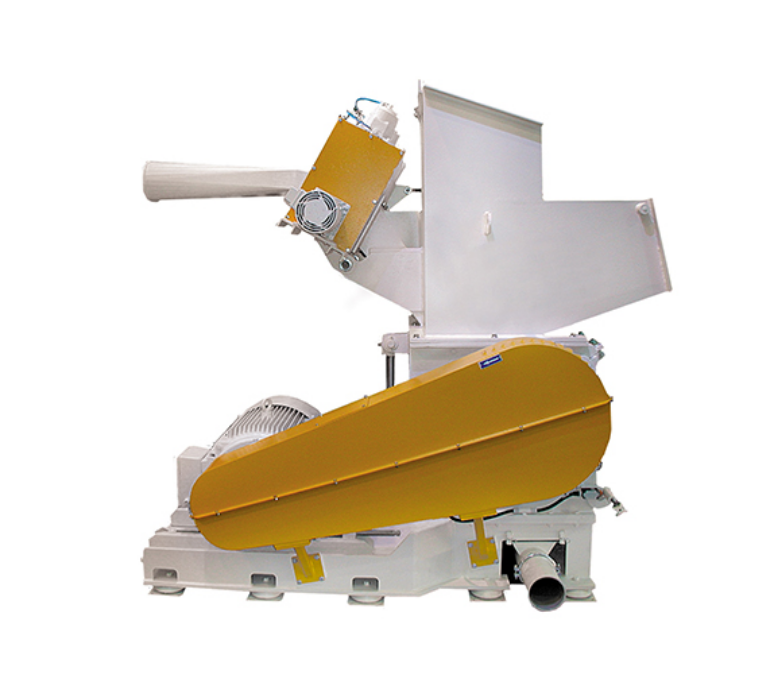

WSM Granulator Series

Either as a stand-alone solution or as stage of a two part process (downstream of a primary shredder) the WSM is a straightforward and economical size reduction solution.

The various sizes and different versions make it possible to match the WSM to your specific material and throughput requirements.

Puehler C Series

Puehler G Series

The use of machines in the ReWork process places high demands on quality, machine safety and hygiene standards. Weima have developed drainage presses specially optimised for ReWork applications, which are HACCP-compliant and achieve the highest material throughput rates with maximum reliability. With a production of 300 mm pellets the PUEHLER G.300 ReWork achieves an output of up to 12 m³ material per hour.

Puehler E Series

The PUEHLER drainage press produces pellets with an output of 200m. The Puehler series work electro-hydraulically by means of different hydraulic cylinders.

Puehler A Series

The WEIMA range of hydraulic drainage presses are used to dispose of old labels in bottling facilities, not only efficiently, but economically too. The PUEHLER drainage press produces pressed labels with an output of 200m.The discharge labels are picked up by the label press, before being pressed and transported drip-free into a container.

F Series − 250-450 Indoor Filter

Manufactured from heavy-gauge corrosion resistance steel, with a hard-wearing painted finish, it is designed to protect and look good for many years of service.

TRV Series − Dust Extractor

Classified as low pressure − high volume, they are intended for use with close coupled ducting systems for the capture, transportation and separation of course dust participate.

GFO − XT

GFO XT − up to 99% filtration of oil mists.

Q recommended from 1.800 to 7.200 m³/h.

Q peak load: up till 9.600 m³/h.

From 14,7 to 58,8 m² polypropylene filter cartridge.

20 litres reservoir with discharge tap and sight glass for oil level control.

Comes in galvanised finish.

Pre-filtration can be installed.

The filter media in polypropylene is a filter membrane that can handle mists and fumes from all types of cutting oil such as pure oil, semi-synthetic and synthetic oils and water-based solutions.

GeoGo Series

WW Series − Water Spray Booth

DB Series − Spray Booth

U Granulator Series

LM Granulator Series

LP − SR Granulator Series

Generally LP versions will be used for PVC profiles, with the specially designed rotor grabbing and pulling material into the cutting chamber, while the SR version are better suited for the most demanding applications such as extremely thick-wall PVC, PP and PE pipes to achieve optimum throughput, through an enclosed hopper to ensure safe and reliable size reduction.

SM Series Granulators

The SM Series rotor and stator knives are arranged counter angle to each other to produce a true scissor cutting action. The result is a cleaner, more uniform granulate with minimal heat build-up and minimal energy consumption and sound output.

About us

Our Products Include:

- Shredders

- Briquette Presses

- Dewatering presses

- Granulators

- Drainage Presses

- Dust Extractors

- Fume Extractors

- Spray Extractors

- Spares & Consumables

In order to provide the most up-to-date solutions, we constantly explore new technologies.

We provide an extensive range of industrial shredders, briquette presses, and granulators, so that you can recycle efficiently, responsibly, and often for revenue.

By using our ventilation systems, your factory will be able to safely and legally extract all types of dust, exhaust fumes, welding fumes, and paint spray particles.

In addition to our headquarters in Aylesford, Kent, we have a regional office in Stoke-on-Trent, West Midlands.