Company details for:

Firstpress Plastic Moulders Ltd

15 Pritchett Street,

Birmingham,

West Midlands,

B6 4EH,

United Kingdom

Quick Links:

Products / Services

Concept Development

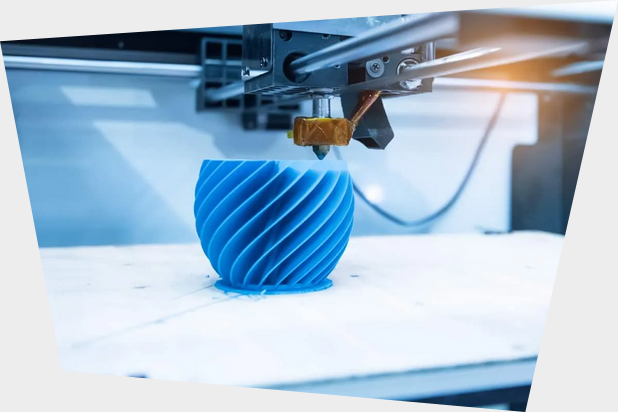

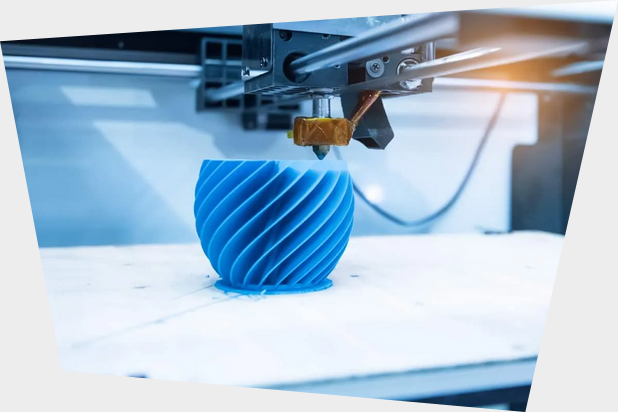

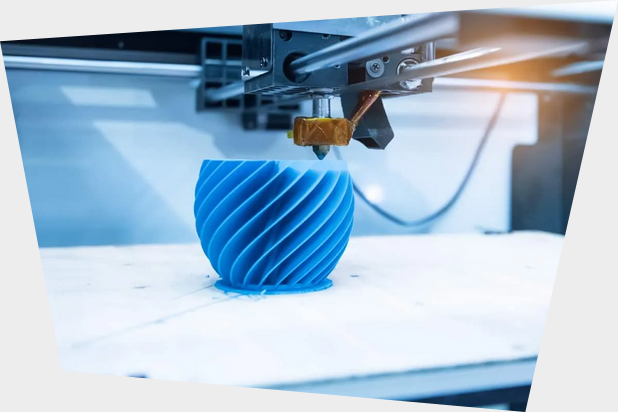

Prototyping for the Injection Moulding Industry

For every great idea that gets successfully developed, there are thousands of great ideas that don’t see the light of day. Great ideas come and go like seeds blowing in the wind. Only when they stop blowing around do they find a space to grow and develop.

If you have an idea for an injection moulded product, but don’t know where to start or how to develop your idea, then come and talk to us at FirstPress. We love a challenge and like nothing more than to see our customers develop their original concepts into successful and profitable products.

Design

Plastic Injection Moulding Design Services

Our pool of highly experienced designers, under the watchful eye of General Manager, Djilani Daoudi, know what it takes to design for injection moulding. There is no ‘one-size-fits-all’ solution.

Each moulding material has different qualities. Flexibility, rigidity, opacity and shrinkage all have to be taken into consideration when designing a product for plastic injection moulding. Your project is in safe hands with FirstPress.

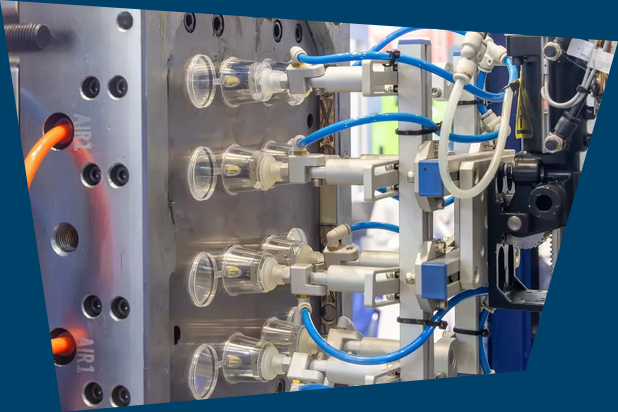

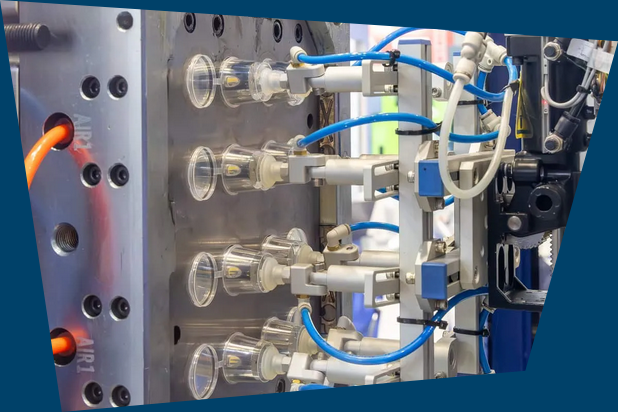

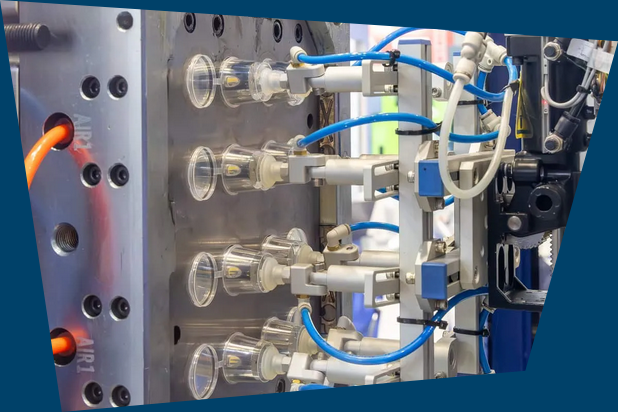

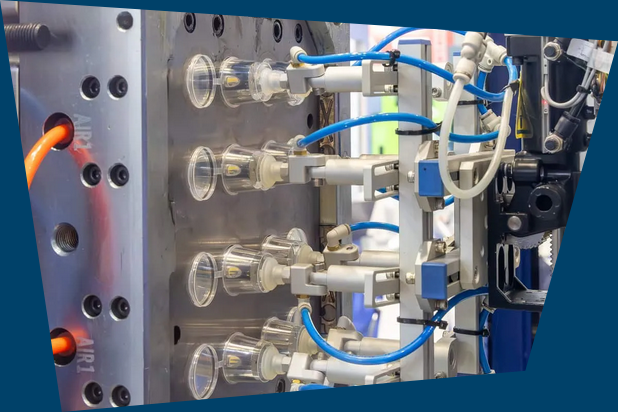

Tool Design & Manufacture

Inject Mould Tool Design in Birmingham

Injection Mould Tools come in many forms, from small simple tools not much bigger than a shoebox, to giant tools the size of an elevator, weighing several tons.

At FirstPress we know that tool design is key to a quality result. The time and effort put into the tool design and manufacture is greatly rewarded with a far superior end result. Whether it be an aluminium tool for small quantity runs or a fully-hardened steel tool designed for long life and high quantities, we have the expertise to get it right first time.

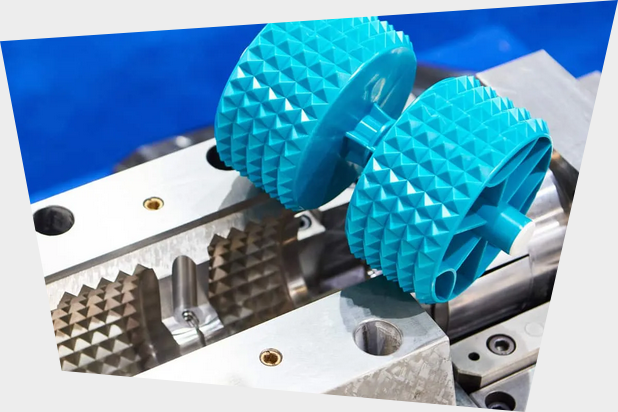

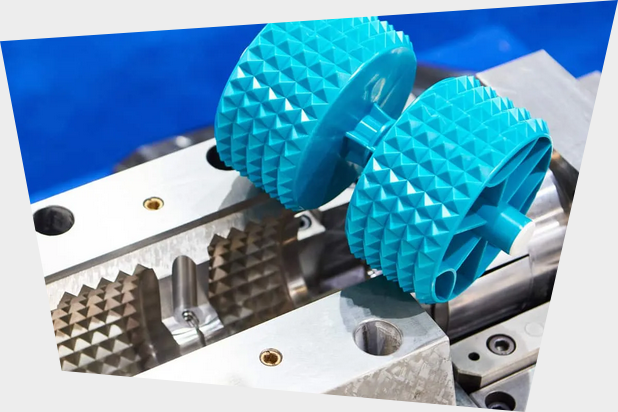

Sampling & Prototypes Service

Before any full production run, prototypes and sample mouldings are produced and presented to the customer. This gives the customer the opportunity to examine the full size product sample, checking the colour and textured finish for example, ensuring it meets with their expectations.

It is at this stage that we also check the quality of the end product and ensure that there are no minor defects present. At this stage we can still make minor changes to the mould tool if required.

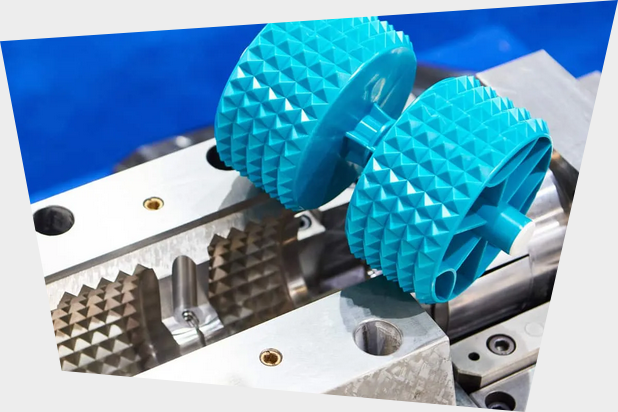

Moulding & Assembly Service

In addition to a full spectrum of plastic injection moulding services, we also provide a complete assembly service of additional component parts, such as threaded inserts for example. failures can occur due to … Brass and aluminium are common choices. for example when printing, labelling, assembly and packaging

It is at this stage that we also check the quality of the end product and ensure that there are no minor defects present. At this stage we can still make minor changes to the mould tool if required.

Packaging & Delivery Service

Our packaging and delivery service includes printing, labelling, full parts assembly and appropriate packaging. During this process further quality checks are carried out before each carton is clearly labelled and signed off for delivery.

Cartons are then carefully stacked onto pallets and cling-wrapped before being loaded by fork-lift onto our curtain-sided Mercedes-Benz Atego delivery vehicle.

Plastic Injection Moulders

Firstpress Plastic Injection Moulders is a trusted leader in precision plastic moulding, delivering high-quality, cost-effective solutions for a wide range of industries.

With decades of experience, we combine technical expertise with state-of-the-art technology to produce complex, high-performance components. Our commitment to quality, innovation, and customer satisfaction has earned us a reputation as a preferred supplier for sectors that demand excellence.

About us

Firstpress Plastic Moulders Ltd is a reliable expert in precision plastic moulding, providing efficient, high-quality solutions tailored to various industries.

Backed by decades of experience, we blend advanced technology with technical know-how to manufacture intricate, high-performance components. Our focus on quality, innovation, and client satisfaction has made us a trusted supplier in demanding industries.

At Firstpress, we focus on delivering precision, efficiency, and dependability. Our end-to-end process—from initial concept to final delivery—guarantees smooth production and consistent, high-quality results.

Our Services Include:

Concept Development

Have an idea for an injection moulded product but unsure how to move forward? Talk to us at Firstpress. We thrive on challenges and take pride in helping customers transform their concepts into successful, market-ready products.

Design

Every moulding material has unique properties—such as flexibility, strength, opacity, and shrinkage—that must be carefully considered during the design process. At Firstpress, we ensure your project is expertly handled from the start.

Tool Design & Manufacture

At Firstpress, we understand that precise tool design is essential to achieving exceptional results. Investing time and care in tooling pays off in product quality—whether it’s an aluminium tool for short runs or a hardened steel tool for high-volume production, we get it right the first time.

Sampling & Prototypes

Before starting full production, we create prototypes and sample mouldings for customer review. This allows clients to assess the product’s size, colour, texture, and finish, ensuring it aligns with their expectations before moving forward.

Moulding & Assembly

Along with our comprehensive plastic injection moulding services, we offer complete assembly of additional components, such as threaded inserts. We also handle tasks like printing, labelling, and packaging, ensuring quality and precision in every step. Brass and aluminium are often used for these parts.

Packaging & Delivery

Our packaging and delivery service covers printing, labelling, complete assembly of parts, and secure packaging. Throughout this process, we perform additional quality checks to ensure each carton is properly labelled and approved for delivery.

With our expertise in plastic injection moulding, combined with a skilled team and cutting-edge manufacturing techniques, we are able to meet the highest standards across various industries.

Whether handling small-batch prototypes or large-scale production, we offer customised solutions that ensure top-notch performance and long-lasting durability.

Whether you're starting a new project or seeking expert guidance on plastic injection moulding, our team is ready to assist. Get in touch with Firstpress to discuss your needs and explore how we can support your manufacturing goals.

Images

Reviews

Trade Associations