Company details for:

Franklin Hodge Industries Ltd

Quick Links:

Products / Services

Galvanised Liquistore / Firestore

Using site assembled components, consisting of overlapped and bolted galvanised steel panels with either a trough deck or aluminium sectional site assembled cover, together with an internal, open top membrane liner, the Liquistore ® / Firestore ® offers a truly long life and low maintenance water storage system.

Aluminium Liquistore / Firestore

In addition the tank is fitted with an open top internal membrane liner. The assembled tank is clamped down with anchor bolts fixed to the base.

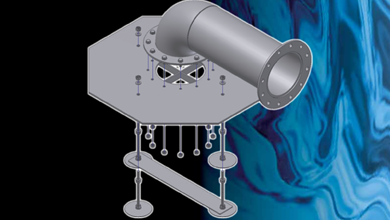

VORTIBREAK® Anti-Vortex Plates

U.K. Loss Prevention Certification Board (LPCB)

U.S. Factory Mutual (FM Global)

For further information contact us on sales@franklinhodge.co.uk or telephone our team on 01432 269605

Galvanised Tritainer

Using triangular shaped galvanised steel panels which make up 1.0m2 modules that are then bolted together on site, a rapidly assembled rectangular tank that can fit into small and difficult spaces can be provided. Internally a hot vulcanised tailor made membrane liner is fitted to the tank. Any length and width can be catered for, with a maximum height of 2.575m.

Galvanised Liquitainer / Firetainer

Using steel sections of either rectangular, circular or u-beams, a structure is formed which eliminates the need for internal bracing. Galvanised steel panels are bolted between the sections and the interior is fitted with an open top tailored membrane liner. Alternative covers are available either flat with a raised ball valve housing for indoor use, or with a low profile pitch for outdoor use.

Glass Coated Liquistore

Water Tank Refurbishment

• Fire sprinkler

• Potable / Cold water services / Building services

• Industrial process water

Refurbishment of existing tanks can save both time and money, as well as cutting to the minimum the inconvenience of a shut off water system, be this for a fire sprinkler or potable / cold water services / building services tank. In the case of potable / cold water services / building services tanks, it is vitally important that the stored water be kept in a wholesome condition, as required under the Water Supply (Water Fittings) Regulations 1999, Health & Safety at Work Acts and Control of Substances hazardous to health regulations.

Tank Inspection & Refurbishment Service

External Inspection & survey

Internal inspection & survey following a full drain-down of the tank

Internal inspection & survey with the tank full, using a remote controlled submarine camera unit

External Inspection & Survey. What we provide for our customers:

Visual inspection and assessment, including if necessary the use of an ultrasound-scanning device, to assist in the assessment of the condition of:

Tank wall sheets

Pipe work, spools and flanges

Covers

Ancillary equipment, including immersion heaters, valves, contents gauges and level control switches

Ladders, platforms and hand-railing

Top and bottom rolled angles

Holding down brackets and bolts

Water Tank Liners

Underwater Camera

A video of the interior of the tank can be produced and presented as part of an assessment report. Using the submersible camera unit means that the tank does not need to be drained, thereby avoiding the need of increased insurance premiums in the case of a fire tank and for alternative water supplies to be arranged, in the case of drinking water or process water tanks. The cost replacing the stored water and the overall environmental impact is eliminated or greatly reduced.

Grain Silos

For over 45 years the Brice-Baker range has been continuously developed to meet the evolving market demand for high quality grain storage and handling equipment. Franklin Hodge Industries building on that legacy have retained capability to design, manufacture, supply and install grain storage plants from the extensive range of Brice-Baker silos, dryers and associated handling equipment provided by market leading partners. Brice-Baker silos are renowned for their robust construction and high galvanising standards, with shallow profile wall sheets and external wall stiffener columns designed for a cleaner discharge and long life.

Services & Support

About us

Franklin Hodge has been a trusted UK manufacturer of water storage tanks, cooling towers, and grain silos since 1973. With over 50 years of experience, we specialise in designing, manufacturing, and installing high-performance systems for a wide range of industries, both in the UK and globally.

We offer water tanks for fire protection, drinking water, and waste storage. Our tanks are designed for durability, easy installation, and long-term reliability. From cylindrical fire tanks to sealed waste storage systems, every product meets the highest safety and quality standards.

Our cooling towers, supplied under the Carter Environmental brand, are engineered for performance and sustainability. We manufacture both forced and induced-draught cooling towers, along with dry air blast coolers, all supported by our dedicated UK servicing and spare parts team. These systems are ideal for industrial sites requiring efficient and reliable water cooling.

For grain storage, we supply Brice-Baker silos, known for their strength, innovative design, and long lifespan. These silos are made from galvanised steel and supported by drone-assisted inspections, refurbishments, and expert servicing to maintain optimal condition.

As part of our commitment to innovation, we use advanced drone and ROV technology to improve site safety and inspection accuracy. We also offer full project support, from design and manufacture to installation and maintenance, ensuring a smooth and efficient process for every client.

Franklin Hodge delivers trusted solutions that stand the test of time and are designed to meet your needs, backed by expert service.

Sponsored Links

Reviews

Trade Associations