Company details for:

GB Innomech Ltd

Quick Links:

Products / Services

Bespoke Automation

GB Innomech take a step by step approach to evaluate the project approach, feasibility and the risk.

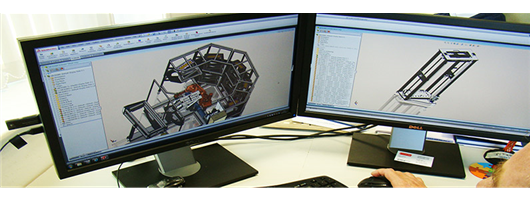

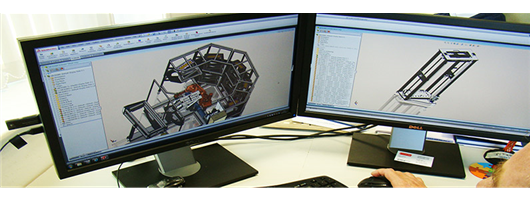

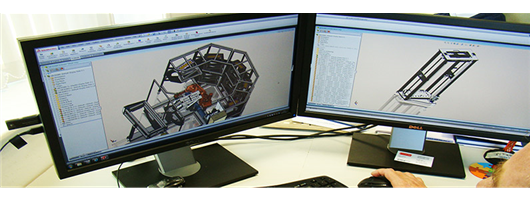

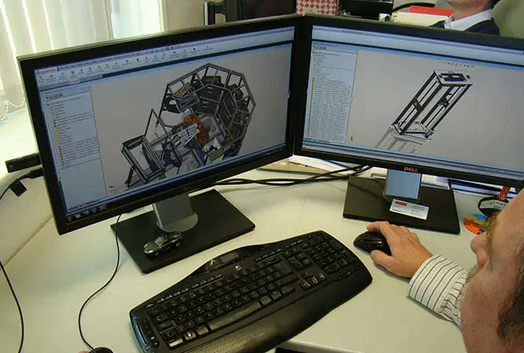

We have the expertise and experience to analyse, design and implement prototypes or full industrial process automation or laboratory automation equipment.

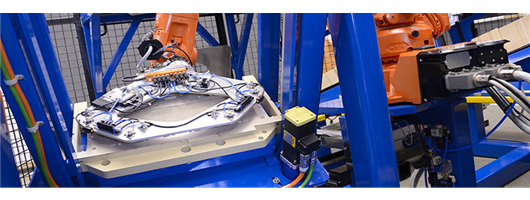

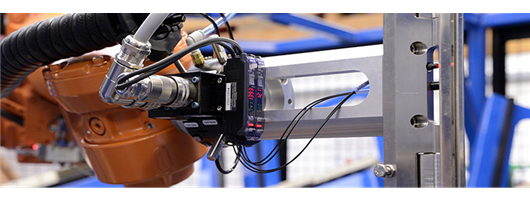

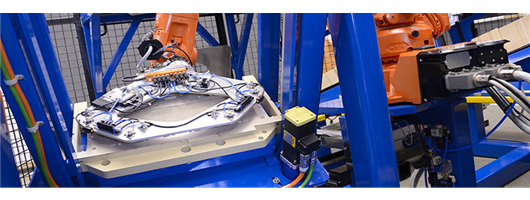

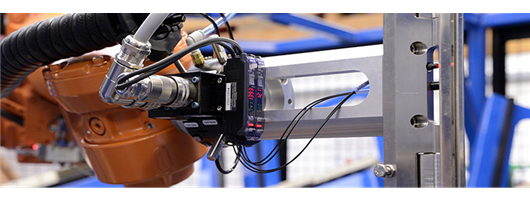

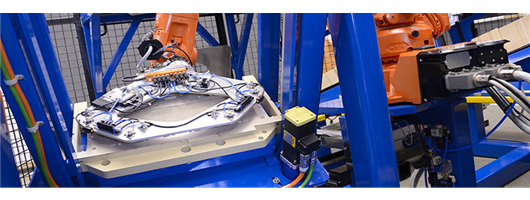

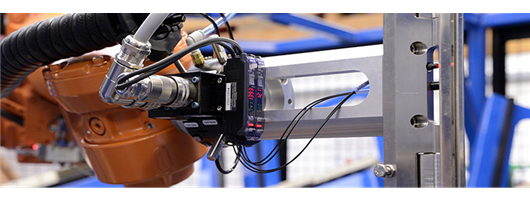

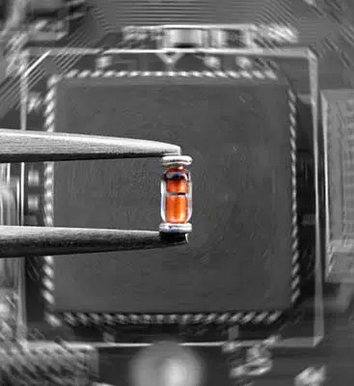

We do this across all industry sectors, using diverse technologies, including vision inspection systems, robotics and accurate product placement systems for a range of clients.

Medical Device Automation

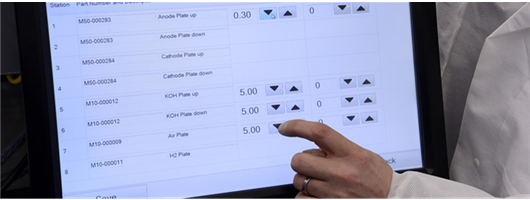

Peter leads a multi-disciplinary team to design and build automation equipment for developers and manufacturers of products such as drug delivery pens, contact lenses, diagnostic kits and surgical instrumentation. Innomech offers everything from feasibility studies through to large-scale system builds. Every system is developed in parallel with a detailed validation document package, including Installation and Operational Qualification (IQ/OQ), CFR21 part11 conformity, Gauge R&R and other relevant studies to enable fast and low cost regulatory compliance.

The company’s track record includes developing machinery for most of the world’s top pharmaceutical companies, as well as many early-stage technology businesses looking to bring first products to market.

Renewables

We have also worked on projects using vision systems to reduce product waste and the recovery of chemicals which otherwise would have gone to waste as well as a feasibility study for solar tracking EV panels.

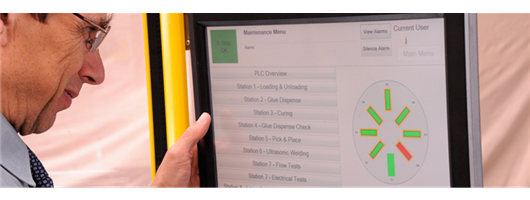

Industrial Automation

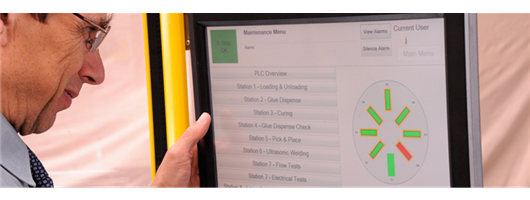

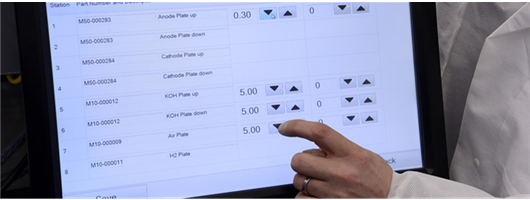

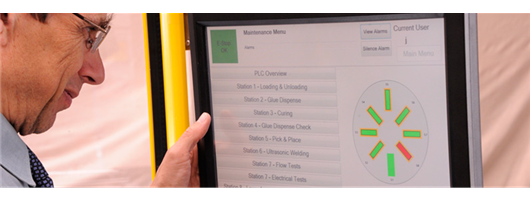

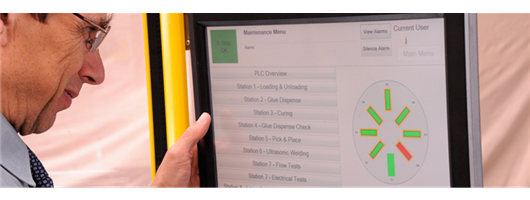

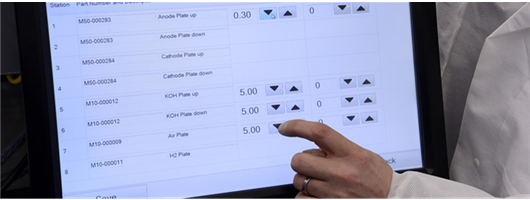

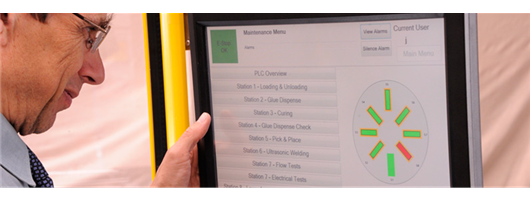

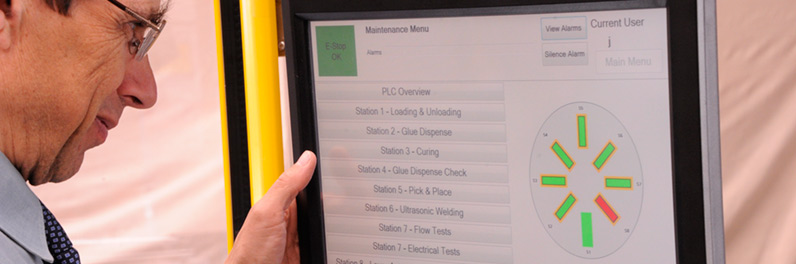

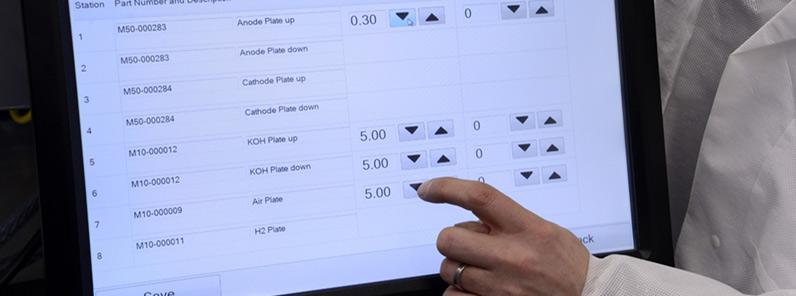

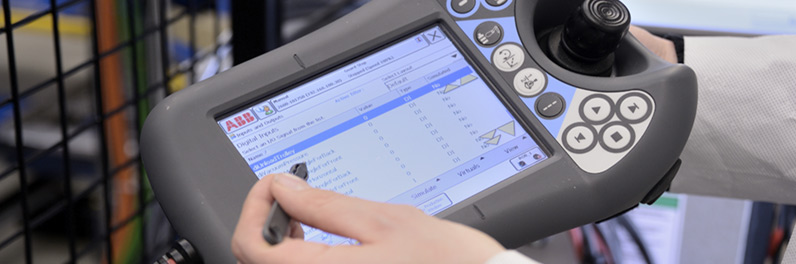

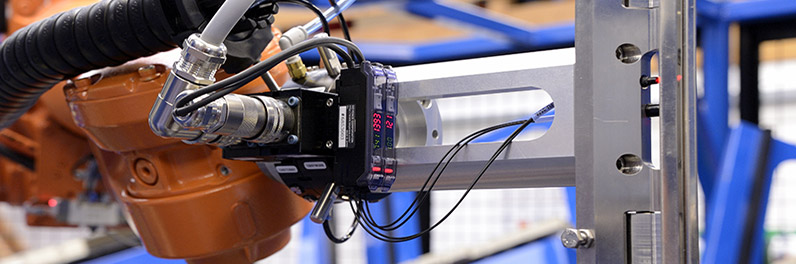

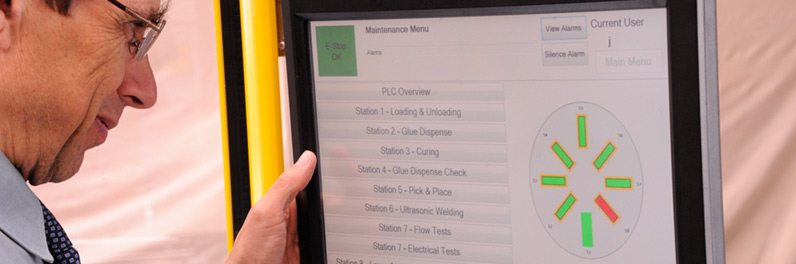

Our special purpose machines often integrate robotic handling, vision systems, PLC / PC based control systems, electro-mechanical and pneumatic positioning systems to reduce risk, increase consistency and quality, and speed up your production processes.

Prototyping & Innovation

Procurement & Build

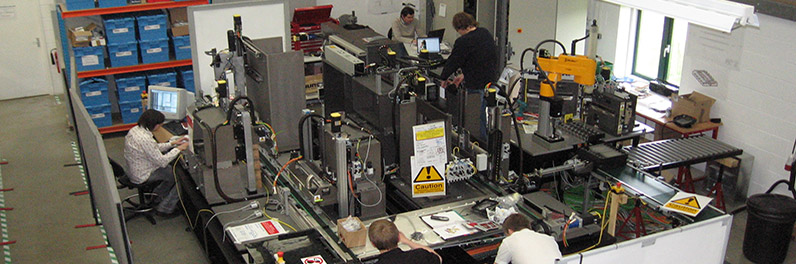

All machines are built within the Innovation centre, the company’s award winning purpose built 60,000 square feet carbon neutral facility.

Integration & Testing

Validation

Innomech can provide a full validation service based on over 20 years experience from delivering projects to the highly regulated pharmaceutical industry.

Innomech’s quality management system, based on Gamp 5 and ASTM E2500, provides revisioned documents, component traceabilty and conformance certification. In addition Innomech can also produce Installation and Operation Qualification (IQ/OQ) documentation as well as Gauge R&R and other relevant studies to facilitate the project implementation.

On-Site Assistance

If for any reason the machine needs to be altered or updated after delivery, Innomech can also provide remote assistance for software updates, on-site assistance for more involved alterations, as well as providing all the relevant documentation for revalidation and revisioned updated specifications.

Robot Integration

Automated Testing

Process Automation

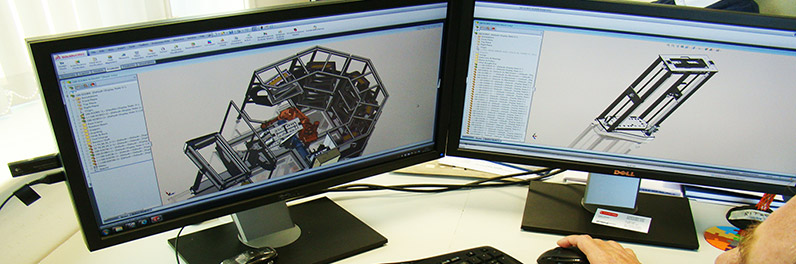

Design & Build

We deliver innovative, purpose-built automated equipment that helps bring your new product to market, giving you a competitive edge, supporting business growth and diversification, and improving efficiency across your entire production process.

Machine Integration

Greater functionality and enhanced manufacturing capability are within reach — with the right automation solutions.

Consultancy Services

We create innovative, purpose-built automated machinery that helps you launch new products, strengthen your market position, expand your business, and boost production efficiency.

Machine Refurbishment

We understand that machinery performance can decline, new technologies emerge, and process improvements become increasingly important. Our engineers review your existing setup to pinpoint enhancements and upgrades that can boost efficiency and modernise key components. Refurbishing your equipment can be a cost-effective way to increase uptime and overall performance.

Send your requirements to info@innomechgroup.co.uk

About us

Automation specialists, GB Innomech Ltd are a leading UK innovator of bespoke automated machinery for the manufacturing industry. Established in 1990, GB Innomech has excelled in many areas designing, developing and producing prototypes and special purpose machines designed to improve productivity, profitability and compliance.

Whether you are looking for a tailor made automation solution or require a build and service of repeat products our approach is founded on the understanding of what you require and the experience of our product knowledge.

Situated in Cambridge, we have years of experience in producing bespoke automated machines including auto control systems, end of line testing workstations, dispensing and assembly.

Our dedicated and highly experienced team excel in all things automation such as robot handling, PLC control, production automation etc and can provide solutions for a range of industries including pharmaceutical, medical, automotive, food & beverage, aerospace and other manufacturing industries.

Bespoke Automation

Here at GB Innomech we pride ourselves with our step by step approach allowing both parties to evaluate the project along with the feasibility and the risk. We analyse, design and implement prototypes or full industrial process automation or laboratory automation equipment.

Medical Device Automation

Dr Peter Woods, a reputable expert in automation for medical devices has vast experience in developing automated manufacturing systems to the pharmaceutical and medical industries.

Renewables

In addition to our skills in the medical industry, we also have experience in building automated systems for building and recycling hydrogen fuel cells helping to reduce product waste and the recovery of chemicals which would normally go to waste.

Industrial Automation

Our diversity in the industrial automation industry and years of unrivalled experience has allowed us to produce automated and special purpose machinery that meet and exceed expectations. We understand your needs and the benefits on which automation can bring to your business and find solutions that can be integrated in to your application. We tailor each machine designing and building innovative solutions that reduce product cost and increase product quality and quantity.

GB Innomech has delivered successful projects within the following areas:

- Precision Handling

- Vision Inspection

- Machine Vision

- Laser Processing

- End of line testing

- Robot Integration

- Precision Cutting

- Needle Winding

- High Accuracy Welding

Images