Company details for:

Greenleaf Contractors

Quick Links:

Products / Services

Sand Jet Cleaning – the Gentle Variation on Sandblasting

We offer a sand jetting service across the UK. Based in Yorkshire, we easily cover Yorkshire, Lincolnshire, Nottinghamshire, and Derbyshire, and often work further afield. Sand jetting—also called grit blasting, sandblasting, shotblasting, JOS blasting, TORC blasting, slurry blasting, or vapour blasting—is a variation we prefer to call “sand jet”. Sometimes referred to as damp blasting, it uses less water than slurry blasting to suppress dust, but isn’t as dry as traditional grit blasting, offering a controlled and efficient surface preparation method.

Dry – Grit Blasting

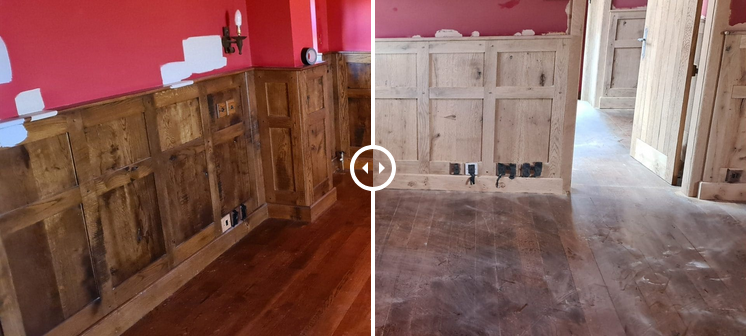

There are times when traditional dry sandblasting offers advantages. These systems are generally more aggressive because the blast pot valve must be more open to maintain a consistent flow of abrasive compared to our wet sand jet system. Without water, the debris doesn’t stick to the cleaned surface, making dry blasting less messy for certain internal work. For example, we use a low-pressure, low-consumption dry sandblaster to remove soot from plaster in fire-damaged properties. When preserving wood rather than cleaning rapidly, dry sandblasting at reduced pressure is our preferred method for internal woodwork.

Environmentally Friendly Chemical Paint Stripping

Sometimes a chemical paint stripper is the best solution. While generally cleaner than abrasive methods, chemical strippers convert paint back to a liquid form, which can still create a mess. We use a slow-acting, hydrogen-peroxide-based product, originally developed in Canada for aircraft, which works over approximately 24 hours. This method is ideal for minimizing surface damage and has been successfully used in projects across Leeds, Lincolnshire, and Nottinghamshire—for example, removing an incorrectly applied sealant coat from tiled surfaces in a new building in Leeds.

While pressure washing is usually the most cost-effective method for removing paint and chemicals, it can damage pointing. More recently, our Thermatec Superheated Steam system offers a gentler alternative, and dry ice blasting is also commonly used for delicate stripping tasks.

Pressure Washing - Rapid Environmentally Friendly Cleaning

Sometimes pressure washing provides a suitable, environmentally friendly alternative to our sand jet system. It is faster, more cost-effective, and effective at removing surface contaminants like algae and grime, with stubborn stains often tackled afterward using the sand jet.

We operate electric, petrol, and diesel-powered machines, with the large diesel unit capable of producing high-pressure hot water and steam. Our Thermatech machine generates medium-pressure superheated steam (150°C), also known as DOFF™. These methods have been successfully applied on projects in Lincoln, Manchester, and Derby.

High Pressure Water Jetting

For more demanding jobs, higher-pressure water jetting is suitable. 500-bar water jets quickly and effectively remove paint from concrete and metal surfaces. One benefit for metalwork—such as railings or fire escapes—is reduced flash rusting compared to grit blasting. High-pressure water removes loose paint and rust while leaving well-adhered primers intact.

If needed, we can use ultra-high-pressure water (up to 2500 bar) to remove all paint. These extreme pressures are generally reserved for tasks like removing playground markings or car park lines.

Low Pressure, Superheated, Steam Cleaning

In recent years, Stonehealth’s DOFF superheated steam system has been widely recommended by conservation officers for gentle surface cleaning. One of its developers later founded Restorative Techniques, and we use their Thermatec machine, which delivers the same service. Superheated steam is highly effective at removing dirt, grime, and even some paints, though it works more slowly than our sand jet system.

Dry Ice Blasting – Grit Free Blast Cleaning

Another option we offer is dry ice blasting, where surfaces are cleaned using solid CO₂ particles. The process works through thermal shock, rapid expansion of the dry ice into gas, and light abrasion, making it completely grit- and sand-free.

The key advantage is that the “abrasive” evaporates on impact, so only the removed material remains, making the process nearly dust-free—though it can still dislodge cobwebs, bird nests, and paint debris. Dry ice blasting is commonly used in the printing industry for rollers, as well as for mould and weld cleaning.

Bristle Blasting – the Hand Tool That Behaves Like a Grit Blaster

One challenge we’ve often faced is finding a way to remove the most stubborn patches of paint or dirt left behind after methods such as pressure washing, chemical stripping, sand jetting, or dry ice blasting.

In 2013, we discovered that a hand tool originally designed for paint shop surface prep—used to clean rust and missed spots on blast-cleaned metal—works effectively on stone and brick too. Its smaller cleaning face allows for much greater control compared to a sand jet.

The tool works much like a handheld belt grit blaster: the wheel’s teeth act like grit particles, and the bristle blaster behaves like a miniature sandblaster. That said, it’s still important to know when to stop!

Zinga Cold Galvanising

Zinga is a single-component, cold-applied galvanic zinc coating. Its unique formula offers environmentally safe cathodic protection for steel, comparable to hot-dip galvanising, but with the added benefit of being applied on-site like paint.

In 2008, a set of six large oil tanks in East Yorkshire were blast-cleaned of rust and then galvanised with Zinga for long-lasting protection.

Priming & Painting

Primers and Topcoats can be applied to protect the steel from corrosion. While Zinga has its place, We now do favour moisture curing urethane products from Trident coatings for example. The Moisture Curing Urethanes work down to -15 degrees C and at high humidity. This allows on site painting to take place, outside in Winter!

Moisture Curing Urethanes are also much more tolerant to solvents in subsequent layers than Zinga is.

This was a complex web of metal in an ex Aircraft Hangar in Warwickshire which had suffered a significant fire. We cleaned and primed it with MCU Aluprime Spring 2009.

Silane Sealing

A common reason houses are painted is to stop water penetrating porous brick or stone. Simply removing the paint won’t restore water resistance. To address this, we offer Silane surface sealing, which, unlike traditional silicone products, leaves no visible colour change before or after application.

That said, we don’t routinely promote sealing—it’s rarely necessary. In fact, in over 95% of cases, removing the paint doesn’t cause water issues and can even help resolve them. The few times we’ve applied sealant straight after cleaning were when access made it practical, such as a project in Scarborough where scaffolding costs far outweighed the price of the sealant.

Farrow System Spare Parts & Machines

Since the closure of Farrow System Ltd, we’ve been approached by many people seeking spare parts, training, and support. As the very first Farrow System franchisee—and one of the last few remaining when the franchise collapsed—we have nearly 25 years of experience with these machines.

Over that time, I’ve frequently diagnosed problems over the phone for both my team and clients, helping to identify faults, suggest workarounds, or confirm when an issue requires a full stop.

We can provide advice and source new or second-hand machines, from basic blast pots and control panels to fully trailer-mounted systems with compressors. When needed, we can also hire out equipment—from spare blast pots to complete machines—and have even stepped in directly to help clients finish contracts.

Farrow System Training

We provide training on our machines, covering everything from setup, operation, and cleaning to basic fault diagnosis and job-specific applications. Each course includes a printed colour manual with settings advice, and the aim is to make you and your team familiar with the machine’s parts so any issues can be diagnosed quickly and effectively.

Training can take place either at our site or yours. On-site training has the advantage of working directly with your machine, though we ask that equipment is functional beforehand, as we can’t guarantee to resolve major issues—like a non-starting compressor—within the course time.

Before training, we’ll discuss your requirements and business goals to ensure we bring the right materials. (For example, one client prepared for white line removal, but actually needed to refurbish wooden window frames, requiring completely different abrasives!)

After a one-day course, you’ll have a solid foundation, though we recommend a few days of practice before starting work for paying clients.

Dirty Brick Cleaning

We can clean dirty bricks, or remove paint from them; we have various techniques or options for this depending on the dirt or paint, and the quality or softness of the brick – from the Sand Jet, to a full on Sand Blast, or even more aggressive high pressure water systems.

This page is dedicated to Dirty Brick Cleaning and the various techniques we might use to achieve this.

We specialise in using a listed building approved low pressure sand jetting system that has been used nationwide for property restoration. The system, in our trained hands, causes minimal damage to an underlying surface and is flexible enough to tackle most property restoration cleaning tasks.

Painted Brick Cleaning

We offer brick cleaning services to remove paint or dirt, using different methods depending on the type of contamination and the condition or softness of the brick. Options range from our Sand Jet system to full sandblasting or even high-pressure water cleaning. More details on our brick cleaning methods are available on this page.

Dirty & Painted Stone Cleaning

Greenleaf Contractors provide professional stone cleaning services across the UK. We use a range of techniques tailored to the condition of the stone and the type of contamination—starting with superheated steam (DOFF-type systems), through sand jetting, sandblasting, and grit blasting, up to high-pressure water cleaning when required. Whether you need general dirt removal or paint stripping, we can help.

After cleaning, we can also seal the surface to protect against future discolouration. While much of our work is in Yorkshire, Nottinghamshire, and Lincolnshire, we frequently travel further afield, including London, Derby, Newcastle, Manchester, Scotland, and Wales.

Dry Ice Blasting

Sometimes alternative cleaning methods are needed, such as dry ice blasting. This process propels solid CO₂ particles at a surface, cleaning through thermal shock, rapid expansion into gas, and light abrasion—making it completely grit- and sand-free.

The main benefit is that the abrasive evaporates on impact, leaving only the removed material behind. It is almost completely dust-free, though it can still dislodge cobwebs, nests, or paint debris.

Dry ice blasting is widely used in the printing industry for roller cleaning, as well as for mould and weld cleaning.

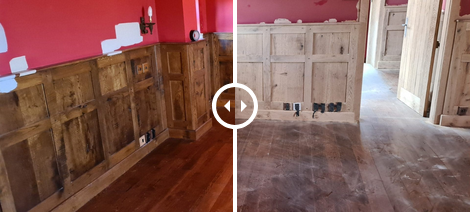

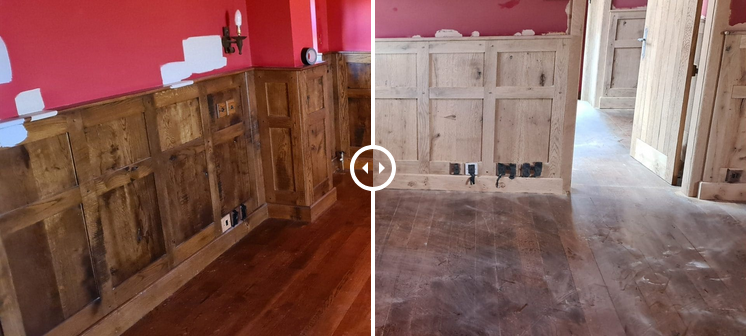

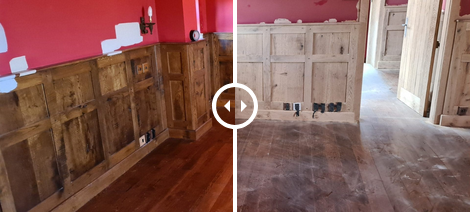

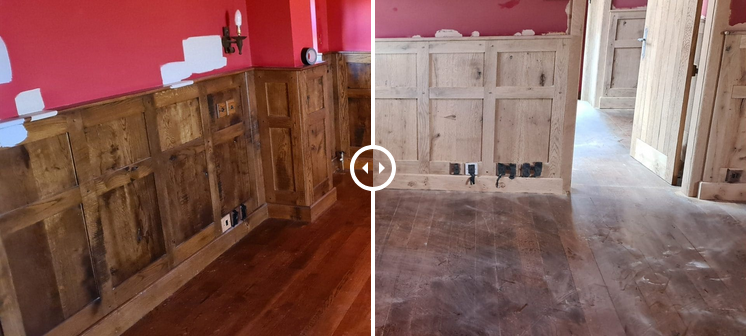

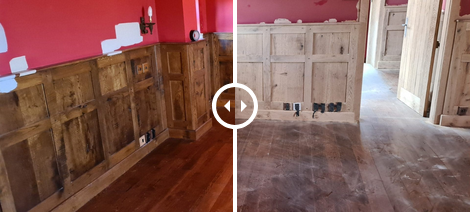

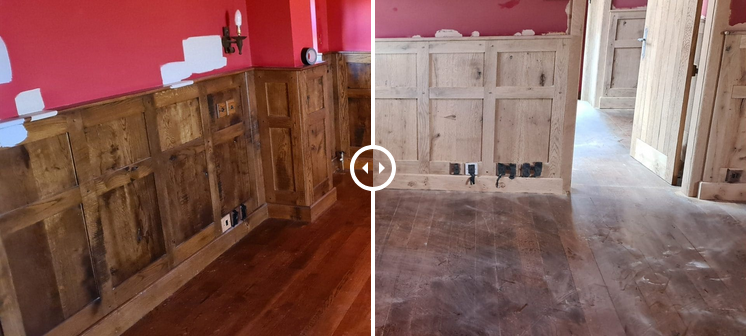

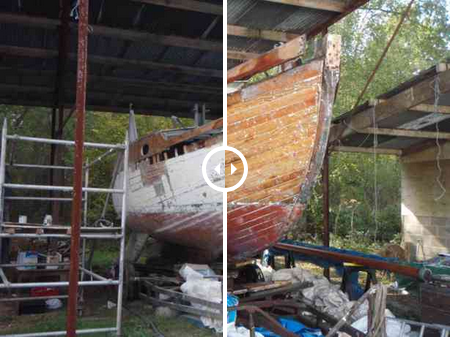

Wood Sand Jet Cleaning

We specialise in low-pressure sand jetting, a method used nationwide for property restoration, including approved work on numerous Listed Buildings. In trained hands, the system minimises surface damage while being flexible enough for most restoration cleaning tasks.

The low-pressure, “wet” sand jet cleans bricks without saturating them with water and captures the abrasive and removed dirt, reducing health and safety risks compared to dry blasting. While the damp process can leave debris sticking to surfaces—washable or brushable later—we’ve also reintroduced careful dry blasting. Though it produces more dust and uses more abrasive, it can sometimes be easier to clean immediately.

Wood – Traditional Grit Blasting / Sandblasting

We offer wood sandblasting (also called grit blasting) nationwide, though we most commonly work in Yorkshire, Lincolnshire, Nottingham, and Derby. We’ve also completed jobs as far south as London and a large project in Cheshire. Traditional sandblasting relies on gravity to feed abrasive into the blast stream, making it more aggressive than some of our other methods. While it produces significant dust, it can be a highly cost-effective solution.

Laser Cleaning

Laser cleaning is now becoming affordable for both domestic and small-scale industrial use. The system uses a scanning laser beam to vaporise surface contaminants. While not the cheapest option, it’s ideal for open-plan properties. It is highly effective at removing smoke damage, though less so for white paint.

Steel, Cast Iron, Aluminium & Alloy Cleaning

We specialise in low-pressure sand jetting, though traditional sand or bead blasting may be better suited for some metal cleaning tasks. The damp system captures both dirt and abrasive, reducing the health and safety risks of dry blasting, while also acting as a coolant to prevent thin metals—like steel vehicle shells—from warping.

The system is safe for lead-based paints on structural steel and cast iron, gentle enough for aluminium and alloy surfaces, yet still creates enough profile for paint to adhere properly. It also uses far less abrasive than traditional blasting, making costly materials like garnet more economical, reducing waste, and avoiding cross-contamination between jobs. In most cases, abrasive costs are minimal.

Graffiti Removal from Brick, Metal or Concrete

Bricks can be treated with Silane or other slick coatings to make it difficult for graffiti to adhere—paint that does stick can usually be wiped or pressure-washed off. Sealing surfaces can help reduce repeat graffiti, but care must be taken not to create a primed background that encourages new paint.

In some cases, chemical stripping provides a fast and effective solution, especially for graffiti on painted surfaces or on materials like galvanised steel that could be damaged by abrasive methods.

Spray Foam Insulation Removal

Over the past twenty years, sprayed polyurethane foam (open or closed cell) has been widely used to provide fast, consistent, and structurally sound insulation under roofs. However, homeowners have recently discovered that when selling their property, surveyors cannot properly assess the roof timber, as the foam is stuck to it, and therefore cannot guarantee the roof’s condition. This can prevent prospective buyers from obtaining a mortgage.

We can remove the foam, but it’s important to note that all three of our methods have drawbacks and can be very messy, especially if there’s no rooflight or window in the loft. If access is only through a small landing hole, that becomes the single point for entry, exit, and foam removal.

New Build Brick Cleaning

We’re not particularly fond of new build brick cleaning. Unlike most of our projects, it usually occurs toward the end of a contractor’s schedule, which brings two main challenges.

Firstly, the site is often in a flurry of completion work, making access difficult as scaffolding is removed and paving is laid. Secondly, there’s sometimes a risk that the end customer resists paying, as we experienced on a 2007 job in Leeds, leaving brick cleaners caught in a tricky situation.

Typically, pressure washing and brick acid are sufficient, though more clients are now opting for superheated steam, which is gentler on mortar. For large amounts of mortar debris or heavily soiled bricks, our sand jet machine provides a cost-effective solution while causing minimal damage to pointing.

Fire & Smoke Damage Cleaning & Restoration

Smoke and soot can leave significant mess on both internal and external surfaces. While dry ice blasting is often requested for cleaning soot, we also offer alternatives. Dry ice tends to displace soot rather than capture it, whereas tools like our sand jet system collect the soot as it cleans, leaving a much tidier result.

About us

Greenleaf Contractors Ltd offers nationwide surface cleaning and preparation services, including sandblasting, sand jetting, superheated steam cleaning, pressure washing, and more. Founded in 2000, the company began as a Farrow System franchise.

We specialise in surface preparation and cleaning, primarily using our low-pressure damp abrasive system (“Sand Jetting”), but also provide traditional sand/grit blasting, pressure washing, high-pressure (500 bar) and ultra-high-pressure (2500+ bar) water blasting, chemical cleaning, and superheated steam (DOFF™) services. Additionally, we offer post-blast treatments such as priming, painting, on-site galvanising, moisture-curing urethanes, and stone and brick sealing with Silane and anti-graffiti products.

If you need a local or nationwide contractor specialising in surface preparation, including blast and sand blasting, pressure washing, chemical stripping, and steam cleaning, we can help. We cover a wide area with daily access to Yorkshire, Lincolnshire, Nottinghamshire, and Derbyshire, and regularly work in cities such as Leeds, Bradford, Newcastle, Sheffield, Hull, York, and Lincoln.

Our Services Include:

- Surface Preparation

- Surface Treatments

- Machine Support

- Domestic Brick, Stone & Wood Cleaning

- Commercial Surface Cleaning

- Industrial Cleaning & Surface Preparation

- Boat and Vehicle, Surface Preparation & Sandblasting

Due to the nature of the industry, travel is often required, and in recent years we’ve worked as far afield as Edinburgh, Aberdeen, Newbury, Cornwall, Somerset, London, and Kent. During the COVID lockdowns, we spent significant time commuting—at one point traveling 1,000 miles per week in each vehicle to reach sites like Bolton while hotels were closed.

While we specialise in damp sand blasting (“sand jetting”) and other sand or grit blasting techniques, there are times when other methods are better suited. We’re happy to admit this and, whenever possible, will help you find the right alternative to meet your needs.

If you’re looking for a reliable contractor, we can help! We operate across a wide area, including Yorkshire, Lincolnshire, Nottinghamshire, and Derbyshire, regularly serving cities like Leeds, Bradford, Newcastle, Sheffield, Hull, York, and Lincoln. In recent years, we’ve also travelled as far as Essex, Aberdeen, Edinburgh, London, Birmingham, Anglesey, Llandudno, and Cornwall.

Images