Company details for:

Precision Waterjet Ltd

Quick Links:

Products / Services

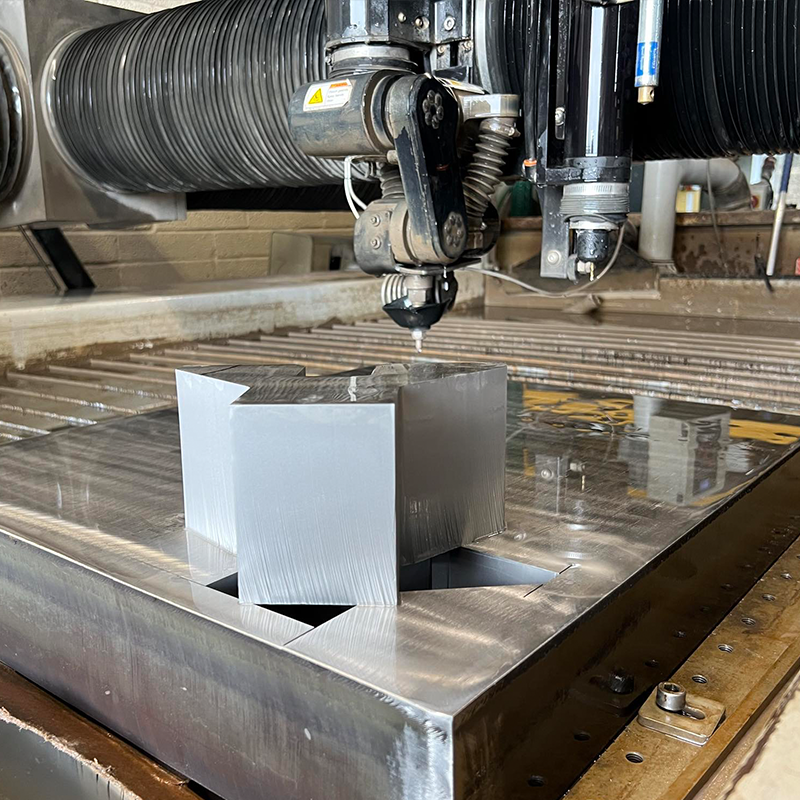

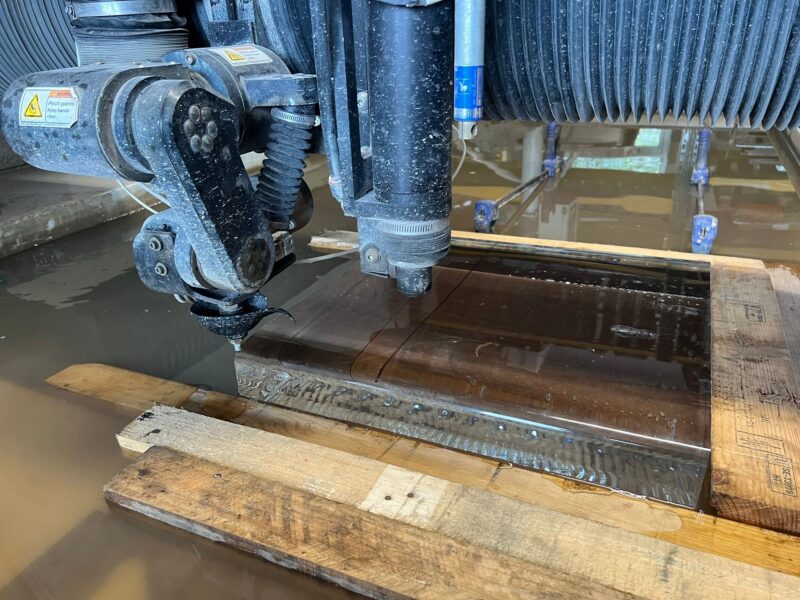

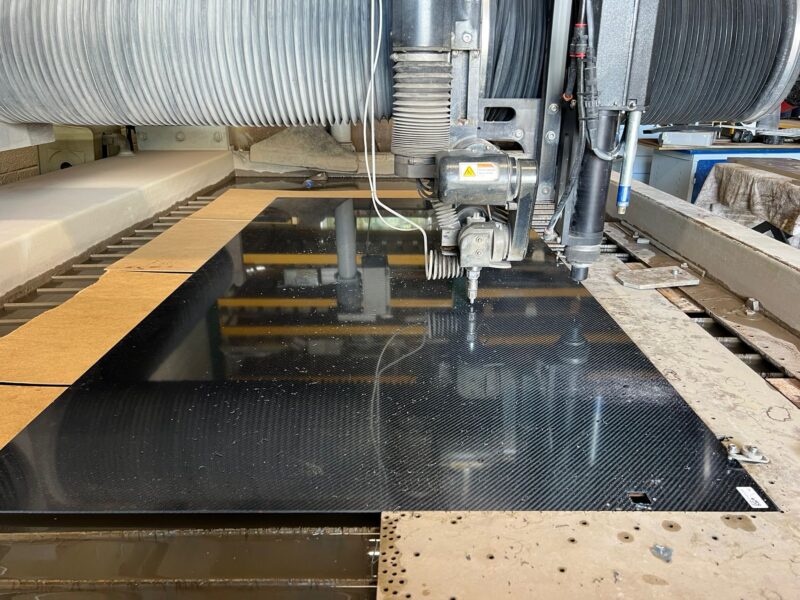

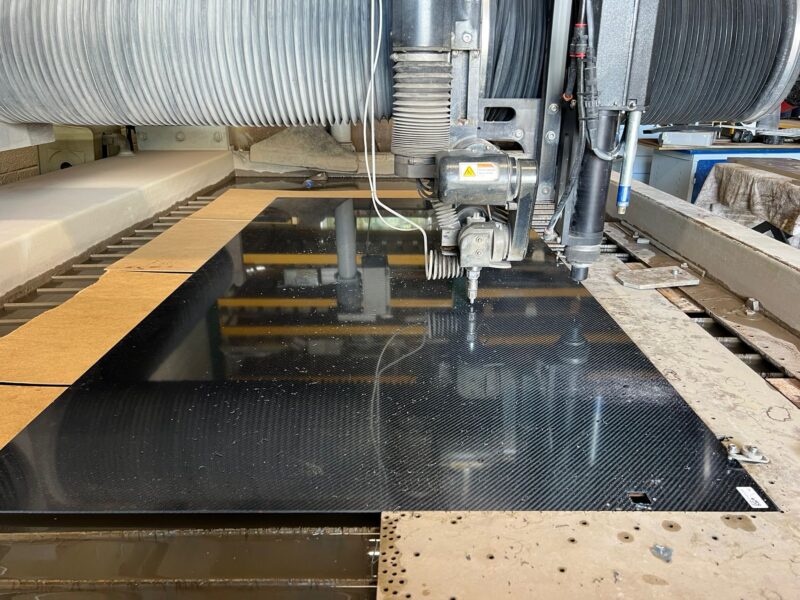

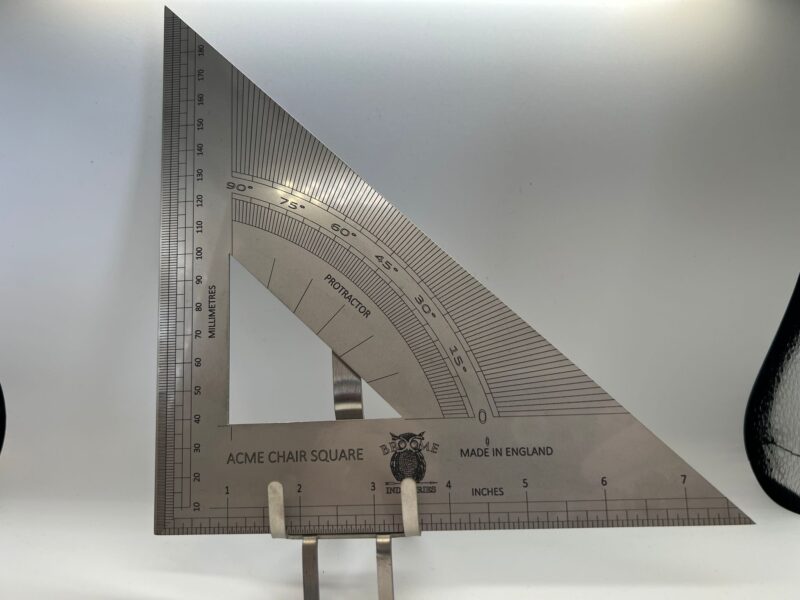

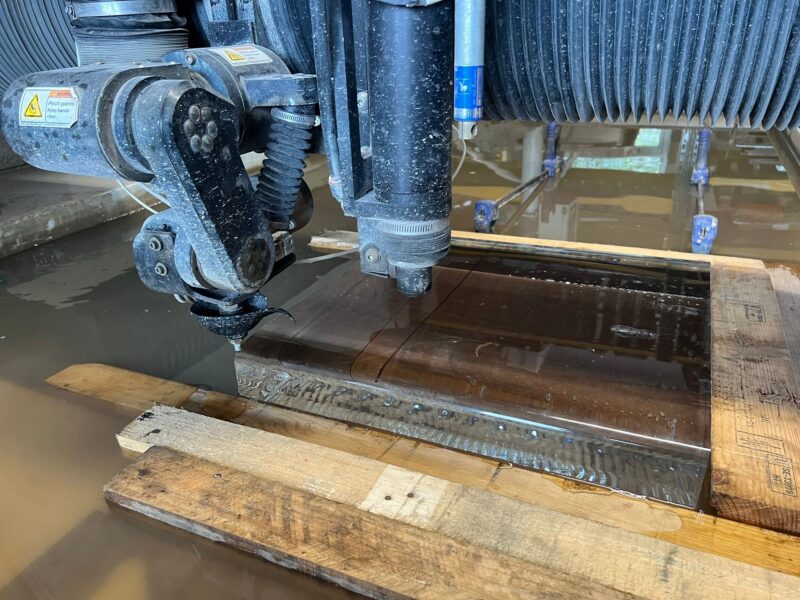

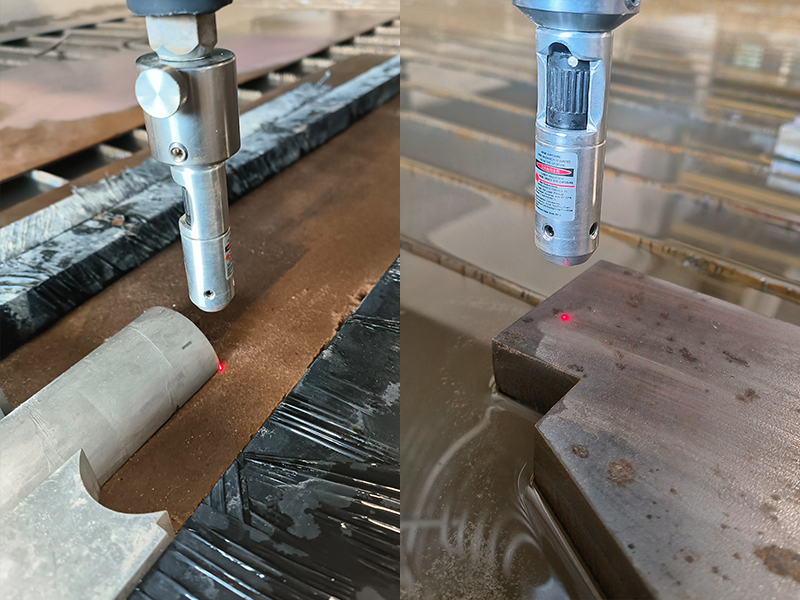

Precision Waterjet Cutting Process

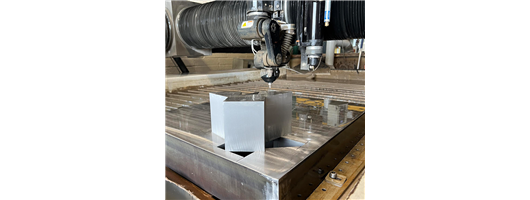

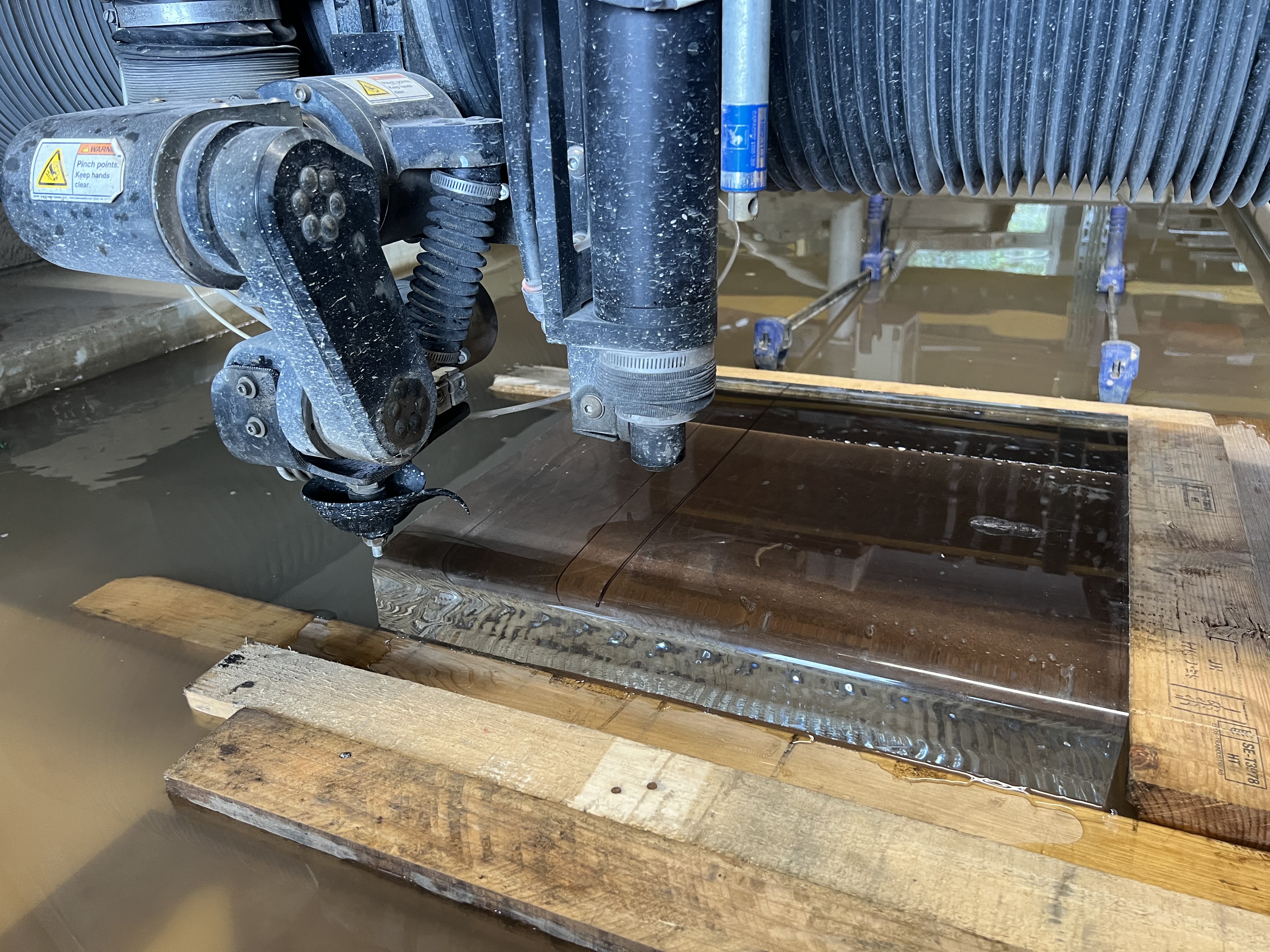

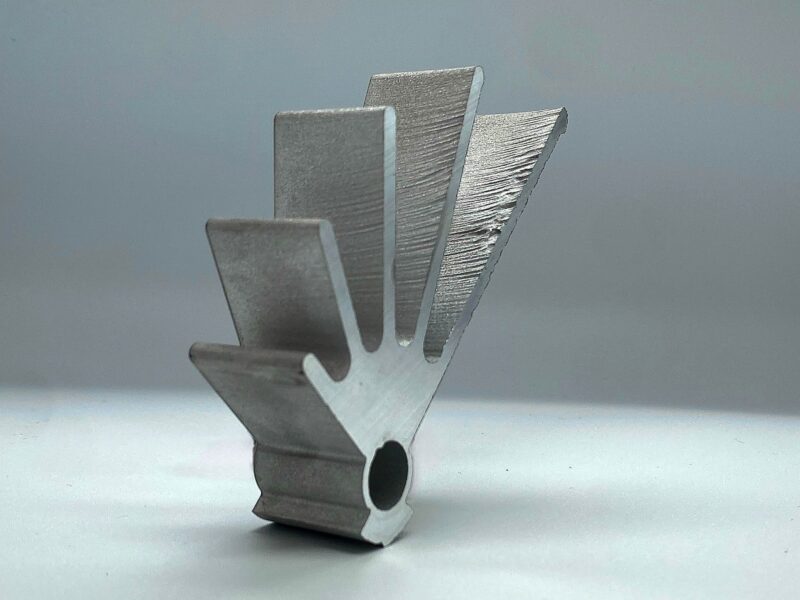

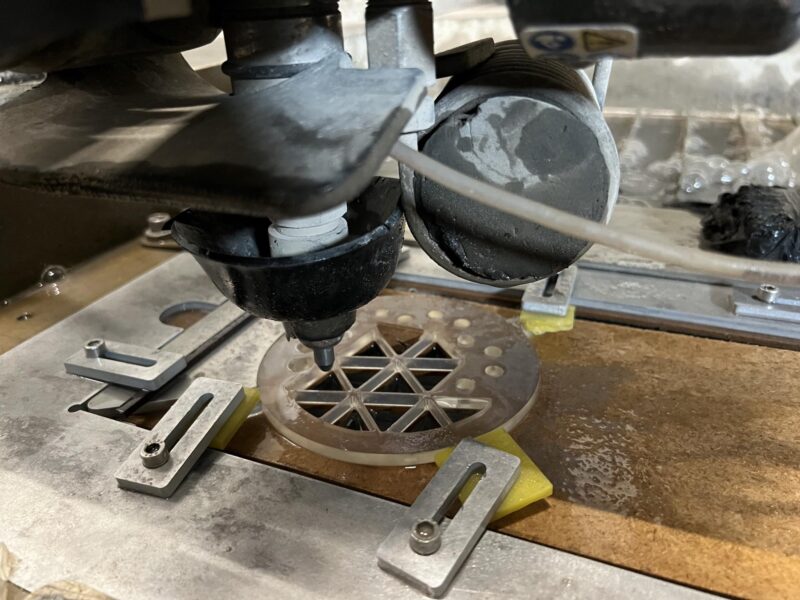

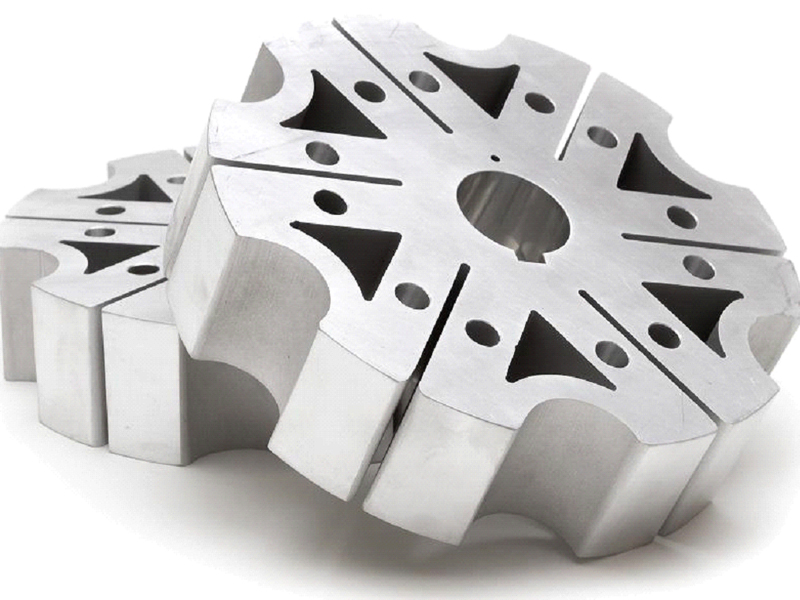

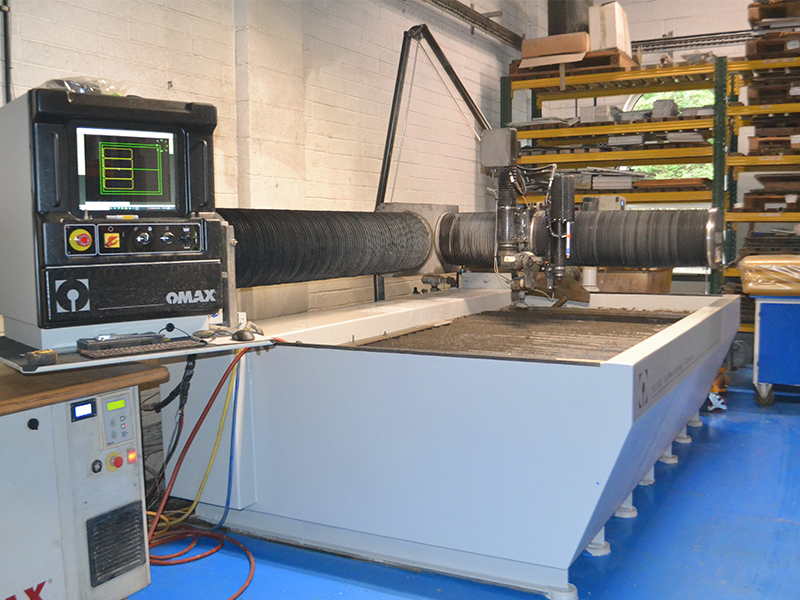

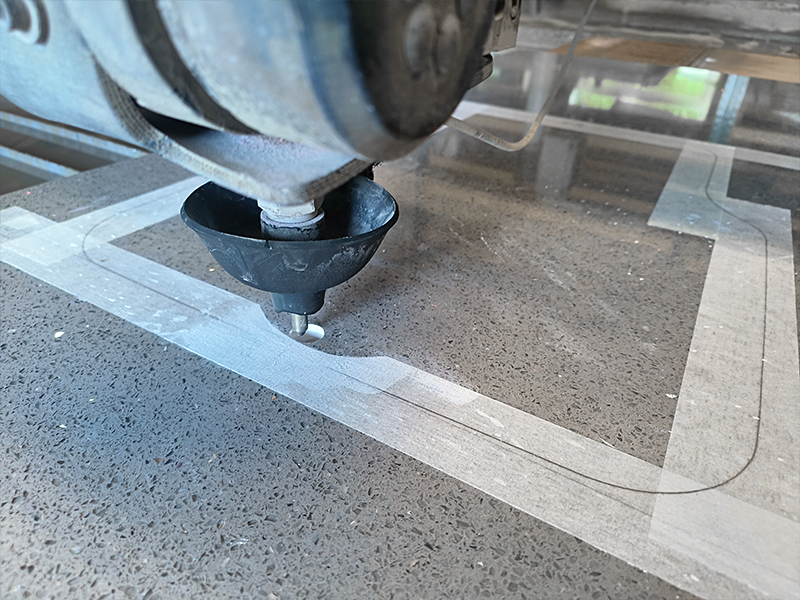

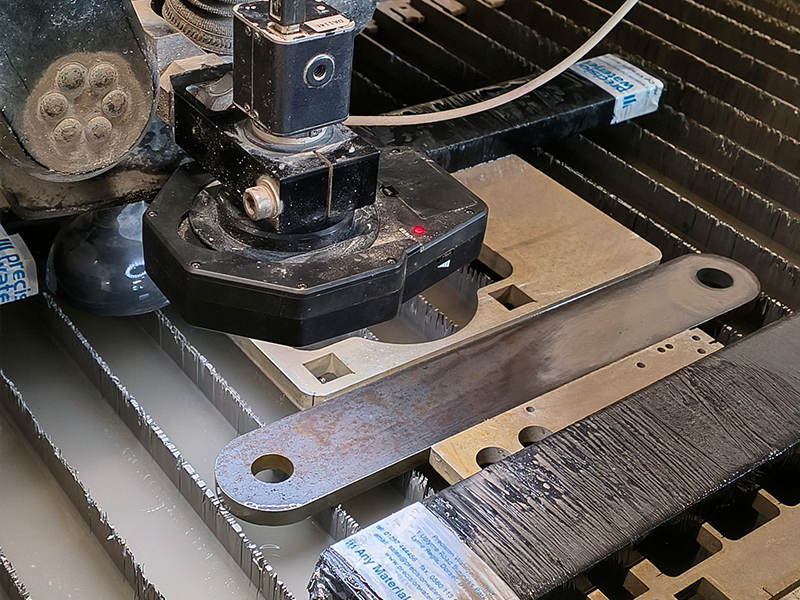

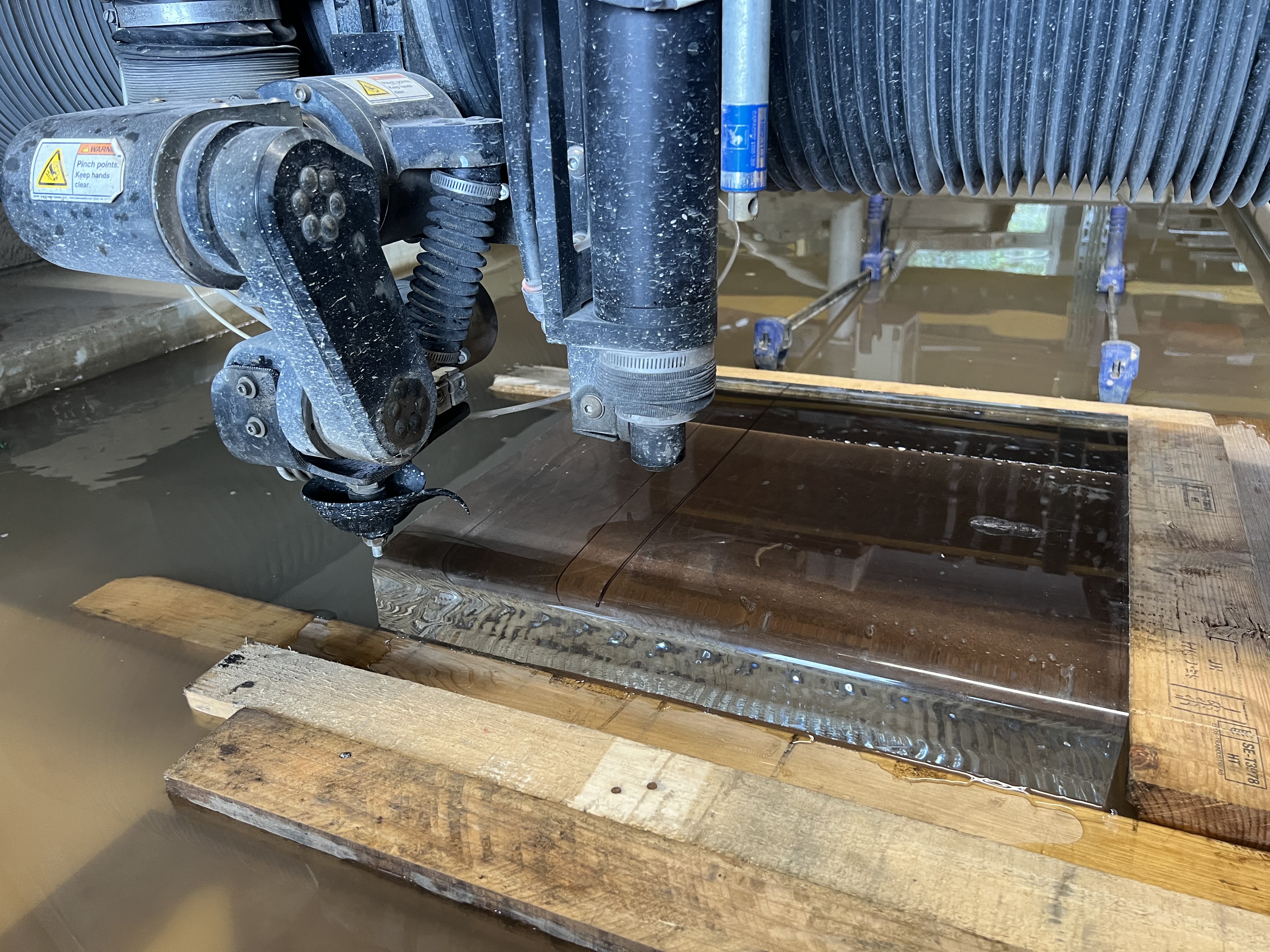

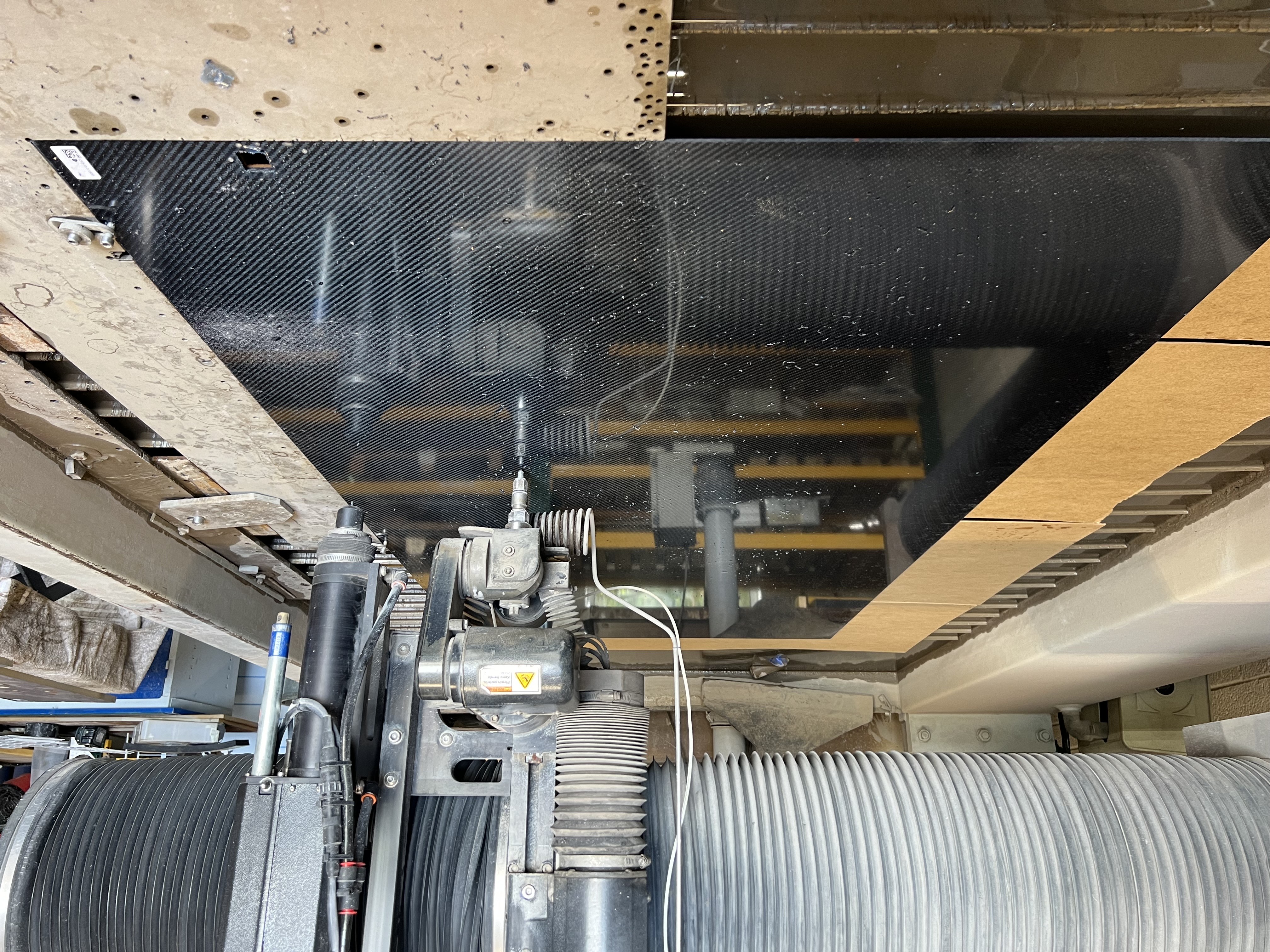

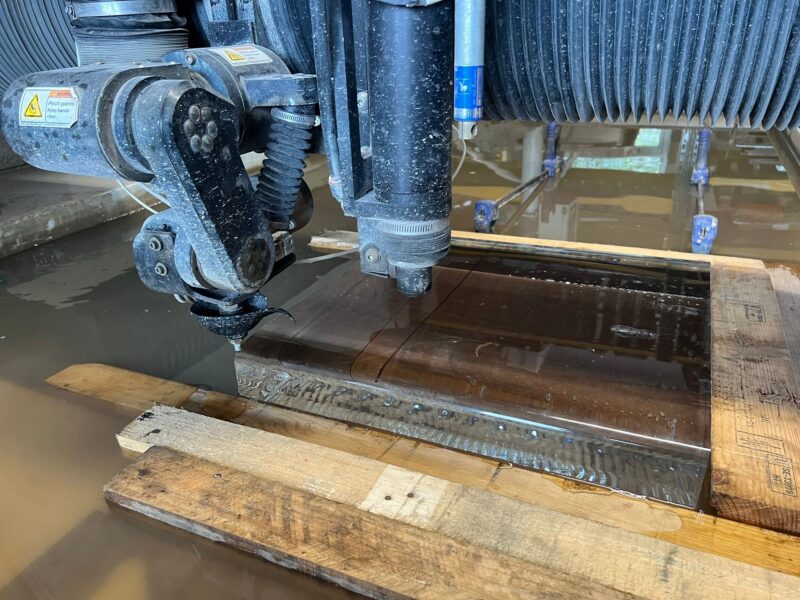

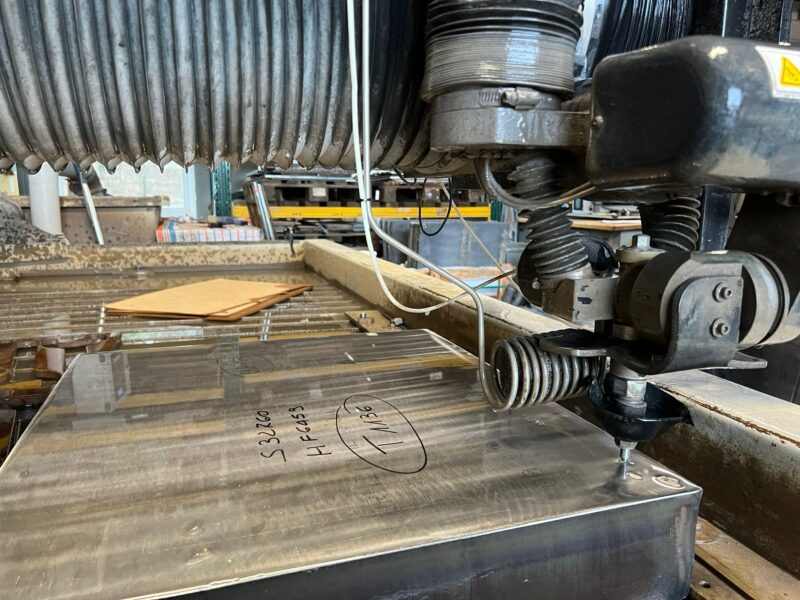

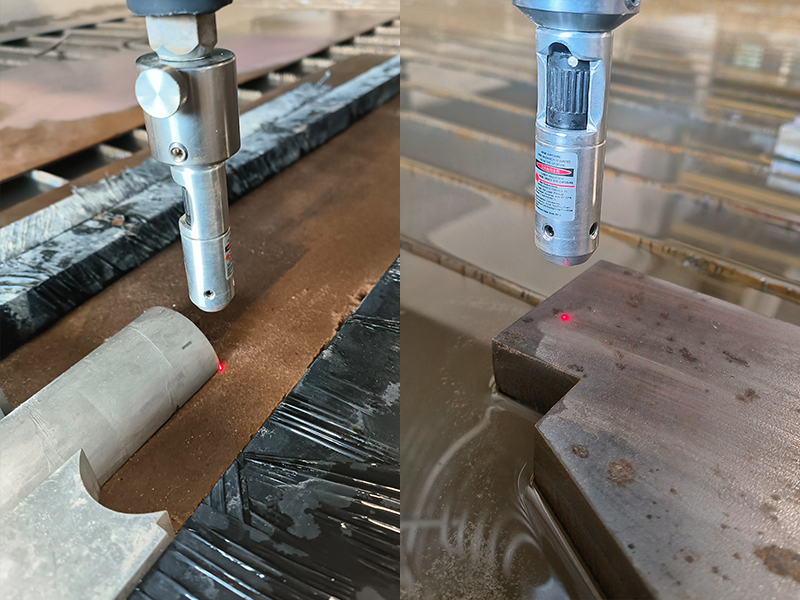

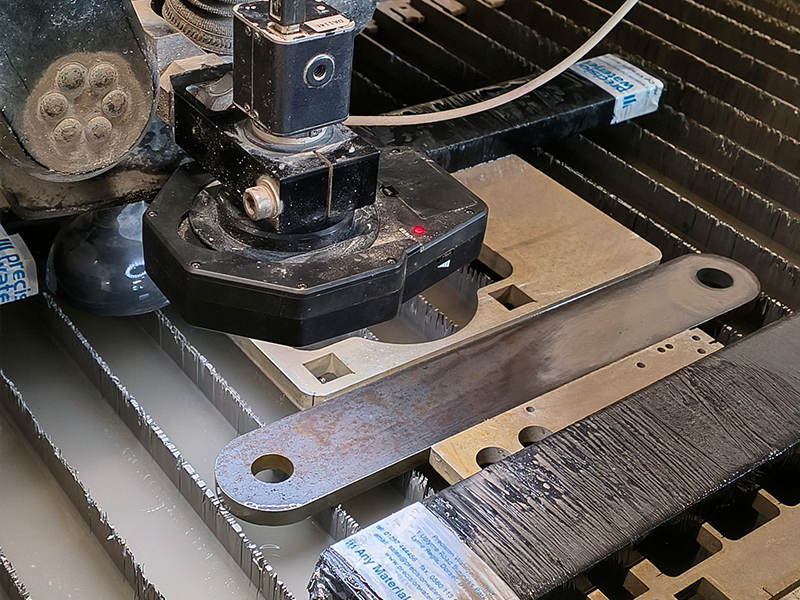

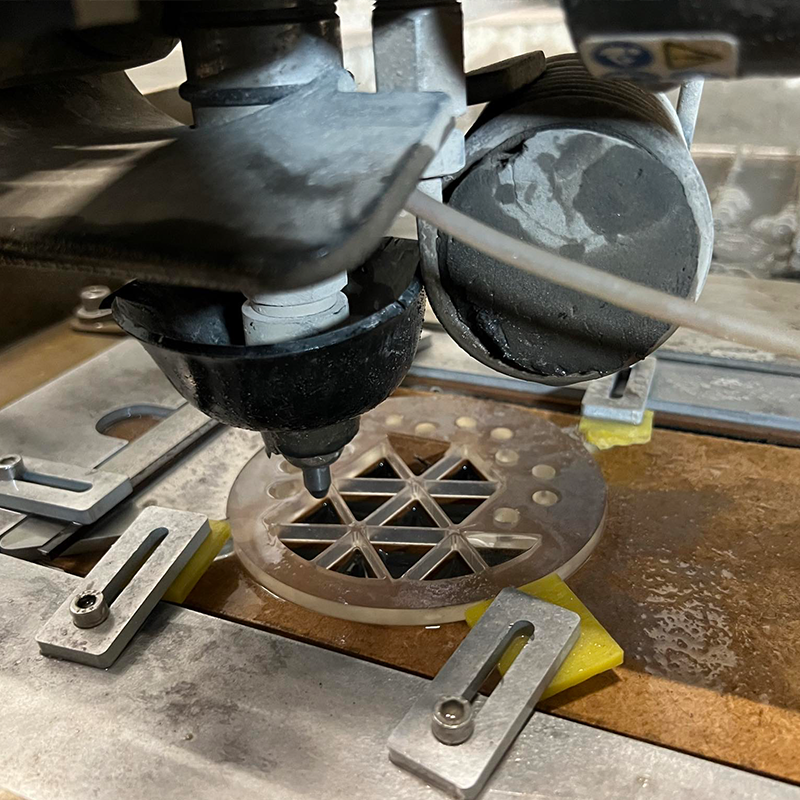

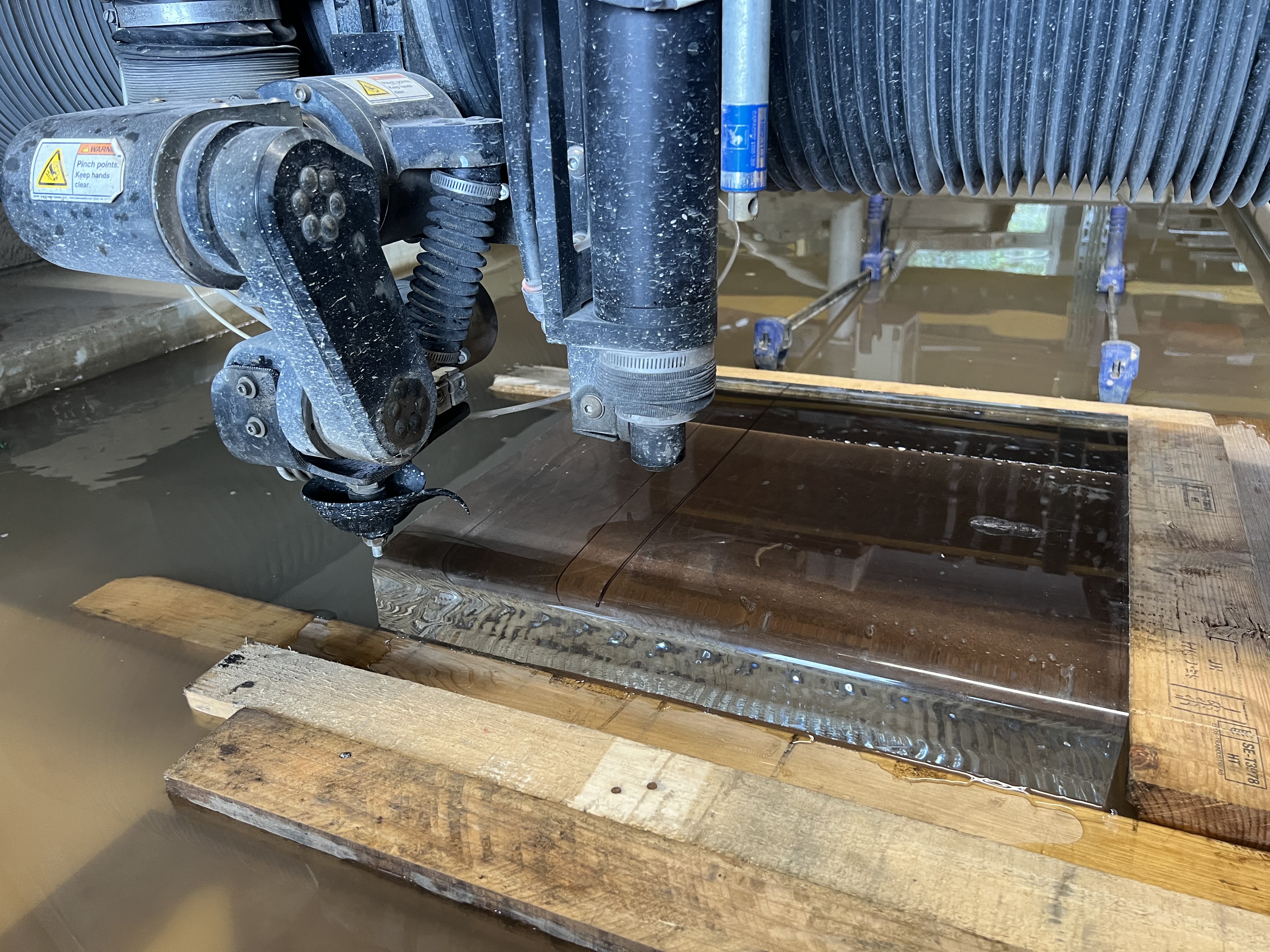

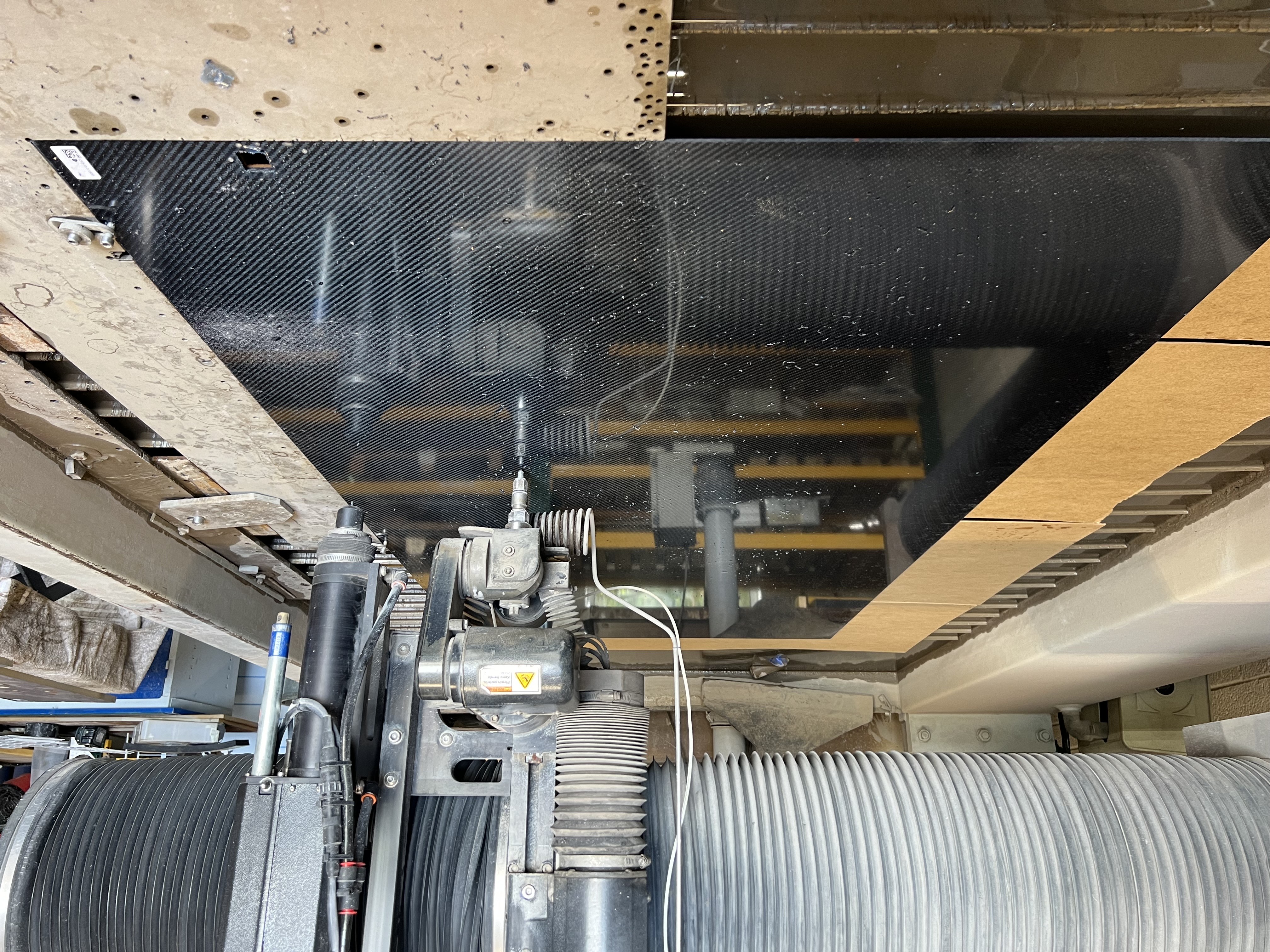

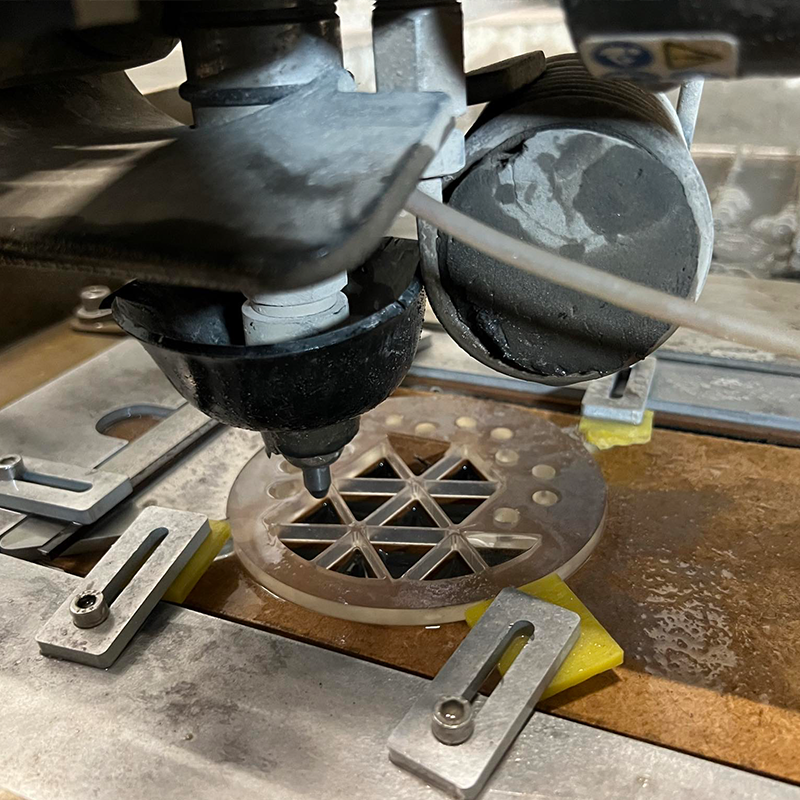

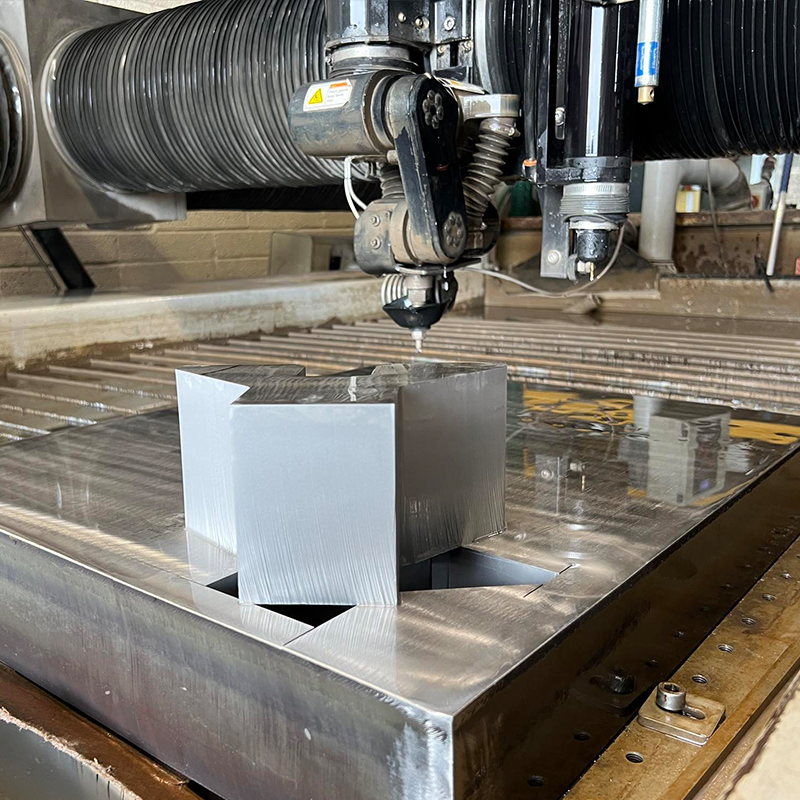

Both Water only, and Abrasive Water Jet Cutting are the technologies used by Precision Waterjet to cut virtually any shape in any material.

You may have heard of the generic terms “Waterjet”, “Abrasive jet” and “Flowjet”. Waterjet cutting technology has been around since the early seventies but was of little value to engineers as then it was only capable of cutting thin gasket and foam materials. High Pressure water cutting with Abrasive feed extended the concept about 10 years later.

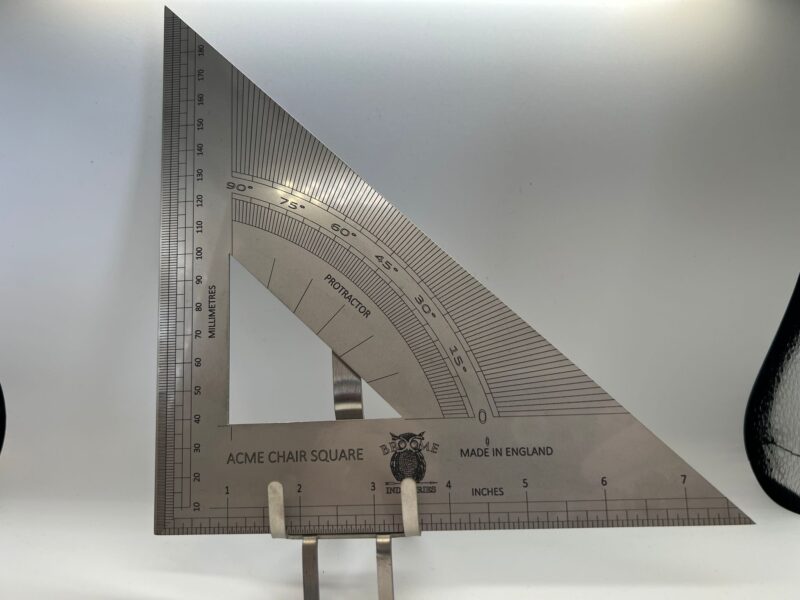

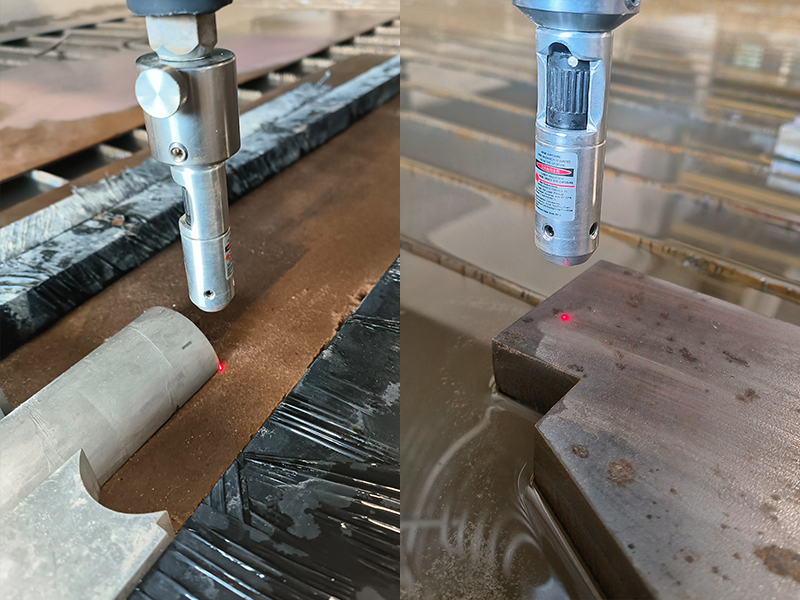

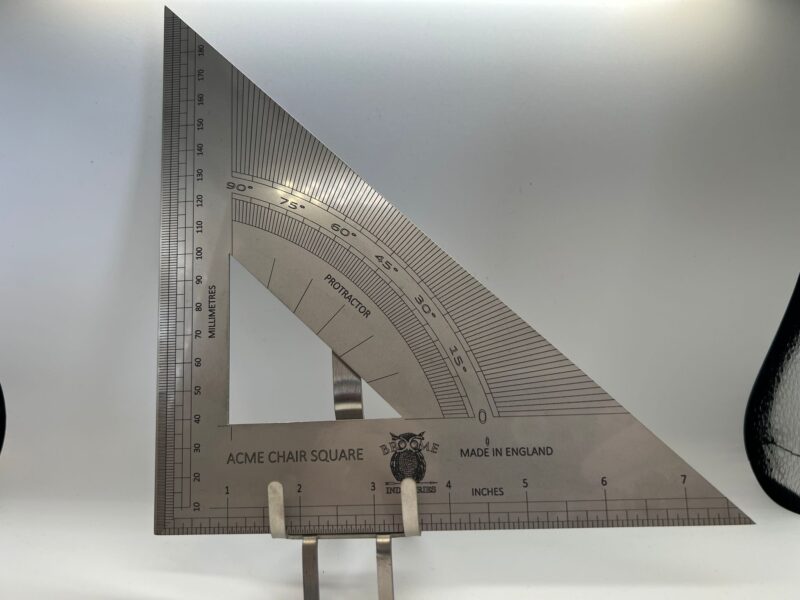

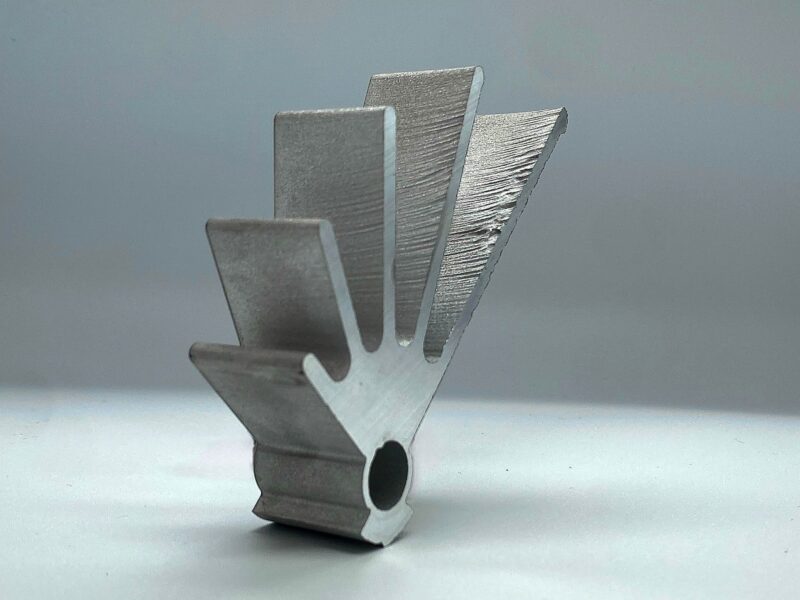

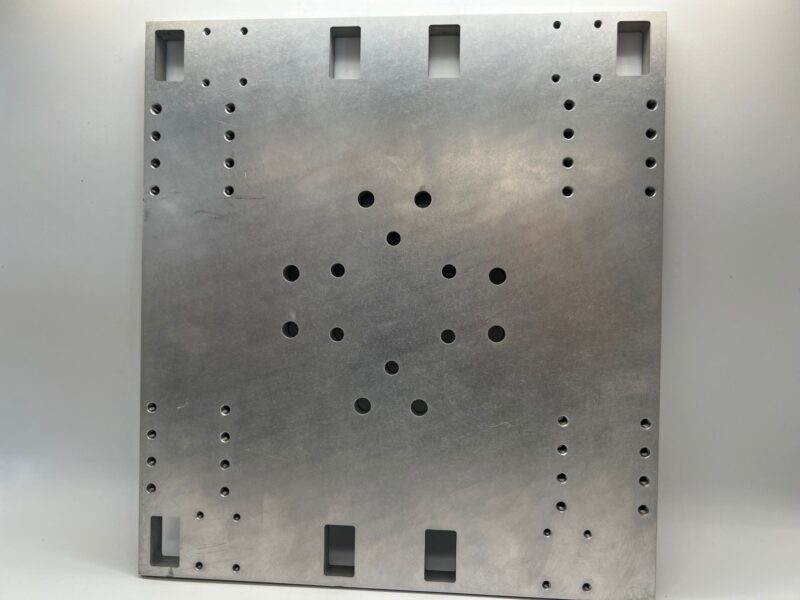

With innovative accessories such as the Tilt-A-Jet®, optical locators and a pneumatic drill we cut virtually any material in the world up to 200mm thick. Omax IntelliMAX Premium Software also provides a world class nesting software to ensure we can maximise material usage, reduce waste and ultimately reduce cost per part.

We carry a large range of material stock in various thicknesses and grades, ferrous and non-ferrous. This enables us to deliver parts in under 24 hours if required. If we do not have the material on the shelf our suppliers ship next day ensuring a swift turnaround.

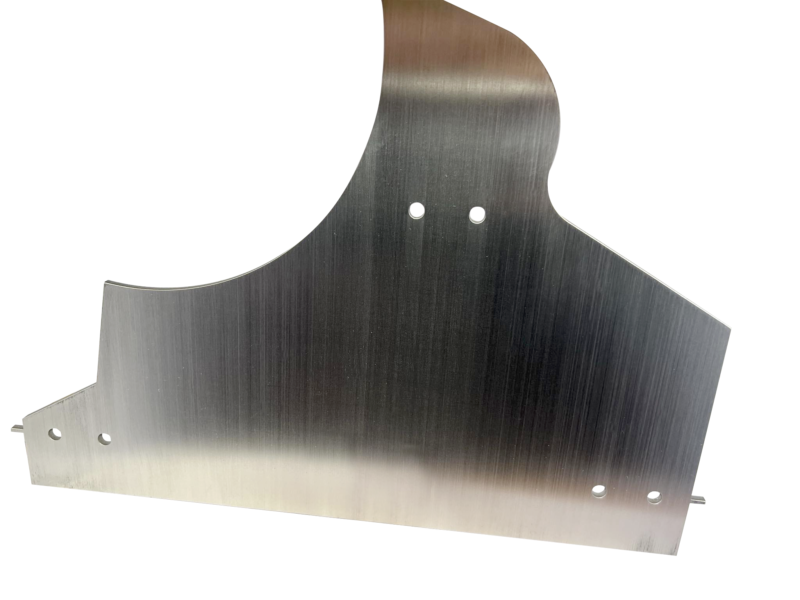

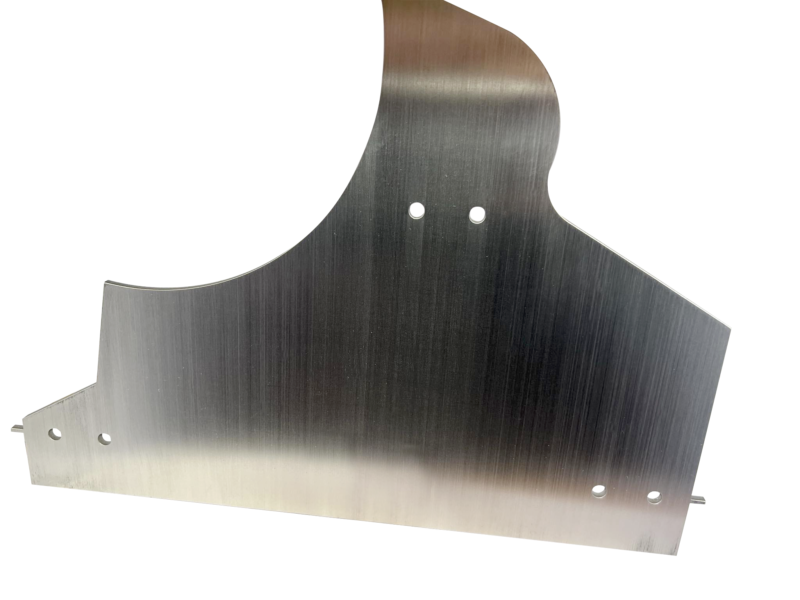

Flat Bed Linishing & Brushing

This allows us to be a ‘one stop shop’ and supply fully deburred and finished components to customers, where required.

This machine provides a combination of both linishing and brushing to produce a satin grained finish on one (DP1) or two (DP2) sides for components up to 300mm wide.

Most metals apart from Aluminium are suitable to be processed this way. We regularly produce dull polished grained finishes on stainless steel, copper and brass.

This often eliminates the need to buy in small costly amounts of pre-grained sheets and plate.

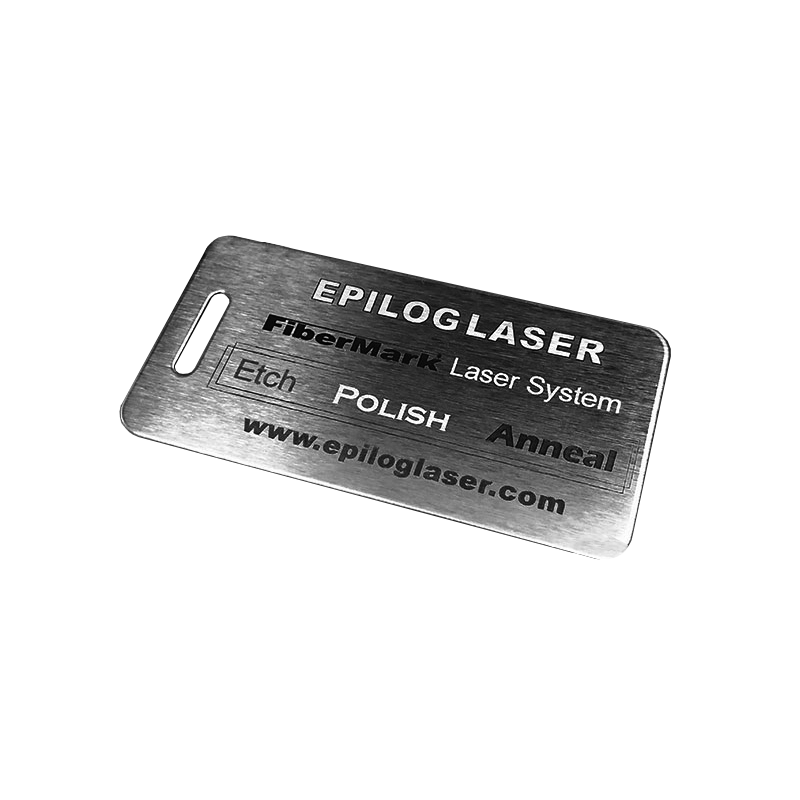

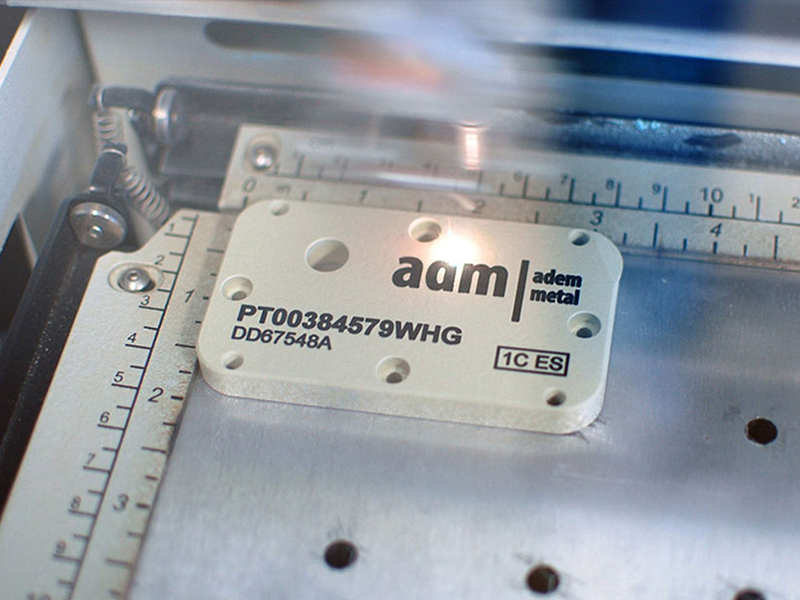

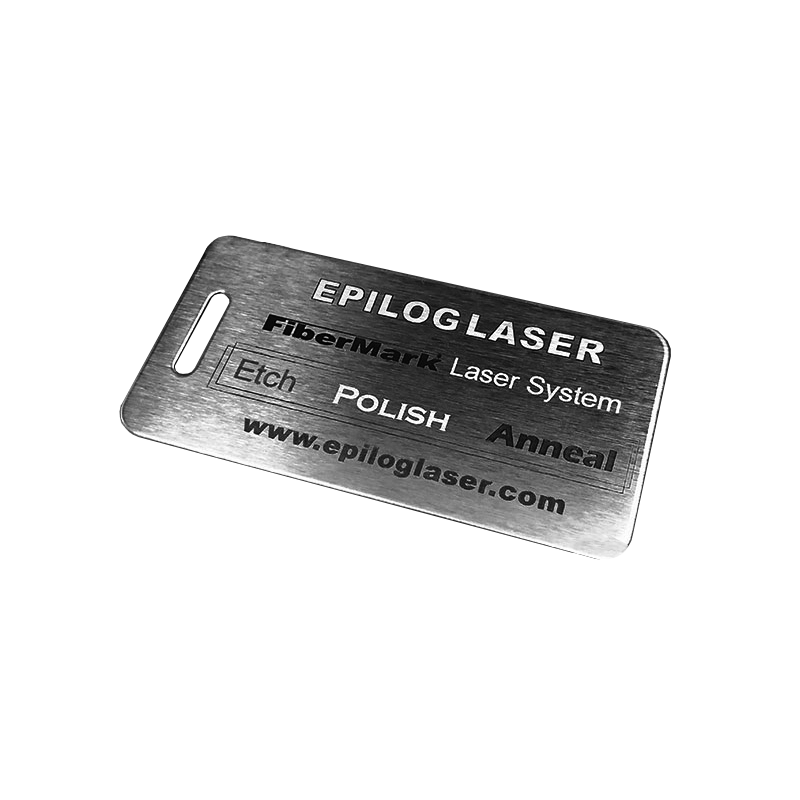

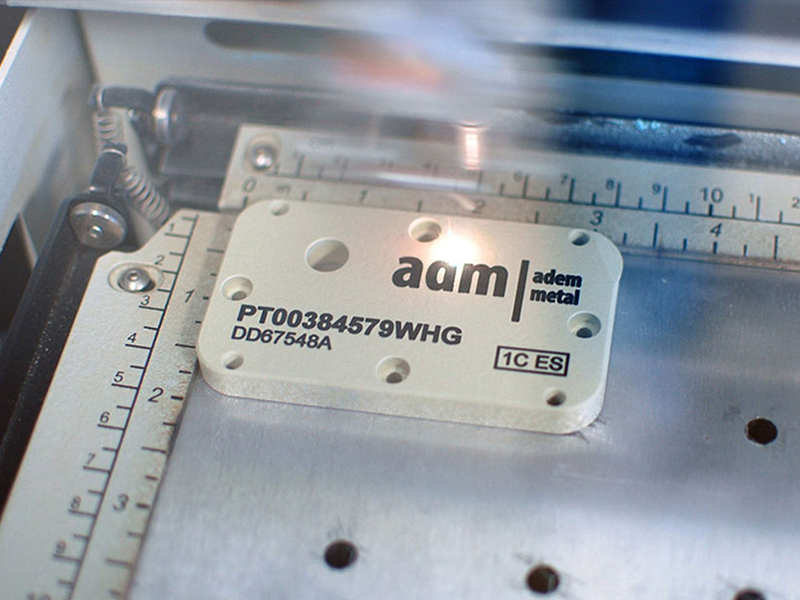

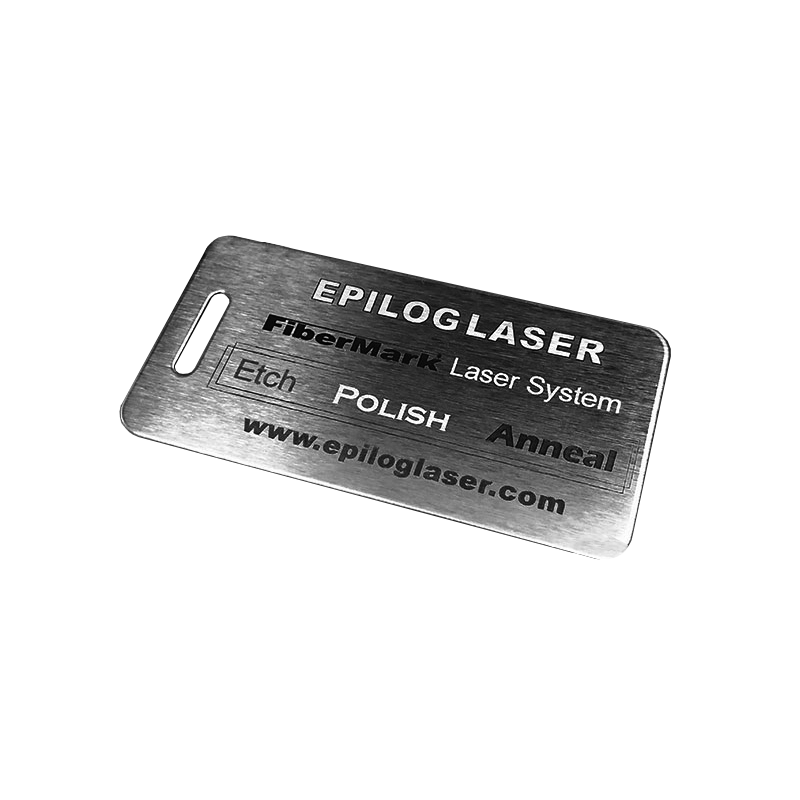

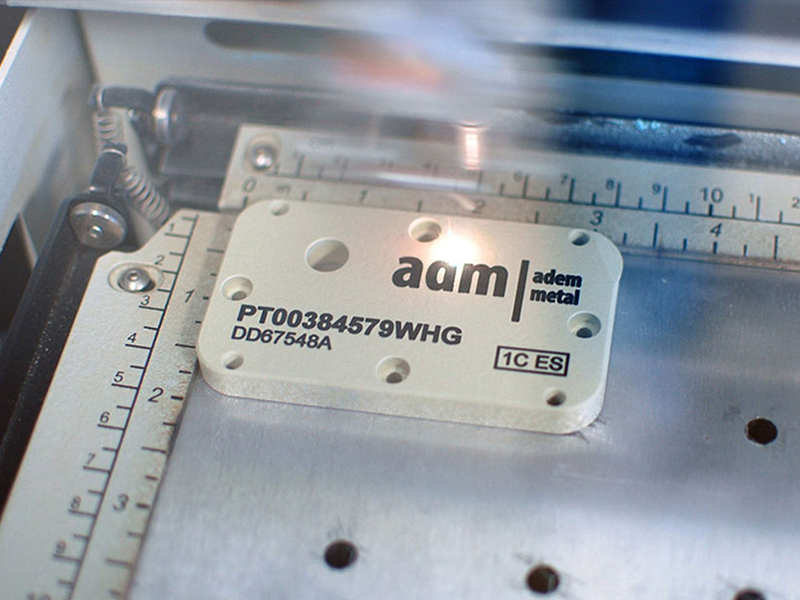

Laser Engraving & Etching

We use the Cermark metal marking process to make high contrast, permanent marks on various metals with our C02 laser. Marks can be made on stainless steel and mild steel.

So if you are looking for a complete nameplate or just to add an ID number we can achieve this for you.

The maximum part size for marking is 600mm x 450mm.

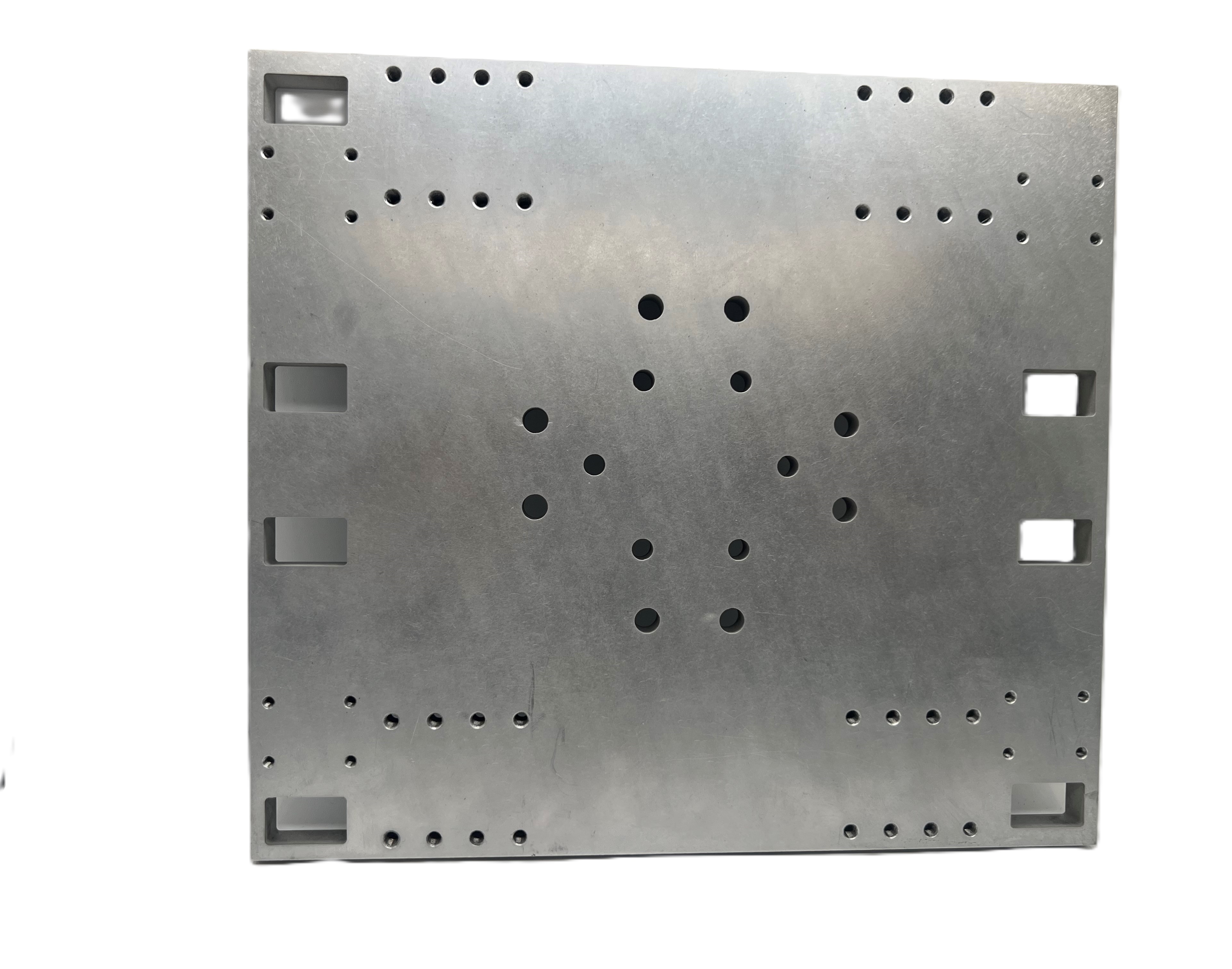

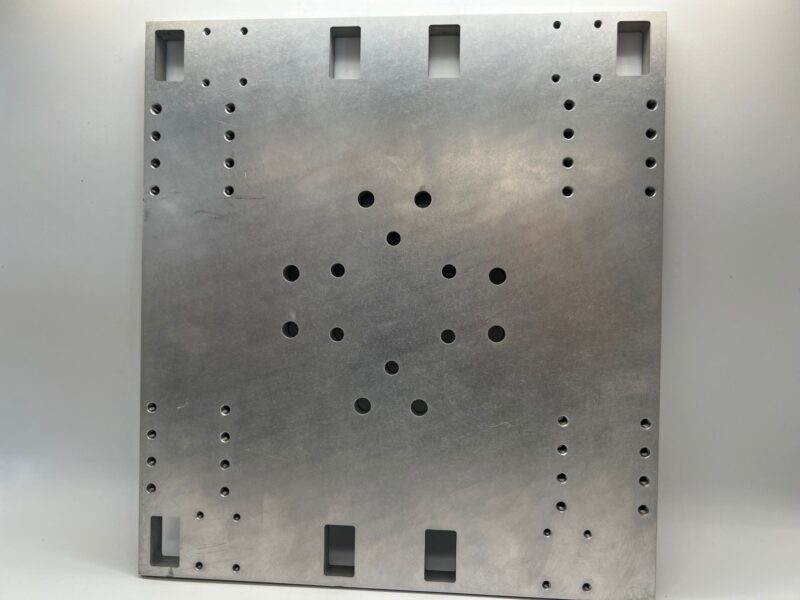

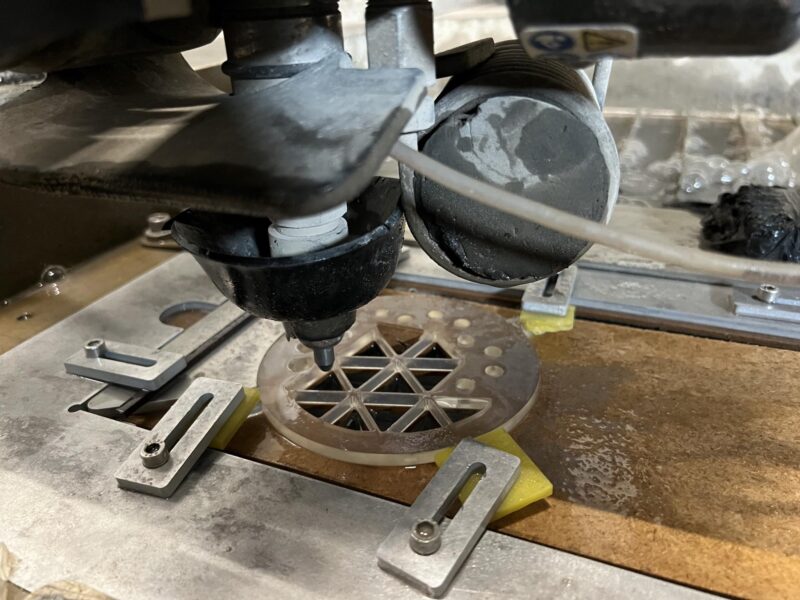

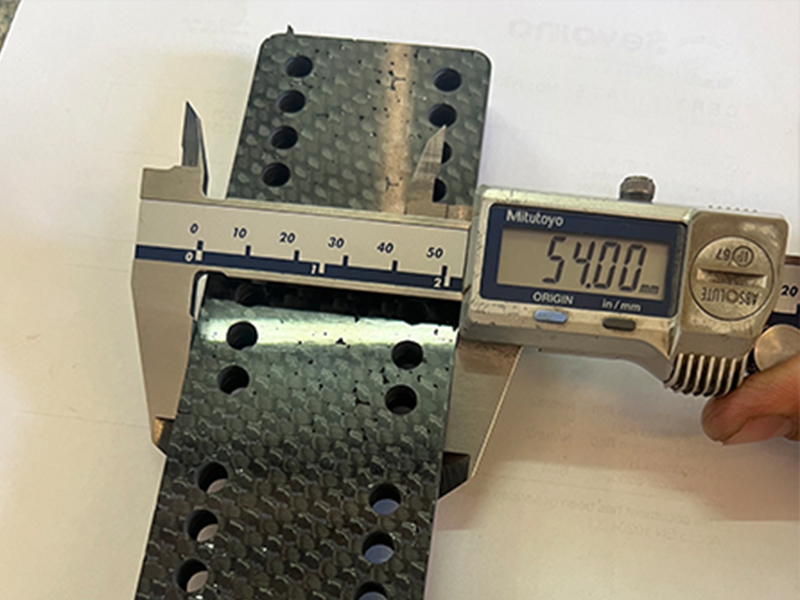

Tapping & Countersinks

This allows us to be a ‘one stop shop’ and supply fully finished components to customers, where required.

With the accuracy of the waterjet, we can tap with not further machining required. This additional process provides a part cut and supplied to drawing where required.

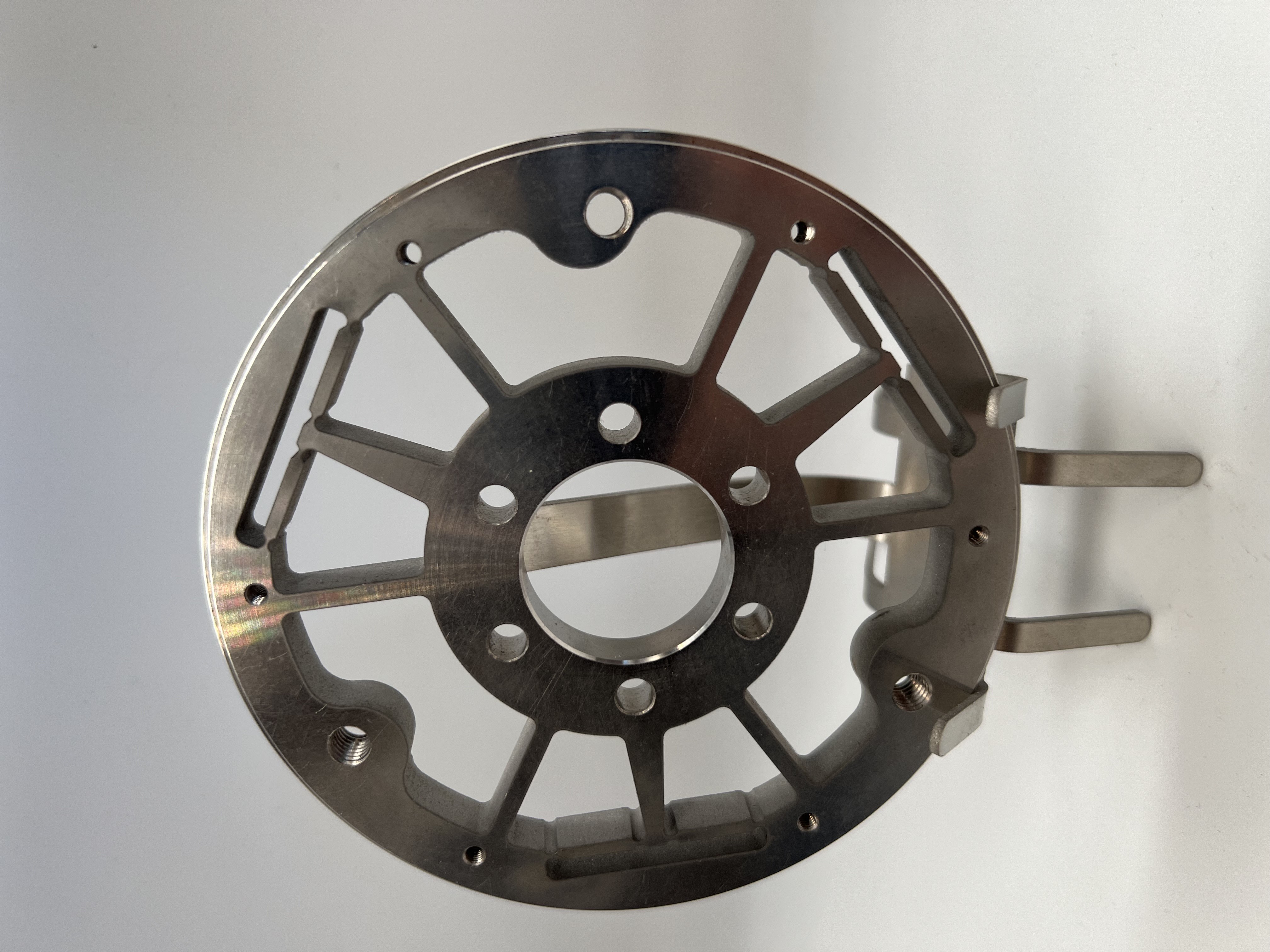

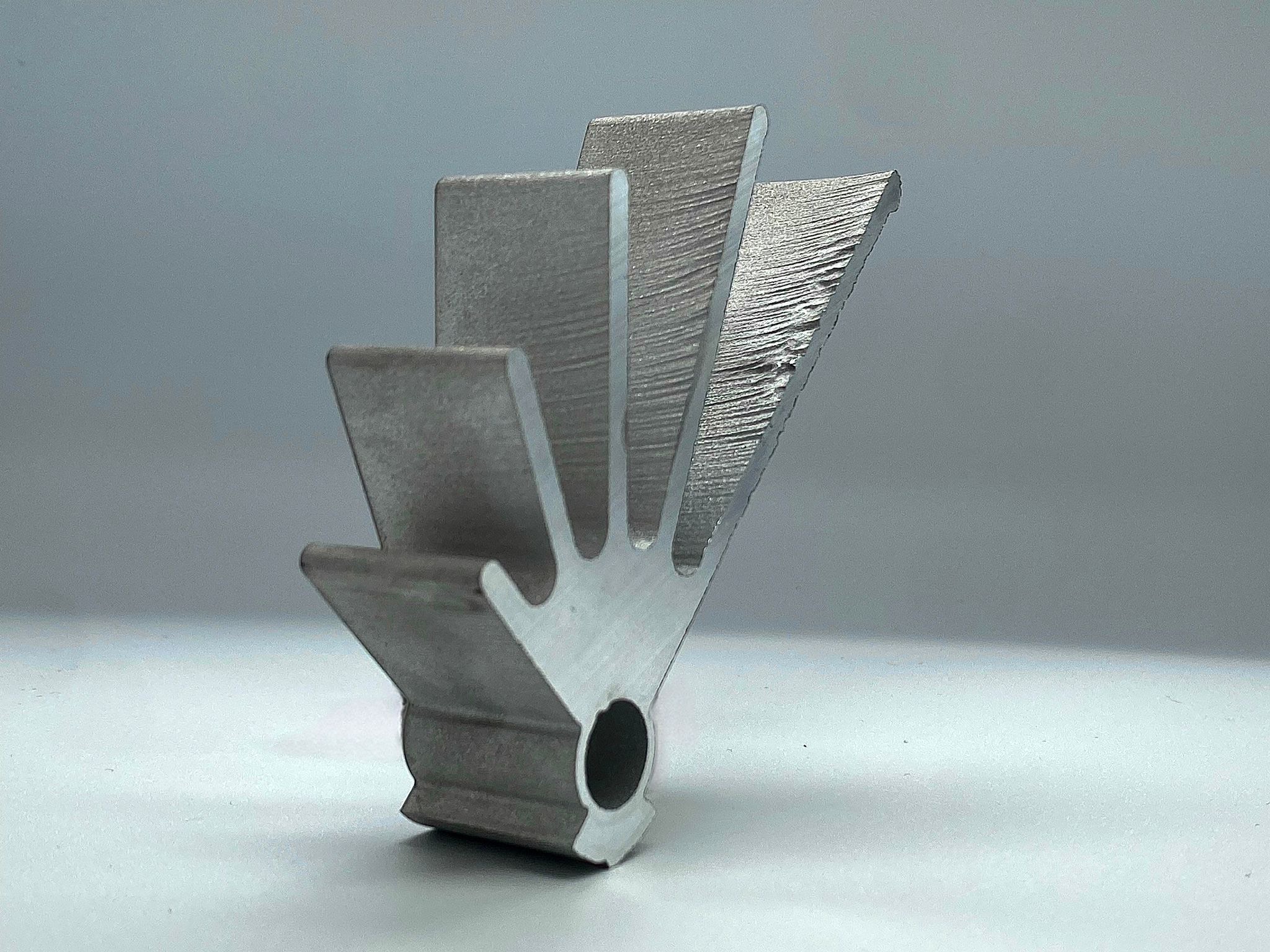

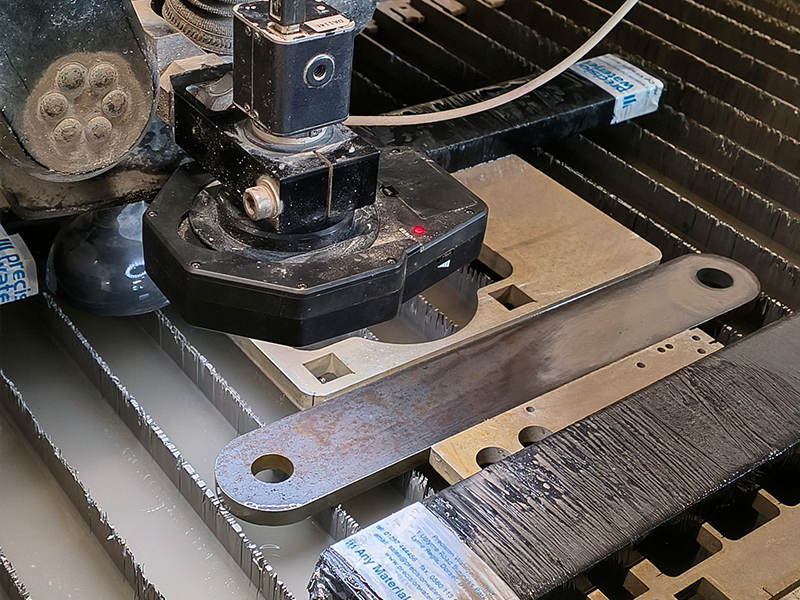

Case Study: Automotive Industry

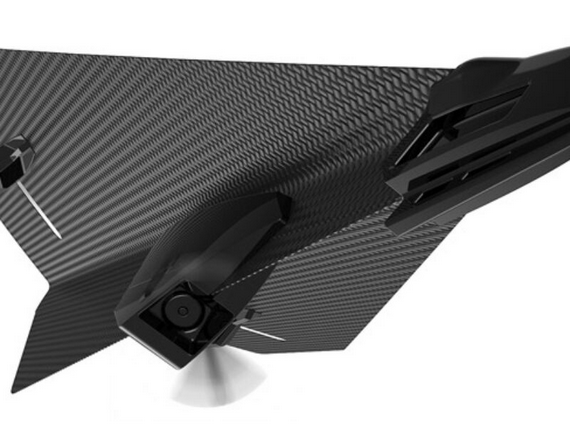

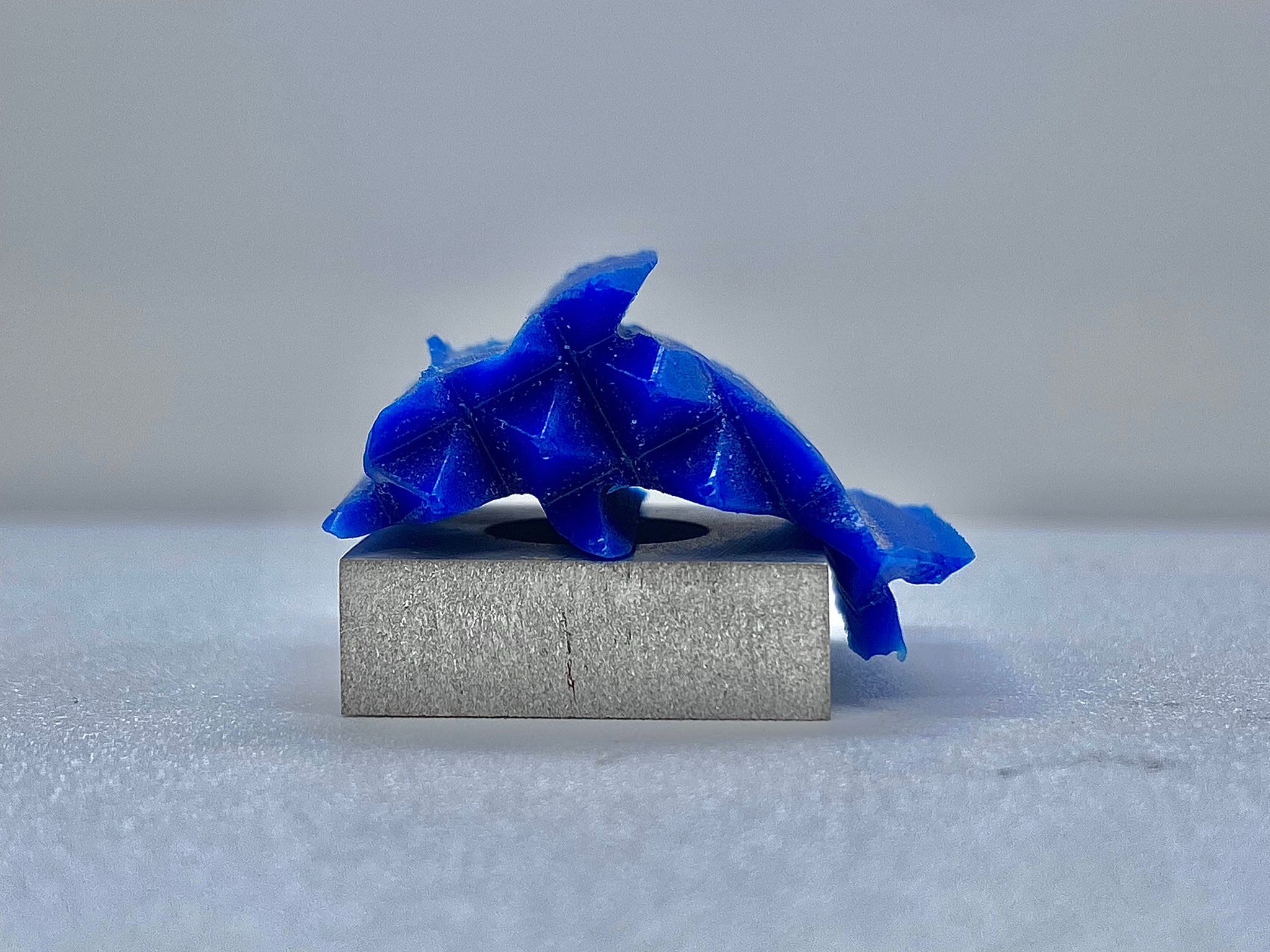

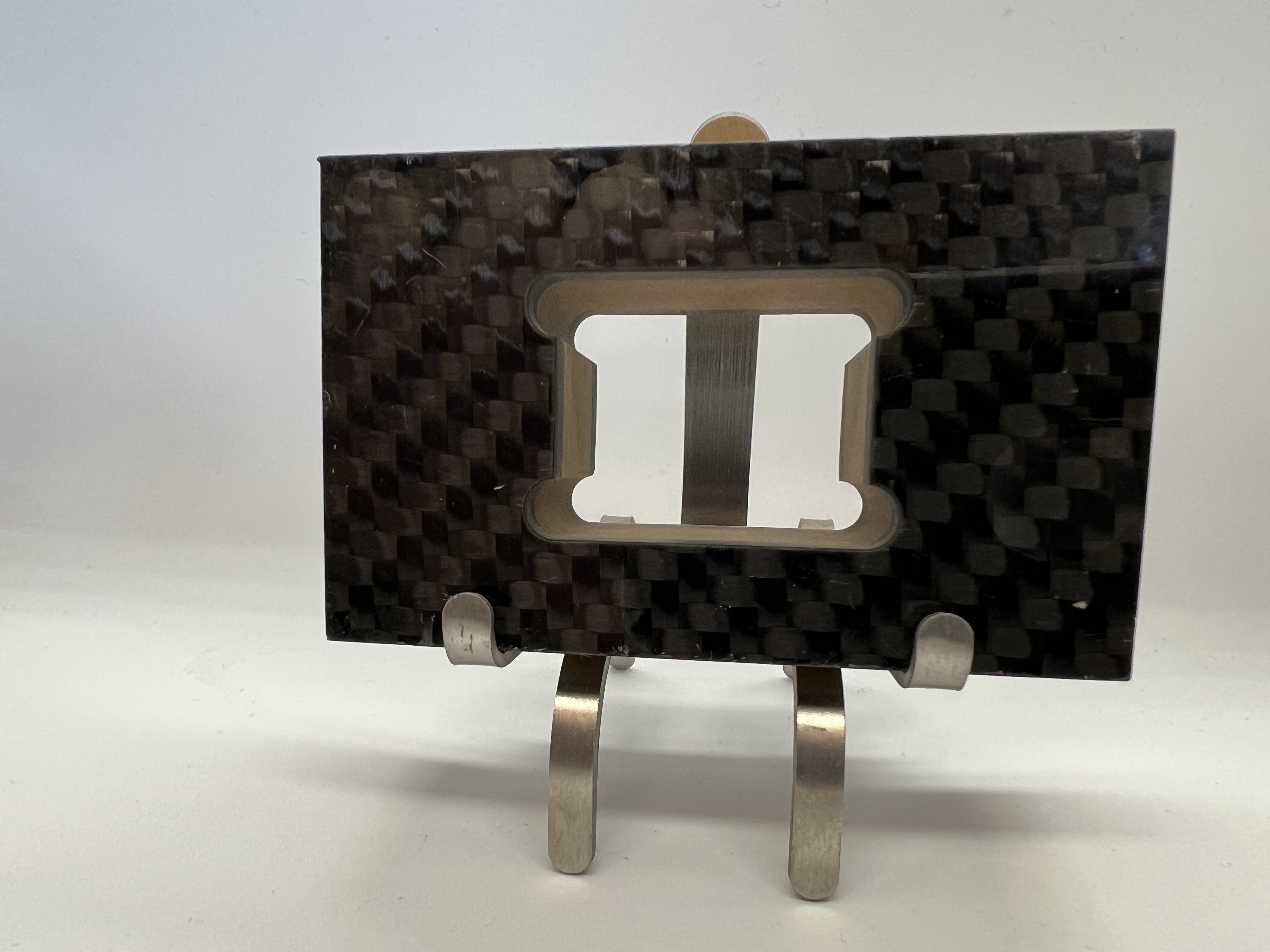

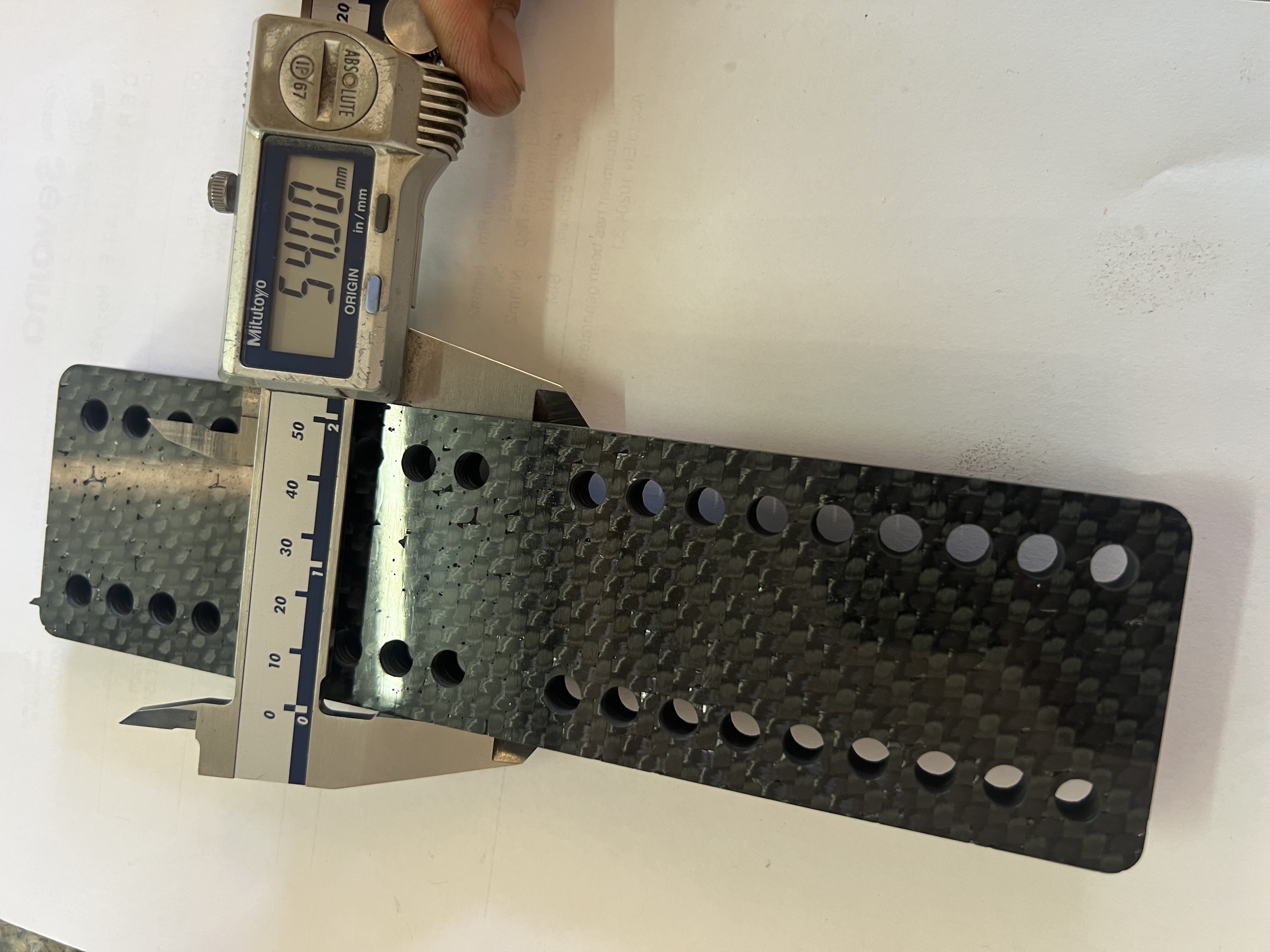

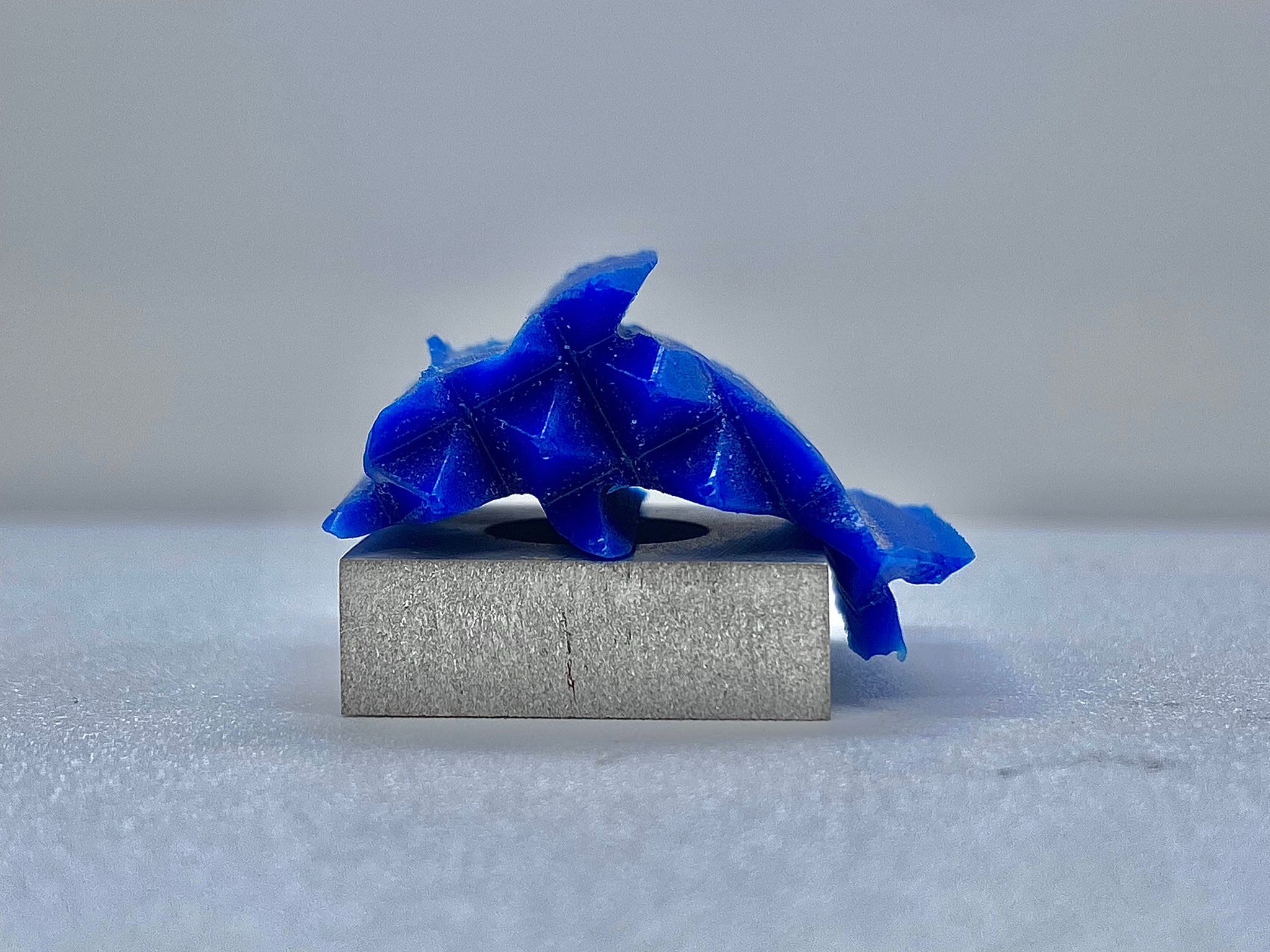

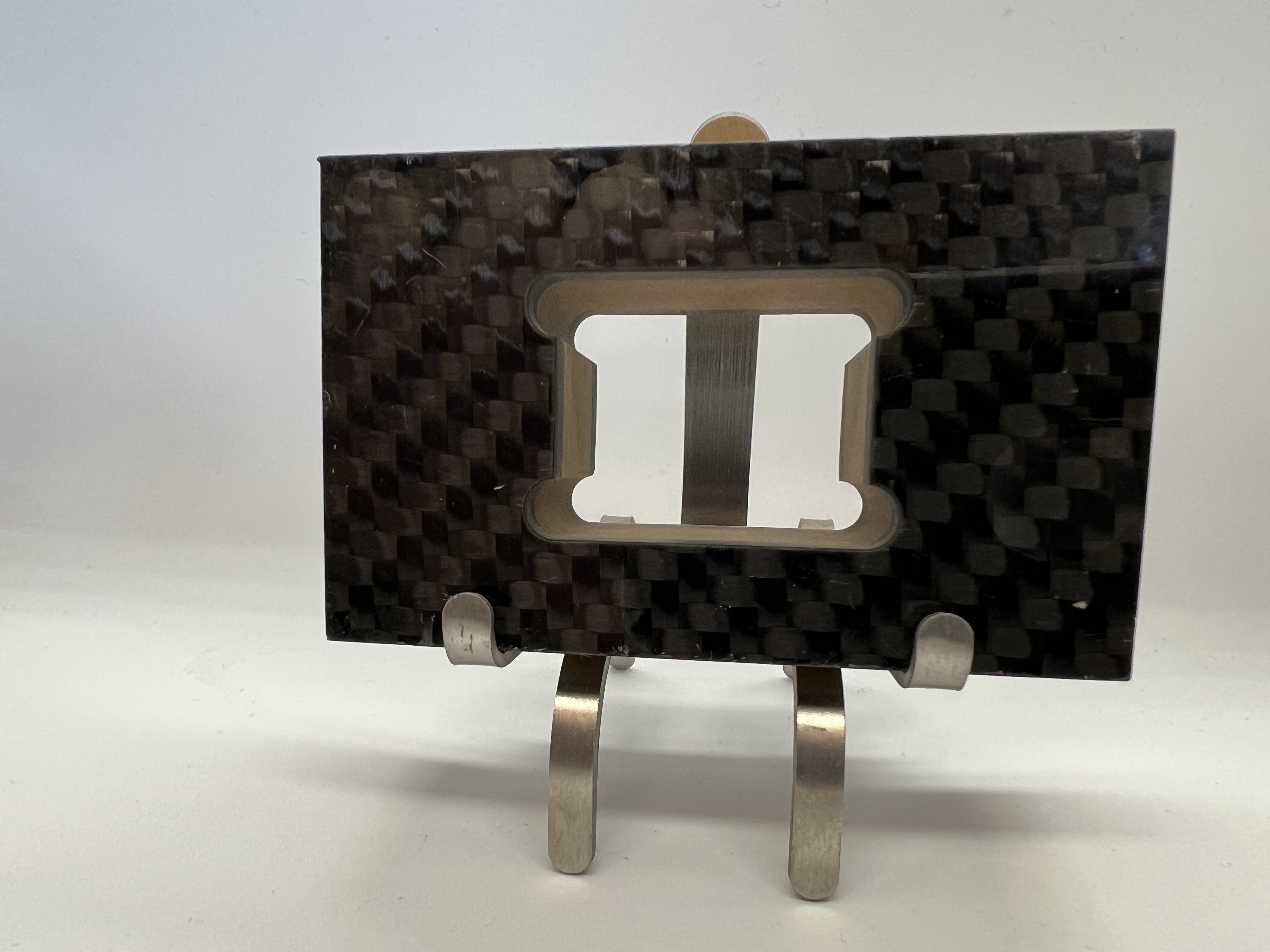

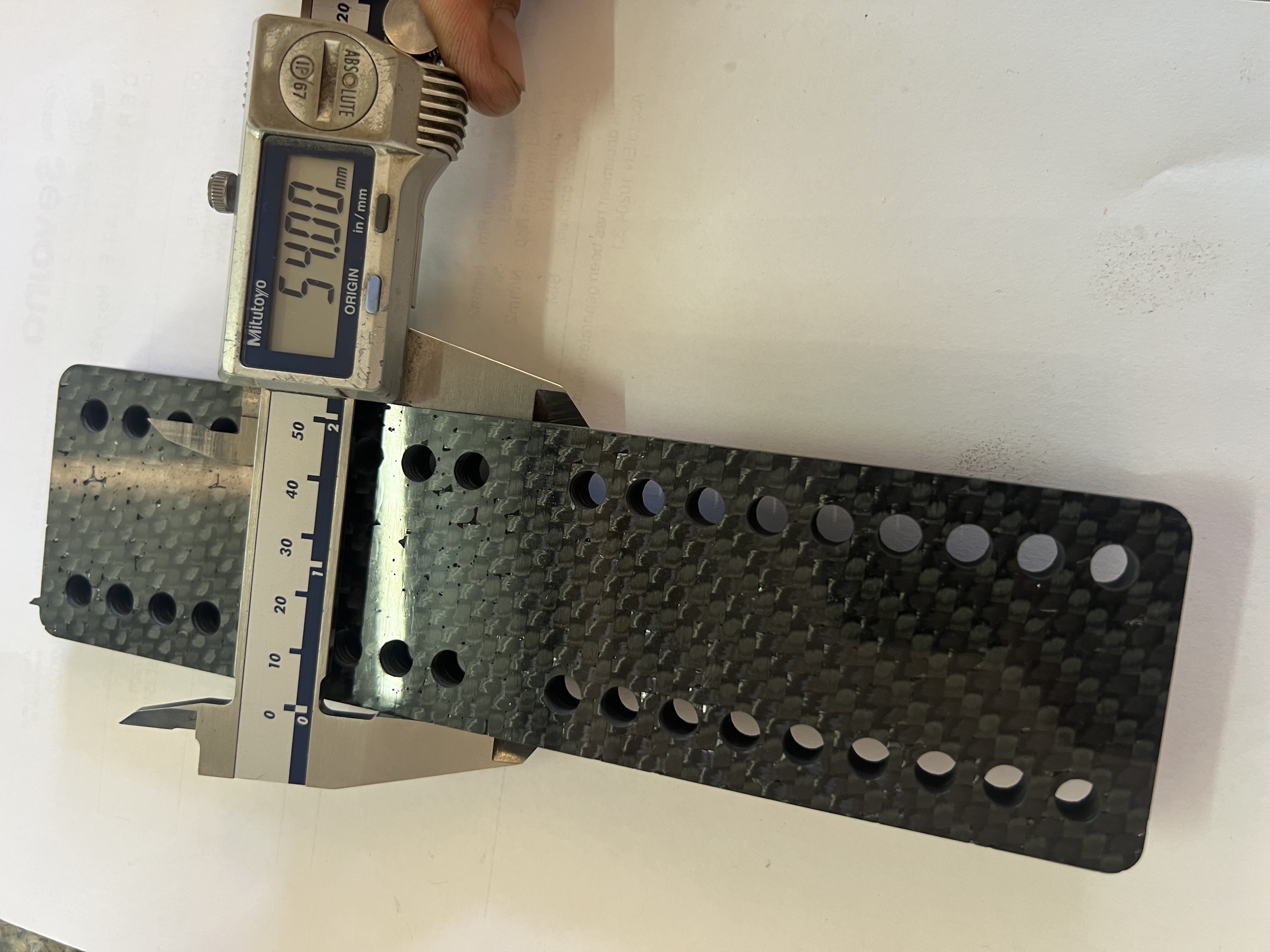

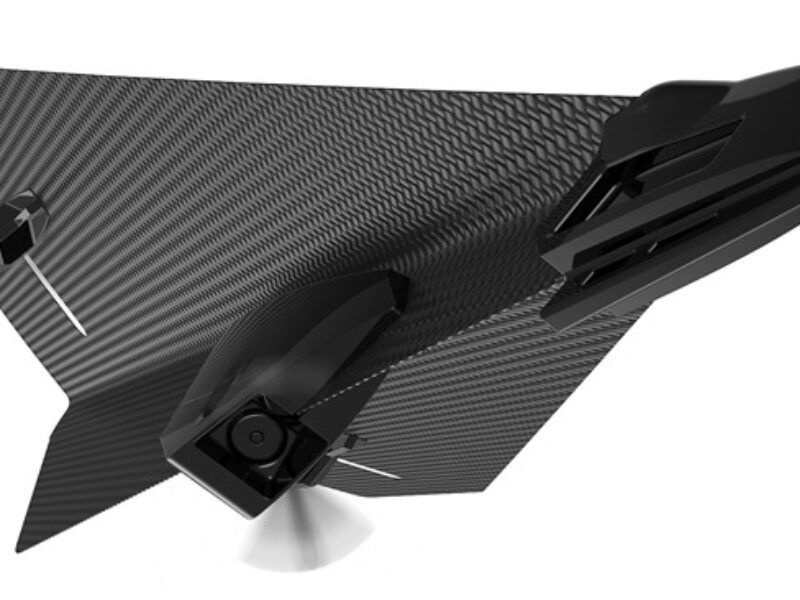

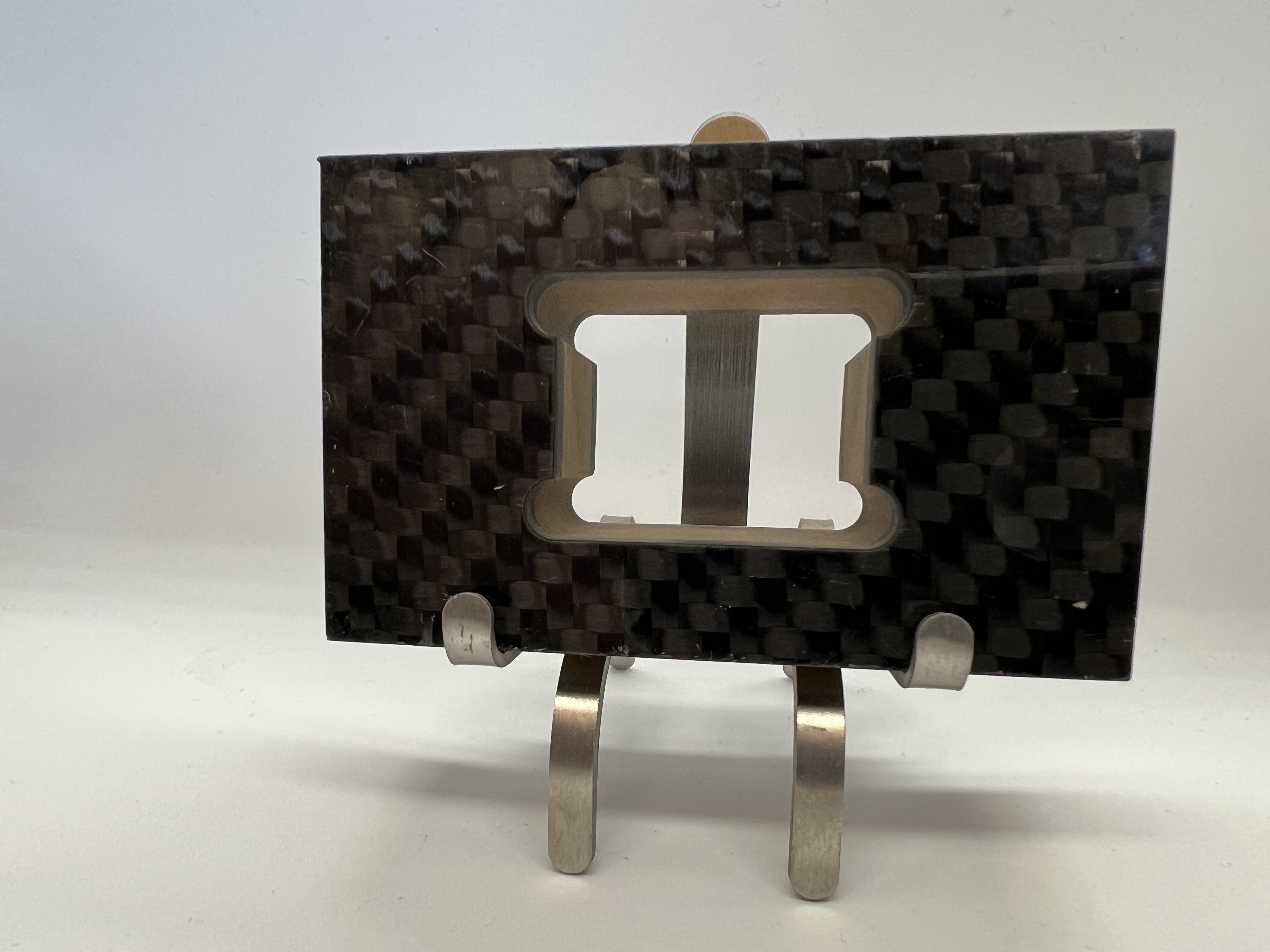

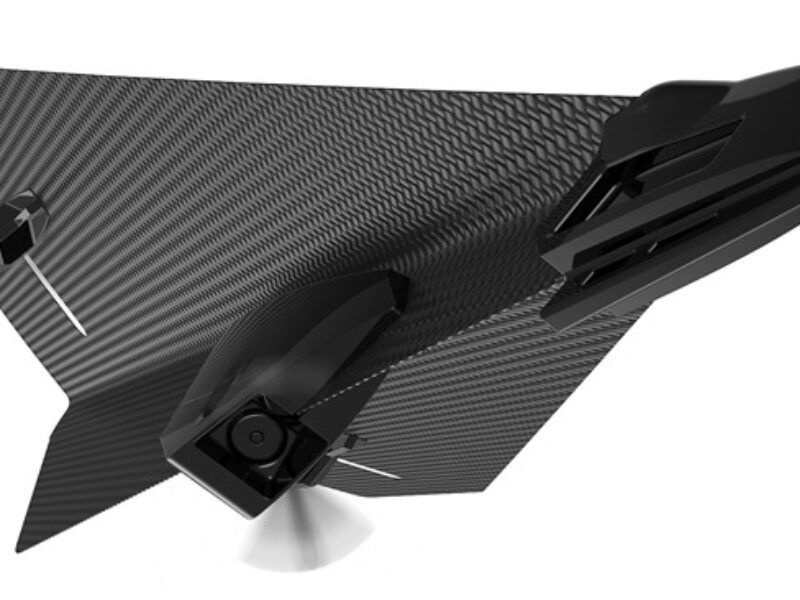

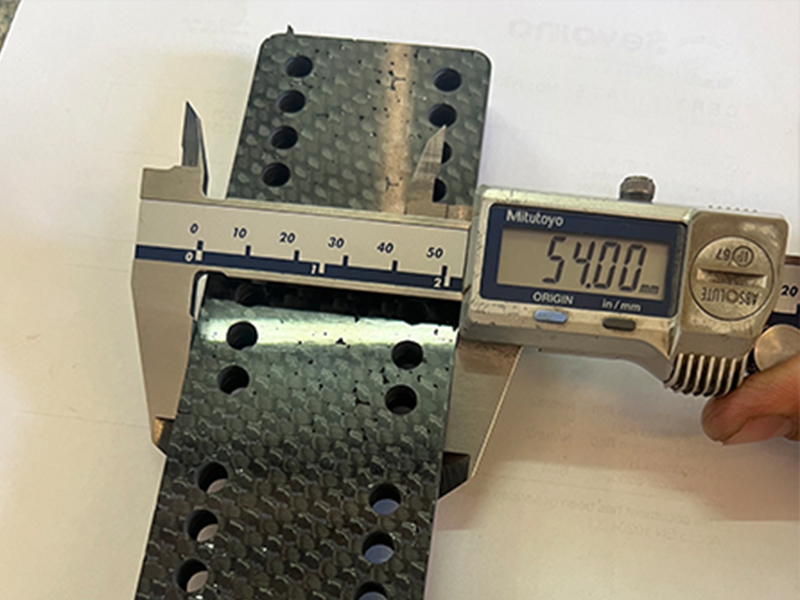

Case Study: Lightweight Composite Materials

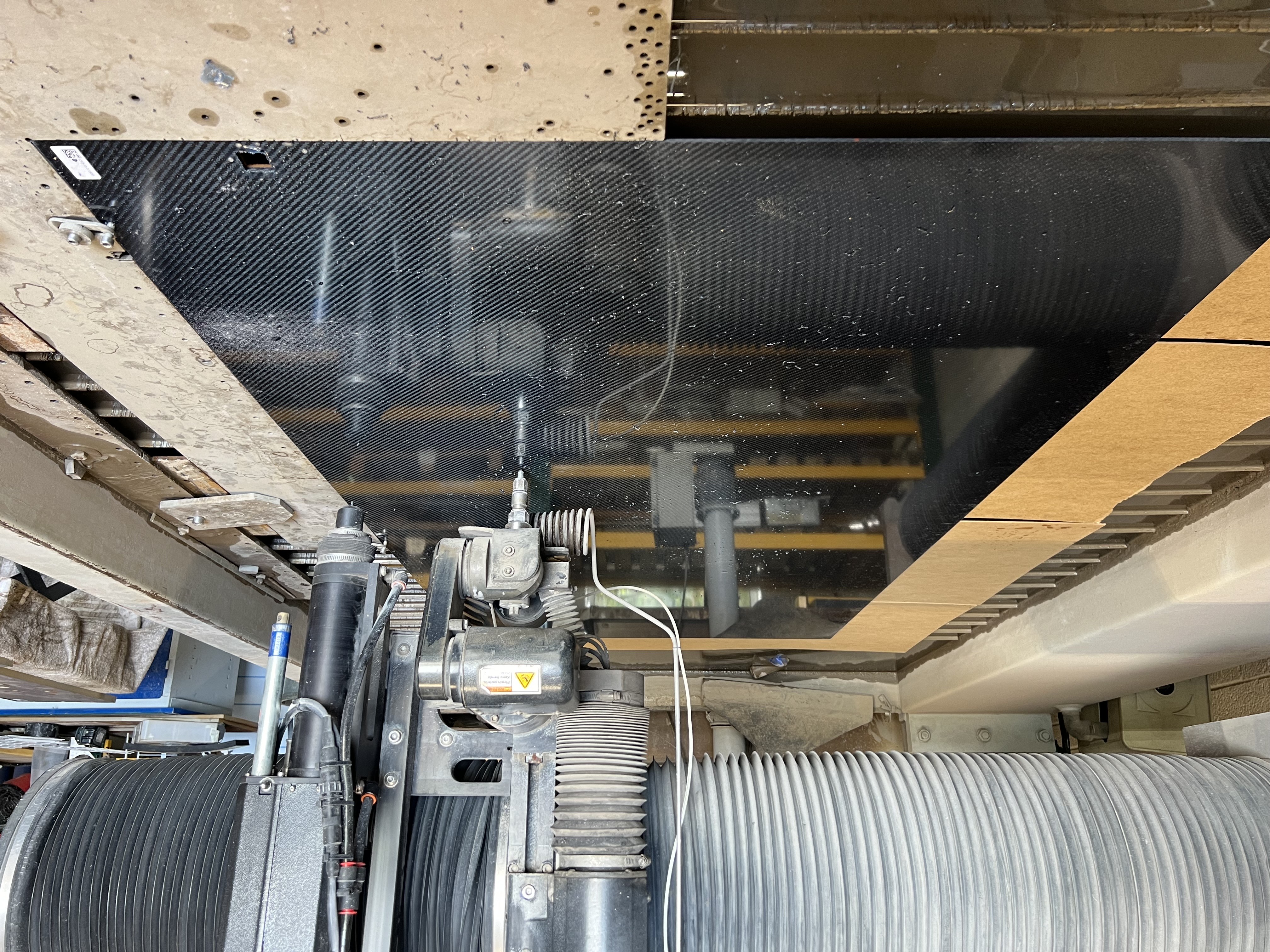

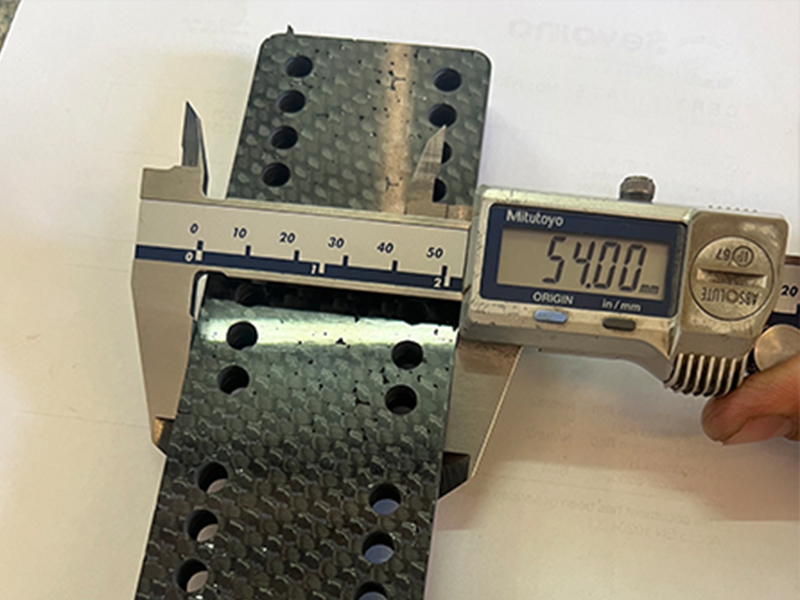

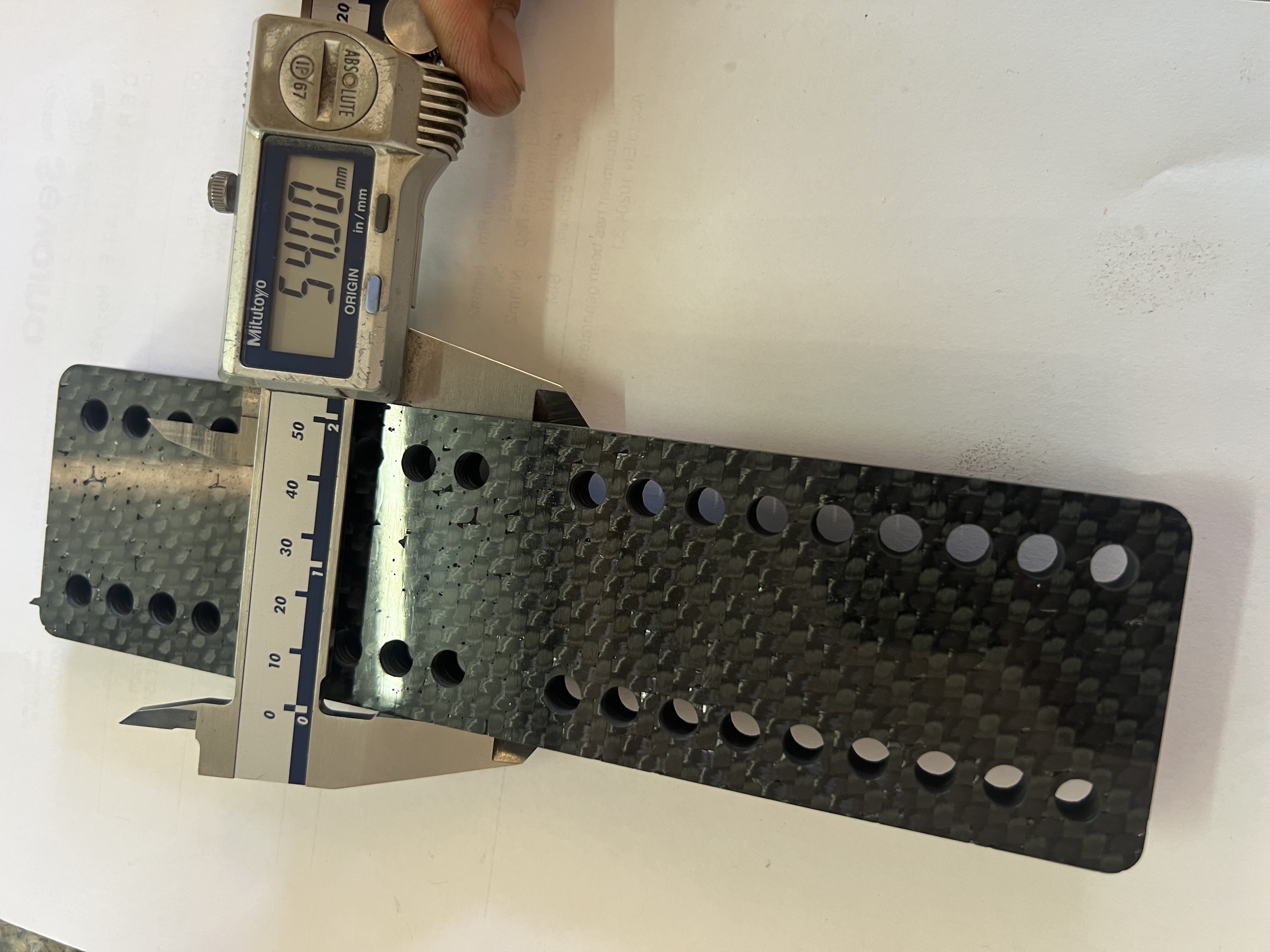

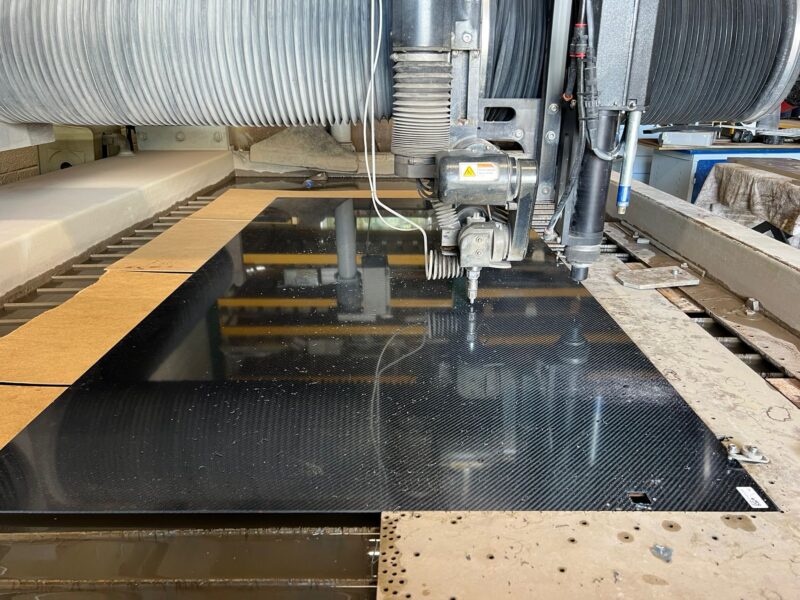

Challenges: A high-profile automotive manufacturer required 10mm high-strength carbon fibre components to be cut with extreme precision, ensuring all parts met strict internal dimensional specifications. The client also needed clean, smooth edges with no risk of material delamination.

Solutions: By leveraging our state-of-the-art waterjet machines and precision pneumatic drilling technology, we eliminated the risk of delamination and removed the need to “pierce” the material. The advanced waterjet cutting process guaranteed every component was accurately dimensioned, arriving ready for immediate assembly on site.

Benefits: The client experienced reduced material waste and lower costs, along with rapid turnaround times. Parts were delivered ready to fit without additional machining, saving further expenses and ensuring all components aligned perfectly with their specifications.

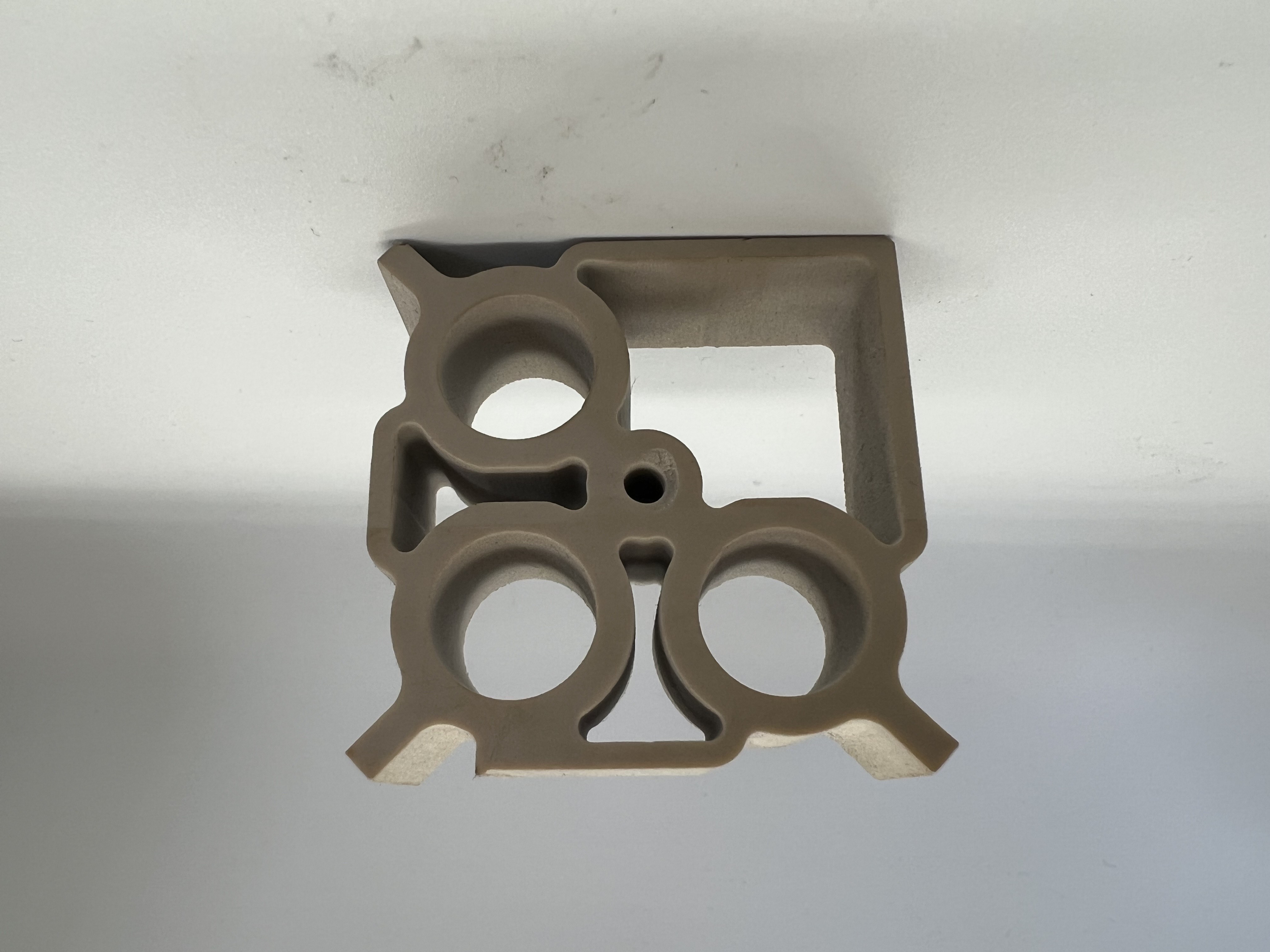

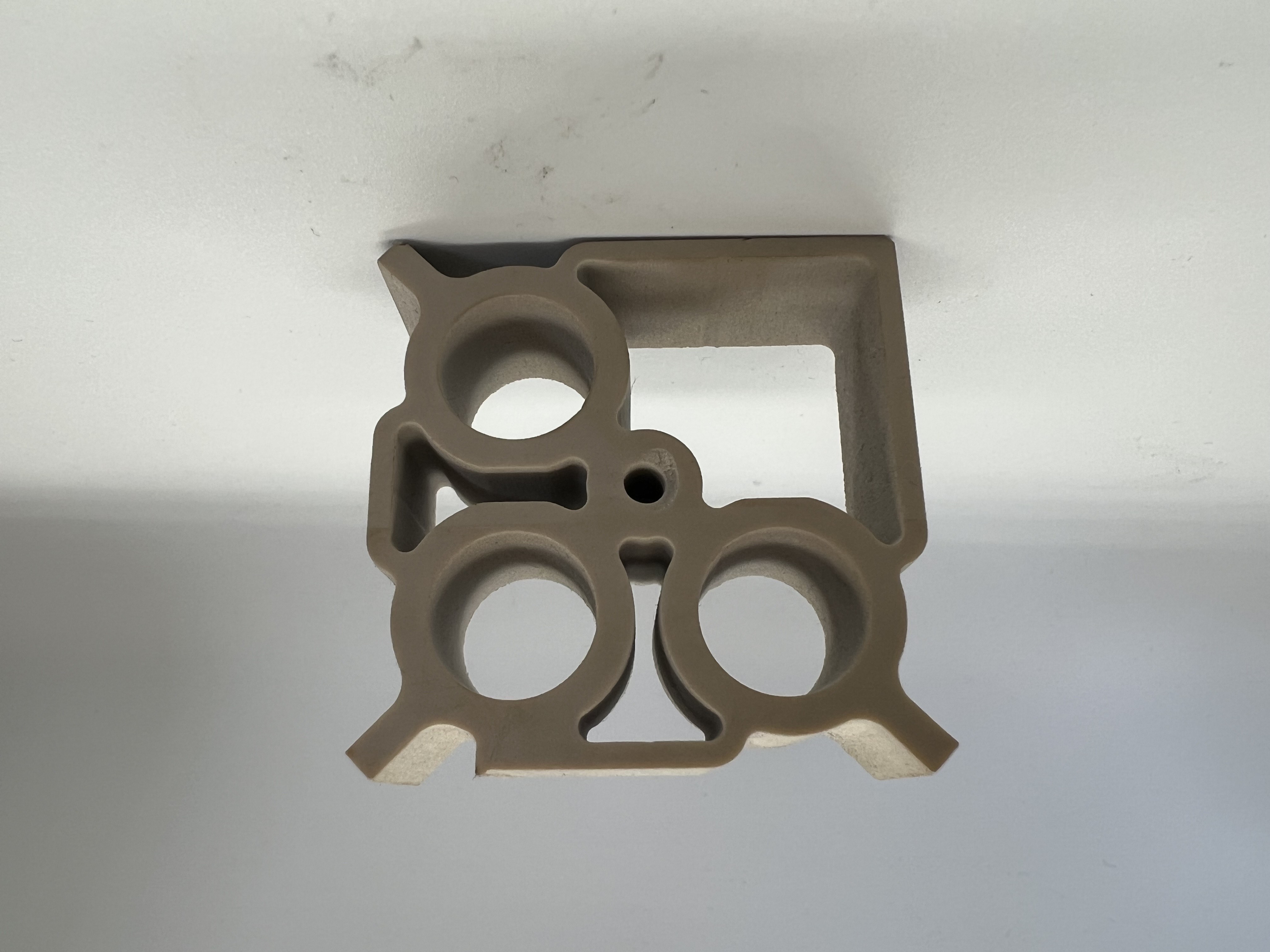

Case Study: Marine Industry

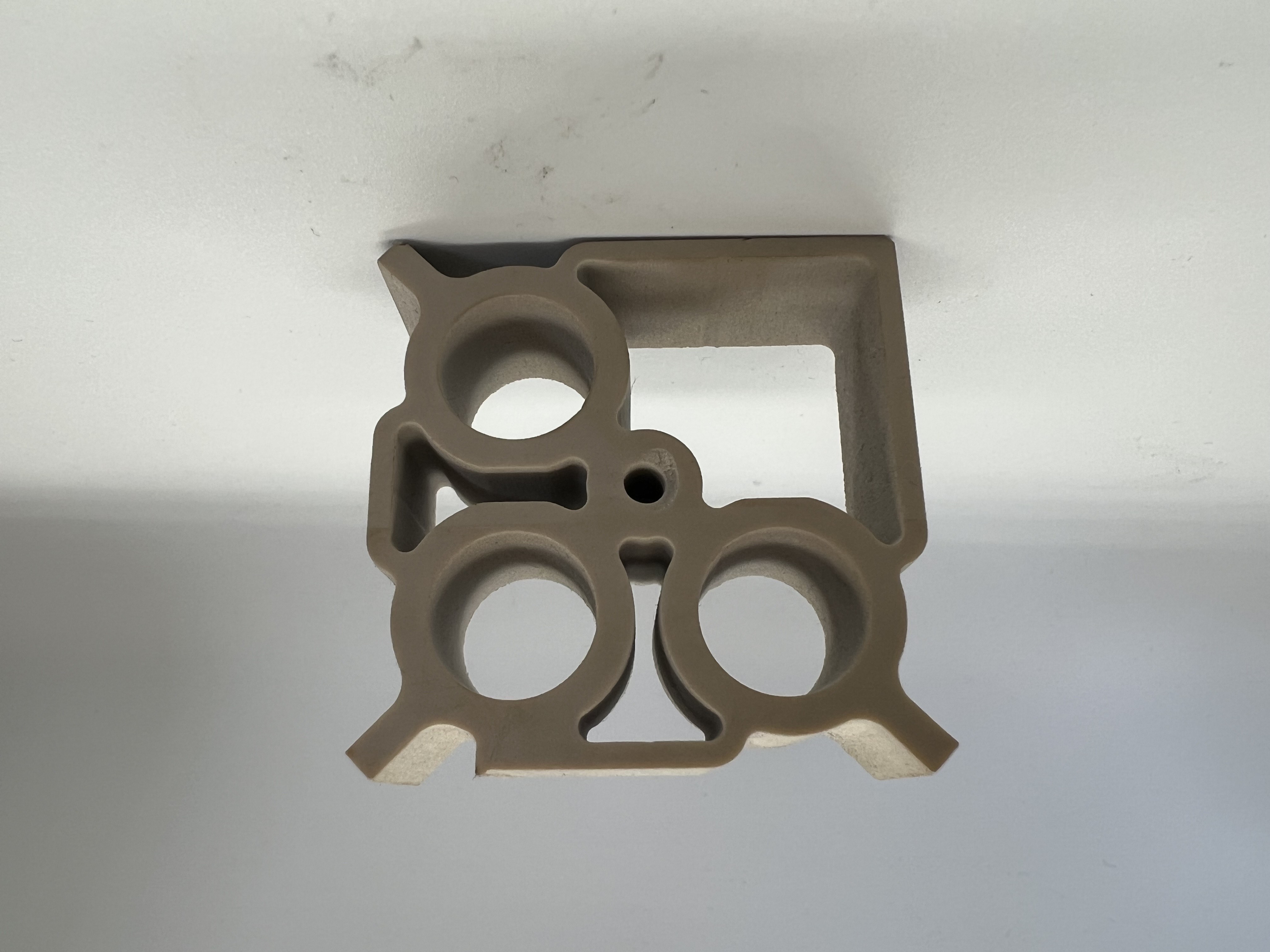

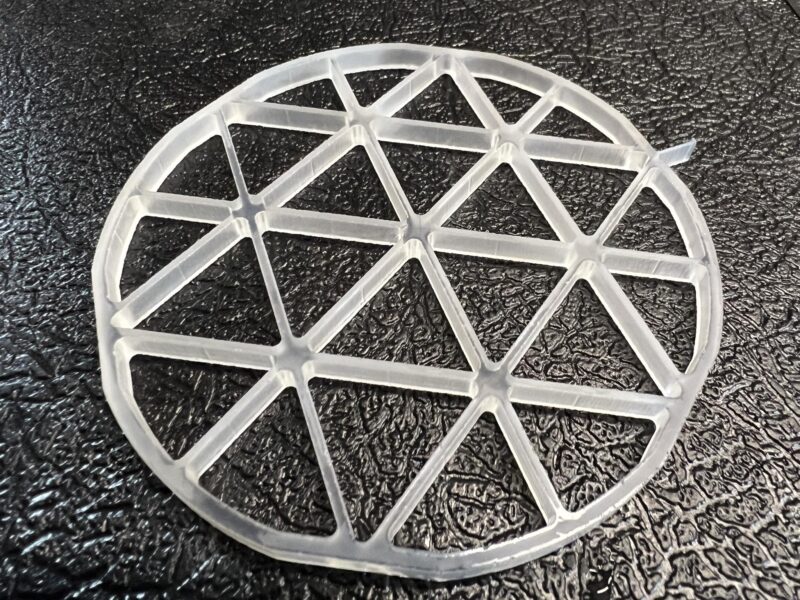

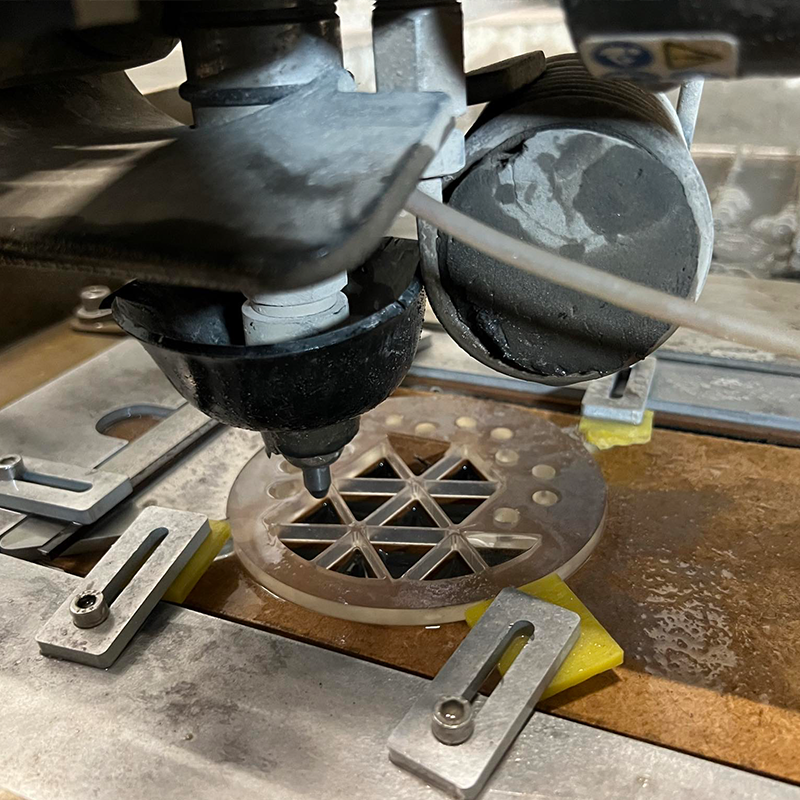

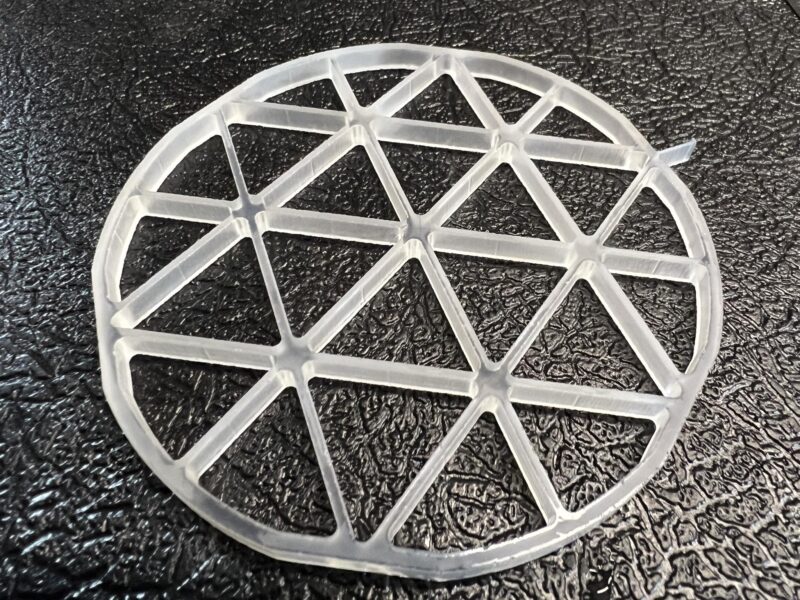

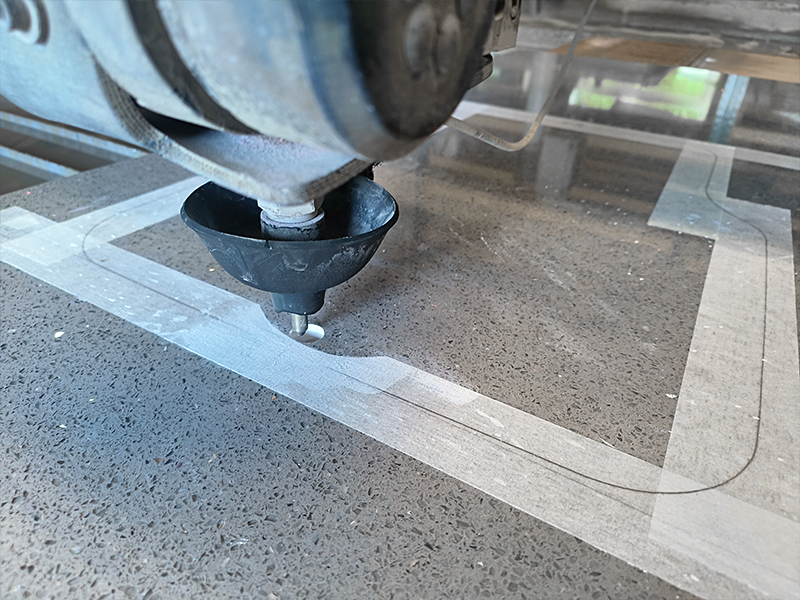

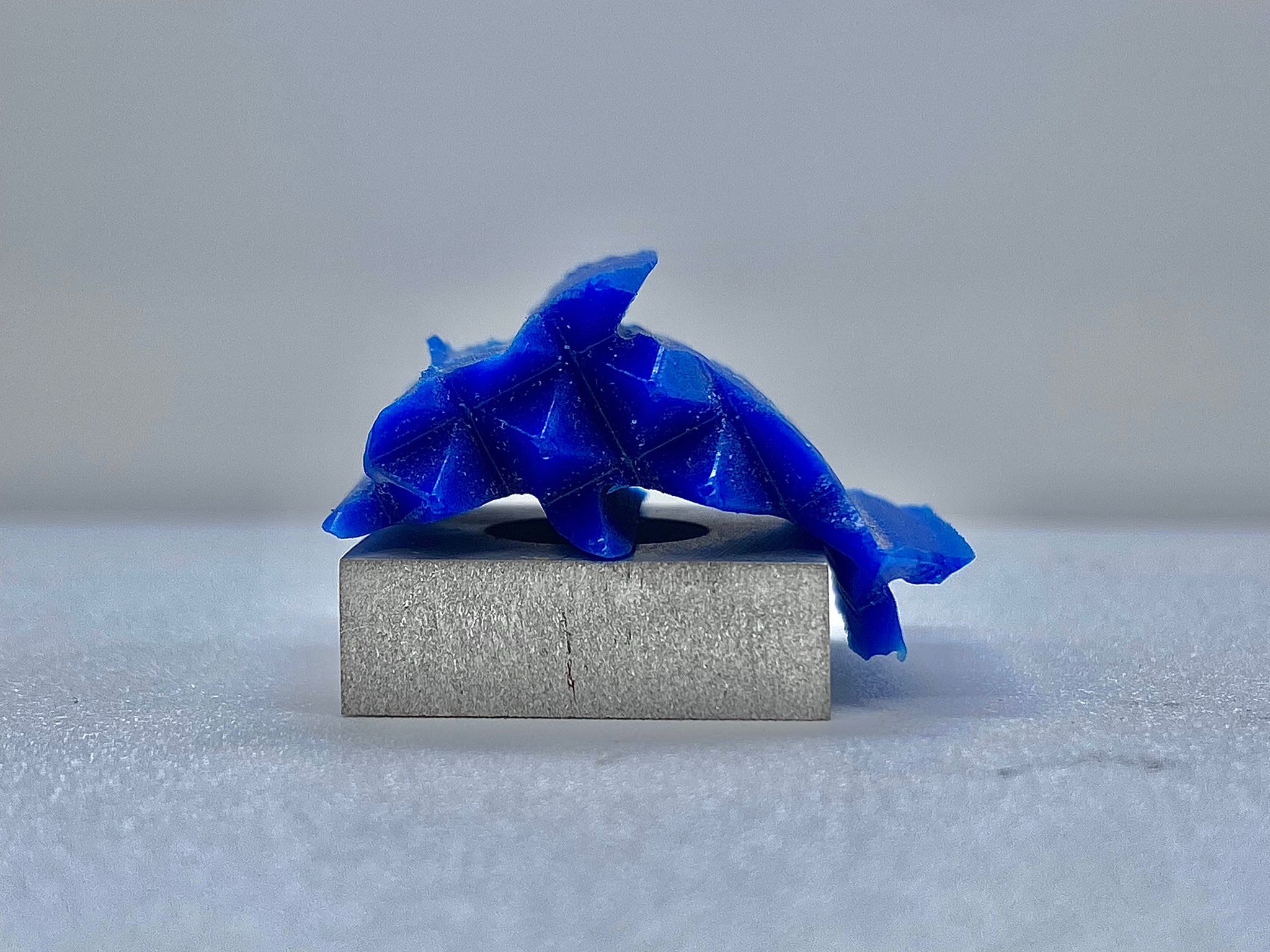

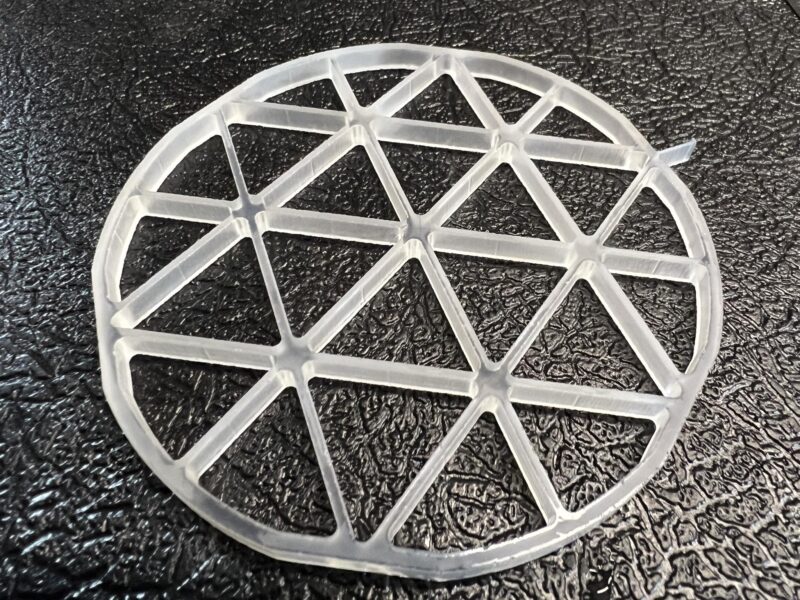

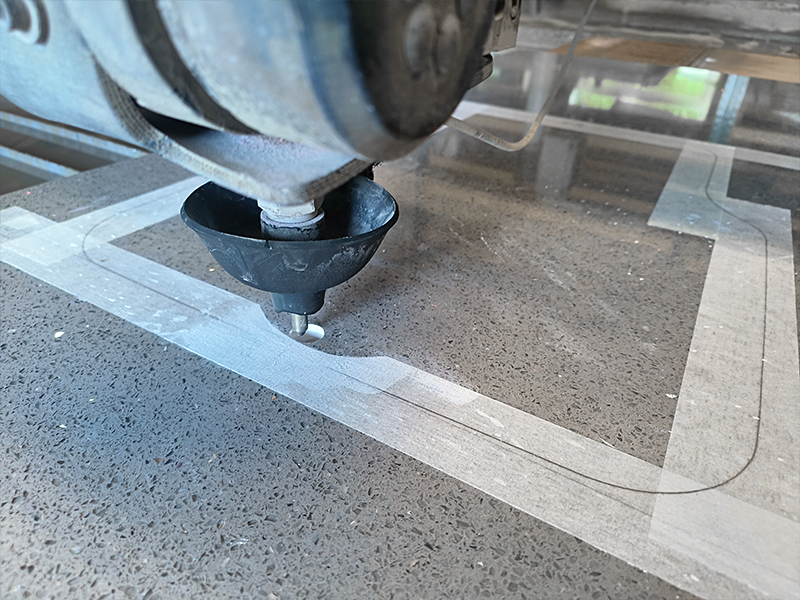

Case Study: HDPE with the Waterjet

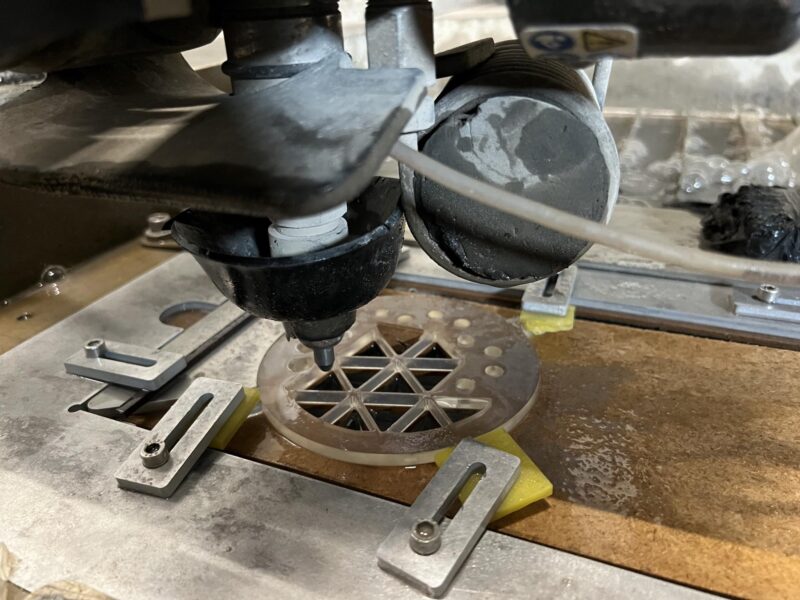

Challenges: An marine company have been testing the use of high-density polyethylene as a material for an unmanned vessel that requires parts with no imperfections and additional tapping and countersinking. Typically they have found HDPE tends to crack with traditional machining methods.

Solutions: Using our world class precision pneumatic drill and top of the range Waterjet machines enabled us to mitigate any issues with cracking and remove the requirement to “pierce” the material. The waterjet process ensured that each piece was cut to precise dimensions. The requirement was also to provide precision countersinking and tapped holes to ensure the parts were ready for assembly once they arrived on site.

Benefits: The customer benefited from the mitigation of hairline cracks that have been found using traditional methods, using the OMAX nesting facilities reduced material usage and cost, we also provided short lead times and parts that fitted the application without further machining reducing further costs and ensuring parts aligned with the drawings provided.

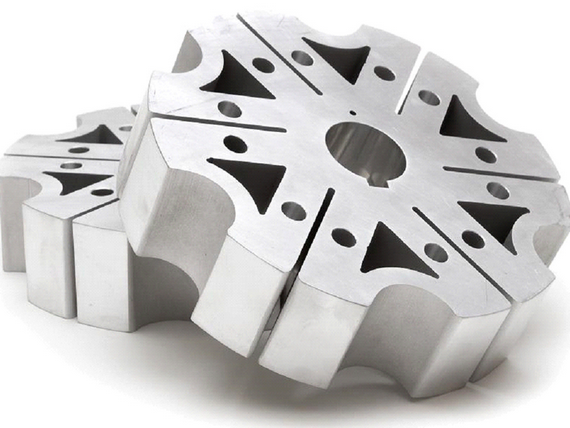

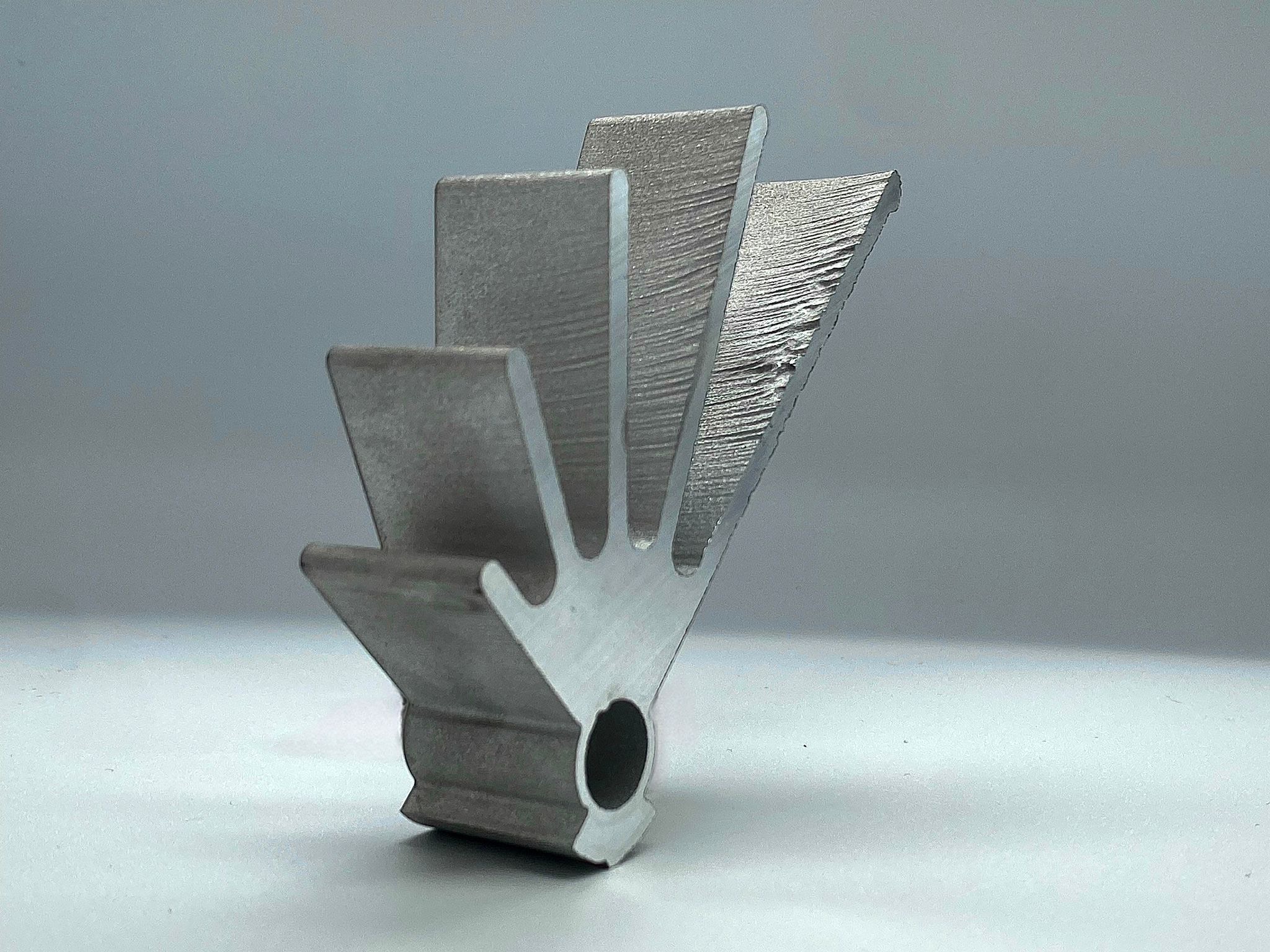

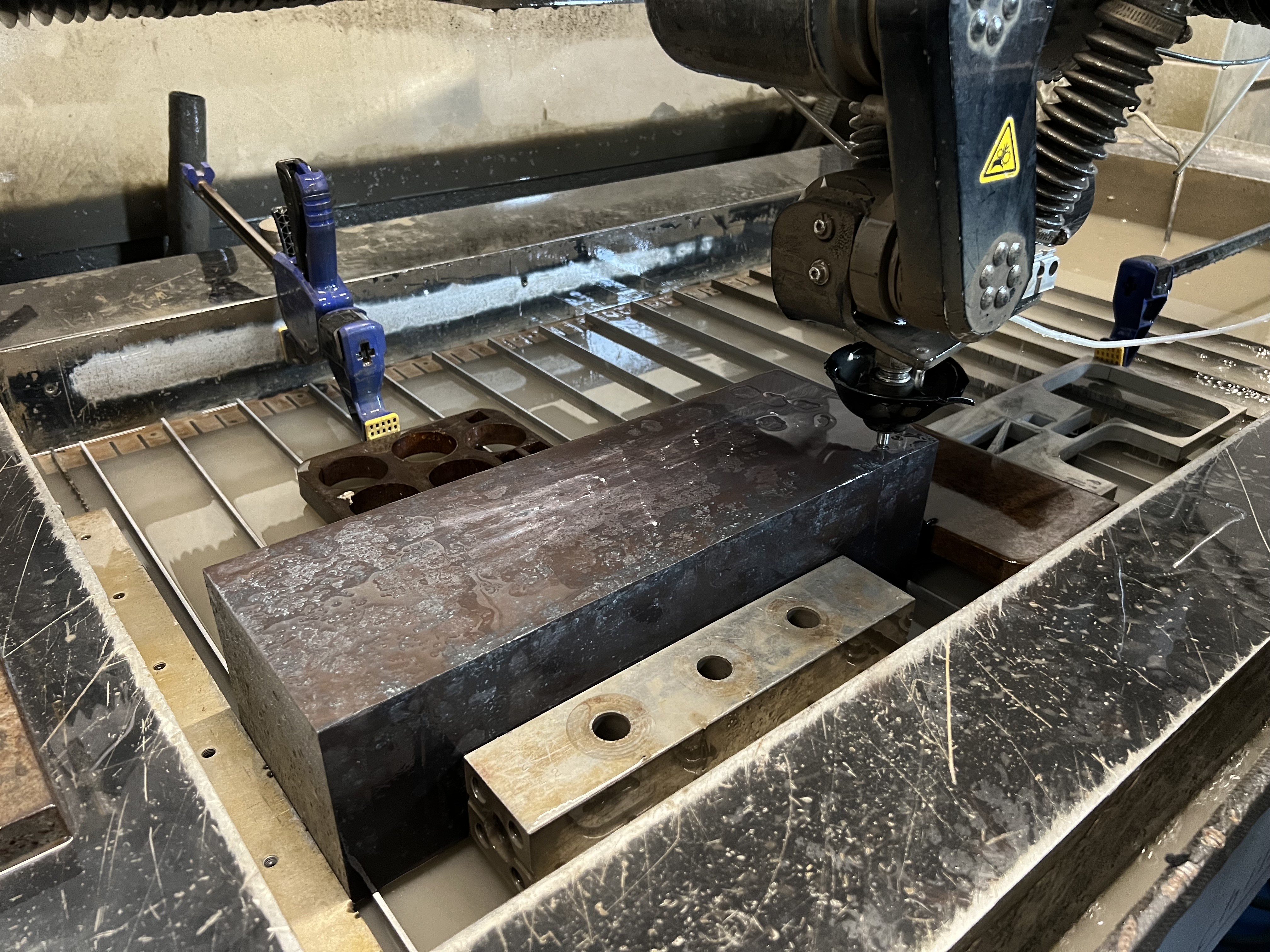

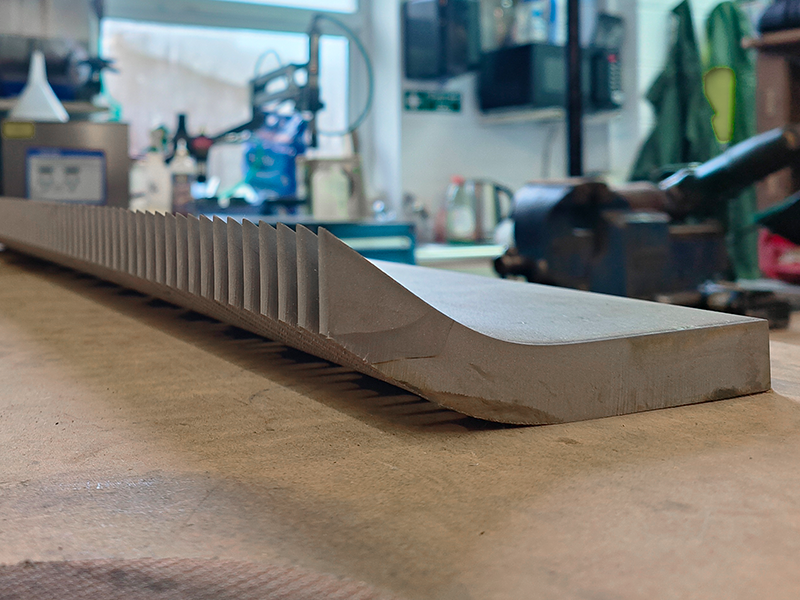

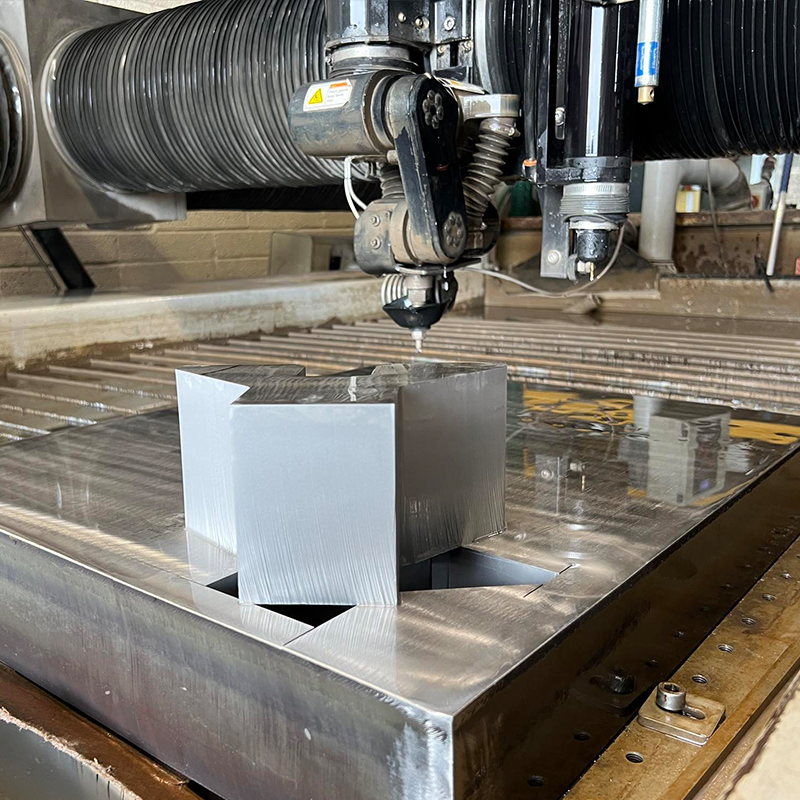

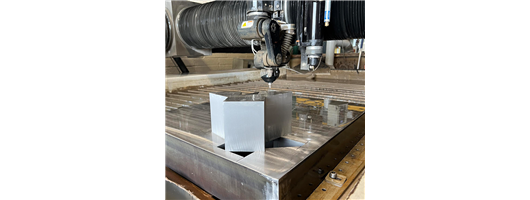

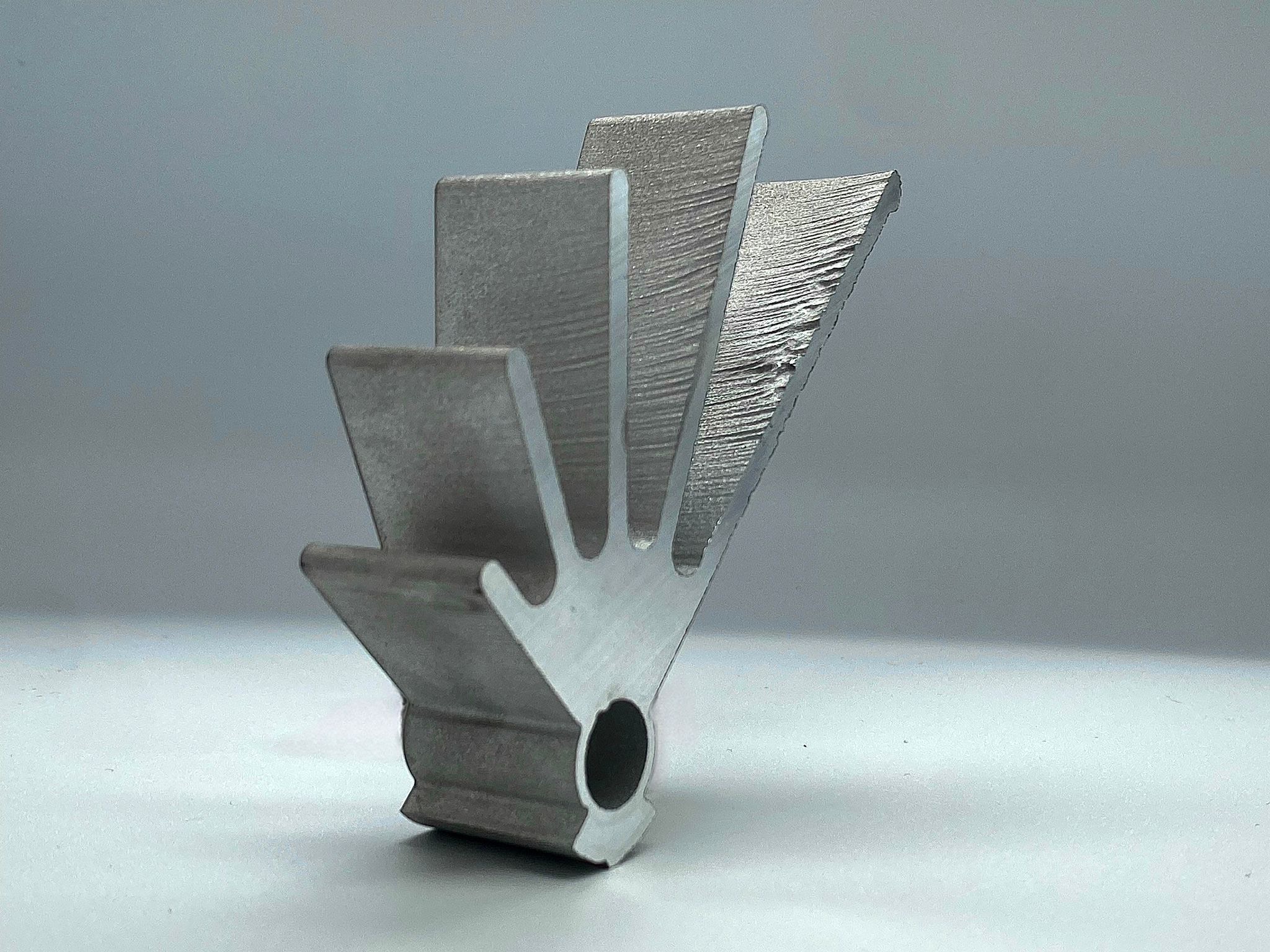

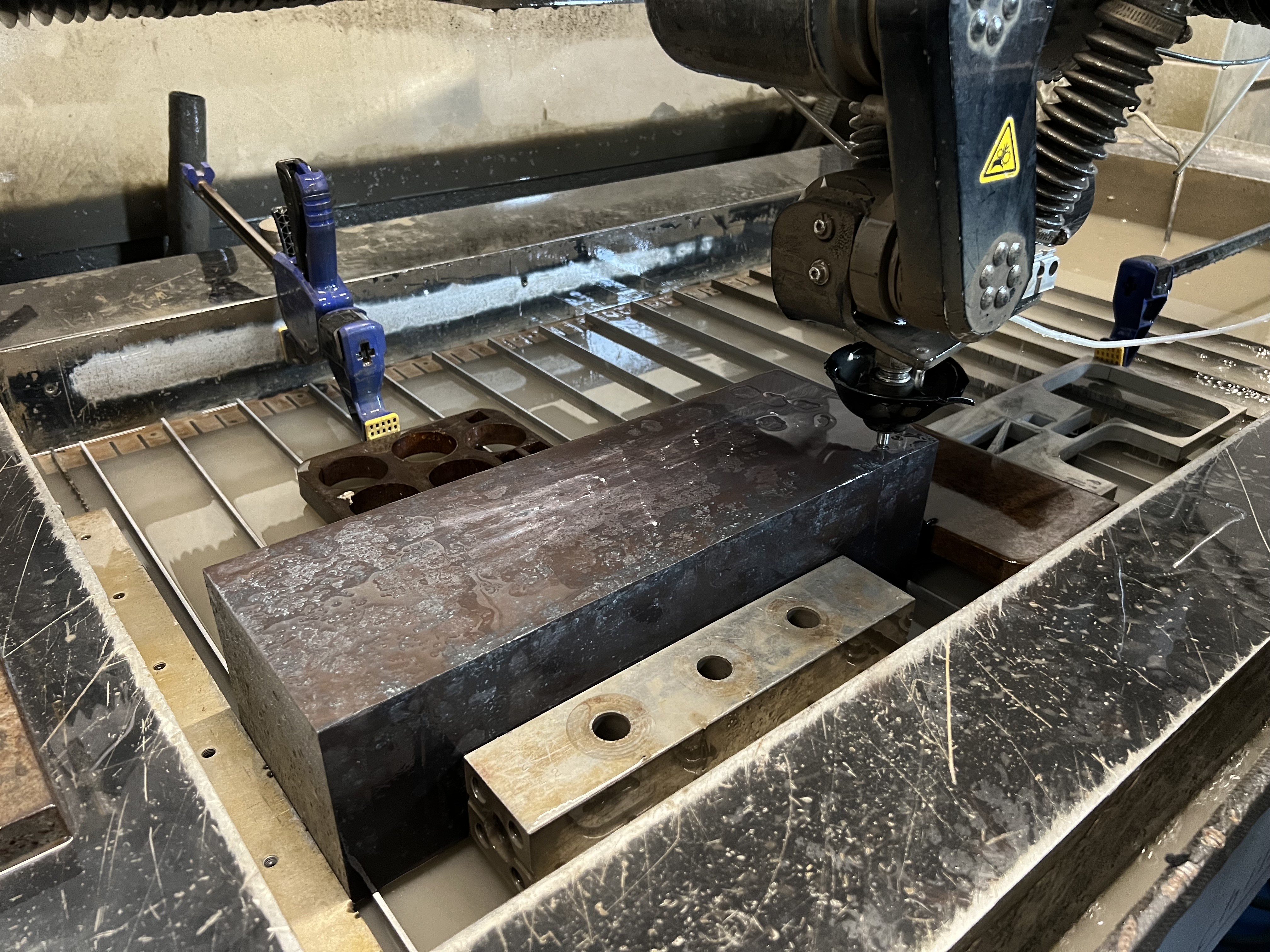

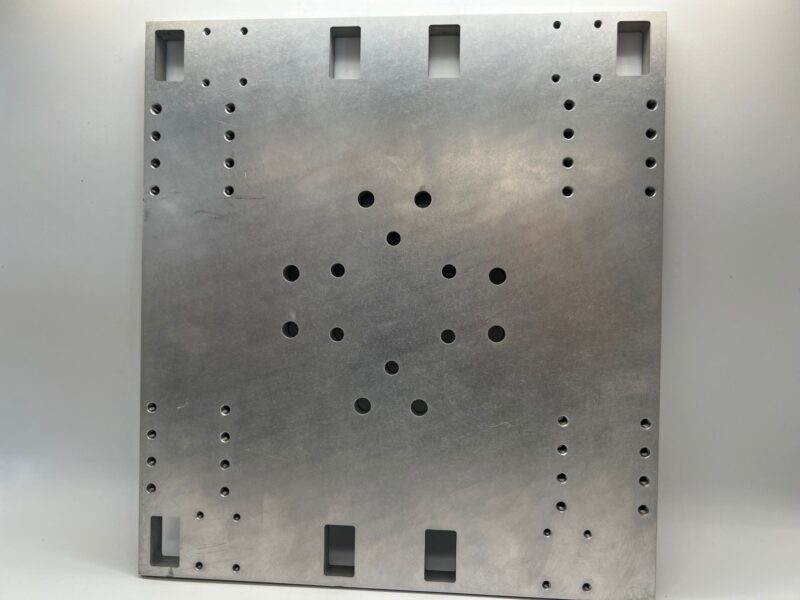

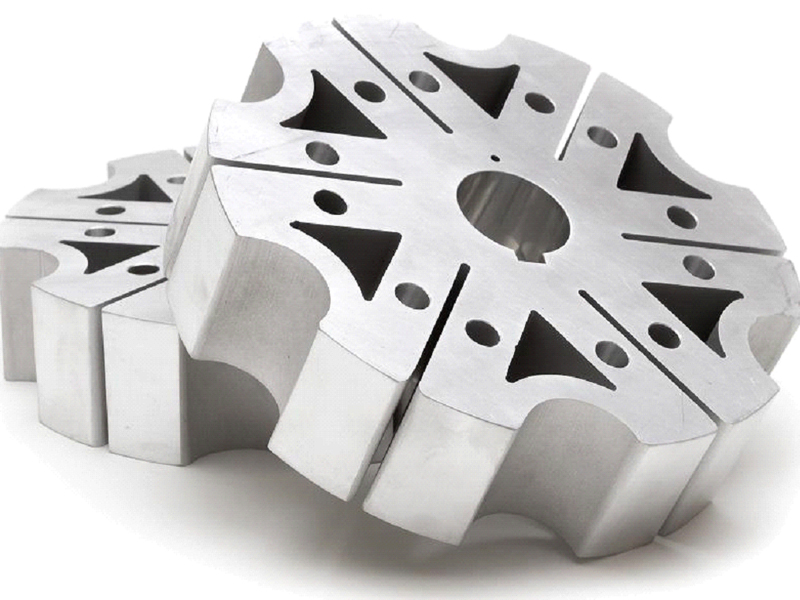

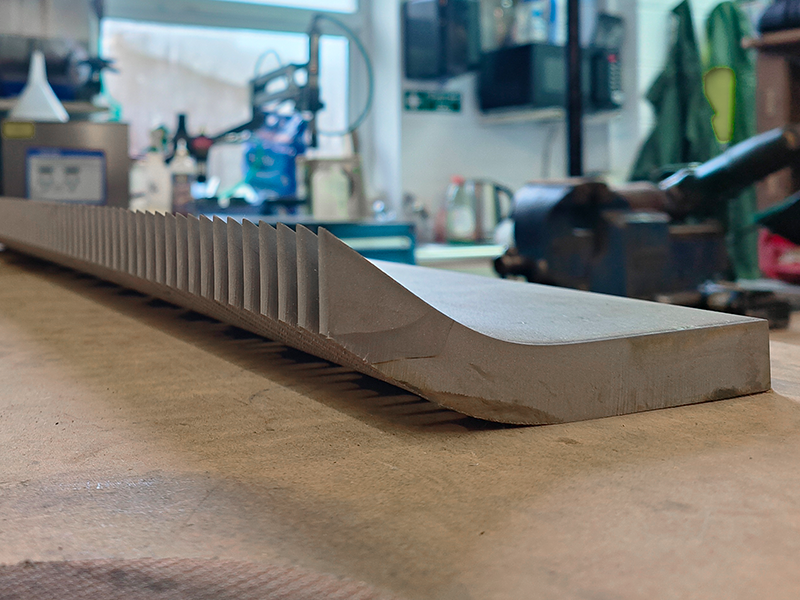

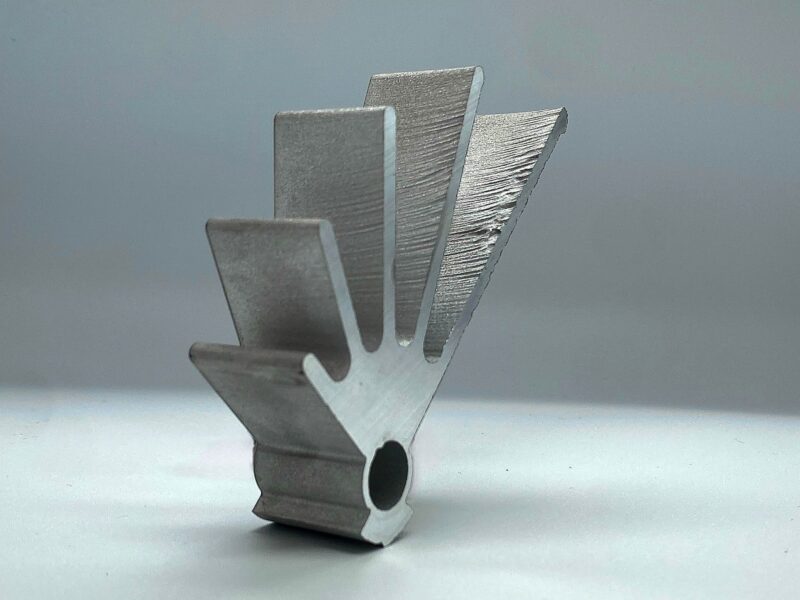

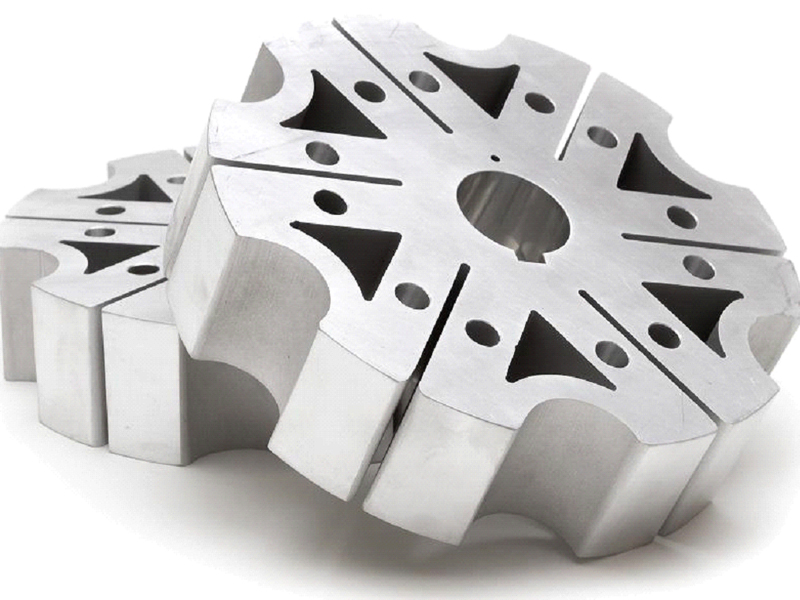

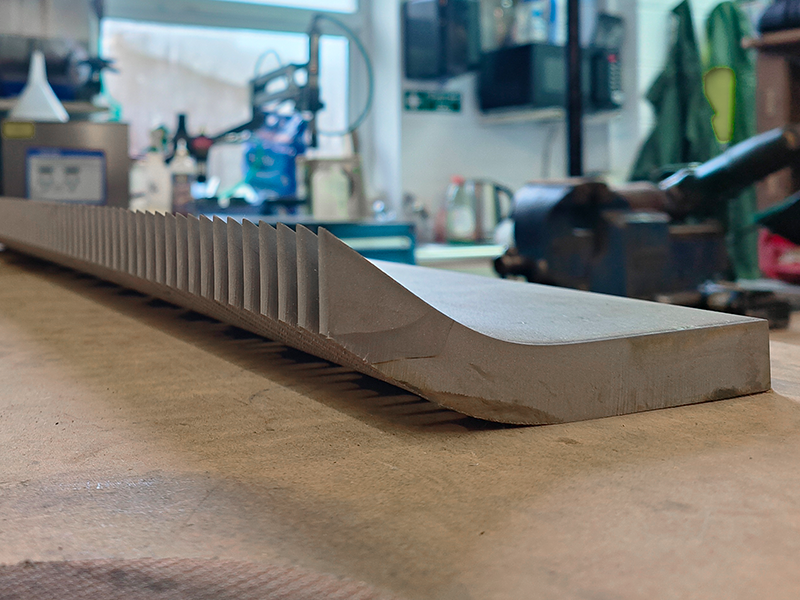

Case Study: Nuclear Industry

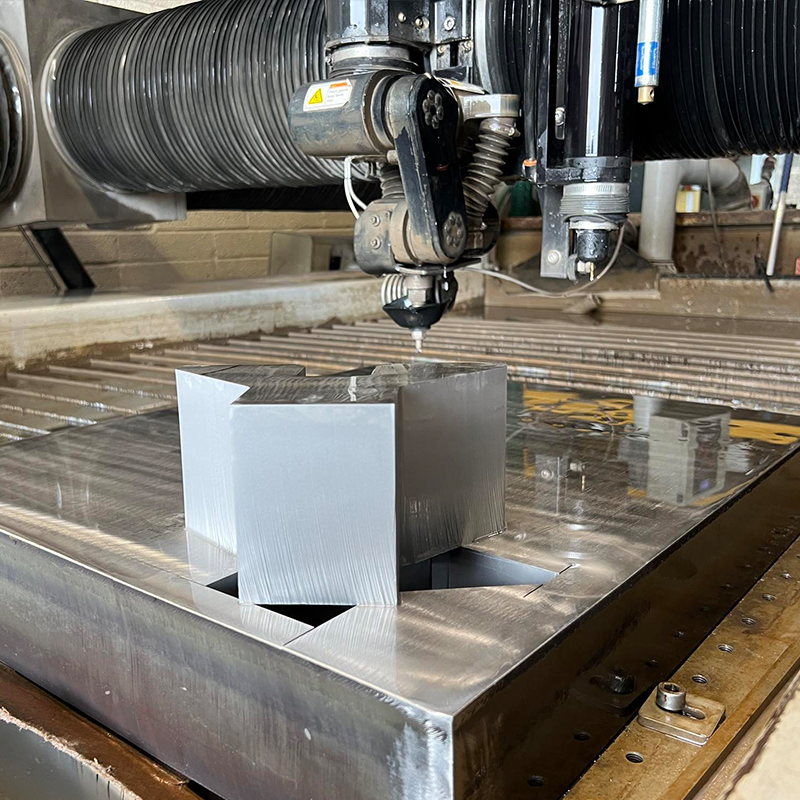

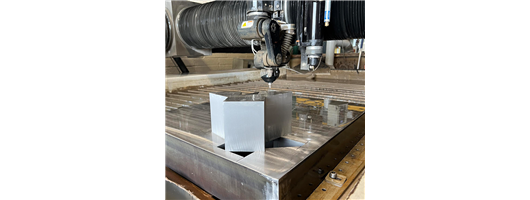

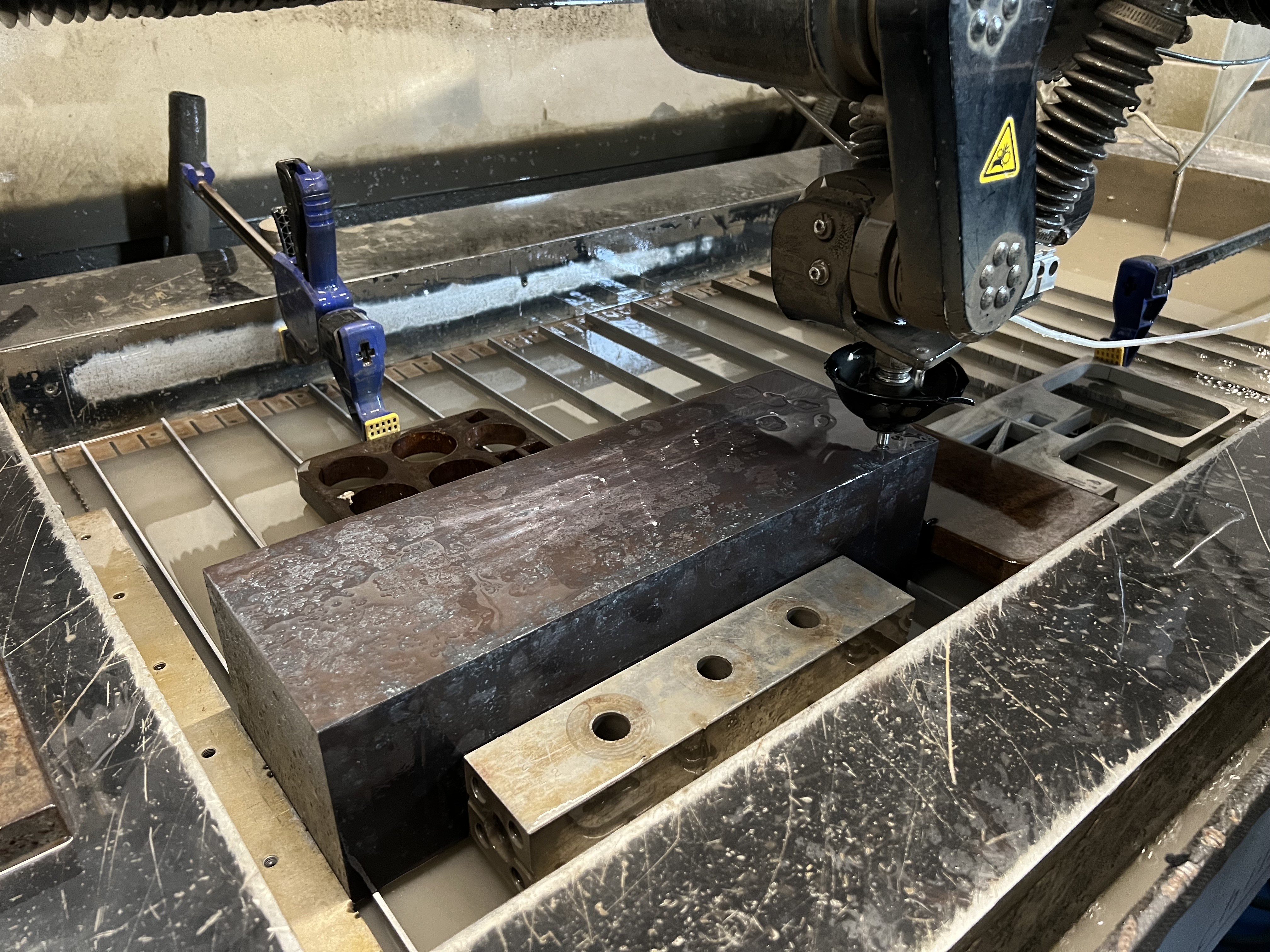

Case Study: 140mm Mild Steel

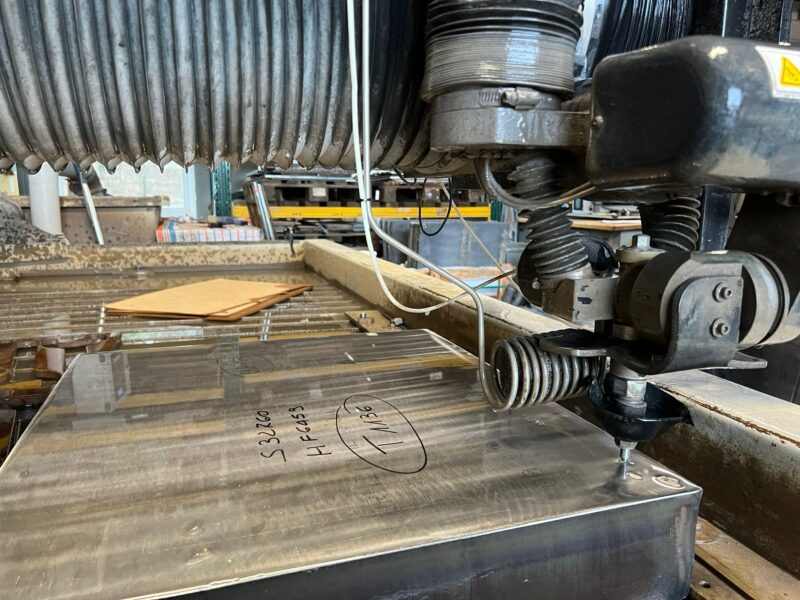

Challenges: A customer in the nuclear sector have been developing parts for a machine that requires thick (140mm) Mild Steel. The customer was looking at options to reduce the cost involved in making the parts away from traditional CNC from solid block. There has also been waste in production cost due to the heat created whilst machining.

Solutions: Our accurate nesting software enabled us to cut 2 parts from 1 solid block of material. Due to the thickness the customer used both the waterjet process and a CNC to provide highly accurate parts but reducing costs with a more efficient cutting method the waterjet process. With no heat affected zones the part was at much less risk of damage and warping. We increased the speed of the cutting providing a part with 3mm all round using a lower quality that could then be machined to customer requirements.

Benefits: The customer benefited significantly using the OMAX nesting facilities reduced material usage and cost. The parts had a reduced machining time and therefor reduced cost to manufacture.

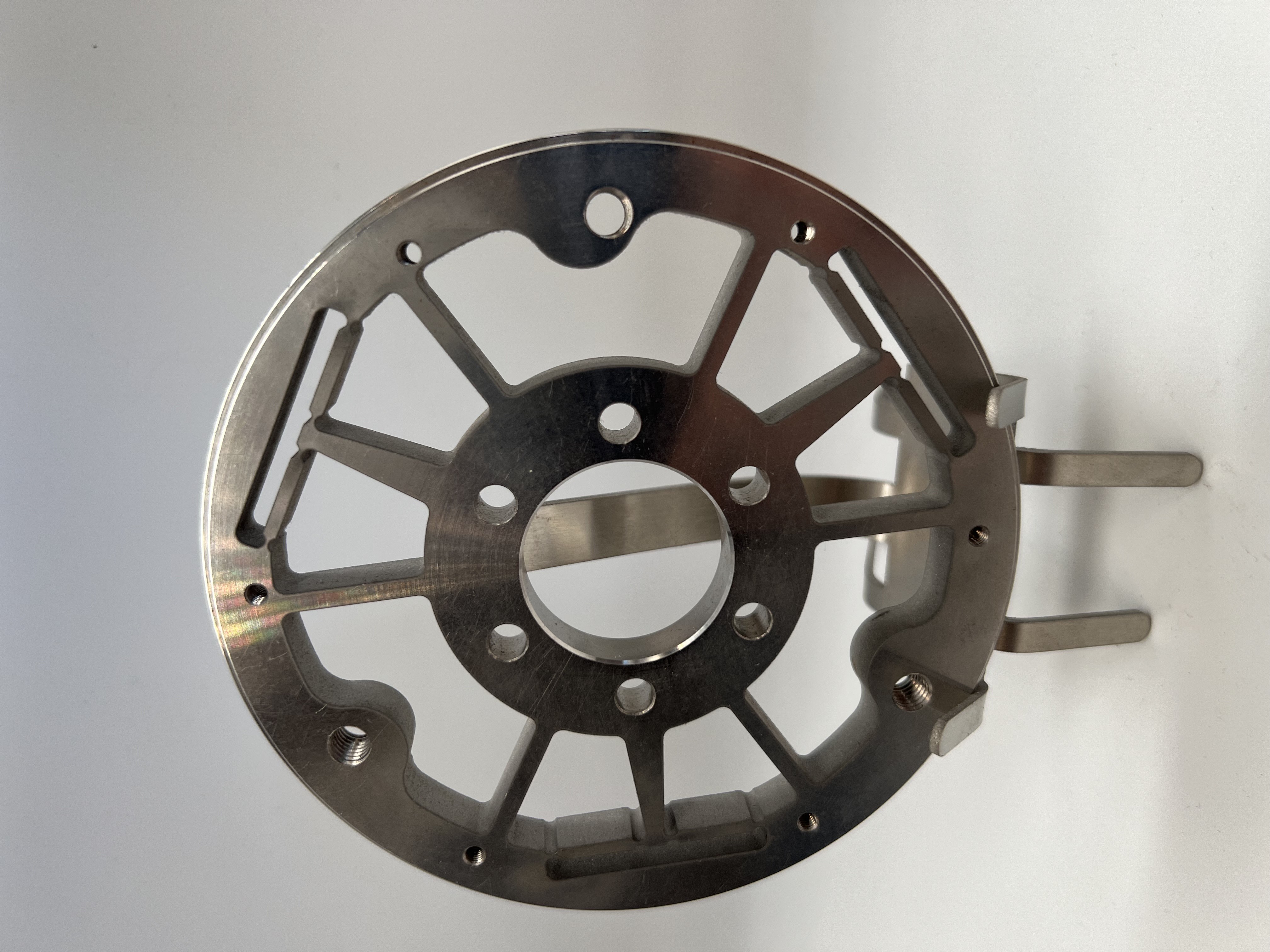

Case Study: Medical Industry – Custom Medical Device Parts

Challenges

A medical device manufacturer needed custom titanium and stainless steel components with a thickness of 20 mm. Initially, the customer considered CNC machining the parts from solid stock; however, the components required extremely high precision and had to be produced to final dimensions without any secondary machining.

Solutions

By using our OMAX waterjet cutting system and advanced nesting software, we efficiently produced high volumes of medical-grade stainless steel and titanium components. Our precision cutting capabilities ensured every part met the required drawings, tolerances, and quality standards straight off the machine.

Benefits

The customer received consistent, high-quality components that improved the performance of their medical devices. Optimised nesting and an efficient production workflow reduced material waste, shortened lead times, and lowered overall costs. As a result, the manufacturer was able to streamline internal assembly and bring the product to market faster than expected.

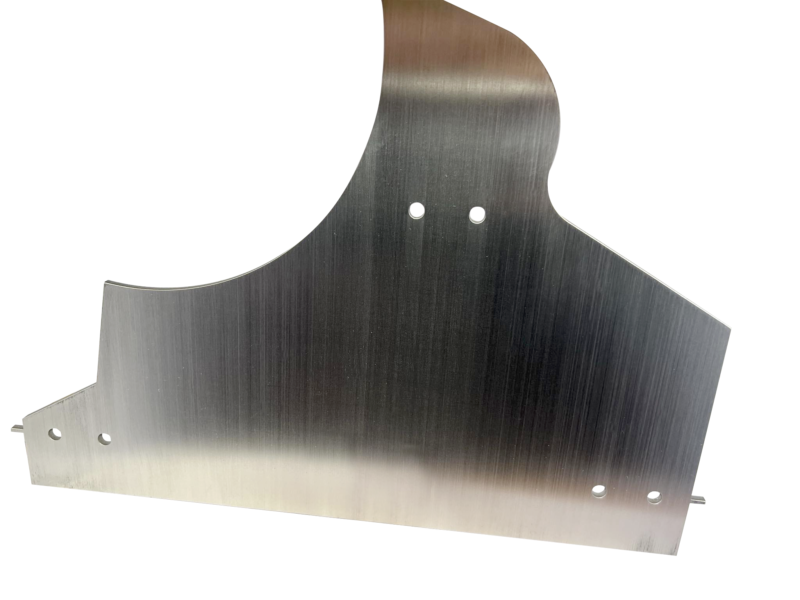

Case Study: Construction Industry – Structural Support Elements

Challenges

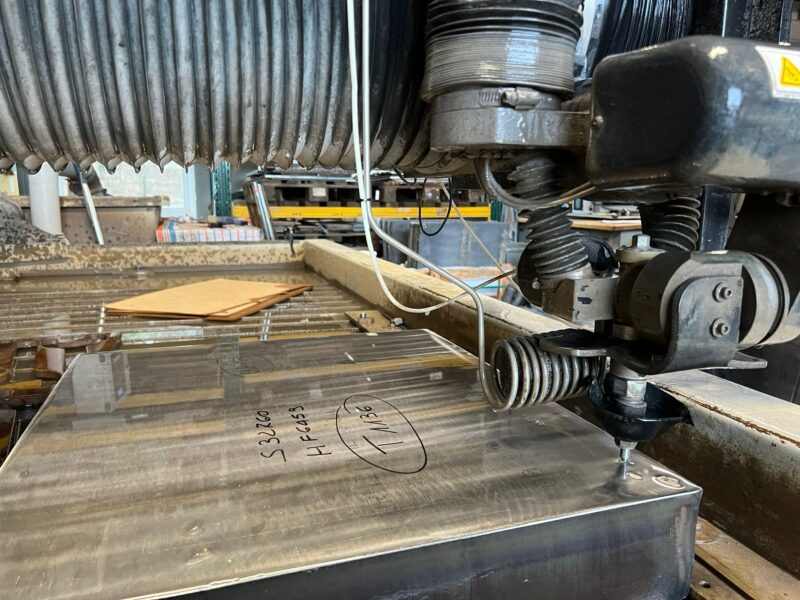

A construction company undertaking a large-scale building project required highly accurate structural support components made from 110 mm thick 316 stainless steel. Tight tolerances of ±0.3 mm were essential to maintain structural integrity and ensure precise fit-up on site.

Solutions

By utilising our state-of-the-art waterjet cutting systems, we produced the required structural elements from 316 stainless steel with exceptional accuracy. The waterjet cutting process delivered precise, clean cuts, ensuring all components were manufactured to exact specifications and arrived on site ready for immediate assembly.

Benefits

The customer benefited from fast turnaround times and components that required no secondary machining. This reduced overall costs and minimised on-site delays, helping the project stay on schedule and improving installation efficiency.

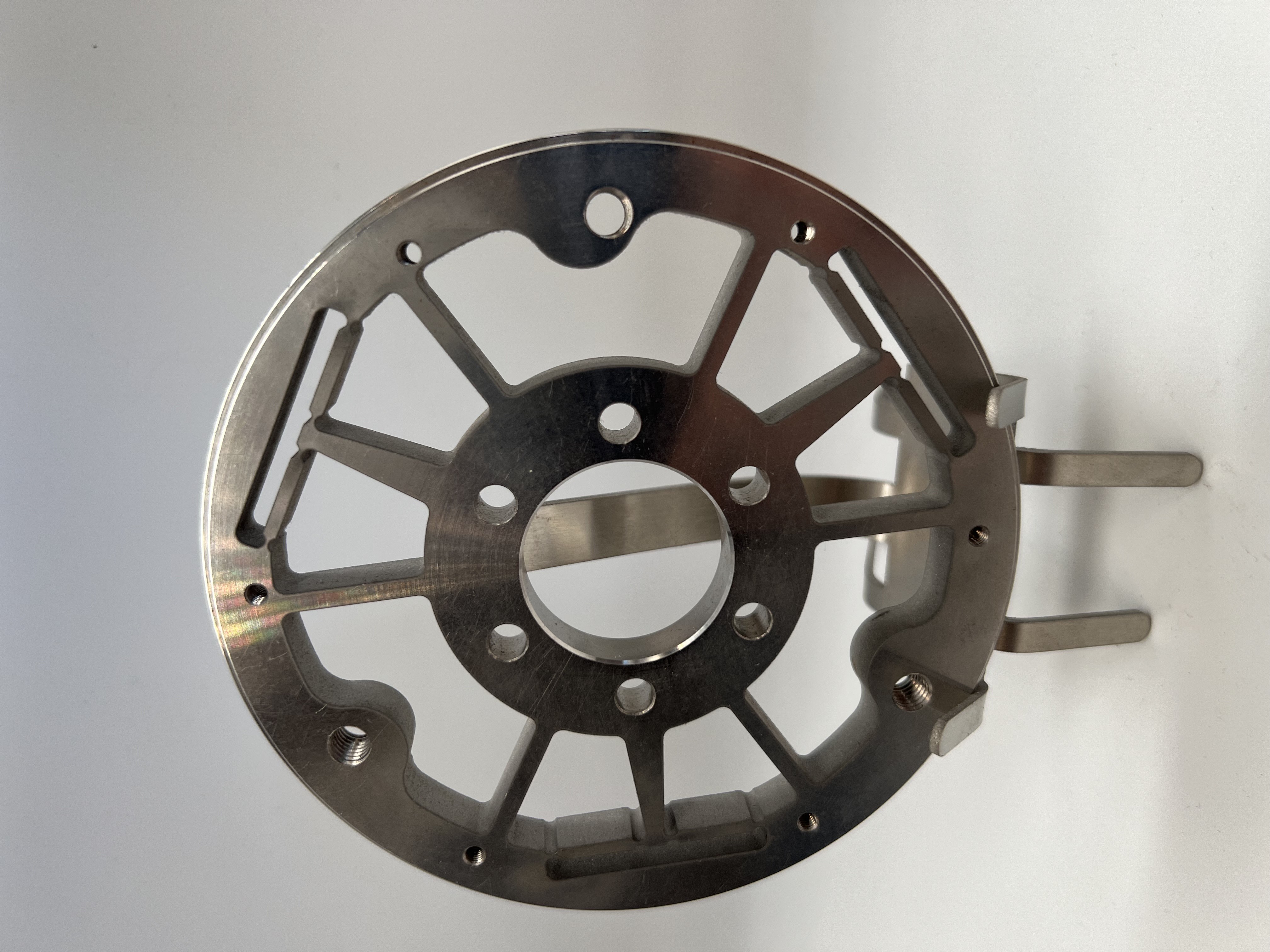

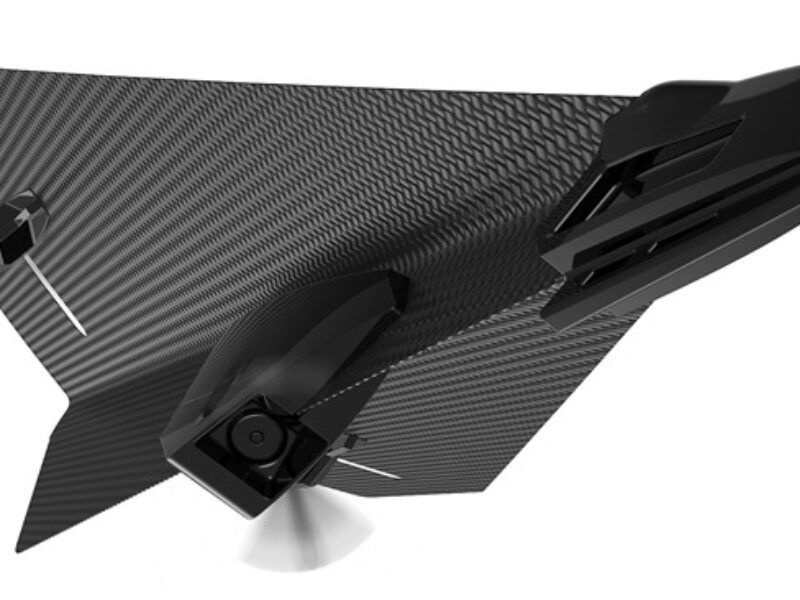

Case Study: Aerospace Industry – Lightweight Aircraft Components

Context

An aerospace engineering company required lightweight yet high-strength components for a new aircraft platform. The parts needed to be cut with extreme precision from advanced composite materials while preserving structural integrity. As demand increased through natural business growth, the company faced challenges in maintaining both production capacity and consistent quality.

Solutions

Our team utilised advanced waterjet cutting technology to manufacture components from premium carbon fibre composites. By combining high-quality materials with a pre-drilling technique to prevent delamination, we ensured exceptional dimensional accuracy while maintaining the inherent strength of the composite.

Benefits

The use of industry-leading cutting methods enhanced production efficiency and optimised material utilisation. This reduced manufacturing time and costs, enabling the client to scale output while gaining a stronger competitive position in the aerospace market.

About us

Serving clients worldwide since 2006.

Professional Waterjet Cutting based in Lyme Regis, Dorset

We were one of the first waterjet companies in the UK to become ISO 9001:2015 certified, and pride ourselves on being the best in the industry.

Our procedures and quality assurance checks provide our customers with 100% of parts aligned to the drawing.

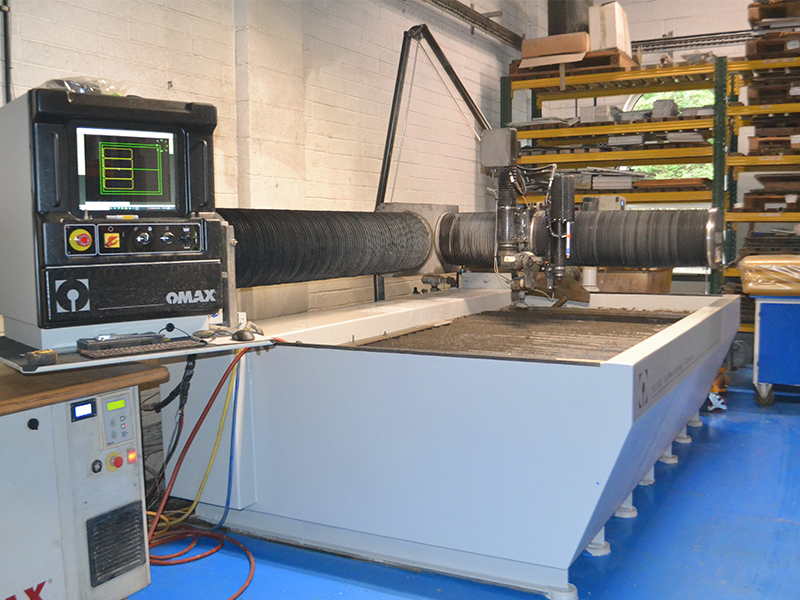

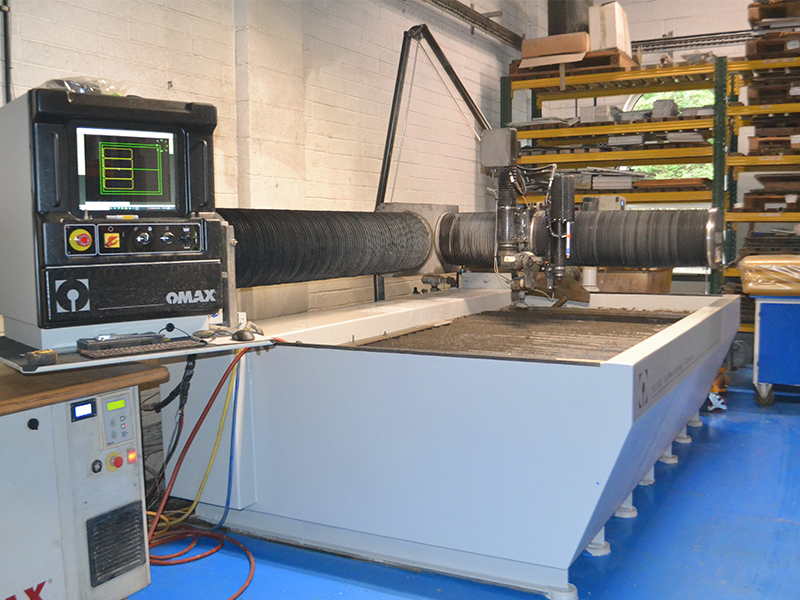

Precision Waterjet has the largest fleet of Omax machines In the world. In total we have 8 Omax precision waterjet machines including 2 brand new machines and in the past year we have upgraded all the existing 6 machines to brand-new hardware and software to ensure we have the most capacity and the most reliable fleet.

We have on stock a large range of material in various thicknesses and grades, ferrous and non-ferrous. This enables us to deliver parts in under 24 hours if required. If we do not have the material on the shelf our suppliers ship next day ensuring a swift turnaround.

Our Services Include:

Precision Waterjet Cutting Process

Precision Waterjet uses both water-only and abrasive waterjet cutting technologies to shape nearly any material, including those up to 200mm thick. Advanced tools like Tilt-A-Jet®, optical locators, and pneumatic drills ensure precision, while Omax IntelliMAX software optimises material usage to reduce waste and cost. With an extensive stock of ferrous and non-ferrous materials in various grades and thicknesses, we can deliver parts within 24 hours. For non-stock materials, our suppliers provide next-day shipping for quick turnaround times.

Flat Bed Linishing & Brushing

Our linishing and brushing machine enables us to provide fully deburred, satin-grained finishes (DP1 or DP2) on components up to 300mm wide, streamlining production for metals like stainless steel, copper, and brass (excluding aluminum). This eliminates the need for costly pre-grained sheet purchases, offering a convenient, all-in-one solution for finished components.

Laser Engraving & Etching

Using the Cermark process with our CO2 laser, we create high-contrast, permanent marks on metals like stainless steel and mild steel. Whether for full nameplates or simple ID numbers, we can accommodate parts up to 600mm x 450mm.

Precision Waterjet boasts the world’s largest fleet of OMAX machines, with eight state-of-the-art precision waterjets, including two new additions and six fully upgraded machines. Our two largest machines offer a cutting area of 2.54m x 1.39m, all achieving a cutting tolerance of ±0.075mm and positional accuracy of ±0.025mm. Equipped with advanced features like pre-loaded linear bearings, precision ball screws, and the MAXJET 5i nozzle delivering 54,000 psi, our machines provide 30% more cutting power than standard waterjets. Innovative tools such as the Tilt-A-Jet®, optical locators, and IntelliMAX Premium nesting software enable us to cut virtually any material up to 200mm thick with minimal waste. Rigorous maintenance ensures maximum reliability and minimal downtime.

We serve a diverse range of industries, including aerospace, automotive, marine, oil and gas, power generation, and precision engineering. Increasingly, architectural and composite companies recognize the advantages of waterjet profiling, which delivers high-precision, high-quality parts with reduced lead times and minimal post-processing. Waterjet's “cold cutting” method avoids heat, allowing precise profiling of ferrous, non-ferrous, nickel alloys, and other materials without structural changes. Capable of cutting intricate designs and holes as small as 1mm, it’s ideal for complex tasks like tapping-sized holes in thick materials. Environmentally friendly, waterjet cutting uses no harmful gases or liquids and produces no hazardous vapors.

Since 2006, Precision Waterjet has focused on reliable, precise cutting with exceptional quality, short lead times, and excellent customer service. We streamline manufacturing by managing material handling and ordering, helping customers save time. Additional services include linishing for satin finishes, CO2 laser part marking with durable Cermark, and finishing options like deburring and tapping, delivering ready-to-use components.

Images

Articles / Press Releases

Brochures

Reviews

Trade Associations