Company details for:

Precision Waterjet Ltd

1 Uplyme Road Business Park,

Lyme Regis,

Dorset,

DT7 3LS,

United Kingdom

Quick Links:

Products / Services

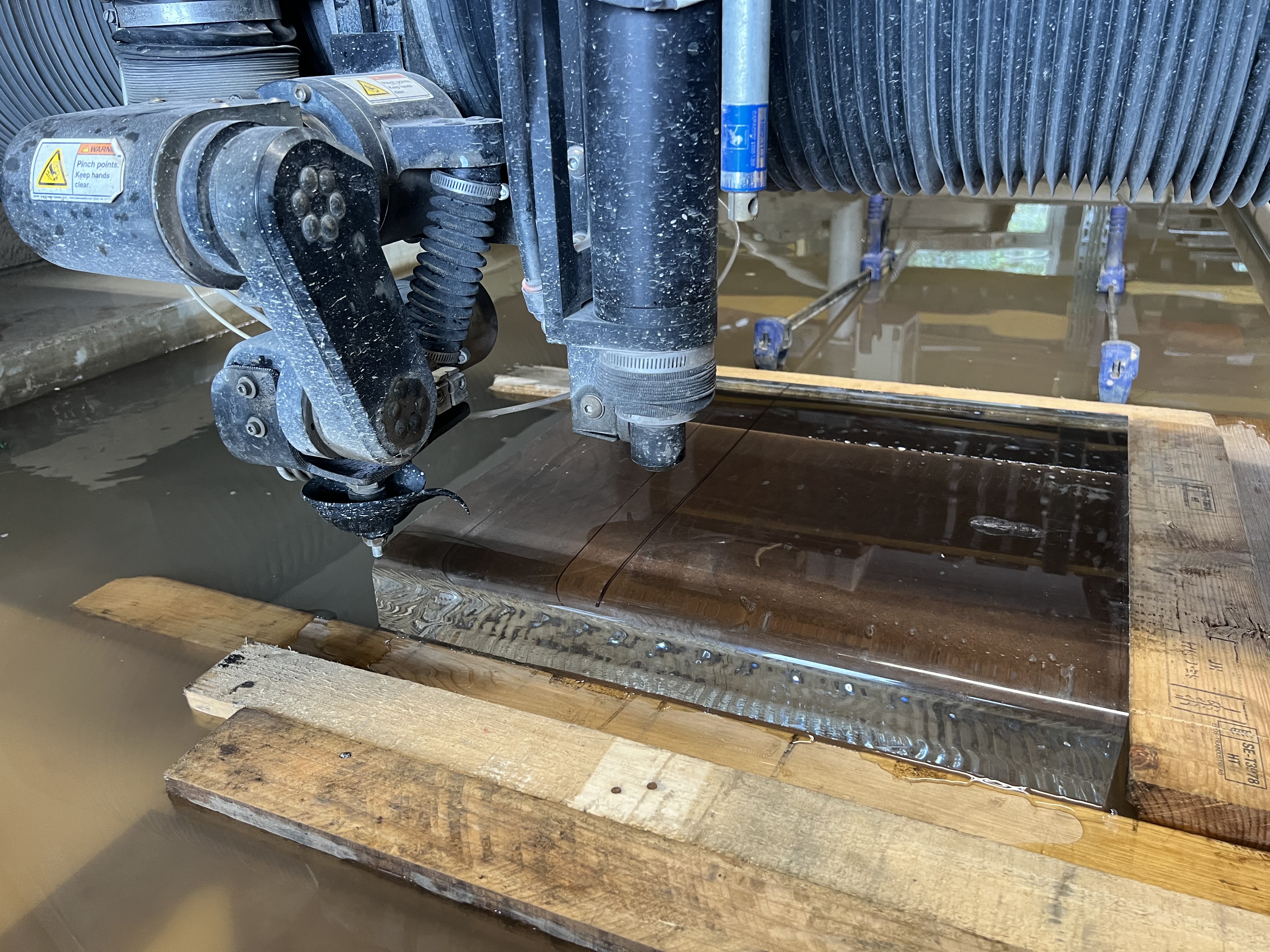

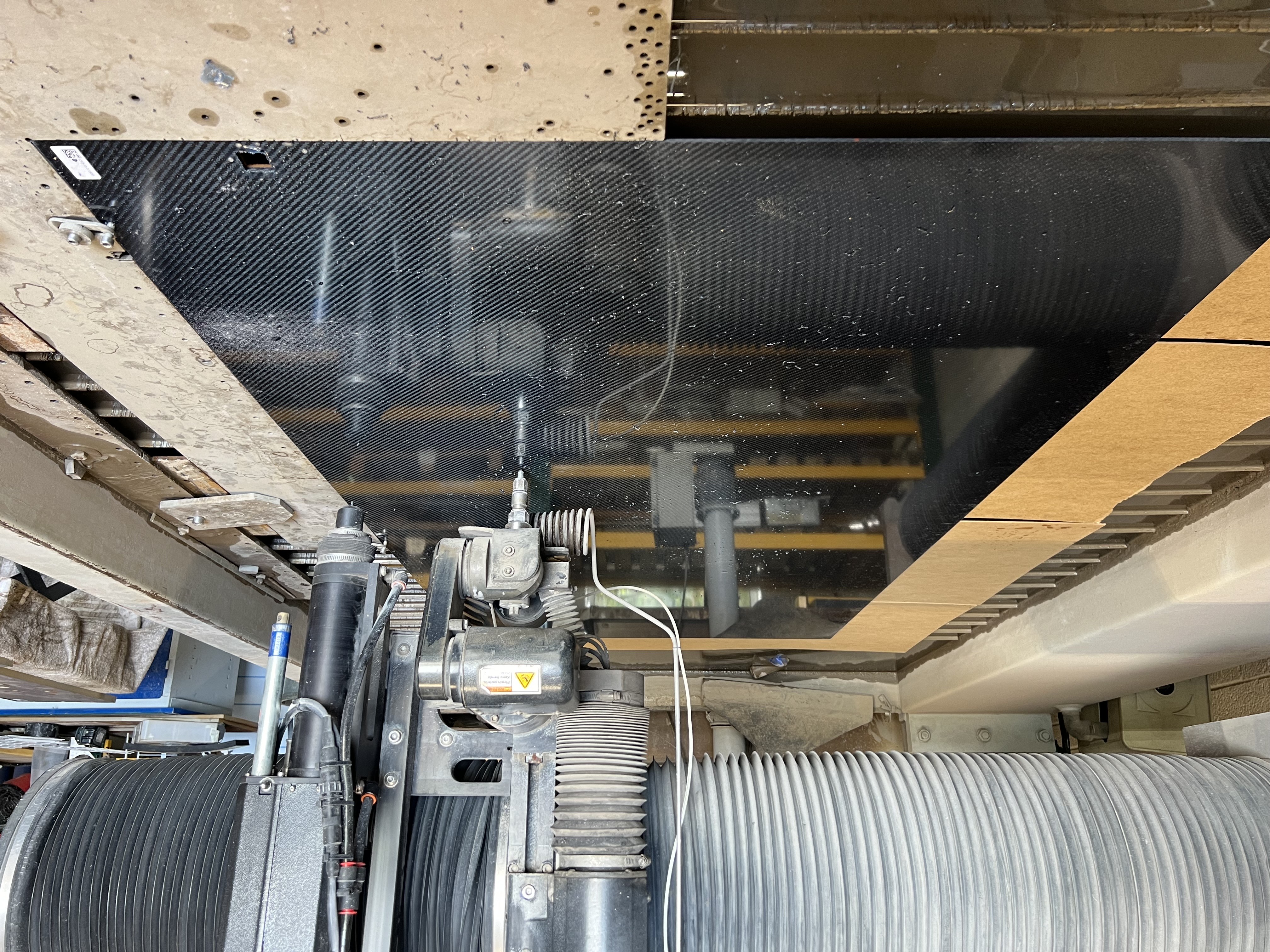

Precision Waterjet Cutting Process

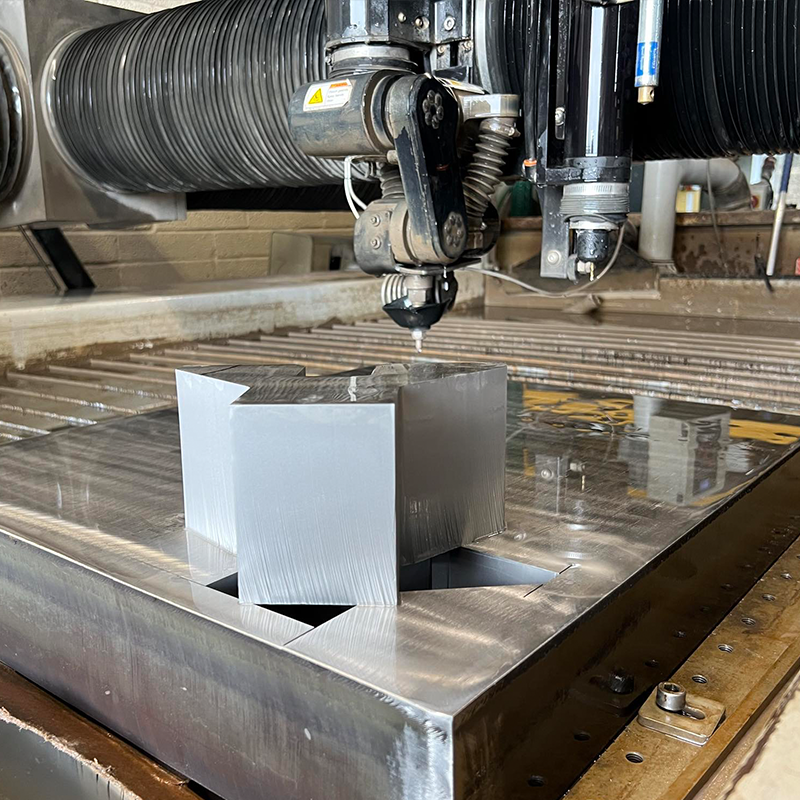

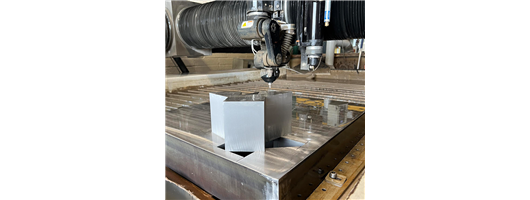

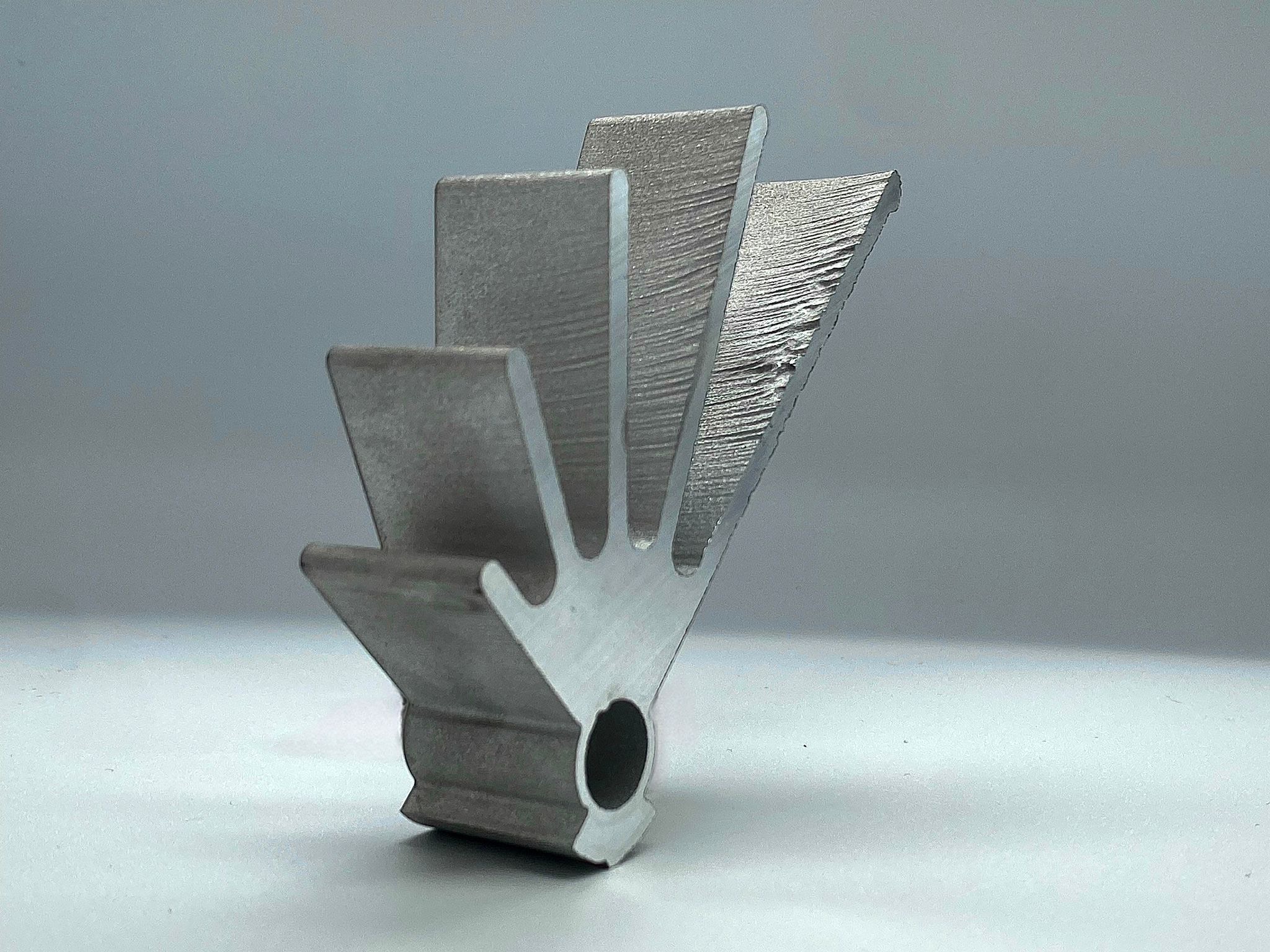

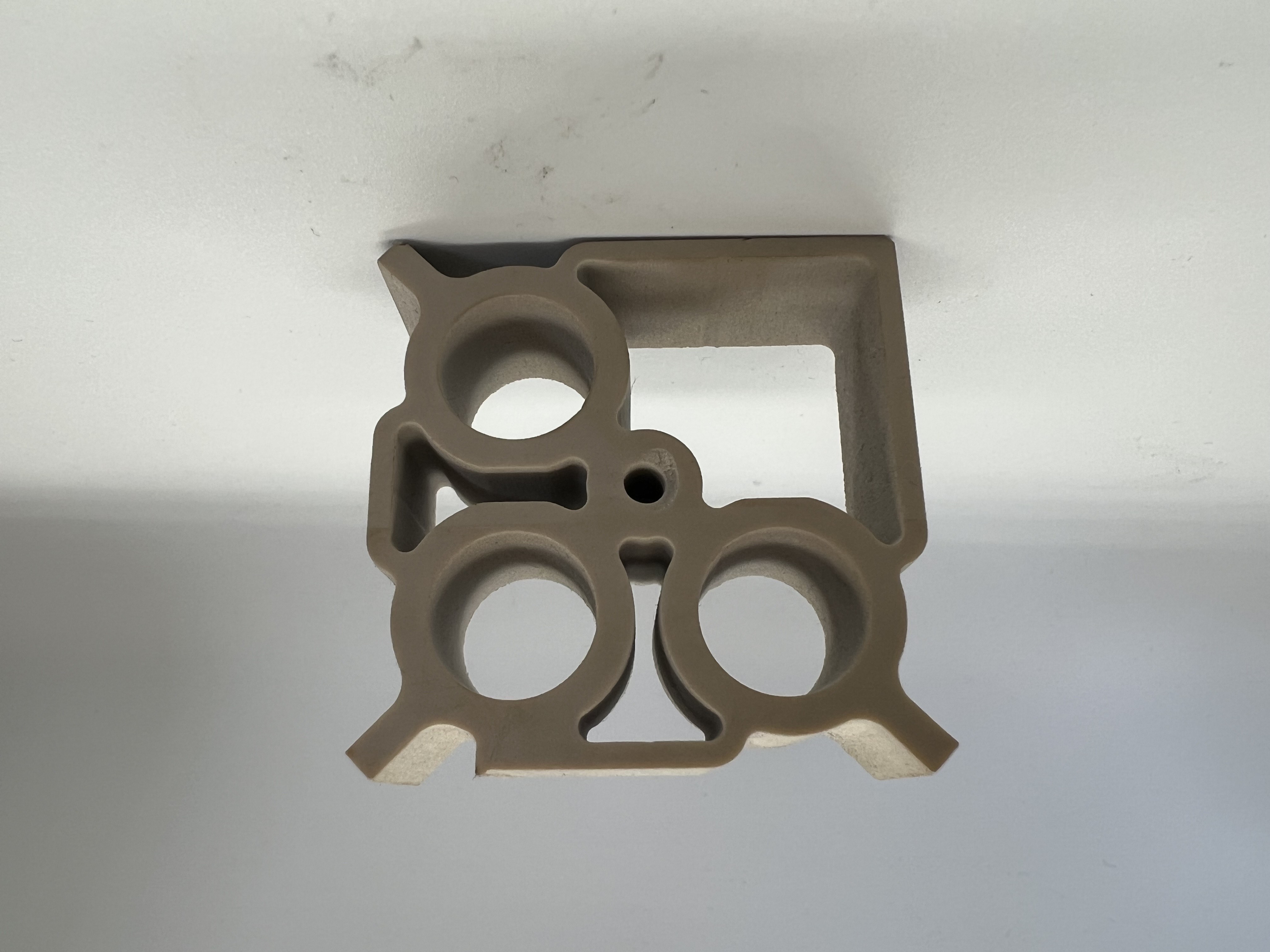

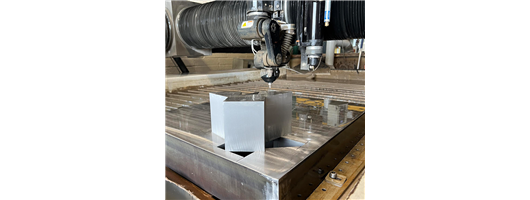

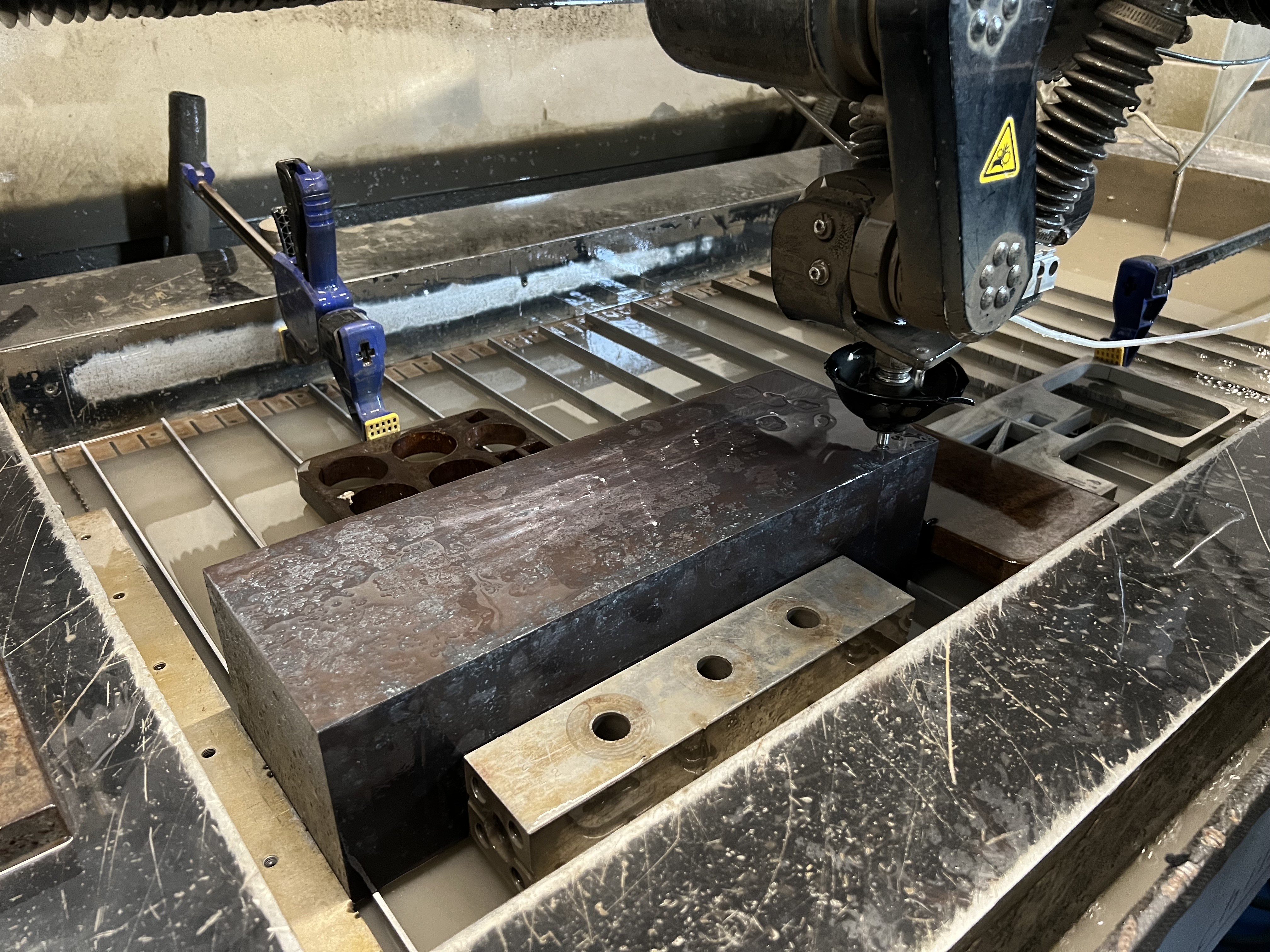

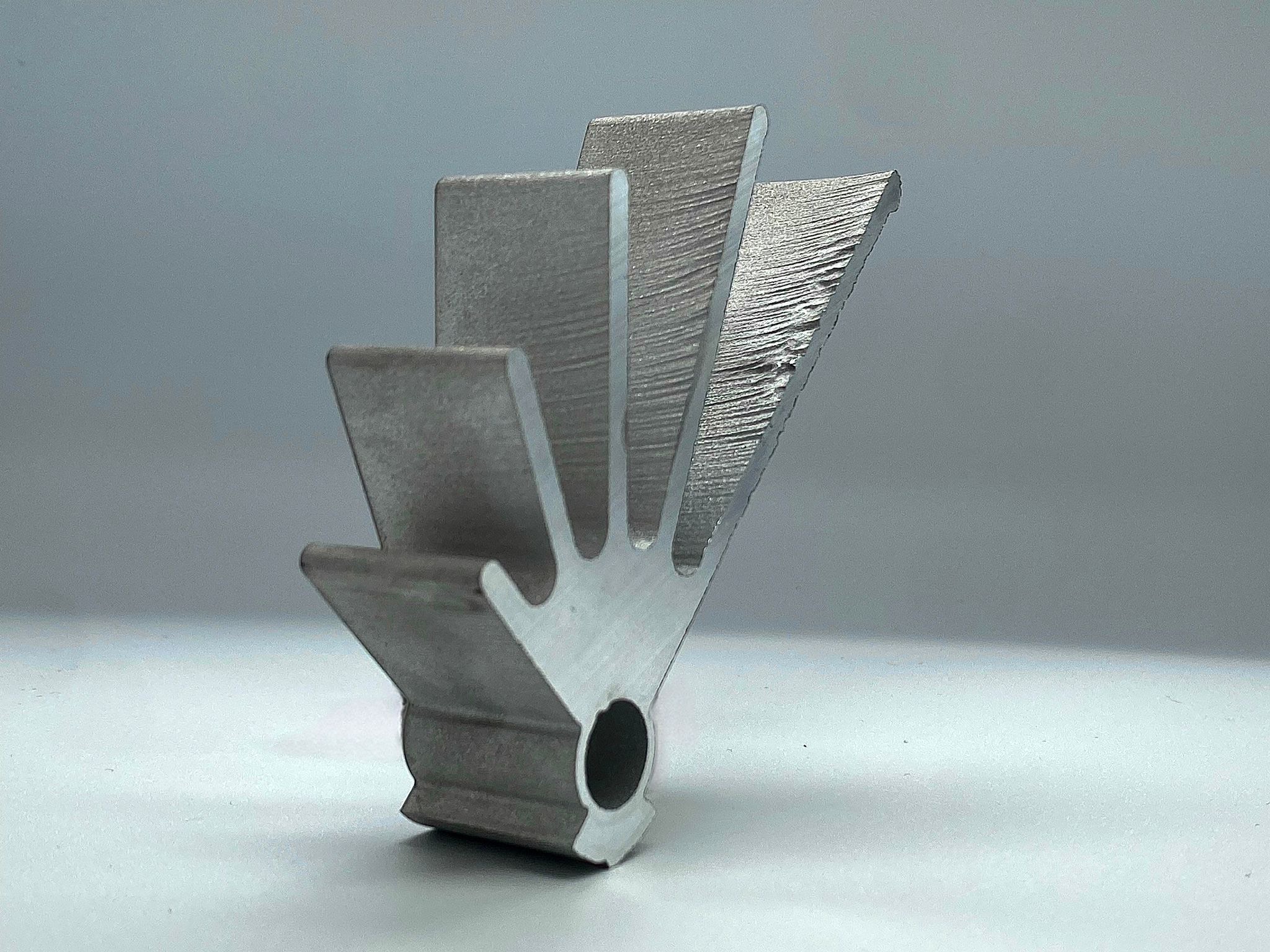

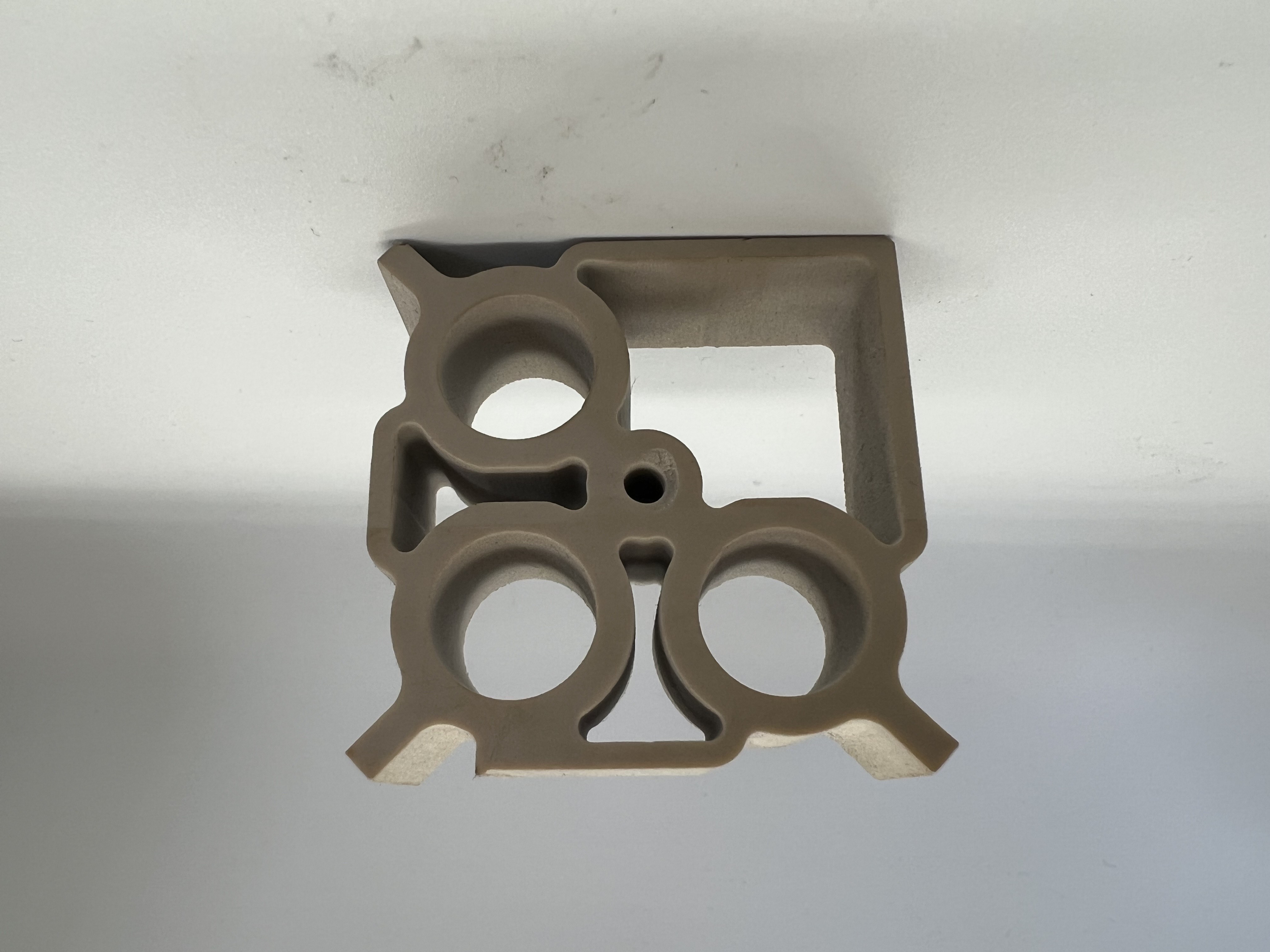

You may have heard of the generic terms “Waterjet”, “Abrasive jet” and “Flowjet”. Waterjet cutting technology has been around since the early seventies but was of little value to engineers as then it was only capable of cutting thin gasket and foam materials. High Pressure water cutting with Abrasive feed extended the concept about 10 years later.

With innovative accessories such as the Tilt-A-Jet®, optical locators and a pneumatic drill we cut virtually any material in the world up to 200mm thick. Omax IntelliMAX Premium Software also provides a world class nesting software to ensure we can maximise material usage, reduce waste and ultimately reduce cost per part.

We carry a large range of material stock in various thicknesses and grades, ferrous and non-ferrous. This enables us to deliver parts in under 24 hours if required. If we do not have the material on the shelf our suppliers ship next day ensuring a swift turnaround.

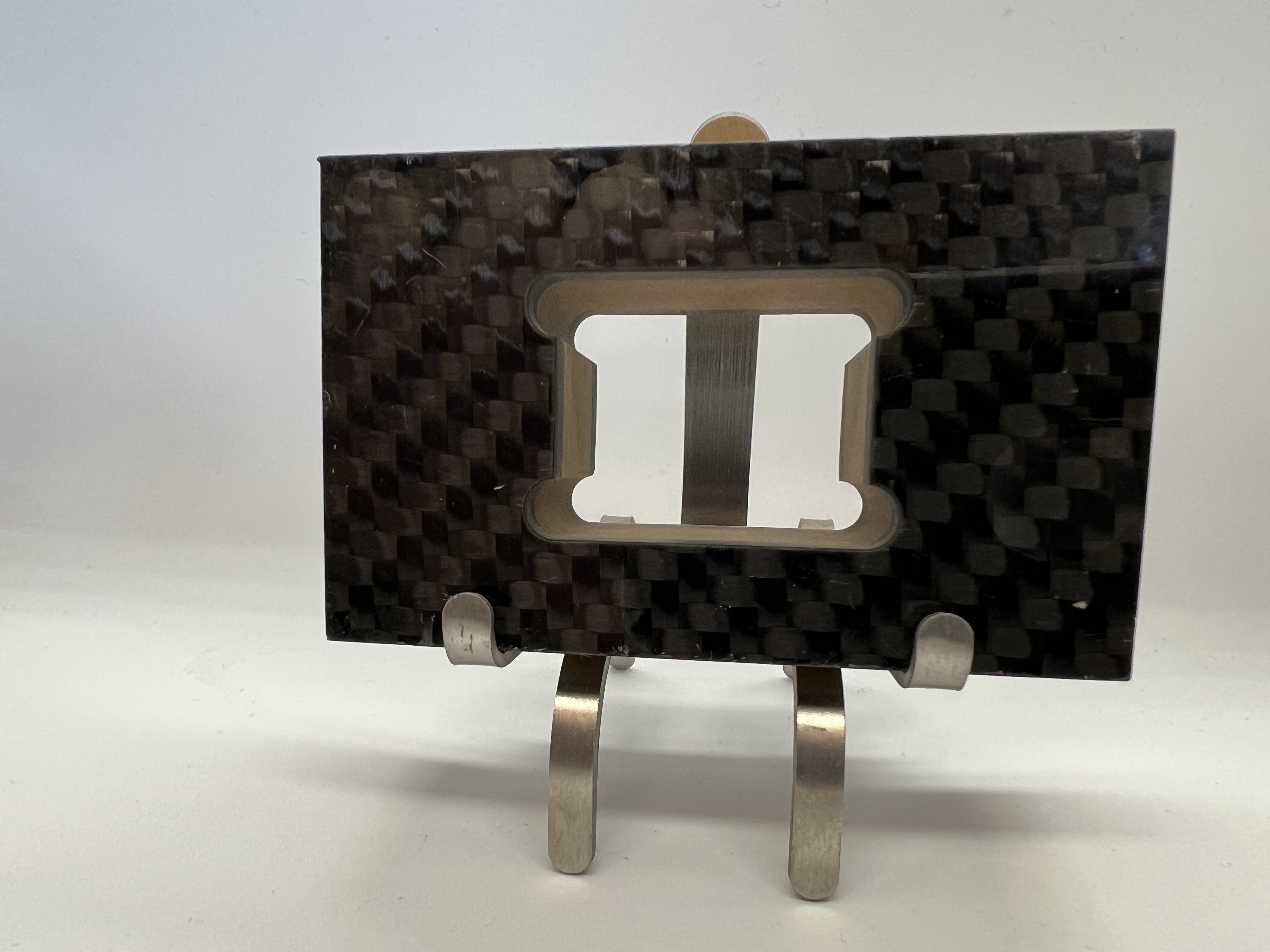

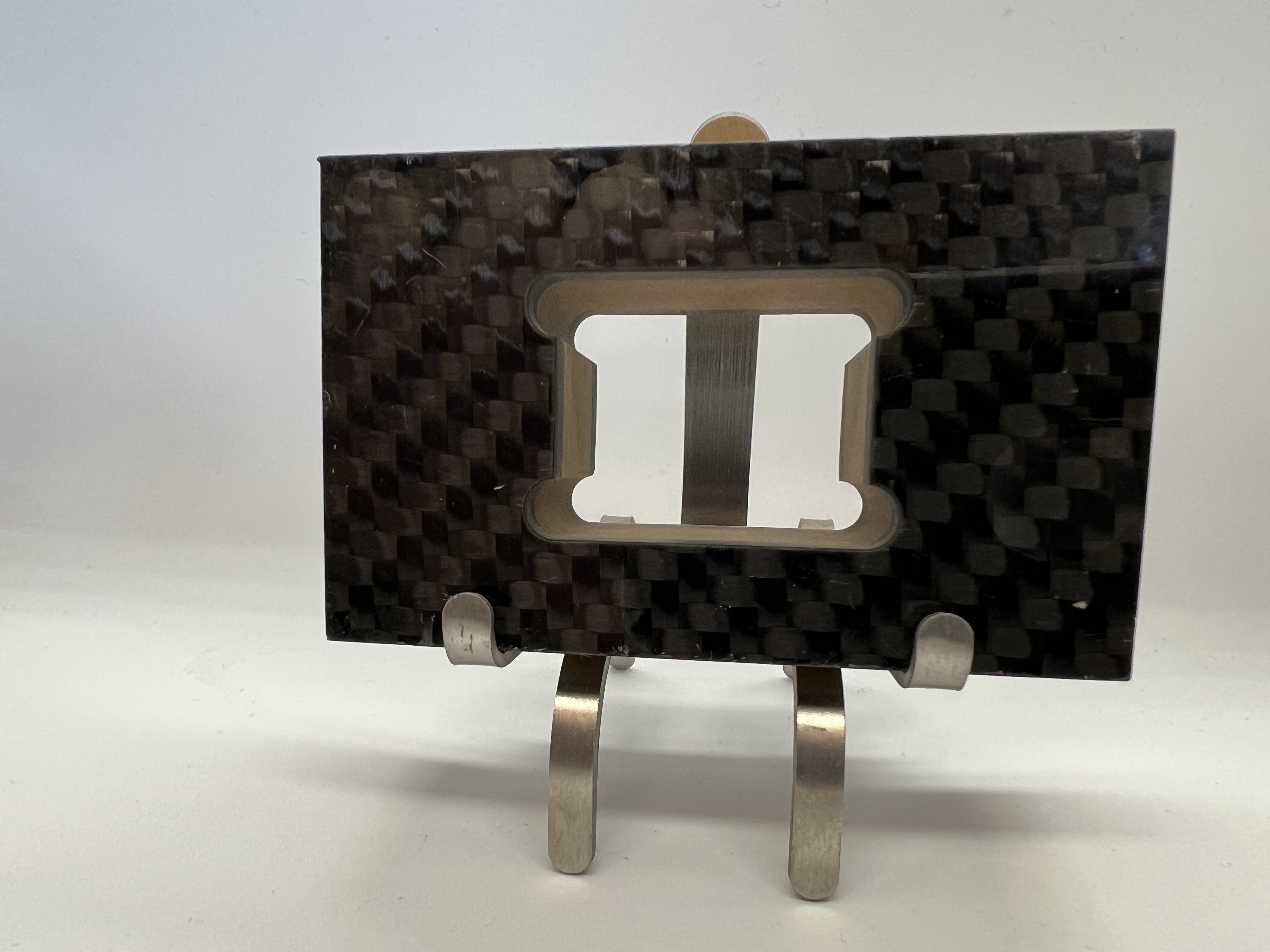

Flat Bed Linishing & Brushing

This machine provides a combination of both linishing and brushing to produce a satin grained finish on one (DP1) or two (DP2) sides for components up to 300mm wide.

Most metals apart from Aluminium are suitable to be processed this way. We regularly produce dull polished grained finishes on stainless steel, copper and brass.

This often eliminates the need to buy in small costly amounts of pre-grained sheets and plate.

Laser Engraving & Etching

So if you are looking for a complete nameplate or just to add an ID number we can achieve this for you.

The maximum part size for marking is 600mm x 450mm.

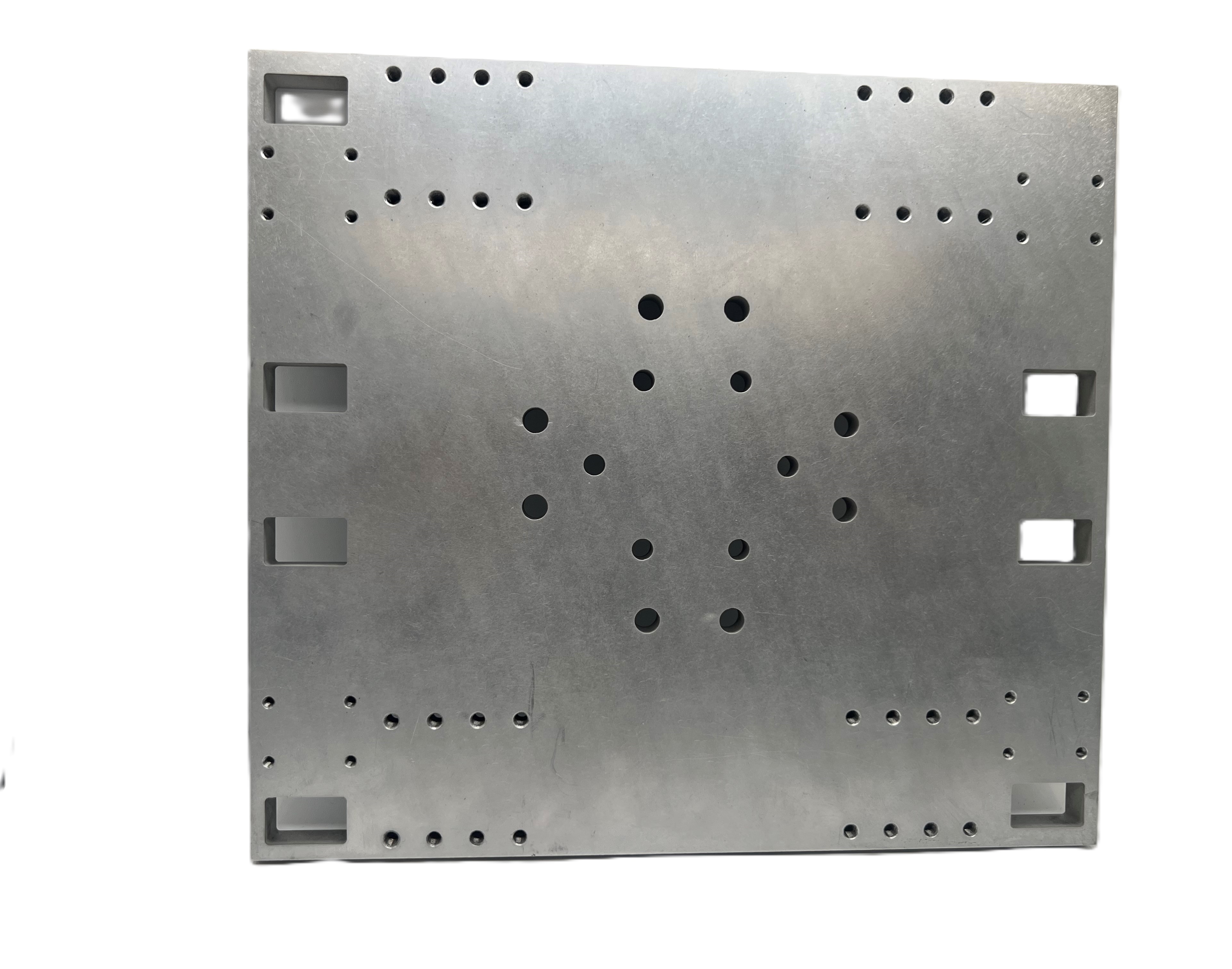

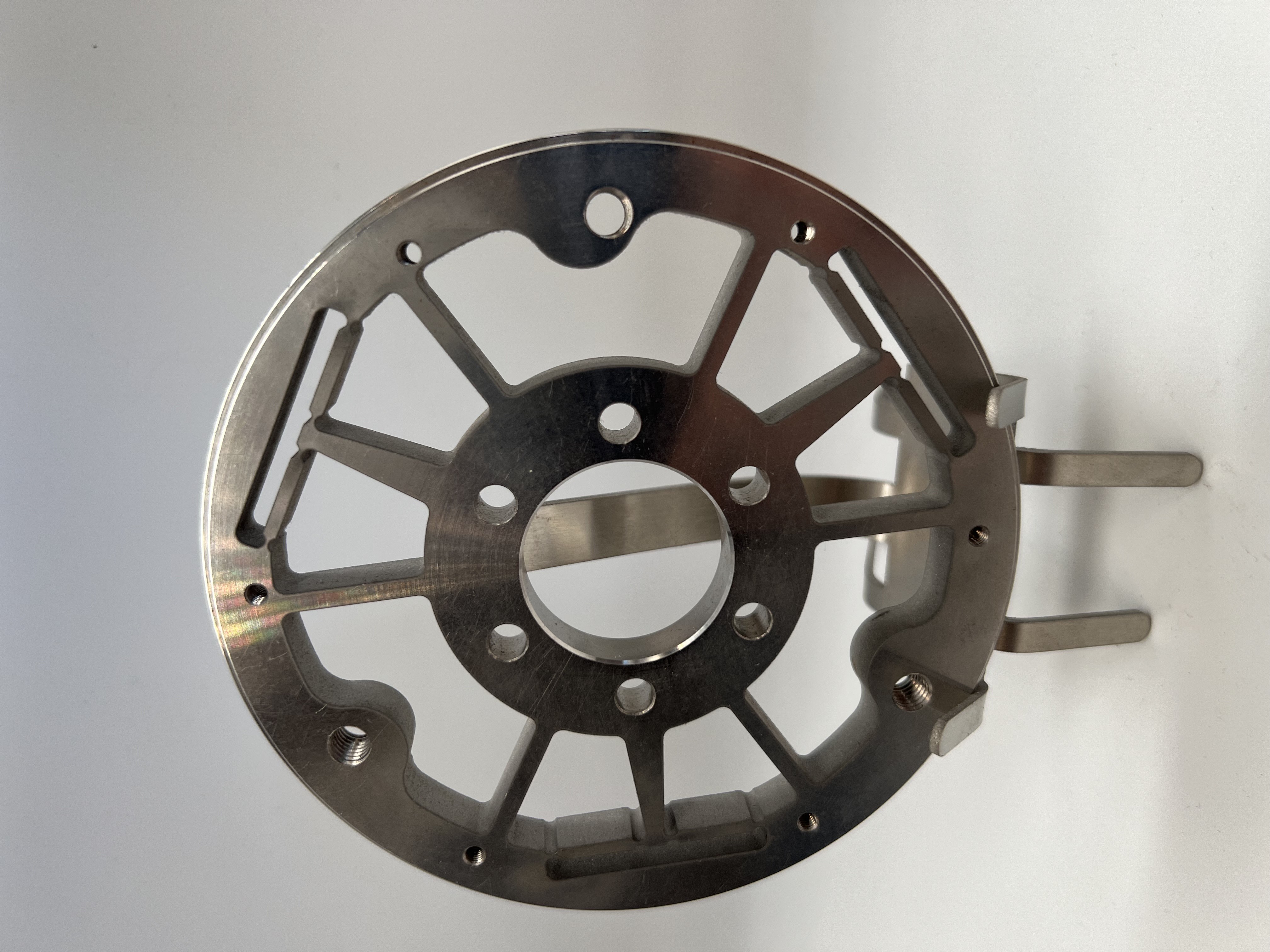

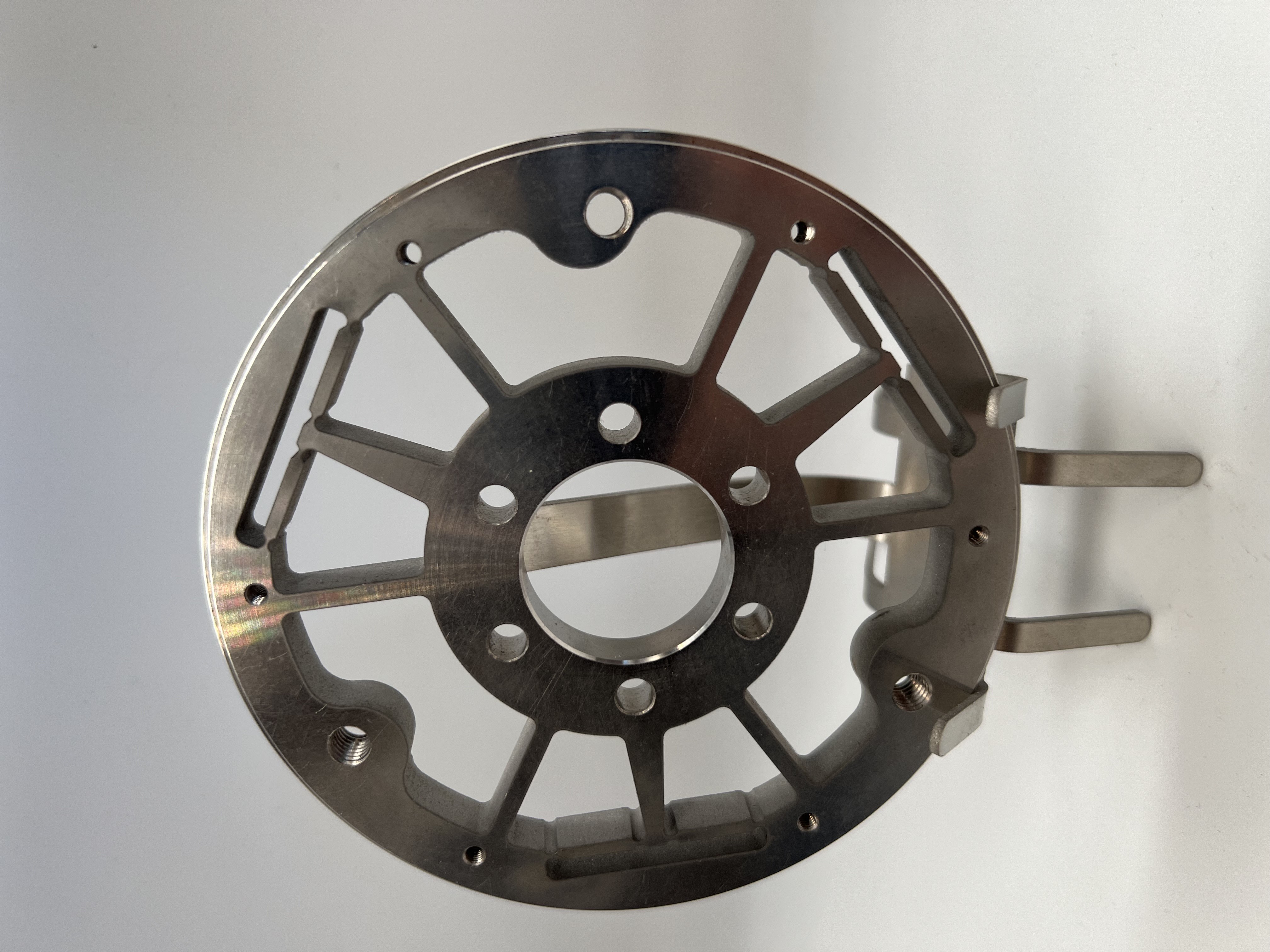

Tapping and countersinks

This allows us to be a ‘one stop shop’ and supply fully finished components to customers, where required.

With the accuracy of the waterjet, we can tap with not further machining required. This additional process provides a part cut and supplied to drawing where required.

About us

Professional Waterjet Cutting based in Lyme Regis, Dorset

We were one of the first waterjet companies in the UK to become ISO 9001:2015 certified, and pride ourselves on being the best in the industry.

Our procedures and quality assurance checks provide our customers with 100% of parts aligned to the drawing.

Precision Waterjet has the largest fleet of Omax machines In the world. In total we have 8 Omax precision waterjet machines including 2 brand new machines and in the past year we have upgraded all the existing 6 machines to brand-new hardware and software to ensure we have the most capacity and the most reliable fleet.

We have on stock a large range of material in various thicknesses and grades, ferrous and non-ferrous. This enables us to deliver parts in under 24 hours if required. If we do not have the material on the shelf our suppliers ship next day ensuring a swift turnaround.

Our Services Include:

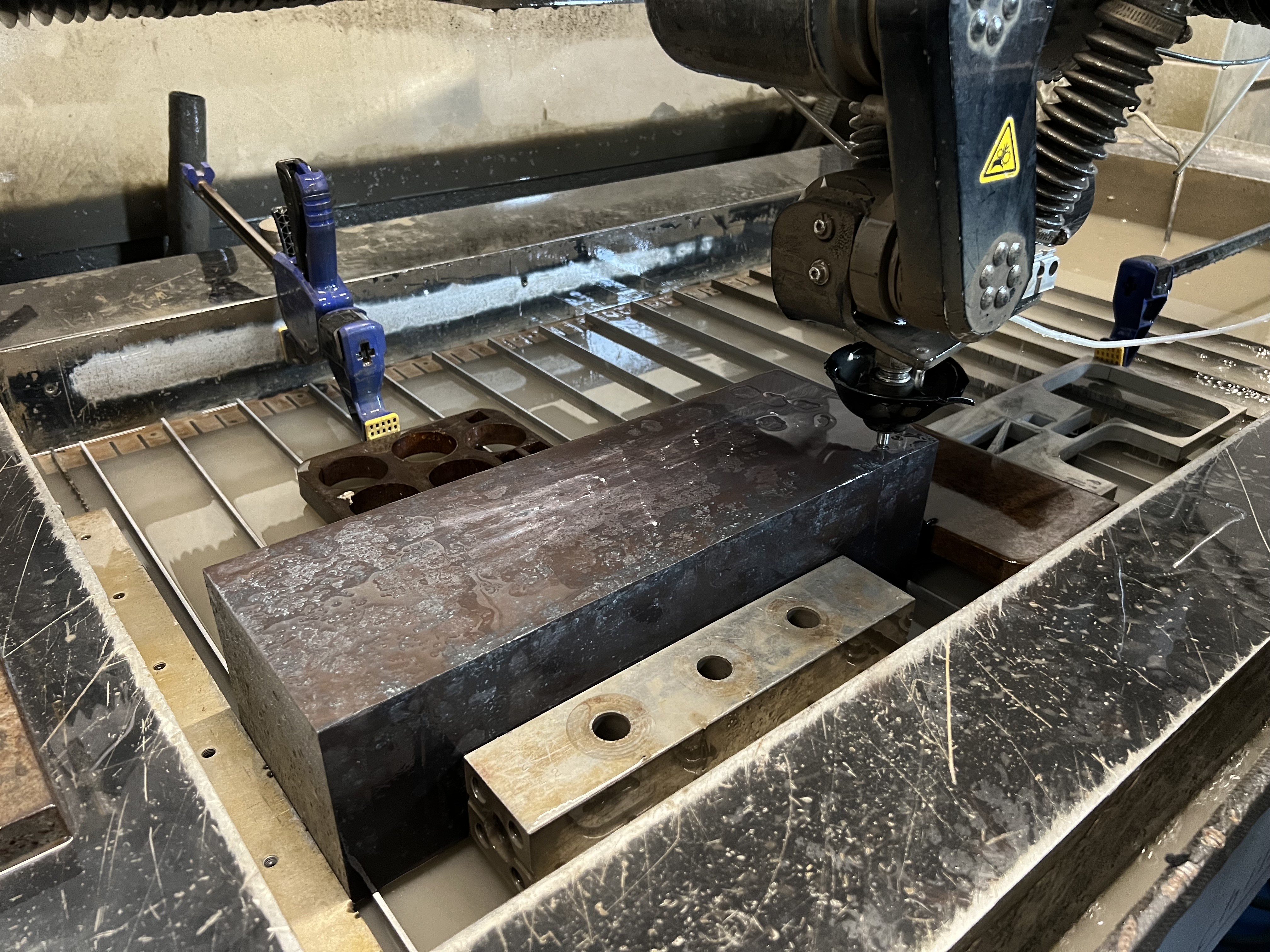

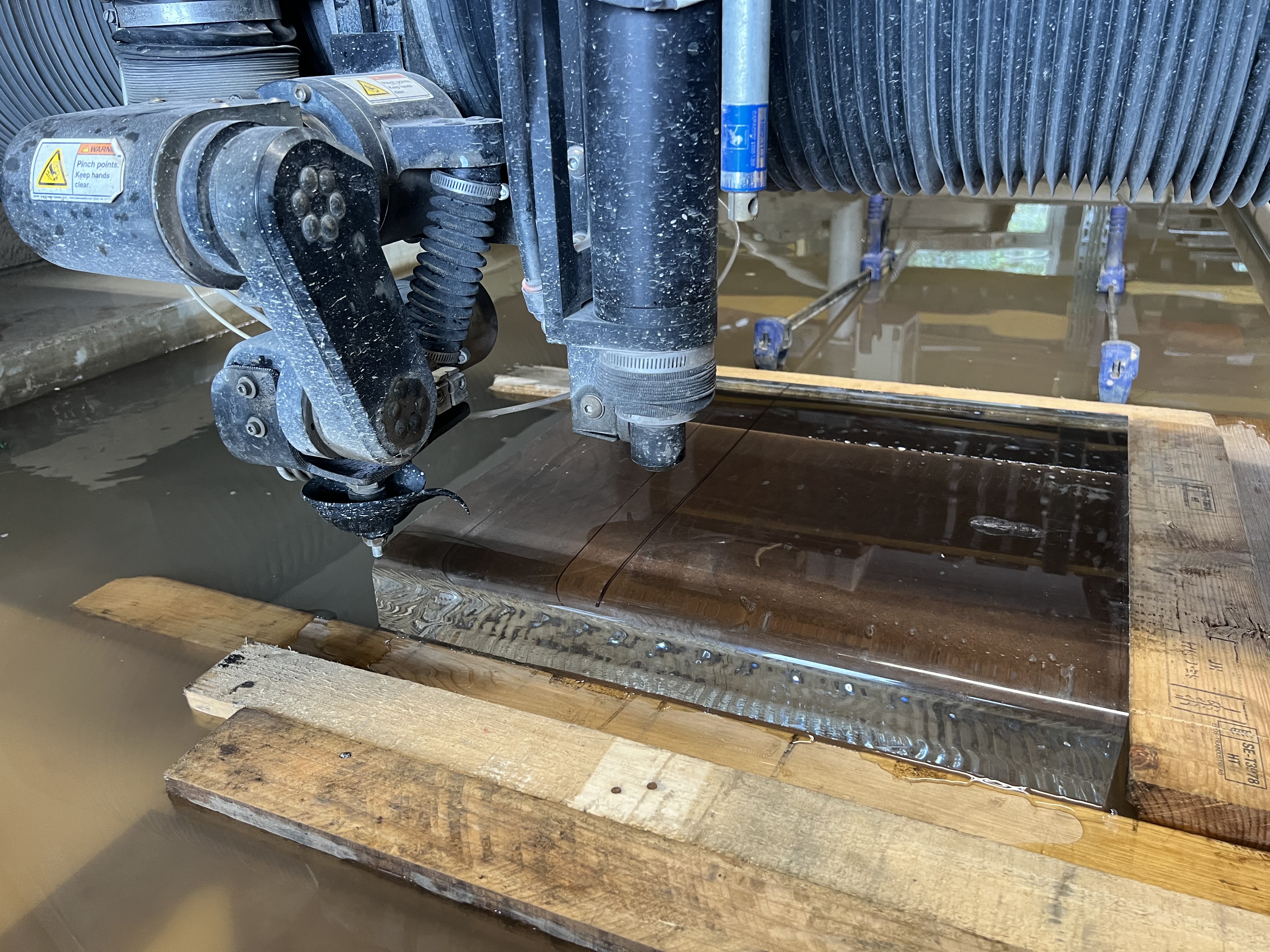

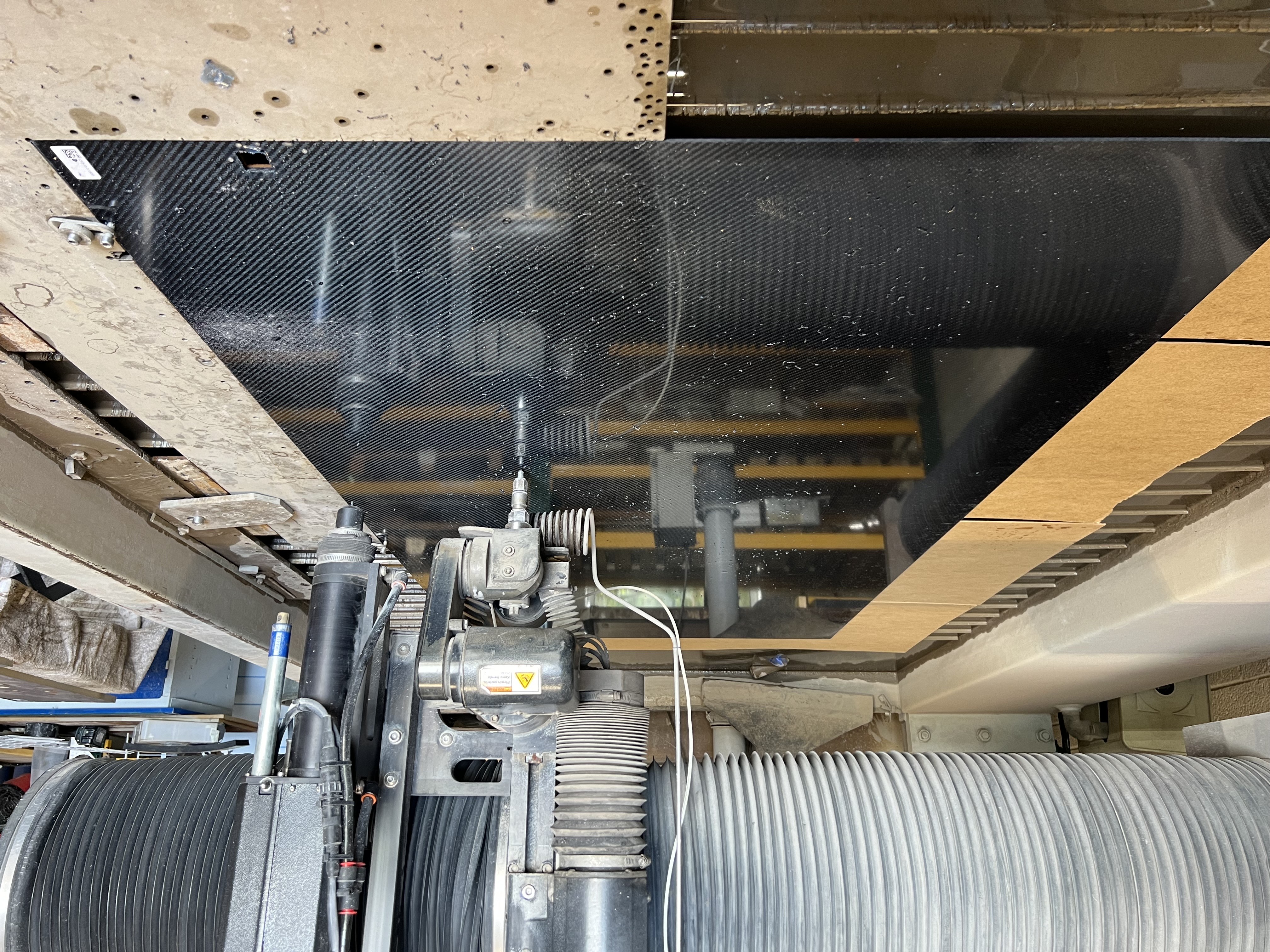

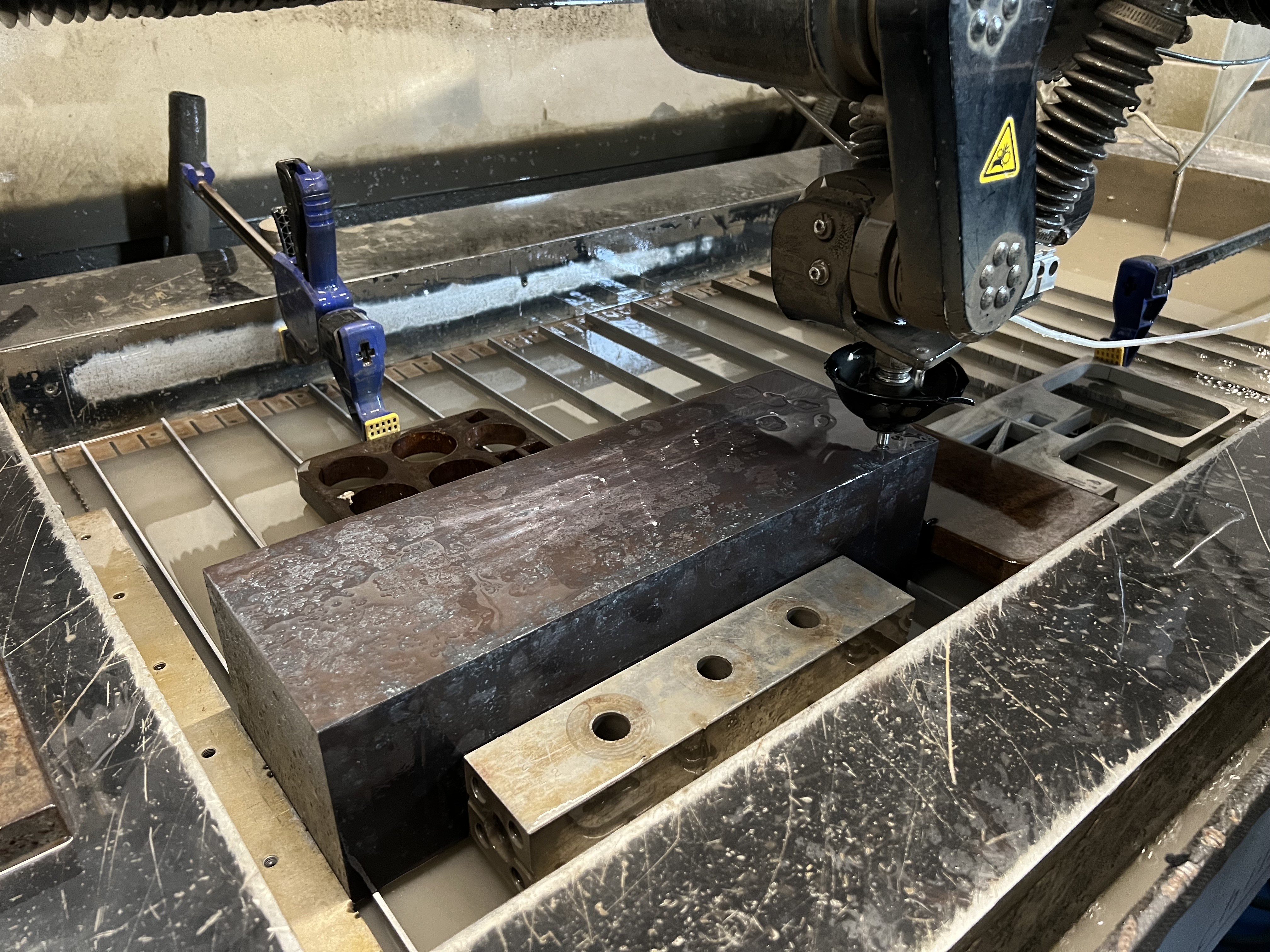

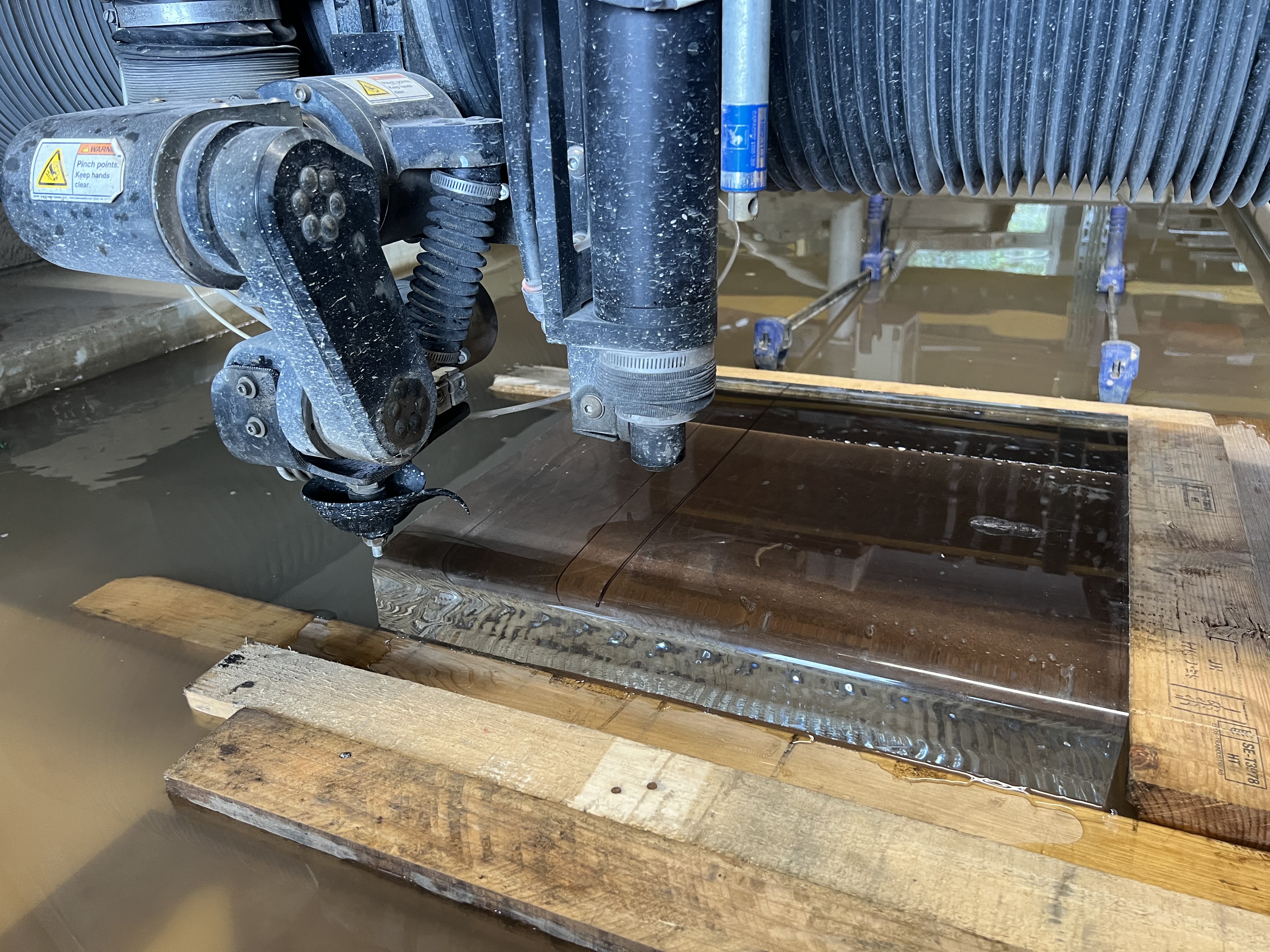

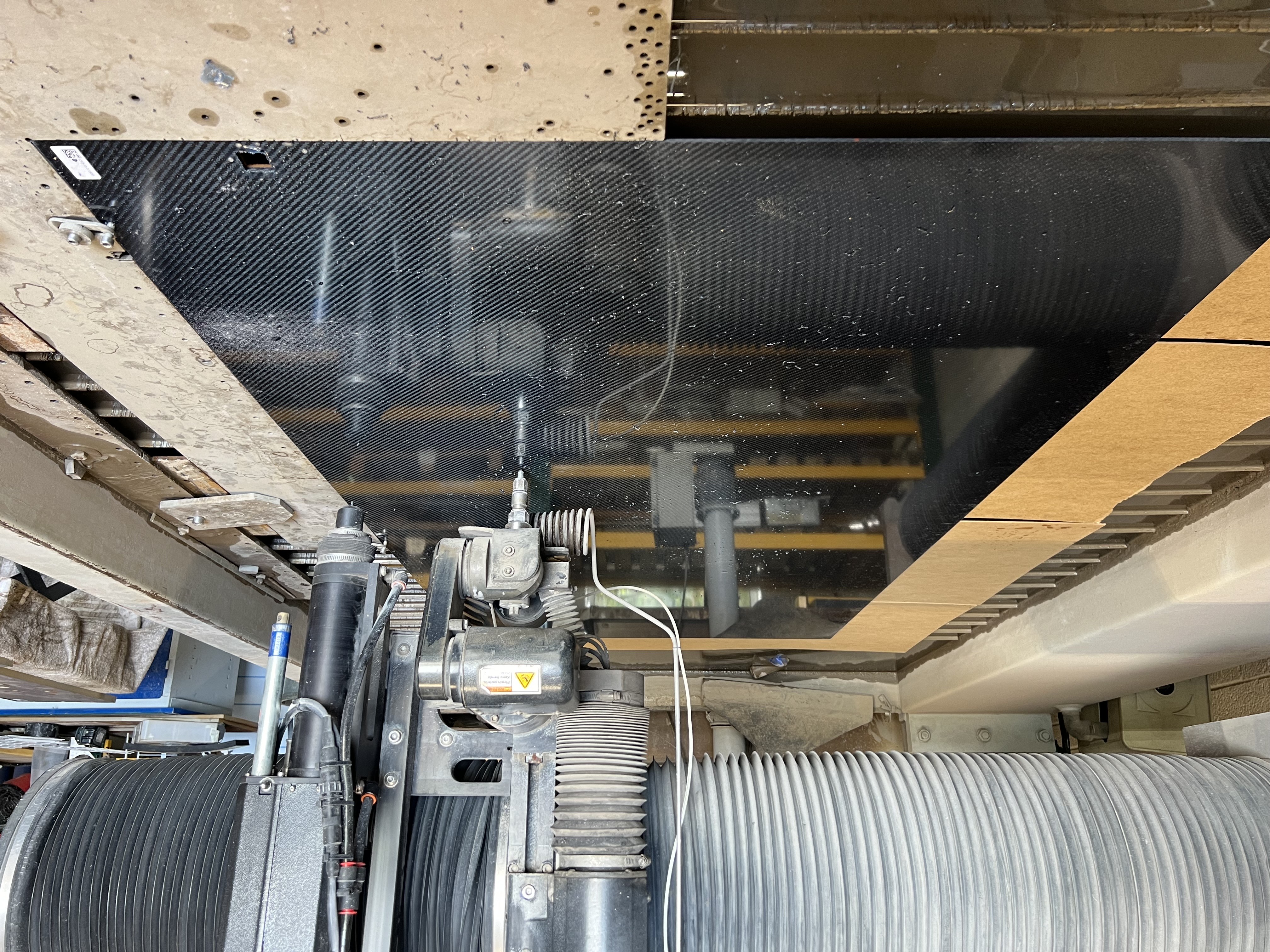

Precision Waterjet Cutting Process

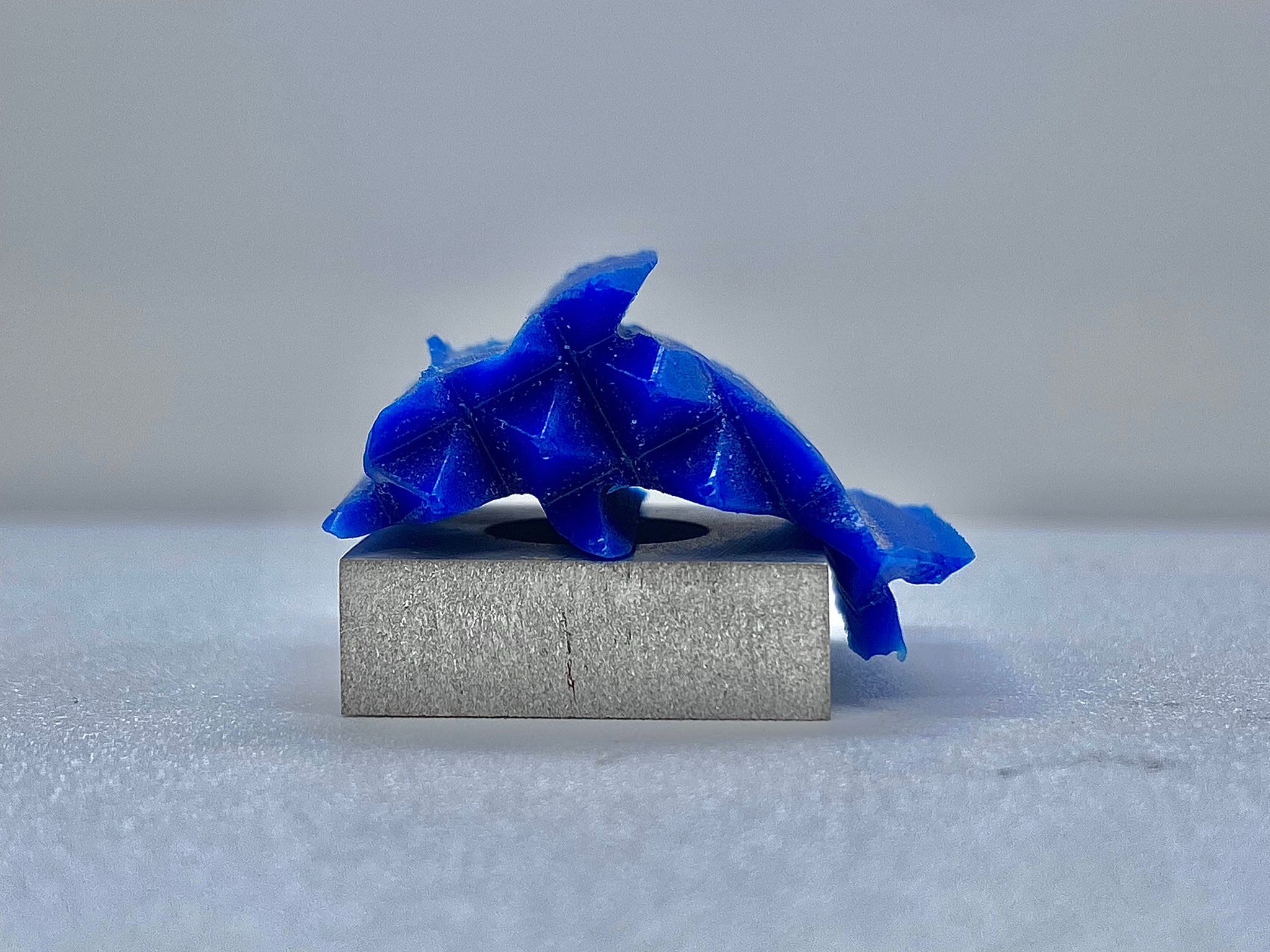

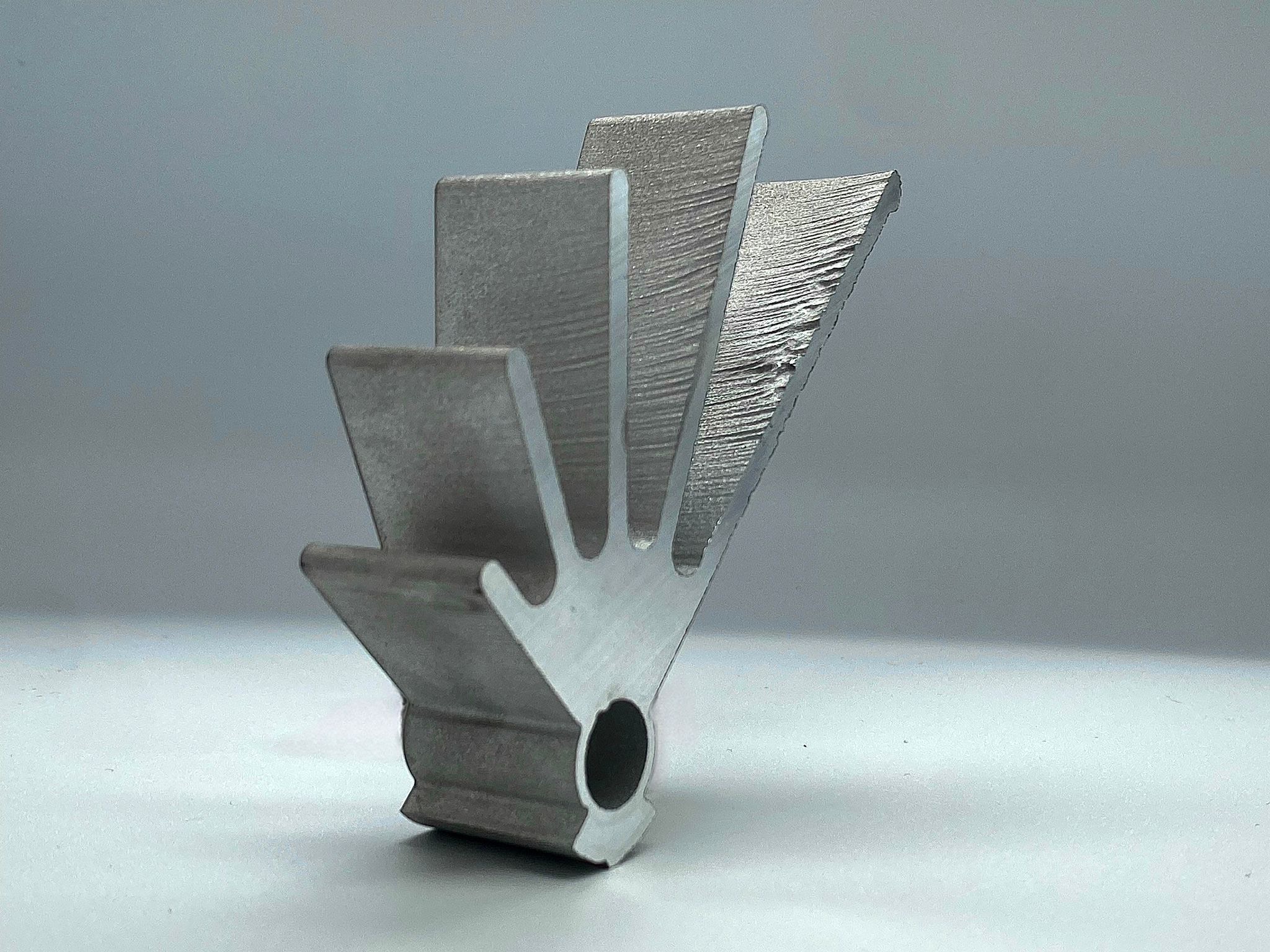

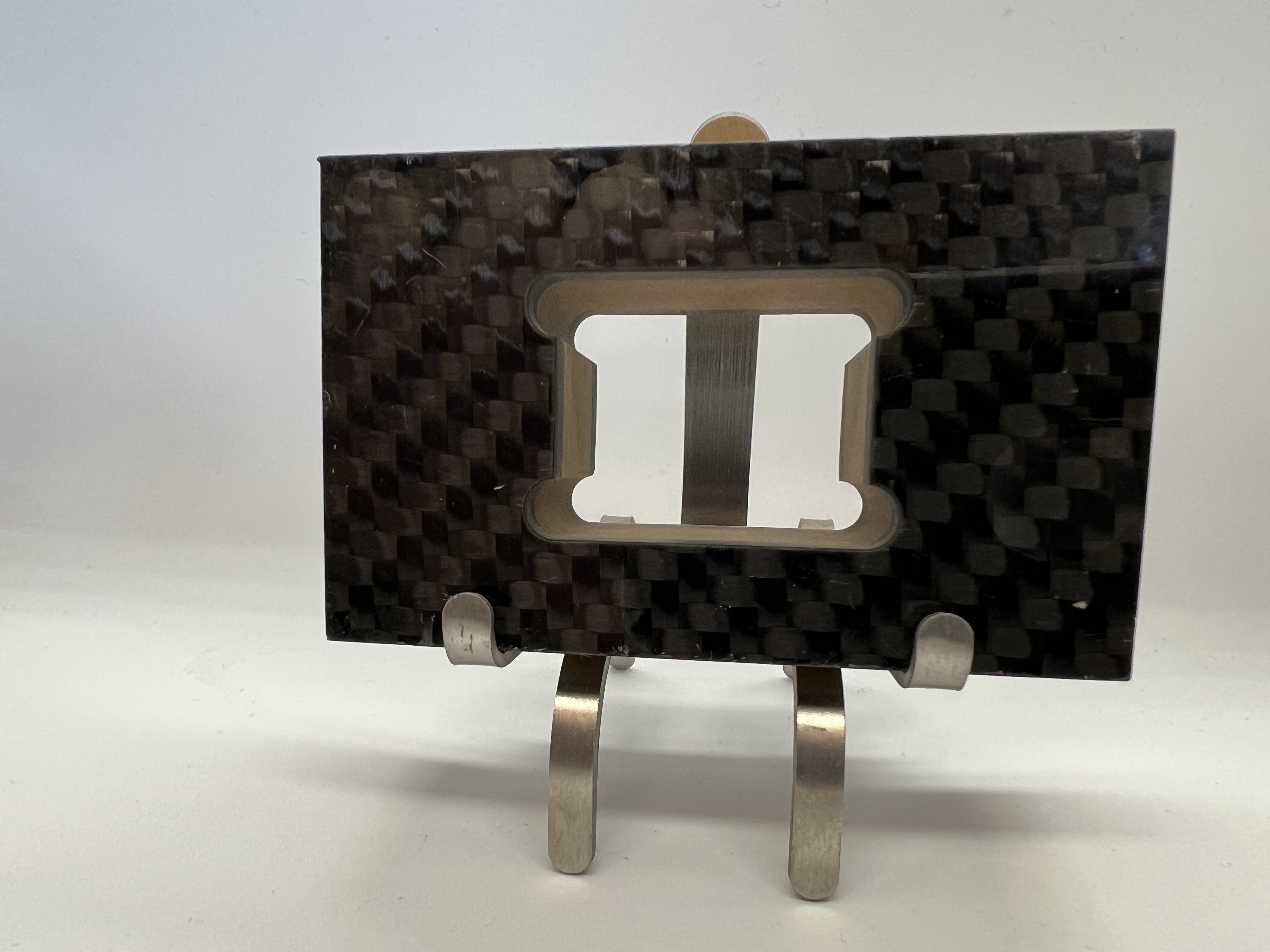

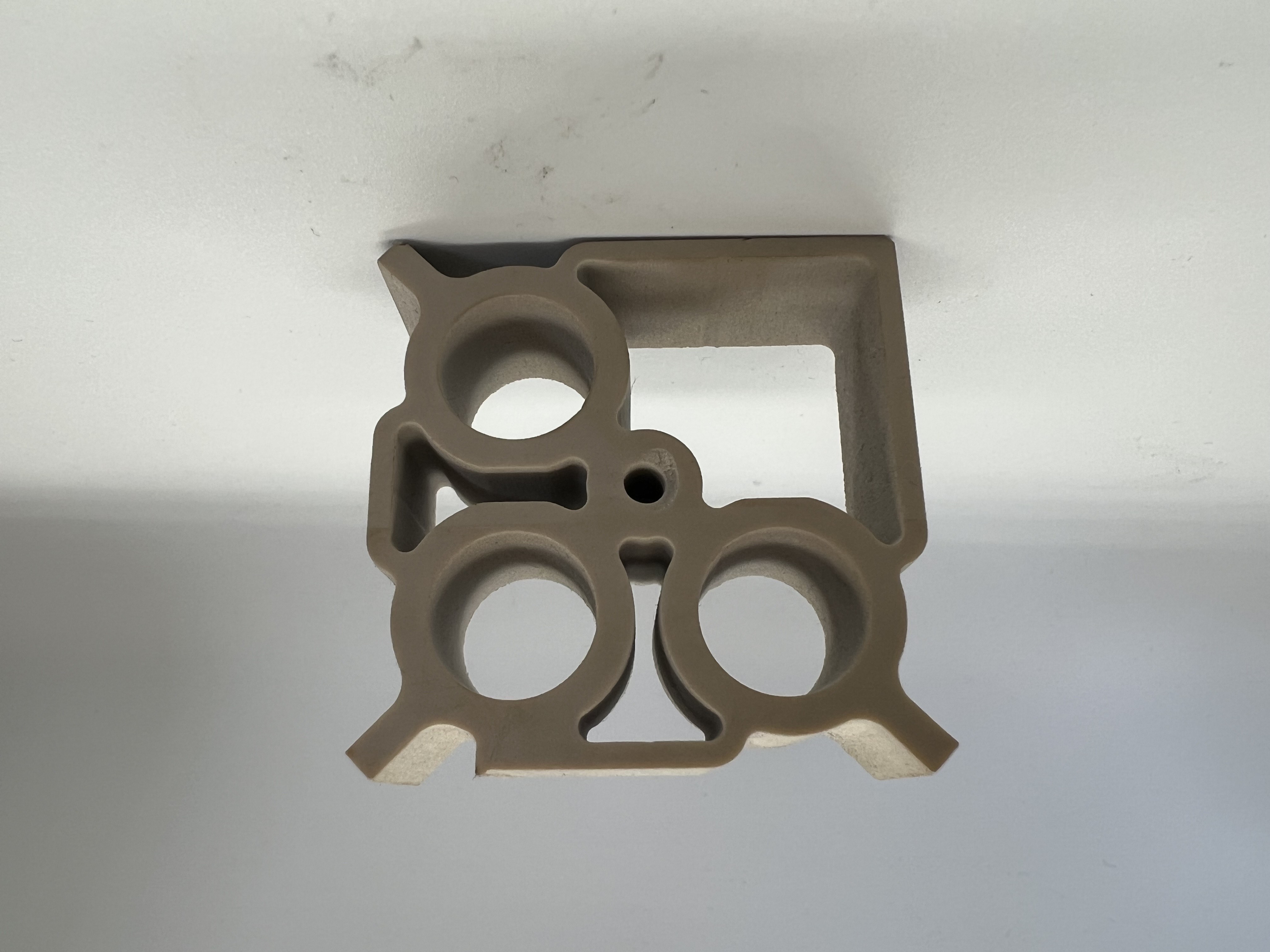

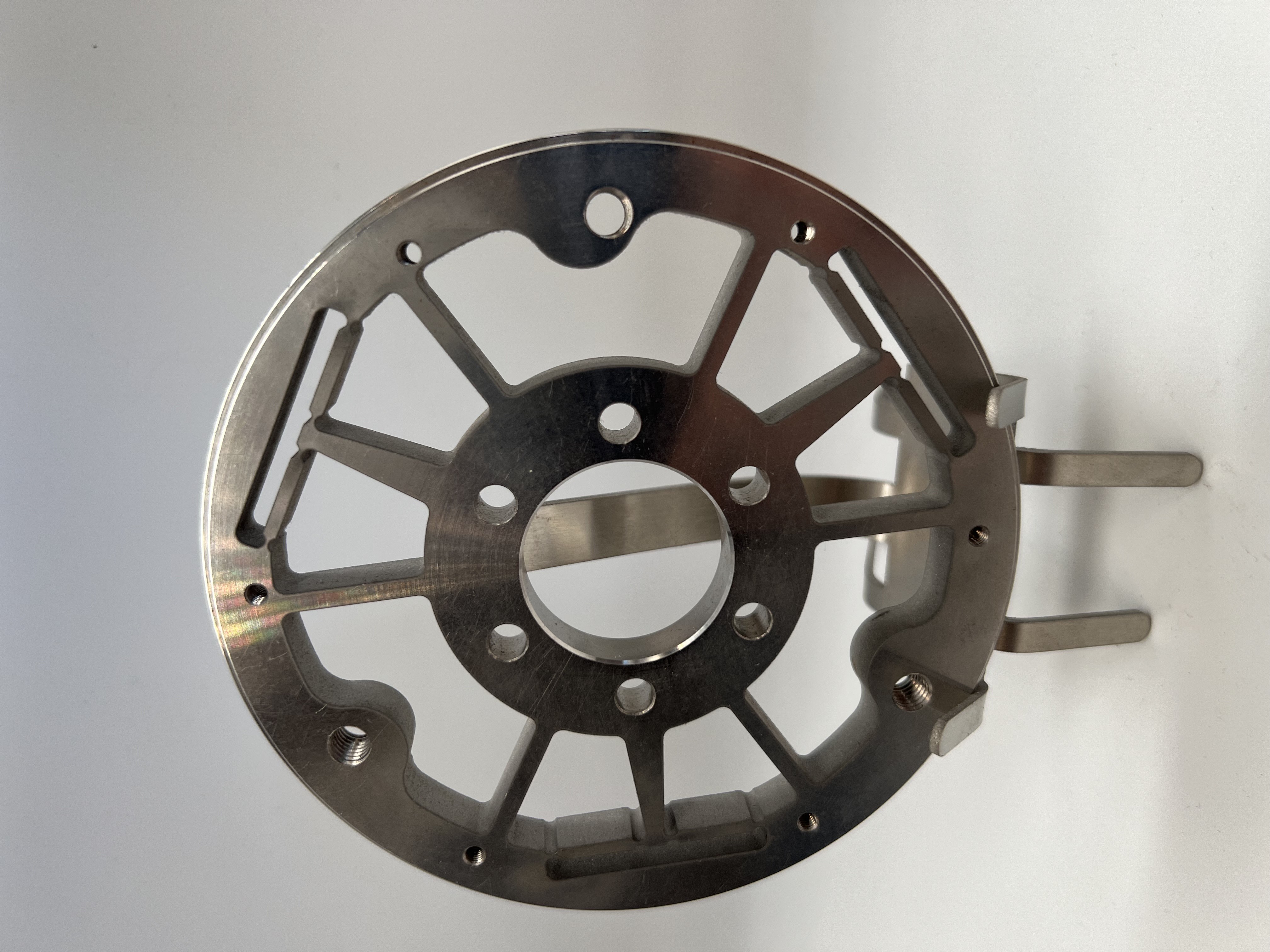

Precision Waterjet uses both water-only and abrasive waterjet cutting technologies to shape nearly any material, including those up to 200mm thick. Advanced tools like Tilt-A-Jet®, optical locators, and pneumatic drills ensure precision, while Omax IntelliMAX software optimises material usage to reduce waste and cost. With an extensive stock of ferrous and non-ferrous materials in various grades and thicknesses, we can deliver parts within 24 hours. For non-stock materials, our suppliers provide next-day shipping for quick turnaround times.

Flat Bed Linishing & Brushing

Our linishing and brushing machine enables us to provide fully deburred, satin-grained finishes (DP1 or DP2) on components up to 300mm wide, streamlining production for metals like stainless steel, copper, and brass (excluding aluminum). This eliminates the need for costly pre-grained sheet purchases, offering a convenient, all-in-one solution for finished components.

Laser Engraving & Etching

Using the Cermark process with our CO2 laser, we create high-contrast, permanent marks on metals like stainless steel and mild steel. Whether for full nameplates or simple ID numbers, we can accommodate parts up to 600mm x 450mm.

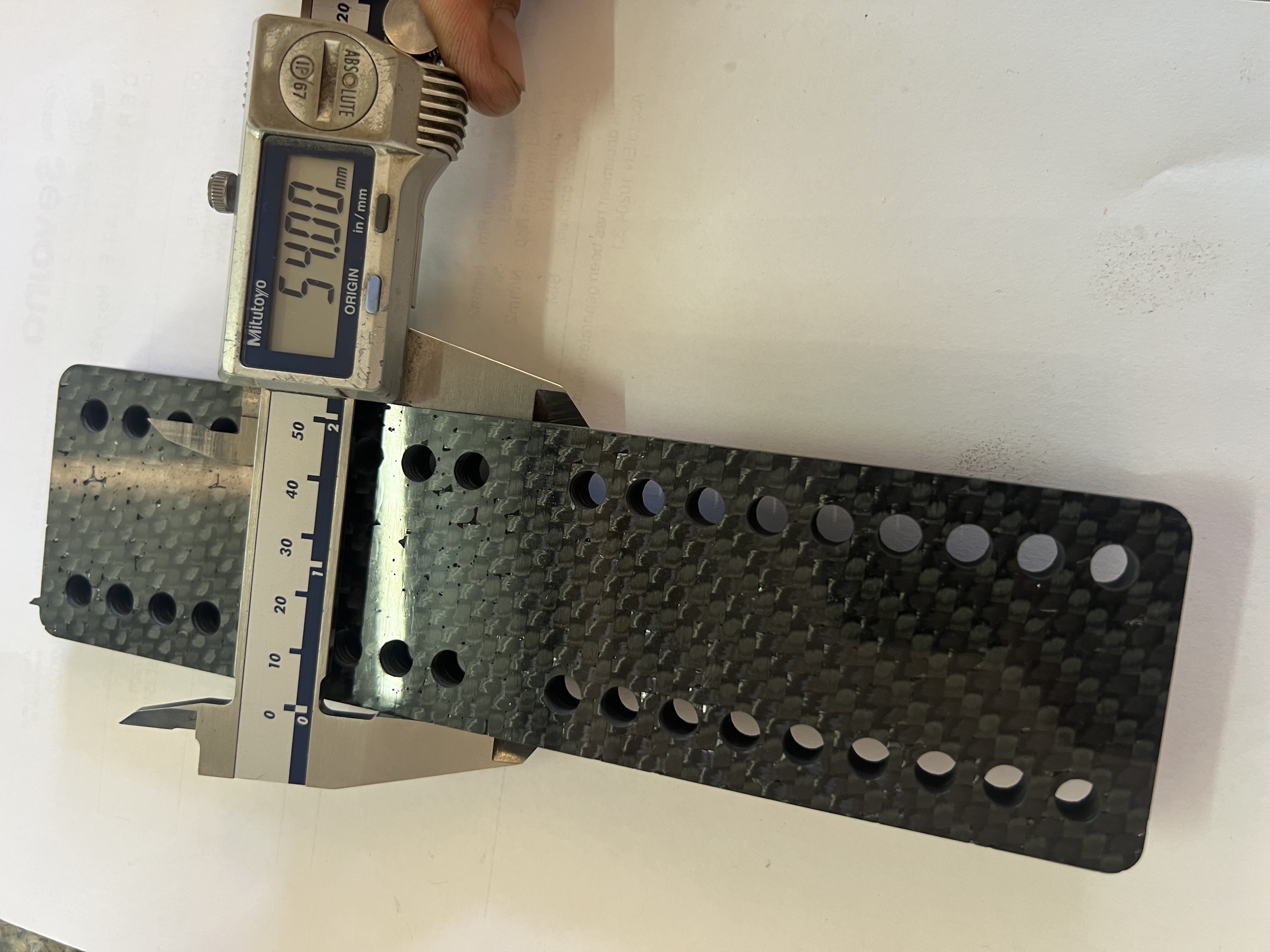

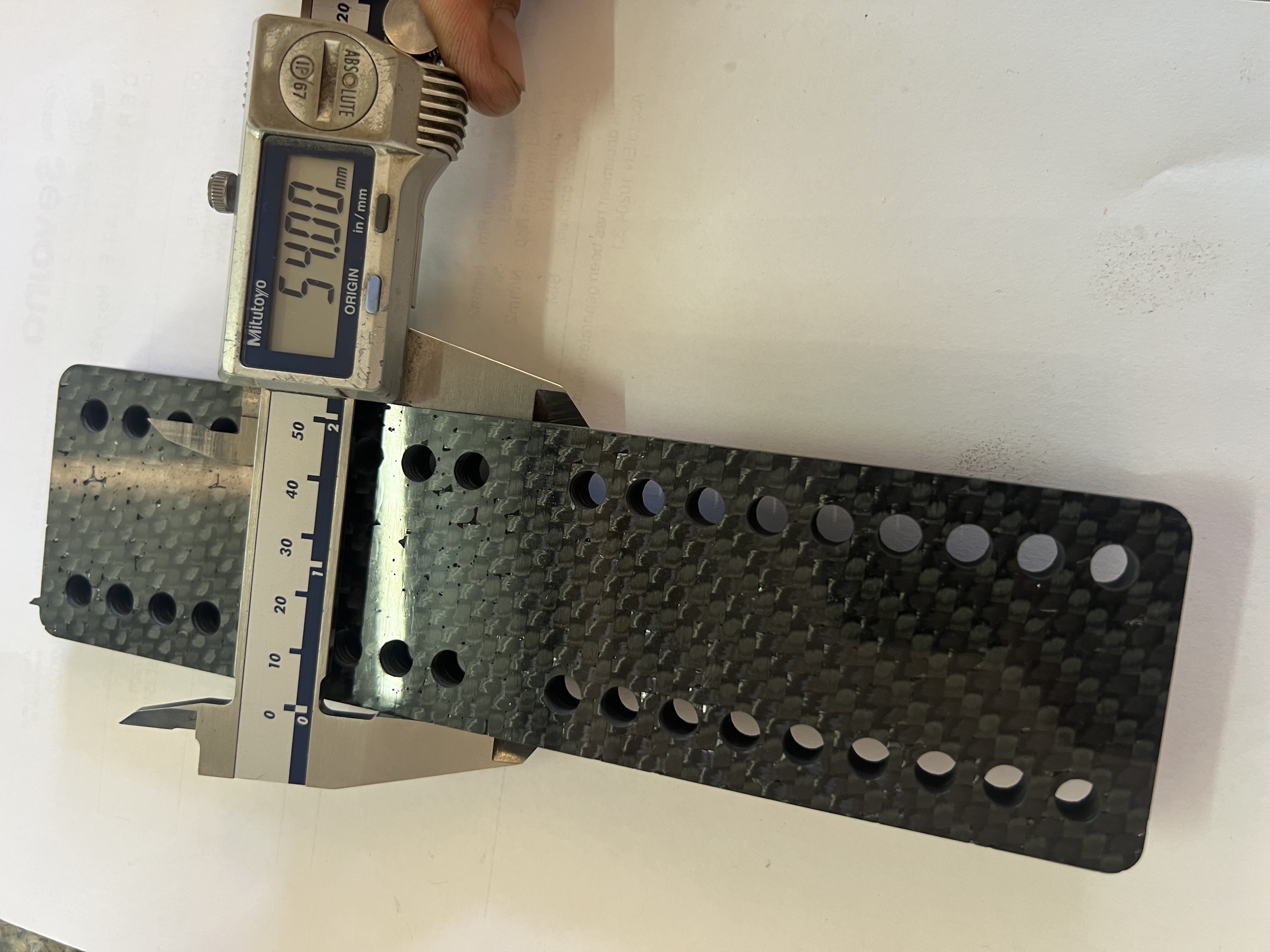

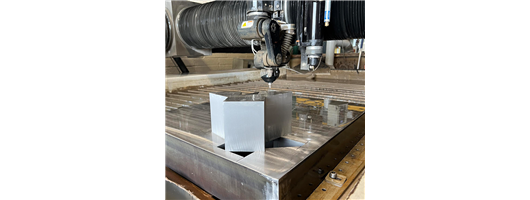

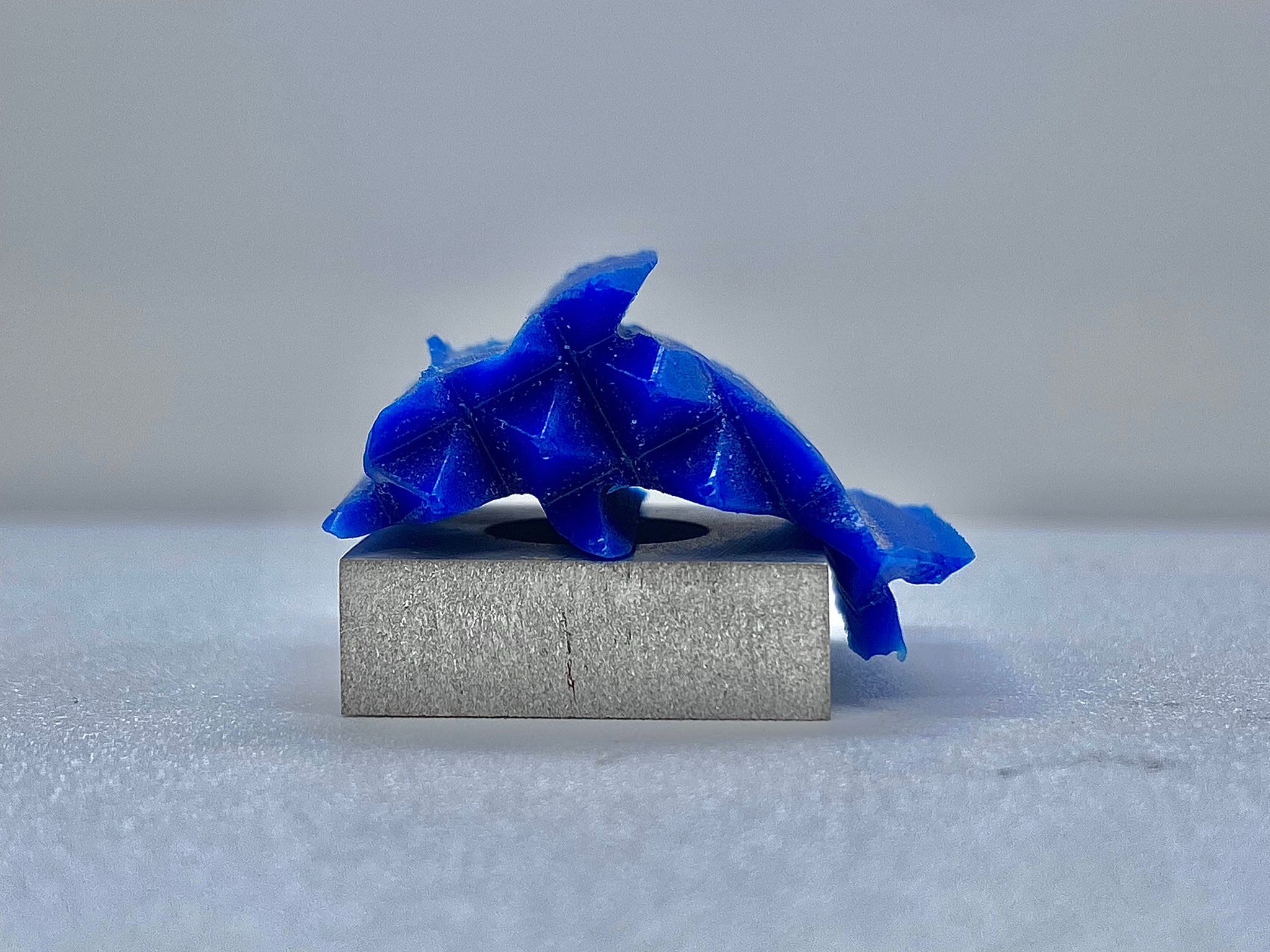

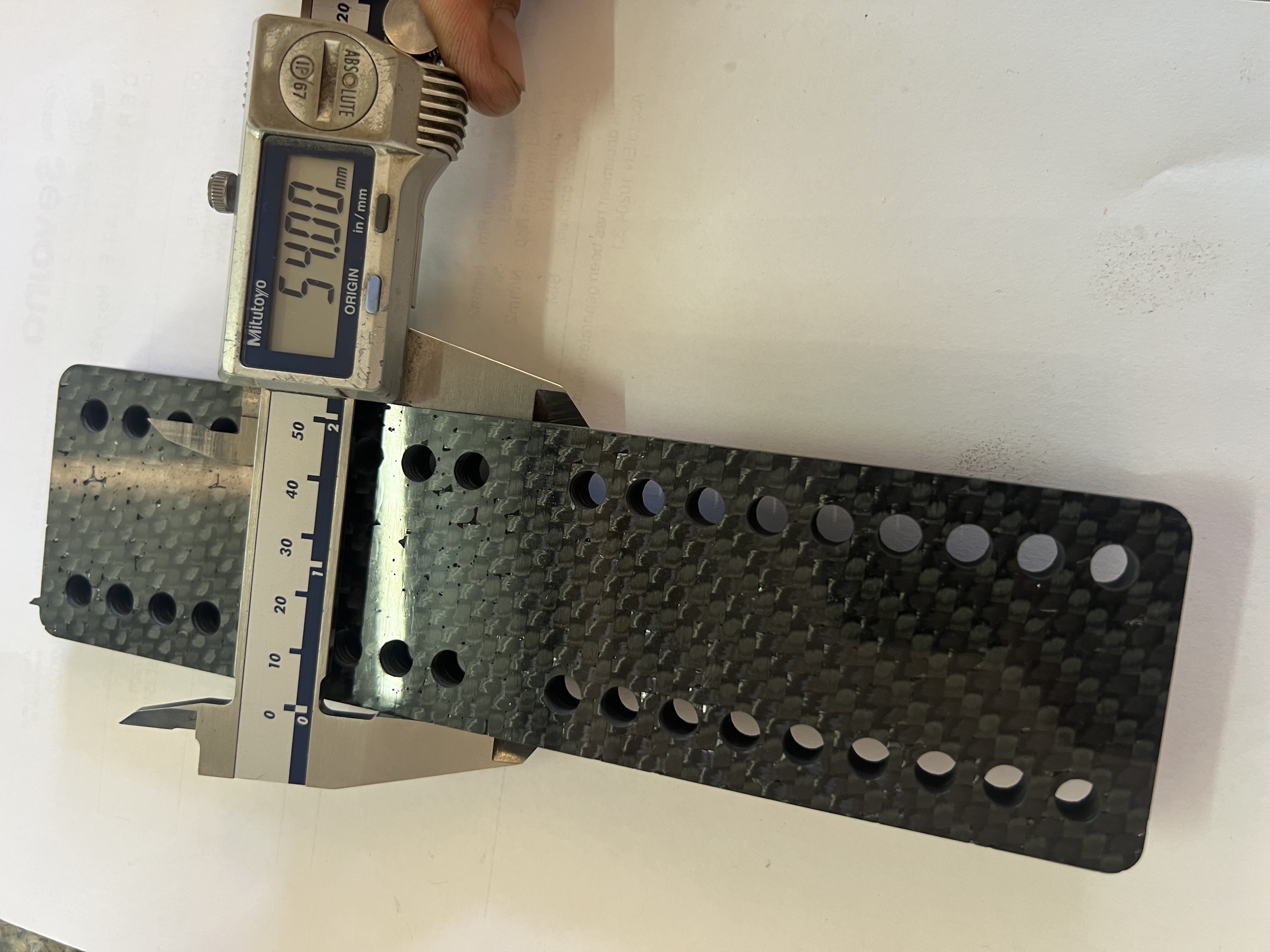

Precision Waterjet boasts the world’s largest fleet of OMAX machines, with eight state-of-the-art precision waterjets, including two new additions and six fully upgraded machines. Our two largest machines offer a cutting area of 2.54m x 1.39m, all achieving a cutting tolerance of ±0.075mm and positional accuracy of ±0.025mm. Equipped with advanced features like pre-loaded linear bearings, precision ball screws, and the MAXJET 5i nozzle delivering 54,000 psi, our machines provide 30% more cutting power than standard waterjets. Innovative tools such as the Tilt-A-Jet®, optical locators, and IntelliMAX Premium nesting software enable us to cut virtually any material up to 200mm thick with minimal waste. Rigorous maintenance ensures maximum reliability and minimal downtime.

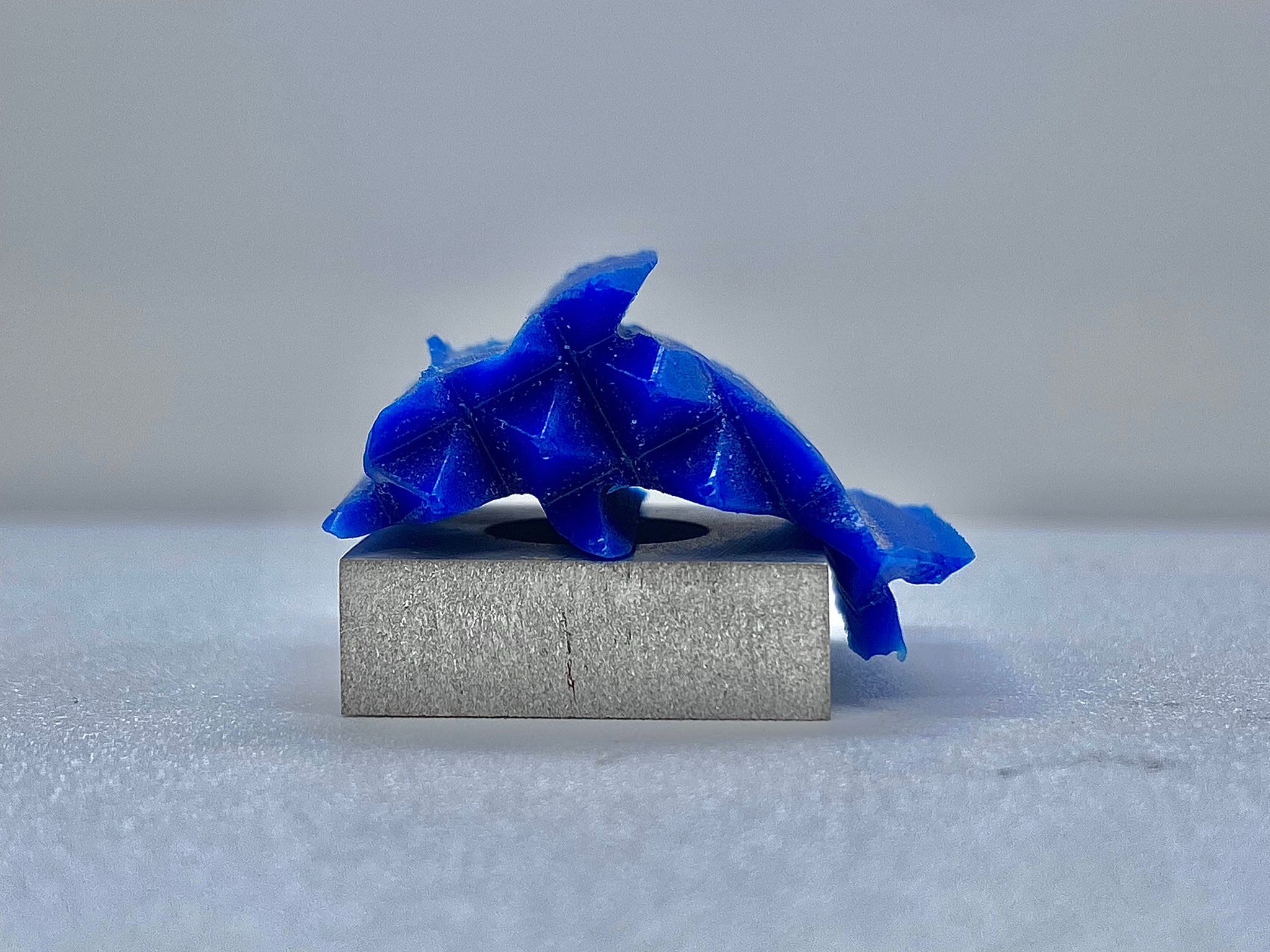

We serve a diverse range of industries, including aerospace, automotive, marine, oil and gas, power generation, and precision engineering. Increasingly, architectural and composite companies recognize the advantages of waterjet profiling, which delivers high-precision, high-quality parts with reduced lead times and minimal post-processing. Waterjet's “cold cutting” method avoids heat, allowing precise profiling of ferrous, non-ferrous, nickel alloys, and other materials without structural changes. Capable of cutting intricate designs and holes as small as 1mm, it’s ideal for complex tasks like tapping-sized holes in thick materials. Environmentally friendly, waterjet cutting uses no harmful gases or liquids and produces no hazardous vapors.

Since 2006, Precision Waterjet has focused on reliable, precise cutting with exceptional quality, short lead times, and excellent customer service. We streamline manufacturing by managing material handling and ordering, helping customers save time. Additional services include linishing for satin finishes, CO2 laser part marking with durable Cermark, and finishing options like deburring and tapping, delivering ready-to-use components.

Images

Articles / Press Releases

Brochures

Reviews

Trade Associations