Company details for:

Rowan Precision Ltd

Units 2/3/4, The Poplars Industrial Estate,

Moor Lane,

Witton,

Birmingham,

West Midlands,

B6 7AD,

United Kingdom

Quick Links:

Products / Services

Services

Extensive manufacturing capability

Finishing is provided to the highest possible standard

Extensive assembly facilities

Kanban and Consignment stock services

Delivery direct to our local market or via courier to our nationwide and overseas customers

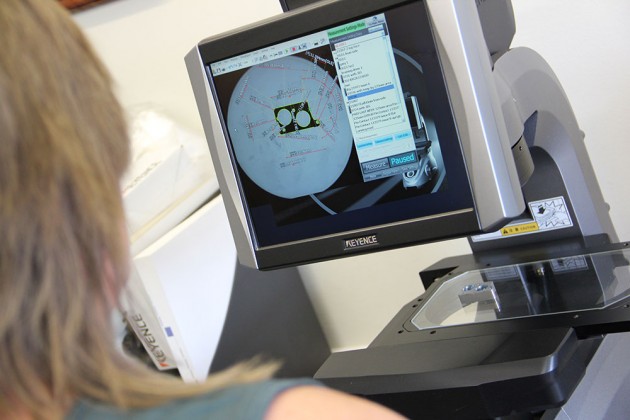

Inspection & Testing

We are confident that our team have the skills and abilities to test and inspect all aspects of component engineering manufacture to ensure we maintain the high standards our customers demand. The inspection and testing department has a wide range of quality control equipment including the latest, State of the Art Keyence IM, image measurement system and methods to achieve this and we are happy to cater for whatever inspection and testing criteria you feel is required.

Green Cleaning

By harnessing the high thermal energy of boiling water, the new Aqueous Degreaser from MecWash Systems effectively cleans and degreases the parts that normal aqueous systems, and in some cases solvents cannot. The machine has already proven effective at removing some of the most difficult and tenacious contaminates including resins, greases, NDT inks, zinc stearate, lapping pastes and polishing components.

Professional CNC Turning Solutions

Sliding Head Machining

Sliding head lathes are highly accurate and consistent multi-axis CNC machines capable of simultaneously processing turned parts. The range of machines allow us to produce parts up to a diameter 32mm quickly, accurately and efficiently. Right quality, right time, right price

Fixed Head CNC Machining

In addition to the sliding head machines at Rowan, we have a range of fixed head lathes, with twin-turret, twin-spindle capability. Working with bars up to 80mm in diameter with bar feed, or up to 200mm on lower volume parts (chuck located) with a maximum length of up to 1 metre. These machines have the capability to perform multiple operations at the simultaneously to minimise cycle time, including having both turrets turning & milling at the same time to support longer components.

5 Axis - Multi Axis Machining

Our machines have capabilities beyond just the standard fixed spindle process and feature multi-axis tooling functions that let us produce complex parts through both milling and turning in just one machining cycle. With lights out efficiency and utilising the twin-spindle, multi-turret cutting capability we can minimise cycle times, deliver precise tolerances, and part finishes.

Component Assembly

Subcontract Component Finishing

Rowan Precision have a wealth of experience in sourcing finishes to military and aerospace standards and have local specialists who can process every finish you can imagine.

About us

Based in the UK, we have been manufacturing the highest quality precision machined components for over three decades, building a strong reputation within the industry and supplying both nationally and internationally. Some of the sectors we cater to include defence, telecommunications, aerospace, safety, automotive, medical, lighting, electronics and many more.

Here at Rowan Precision, all components we offer are designed using the latest solid works CAD software which is guaranteed to achieve exceptional results. Our impressive range of state-of-the-art CNC equipment is controlled by the latest programmable DNC system that has online backup for both security and peace of mind. We are capable of machining almost any material and finish all projects to the highest possible standard.

We employ a team of dedicated professionals who work closely with clients in order to exceed their expectations.

Sponsored Links

Articles / Press Releases

Trade Associations