Company details for:

UB Plastics Ltd

Quick Links:

Products / Services

Tamper Evident Caps

UB Plastics’ tamper-evident caps are relied upon by breweries and keg suppliers across the UK and internationally to maintain product integrity and enable full traceability throughout the supply chain. Compatible with all standard keg spear types, the caps feature a clear visual seal that instantly indicates whether a container has been opened or tampered with prior to use.

Manufactured from robust, food-grade polypropylene, each cap incorporates a tear-off strip for visible tamper evidence and supports up to five-colour custom branding via high-speed in-mould labelling (IML). Offered in three sizes and a broad selection of colours, the caps are produced using either virgin or 100% recycled plastic. They can be fitted manually or with automated equipment and are fully recyclable at end of use.

Plastic Shives

UB Plastics’ two-piece shives provide a dependable sealing solution for stainless steel and select plastic casks used throughout the brewing industry. Each shive features a tough LLDPE body paired with a flexible EVA sealing band, delivering a secure fit while enabling controlled venting during dispense or conditioning.

Produced at our Burton-upon-Trent facility using high-volume moulding technology, the shives are offered in two standard sizes and a variety of colours, with optional printing available for batch tracking or custom branding. Made exclusively from virgin materials and carefully packaged for protection, they offer brewers a reliable, high-quality solution with proven performance.

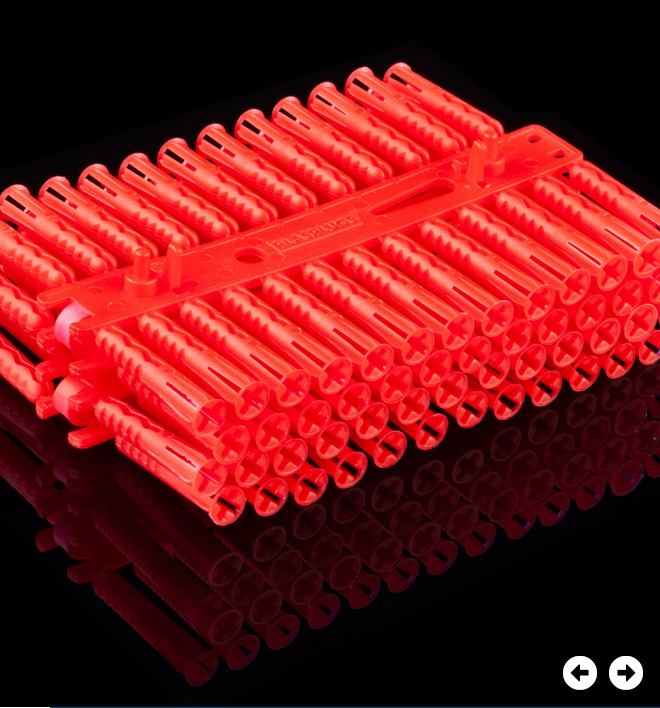

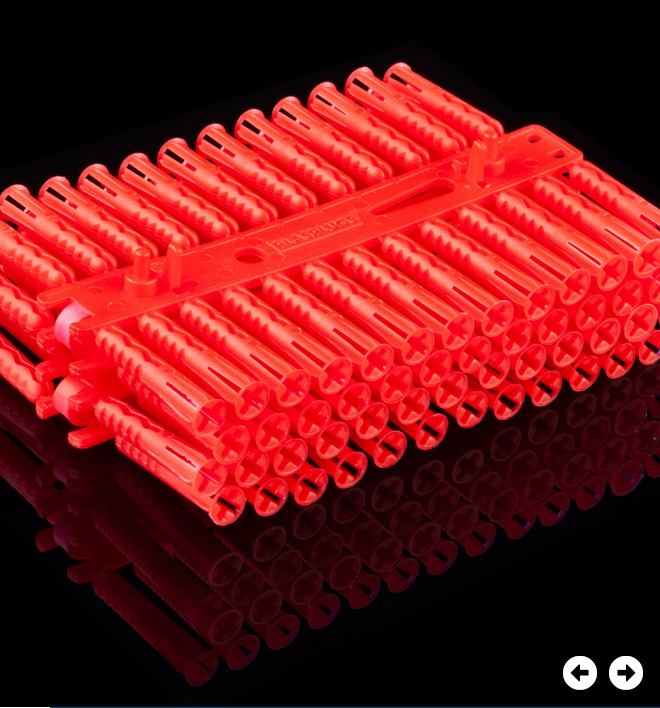

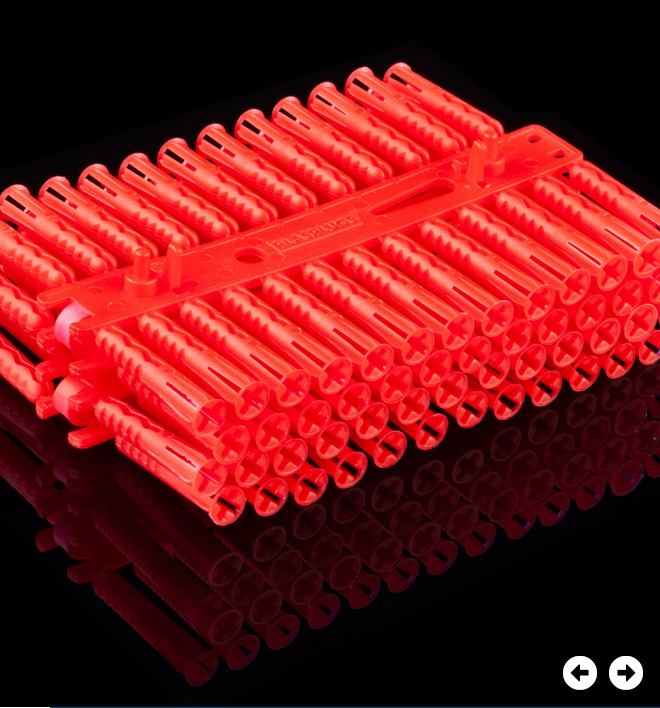

Plastic Pegs

UB Plastics’ injection-moulded pegs are purpose-built for resealing casks and kegs once the shive has been broached. Made from robust high-density polyethylene (HDPE), they ensure a tight, dependable seal that helps maintain product freshness, prevent leaks, and minimise oxygen ingress.

Manufactured in high volumes at our Burton-upon-Trent facility, each peg is precision-engineered for uniform fit and performance across every production run. Supplied in bulk, they provide brewers of all scales with a cost-effective and reliable sealing solution.

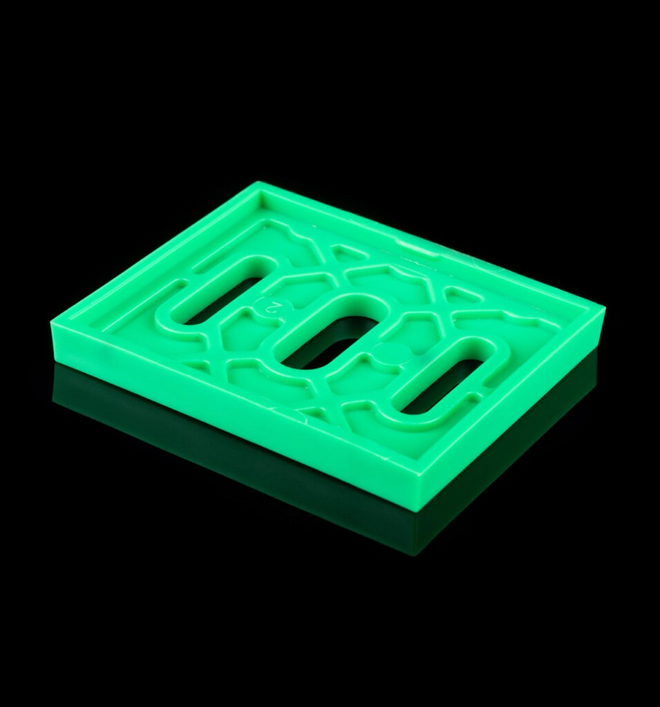

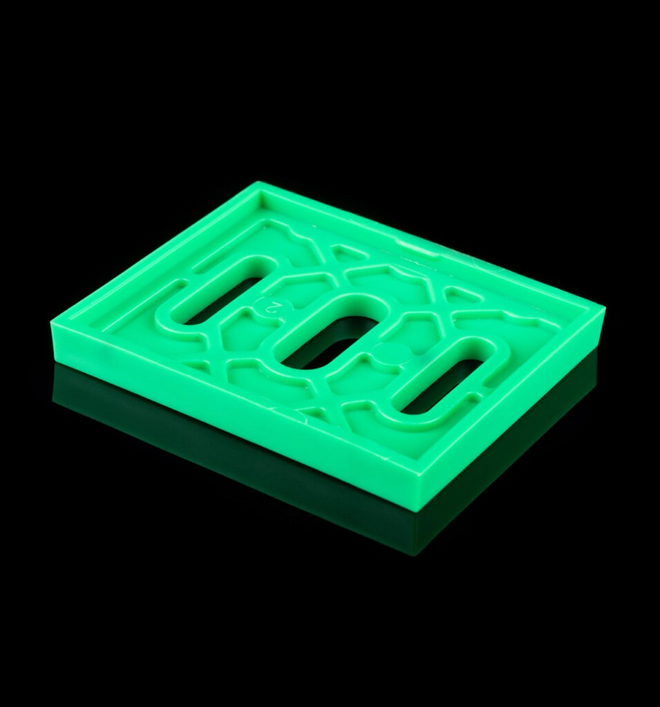

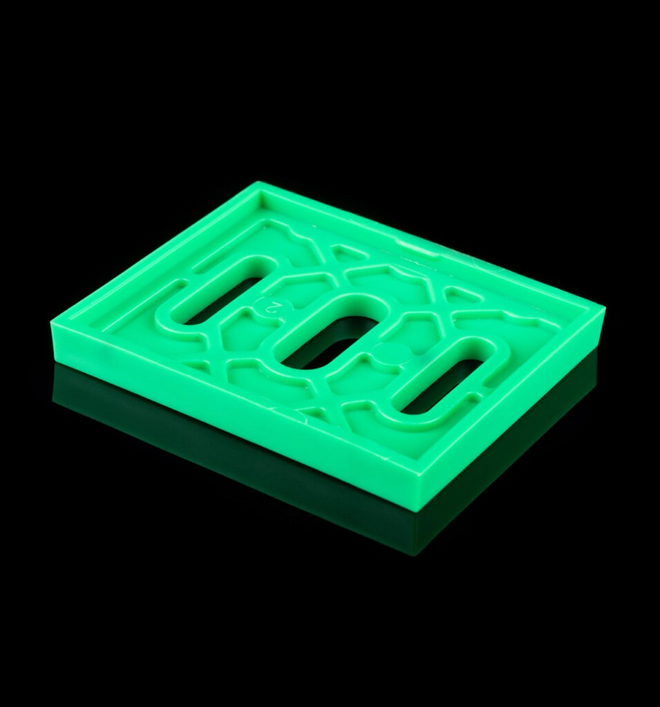

Keystones

UB Plastics’ keystones are a proven sealing component for traditional cask-conditioning systems. Crafted from durable, food-grade thermoplastic elastomer, they deliver a secure, hygienic seal while allowing straightforward one-piece removal, either manually or with automated extraction equipment.

Engineered to withstand the temperature and pressure demands of commercial cask-washing cycles, our keystones are offered in both standard and “tutted” designs to accommodate different handling preferences. Available in a wide range of colours, they also support clear product identification and consistent branding across your cask fleet.

Keystone Bungs

UB Plastics’ keystone bungs are precisely engineered to complement our keystones, offering brewers a practical, efficient solution for resealing casks after tapping and a reliable alternative to traditional cork bungs.

Designed for one-piece removal together with the keystone, the bungs streamline handling and simplify post-use cask processing. Manufactured at our Burton-upon-Trent facility using high-volume moulding technology, they ensure consistent fit, dependable performance, and suitability for breweries of every scale.

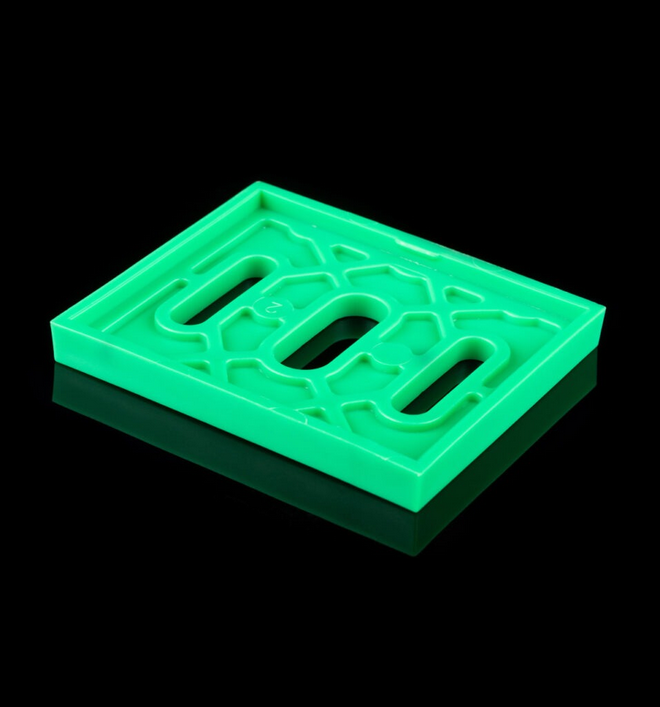

Food Packaging

UB Plastics produces premium injection-moulded packaging for the food and hospitality industry, including bespoke ice cream tubs, branded lids, and integrated cutlery packs. Our packaging solutions are trusted by event caterers, cinemas, visitor attractions, and food service operators throughout the UK.

Using precision tooling and advanced in-mould labelling (IML) technology, we manufacture durable, freezer-safe packaging that combines visual appeal with reliable performance. We work closely with both national brands and independent producers to deliver plastic packaging that enhances presentation and protects product quality.

Our fully customisable branding options include multi-colour IML for logos, ingredients, instructions, and promotional content — all seamlessly embedded into the moulded surface for a clean, durable finish and efficient, automated production.

Manufactured entirely in-house at our Burton-upon-Trent facility, UB Plastics’ food packaging solutions are designed for consistency, hygiene, and an excellent end-user experience from concept through to delivery.

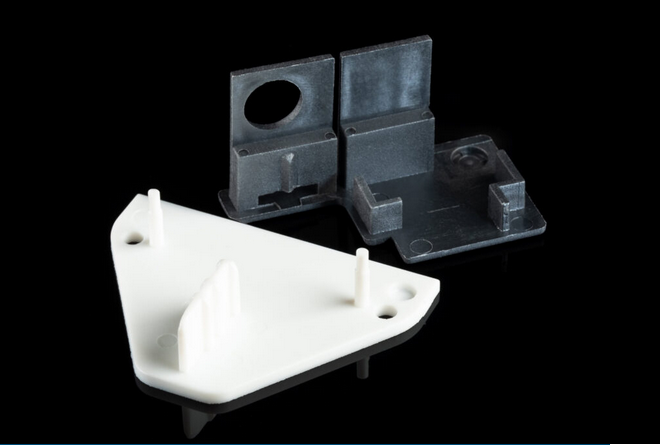

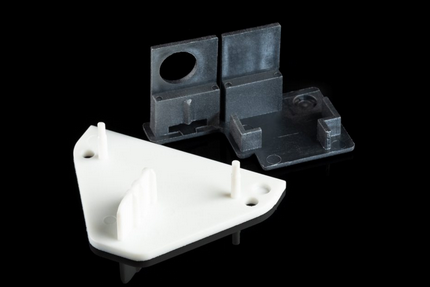

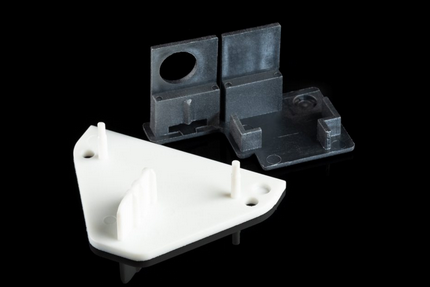

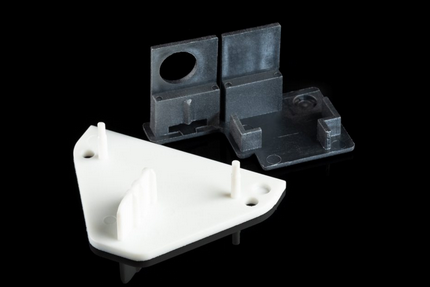

Construction Products

UB Plastics manufactures specialist injection-moulded components for a diverse range of construction applications — from cladding and balcony systems to general-purpose site and structural uses. Each part is engineered to deliver reliable performance while promoting safety, ease of installation, and a neat, professional finish.

Collaborating closely with construction product manufacturers, we produce robust, high-quality mouldings built to withstand the demands of real-world conditions. From protective end caps that enhance installer safety to spacers that improve assembly efficiency or functional elements within building systems, every component is precision-made for accuracy and consistency at scale.

All production is carried out at our UK facility in Burton upon Trent, where we offer full support from initial design to final delivery.

Fenestration Products

UB Plastics produces precision-moulded components for use in the manufacture and installation of windows, doors, and glazed units. Working in partnership with system designers and fabricators, we develop dependable plastic parts that enhance performance, safety, and visual consistency.

Our product range includes weather-resistant seals, drainage fittings, end caps, and fixing covers — all engineered to endure external environments and meet the technical requirements of modern fenestration systems. When needed, we provide custom tooling to deliver bespoke components that integrate seamlessly with existing designs.

All items are manufactured at our Burton-upon-Trent facility, with colour options, branding, and packaging formats tailored to suit both production and trade applications.

Product Design Services

At UB Plastics, we turn ideas into reality through practical, production-focused product design services. Whether developing a new concept or optimising an existing one, our in-house team guides each stage of the process with a strong emphasis on mouldability, performance, and cost-effective manufacturing.

Injection Moulding Services

UB Plastics is a specialist in precision injection moulding, providing high-quality components to clients in the brewing, food, packaging, and construction industries. Backed by decades of experience and fully equipped UK facilities, we offer reliable, high-volume production while retaining the flexibility to accommodate bespoke specifications.

In-Mould Labelling

UB Plastics provides in-mould labelling (IML) as an integral part of its injection moulding services, producing sharp, long-lasting decoration directly embedded into the finished product. By removing the need for secondary labels or printing, IML helps lower costs, streamline production, and deliver a premium, branded finish.

Colour Printing

UB Plastics provides in-house pad printing for plastic components, delivering sharp, durable surface decoration for branding, identification, or instructional purposes. Pad printing is perfect for applying logos, batch codes, symbols, or colour markings directly onto moulded parts, including those with curved or irregular surfaces.

Packaging & Delivery

UB Plastics provides customised packaging and delivery solutions to accommodate diverse product types, volumes, and client needs. Whether supplying bulk packaging for trade or branded, shelf-ready presentation, our in-house team ensures injection-moulded products are protected, fully traceable, and delivered efficiently.

Brewing

UB Plastics was established in 1983 to provide plastic injection-moulded components to the brewing industry, offering modern, hygienic alternatives to traditional wooden parts. From our base in Burton upon Trent, a town with a rich brewing heritage, we have served breweries across the UK from the very beginning. More than four decades later, we continue to produce millions of brewing components each year, blending our long-standing experience with advanced automation and quality management systems.

Over the years, we have grown alongside the brewing sector, supporting both global brands and local independents. Our team understands the technical, logistical, and seasonal challenges that breweries face, and we design our processes to meet these demands consistently and reliably.

Beverage

Building on decades of experience in the brewing industry, UB Plastics has expanded into the broader beverage sector, supplying reliable plastic packaging components for soft drinks, juices, water, and mixed-alcohol products. While beer remains part of our heritage, we now work with producers, co-packers, and distributors across the UK beverage market.

From tamper-evident closures to printed plastic packaging, our solutions help beverage brands of all sizes enhance shelf appeal, maintain hygiene, and ensure full traceability.

Construction

UB Plastics produces robust injection-moulded components for a wide range of applications within the UK construction industry. From site-use items to parts incorporated into building systems, our mouldings are designed for strength, safety, and consistent performance in demanding conditions.

With more than 40 years of injection moulding experience, plus in-house design and tooling support, we assist customers across the construction supply chain in developing and delivering components that satisfy both technical specifications and practical needs.

Custom Mouldings

At UB Plastics, we provide tailored injection-moulded components for companies across a range of industries, designed to meet the specific requirements of each product, process, or system. Whether creating a new part or refining an existing design, we offer a complete in-house service, covering design, prototyping, tooling, moulding, and delivery.

With over 40 years of expertise, we are a trusted partner for brands in manufacturing, packaging, construction, and beyond, delivering high-quality, consistent moulded components at scale.

Fenestration

UB Plastics provides injection-moulded components for modern windows, doors, and glazed façade systems. Collaborating closely with fenestration manufacturers and system designers, we produce durable, high-quality parts that enhance weatherproofing, safety, and ease of installation.

With in-house tooling, rapid lead times, and a proven track record in building product supply, we are a trusted UK partner for plastic mouldings in the fenestration sector.

Moulded Packaging Solutions for Food & Hospitality Brands

UB Plastics provides injection-moulded food packaging to some of the UK’s leading brands, ranging from national foodservice suppliers to independent producers. With decades of experience, in-house manufacturing capabilities, and advanced labelling technology, we create practical, high-quality packaging that combines functionality with visual appeal.

Our solutions are widely used across leisure, retail, catering, and hospitality sectors, designed to deliver hygiene, durability, and user convenience.

Our Machinery & Automation

UB Plastics has consistently invested in advanced technology and automation to support efficient, high-volume production. Our facility now operates 23 modern injection-moulding machines ranging from 35 to 220 tonnes, many equipped with full-servo robots to enable sophisticated processes such as in-mould labelling (IML).

This capability allows us to manufacture over 100 million plastic parts annually, including millions of tamper-evident caps for the brewing and food packaging sectors. Our machinery includes leading brands such as Negri Bossi, Romi, Borshe, Battenfeld, and Haitian, supported by ATM and Compact 2T full-servo robots to ensure consistent, automated handling throughout production.

About us

UB Plastics Ltd, based in Burton upon Trent—a town renowned for its manufacturing heritage—has over 40 years of experience in injection moulding, combining innovative expertise with advanced machinery to produce millions of high-quality moulded parts annually.

Founded in the heart of brewing country, UB Plastics has grown to serve global brands across food, beverage, packaging, construction, and more. With in-house design, IML technology, and sustainable manufacturing, we deliver high-quality, precise moulded parts tailored to today’s demanding markets.

Since 1983, UB Plastics has combined decades of injection-moulding expertise with advanced manufacturing capabilities, operating 23 machines from 35T to 220T equipped with high-speed robotics and in-mould labelling to deliver precise, high-volume production. We provide end-to-end support, including in-house design, tooling, stockholding, and delivery, ensuring projects run smoothly from concept to completion. Trusted by leading brands across brewing, food, packaging, and construction, we also prioritise sustainability, offering recycled materials and low-waste processes without compromising quality.

Our Services Include:

Injection Moulding

From initial concept to finished part, we produce high-volume plastic mouldings with precise tolerances.

Product Design

We transform product ideas into practical, manufacturable plastic components.

In-Mould Labelling

Quick, precise labelling seamlessly incorporated during the moulding process.

Colour Printing

Tailored printing that enhances colour, branding, and legibility.

Packaging & Delivery

We provide flexible storage, packing, and delivery solutions to meet your schedule.

Quality

Each component is inspected, tested, and manufactured to the highest quality standards.

Based on a 1.7-acre site, we operate 23 modern injection-moulding machines from 35 to 220 tonnes, equipped with high-speed automation and in-mould labelling (IML). Our services span product design, tooling, precision moulding, custom printing, packaging, and delivery, supporting clients at every stage.

UB Plastics offers extensive technical capability to support a wide range of projects across multiple industries, from medium- to high-volume automated production of small to medium plastic components, including high-quality printing, branding, and colour finishes. Producing over 100 million parts annually, we are trusted by major global brands and prioritise sustainability, using fully recycled materials in key products such as colour-coded tamper-evident caps.

With decades of hands-on manufacturing experience, we deliver consistent quality and reliable service that clients can depend on.

Images

Reviews

Trade Associations