Company details for:

William Hughes Ltd

Quick Links:

Products / Services

Wire form & spring prototyping

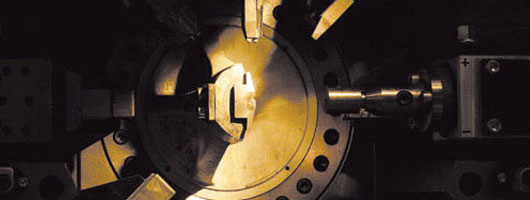

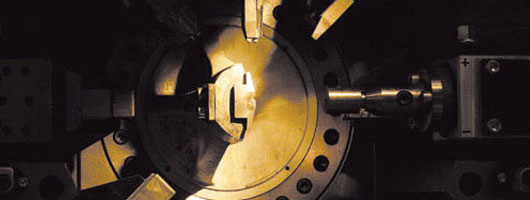

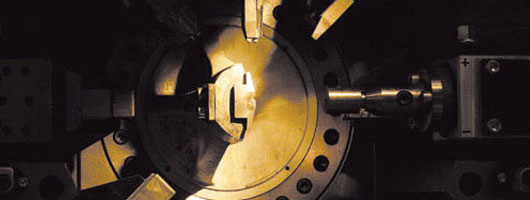

William Hughes focuses on producing high-precision wire form and spring prototypes, offering industry-leading expertise to sectors including automotive, aerospace, defence and medical. Our in-house prototyping services help speed up development while achieving demanding standards for performance, accuracy and surface finish. With deep knowledge in precision wire component design, we ensure every prototype meets strict load and tolerance specifications. Using advanced CNC machinery and robotic automation, we deliver dependable quality and repeatable consistency across all components.

Our design and application engineers enjoy state-of-the-art facilities for the in-house design of products and machine tools.

Spring Manufacturer - Spring Assemblies

Precision springs play a vital role in mechanical systems, providing force, motion management and durability across industries including aerospace, automotive, medical and nuclear. As a major UK spring manufacturer with facilities in Bulgaria and Poland, William Hughes delivers end-to-end support from design through to production, backed by advanced CNC coiling, statistical quality controls and integrated automation. Trusted by assembly-level OEMs as a Tier 1 supplier, we focus on tight-tolerance spring solutions for performance-critical applications. Our engineering team ensures every spring meets exact requirements for load, free length, fatigue life and material standards.

Wire Forms & Assemblies

Prototyping to Scalable Production

At William Hughes, we don’t simply manufacture wire forms, we engineer wire solutions tailored to your application, from concept through to final approval. Our engineering team collaborates with your in-house specialists to create wire components optimised for form, fit, function and lifecycle durability. We machine complex shapes in round or profiled wire, ranging from 0.3mm to 16mm in diameter, using fully robotic and CNC coiling, bending and forming technologies.

With our high-speed precision tooling, geometric CAD/CAM programming and robotic handling cells, we are able to manufacture high-integrity wire forms for such applications as:

- Fluid handling systems

- Surgical assemblies and diagnostics

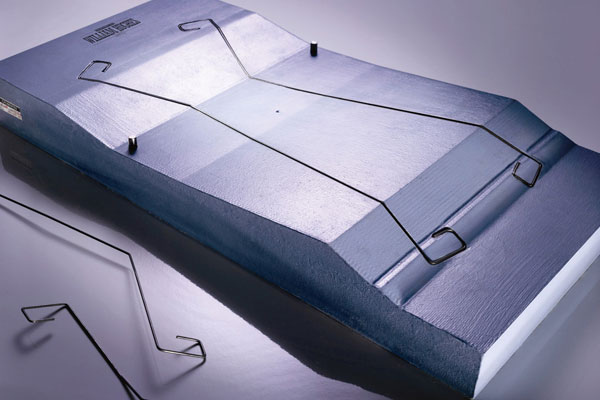

- Automotive linkages, structural brackets and seat mats

- Aerospace airframe and cabin applications

- Defence-critical mechanical interlocks

Whether your requirement is ultra-fine stainless medical wire or high-strength carbon steel for structural load bearing, we provide best-in-class cost-performance ratios with rapid turnaround on prototype and production runs.

Aerospace

Aerospace

William Hughes is a leading UK aerospace components manufacturer, supplying complex spring and wire form sub-assemblies for aircraft platforms, wearable apparatus and UAV manufacture.

AS9100-certified and Nadcap-accredited for chemical processing, heat treatment and materials testing, we serve major OEMs and Tier 1s including Honeywell, BAe Systems, Lockheed Martin, Meggitt and Eaton Aerospace.

Our manufacturing model is built around flight-critical performance. We operate as an engineering partner, integrating directly into R & D workflows to support rapid development, iterative prototyping and compliance with geometric, functional and contamination thresholds with aerospace ultrasonic cleaning and specialist kitting.

The Demands of Flight-Critical Manufacturing

Our role extends beyond manufacturing, we operate as a collaborative development partner where we proactively identify and solve the failure points that compromise repeatability, fatigue life or compliance.

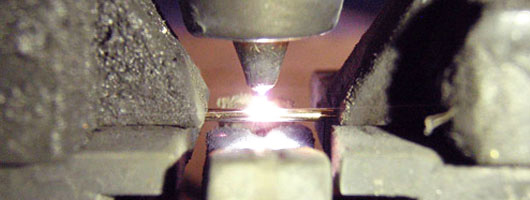

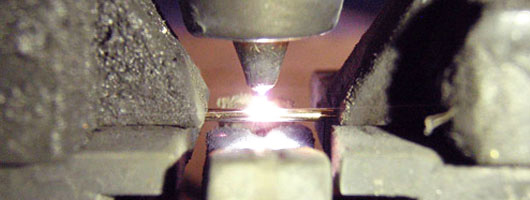

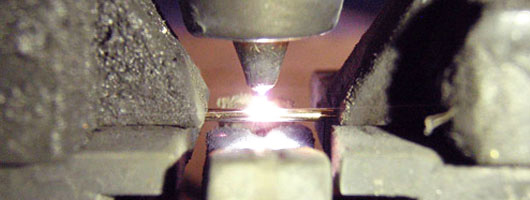

Using exotic aerospace-grade alloys such as Inconel, MP35N and titanium, our facilities deliver closed-loop CNC manufacturing, including coiling, robotic MIG/TIG welding and 100% inspection using in-line vision systems. This integrated capability supports both conventional aerospace assemblies and specialist wire fabrication aerospace manufacture, from miniature UAV components to heavy-duty aircraft actuator springs.

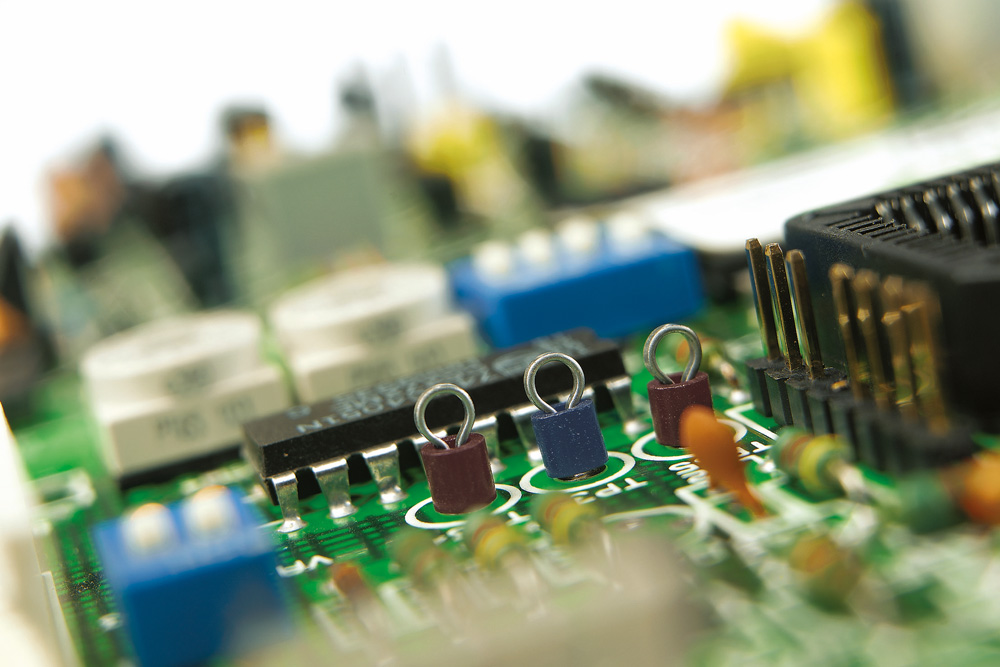

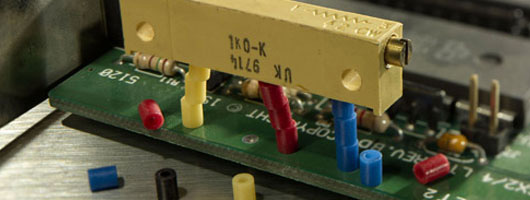

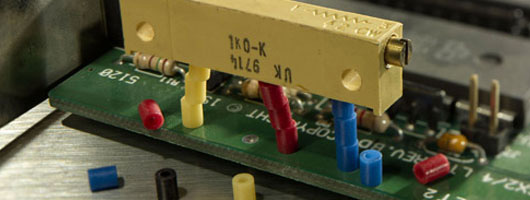

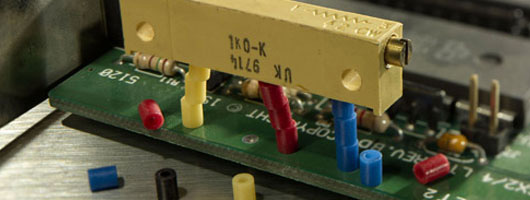

PCB Test Points

Prototype work and volume production

Our PCB test points and terminals feature a large loop for easy probe attachment or to facilitate the clipping on of other components. They are ideal for components which need frequent replacement and are also suitable for raising hot components above the surface of the PCB.

A glass bead in a choice of eight colours for identification purposes ensures a snug fit on the board. White, yellow, black, brown, blue, pink, red and green are available ex-stock with other colours to meet special requirements. The unique shape of the test point will not damage through-plated holes during assembly yet prevents any movement prior to soldering.

Passivation

Passivation

At William Hughes, we specialise in precision passivation for stainless steel, using advanced chemical treatments and rigorous quality control to meet the highest industry standards, including AMS2700 and ASTM A967. Passivation is a chemical process used on corrosion resistant steels to remove free iron and surface contaminants without altering the material’s essential properties. This process restores the natural oxide layer, reducing the risk of corrosion and ensuring optimal functionality across a wide range of manufacturing applications.

Whether you require passivation for medical instruments, precision-engineered components or complex assemblies, William Hughes delivers results that meet stringent industry specifications.

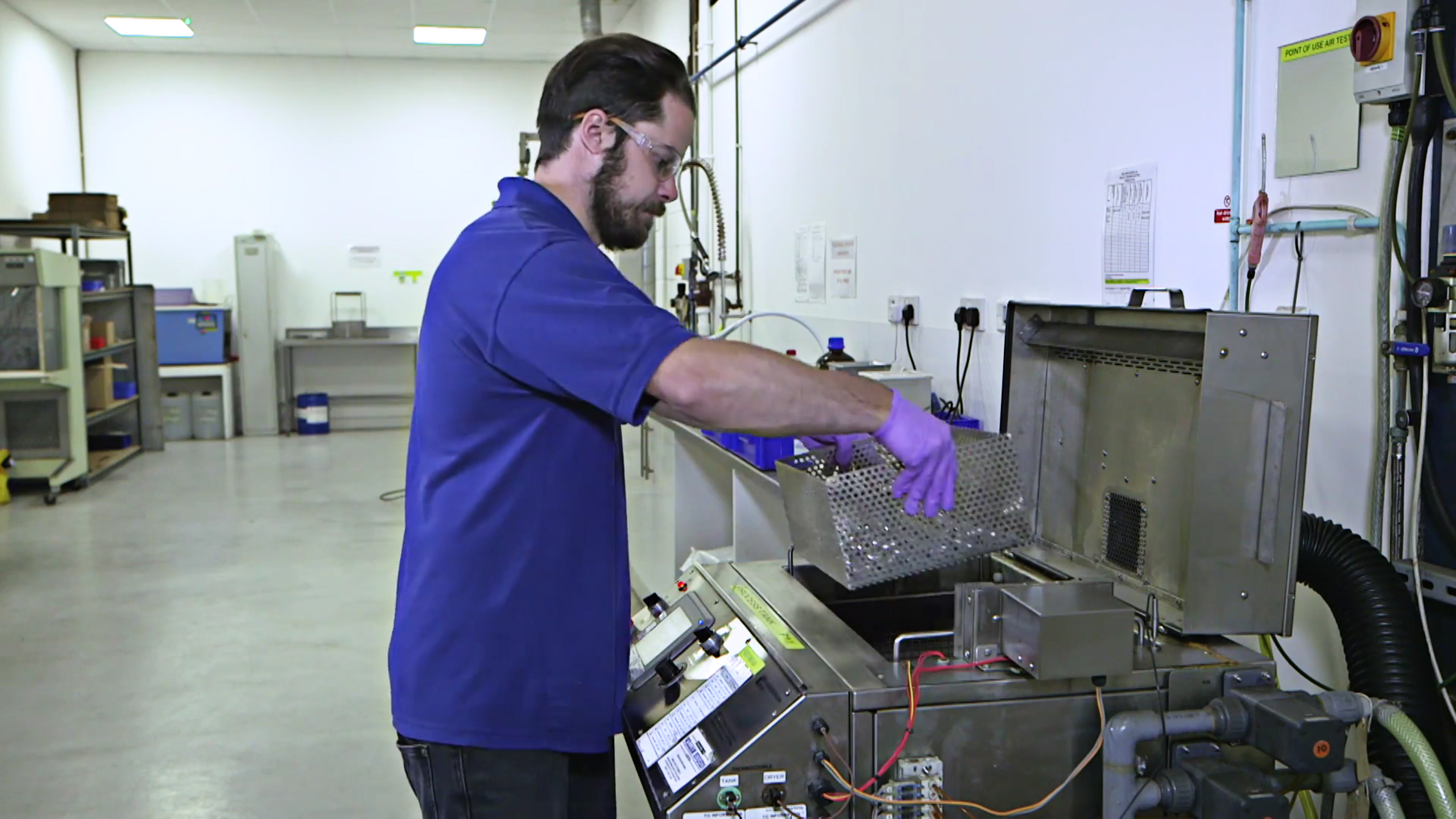

Our Passivation Process

Our passivation process, which is Nadcap accredited and Honeywell Aerospace approved, involves a series of precise chemical treatments that eliminate contaminants from the stainless-steel surfaces. Our facility at Stalbridge incorporates a state-of-the-art automated passivation plant with novel functionality in that there is no manual ‘dunking’ of component baskets from station-to-station, as with traditional systems. Instead, the plant performs a fluid transfer which involves moving chemical solutions from holding tanks into the main processing unit as required, helping to prevent damage as the parts do not move. The entire process is automatic and PLC controlled. Typical treatments are nitric acid and rinse cycles. These are followed by a final rinse in deionised water before a drying cycle.

We offer three service levels: standard five-day, express three-day and super-express 24 hours (subject to any testing requirements).

Cleanroom

Our 80m² Class 7 clean room, is engineered to meet the highest industry standards, offering contamination control through our carefully maintained industrial clean room environment. Our facilities operate in compliance with ISO 14644 classifications, ensuring that airborne particulate levels are regulated and consistently maintained within defined limits. Advanced filtration systems, including HEPA and ULPA technologies, are integrated to achieve optimal air purity, while rigorous environment monitoring guarantees adherence to critical cleanliness parameters.

The integration of advanced clean room facilities within manufacturing environments is important for achieving stringent contamination control, particularly in high-precision industries such as aerospace, medical device production and pharmaceutical manufacturing.

Our clean room services are designed to integrate with diverse manufacturing workflows, offering flexibility for sub-assembly, kitting and final inspection processes. This approach not only supports standalone cleaning requirement but also enhances supply chain efficiency by consolidating quality assurance protocols within a single controlled environment.

Automotive

William Hughes is one of the UK’s and Europe’s leading manufacturers for wire form fabrication and sub-assemblies for the Automotive sector, with facilities in the UK, Poland and Bulgaria.

In automotive manufacturing, every component, no matter how small, is a critical link between design intent and road-ready performance and has a direct impact on safety, comfort and helps to maintain long-term reliability of the vehicle across its full-service life.

The introduction of electric vehicles (EVs), lightweight materials and advanced driver assistance systems has increased the demand for dimensional accuracy, controlled material properties and contamination-free assembly. William Hughes supports Tier 1 and OEM automotive manufacturers with industry-specific expertise that combines wire form and spring design, CNC manufacture, ultrasonic cleaning and tailored kitting to ensure that components arrive at line-side ready for immediate installation.

Meeting the Challenges of the Automotive Supply Chain

We set ourselves apart as a leading manufacturer of wire form assemblies for automotive manufacture, with the knowledge and expertise of our engineering technicians. In the shift from Internal Combustion Engines (ICE) to Electric Vehicle (EV) manufacture, we help resolve design and manufacturing challenges that lead to component failure, high waste or excessive production costs. Our facilities offer advanced automation, precision testing and design validation tools to deliver production-ready solutions from first-off prototypes to full-scale line-side integration.

Fine Wire

We offer a comprehensive range of fine wires. We have been stockists of Webster & Horsfall for over 50 years and can supply 1800 different wire types in various weights and finishes packaged to suit your particular requirements.

Our non-ferrous wire from Little Falls Alloys includes Beryllium Copper, Phosphor Bronze, Nickel Grade, Cupro Nickel, Copper, Nickel Silver, Brass, Zirconium Copper, Cadmium and Chromium-Copper in round, square, flat and shaped formats, coiled, on spools and in straight lengths.

For applications demanding high fatigue properties we also stock Suzuki-Garphyttan stainless steel wire.

William Hughes Poland | High-Volume Wire Forming

One of Europe’s Leaders in Automotive Component Manufacturing

William Hughes Poland specialises in high-volume, welded and formed metal components, and is strategically located to serve major automotive OEMs and Tier 1 suppliers across Central and Eastern Europe. The facility has grown from the foundations of Nosag Polska, a specialist in welded seat structures and complex wire assemblies, acquired by William Hughes in 2017. With decades of specialist knowledge, the Polish site supports William Hughes’ wider manufacturing operations, supporting large-scale production with full quality traceability, consistent throughput, and automotive sector compliance.

High-Volume Welding, Assembly and Wire Forming

Our Polish site specialises in the high-volume manufacture of welded wire assemblies, including automotive seating structures, seat mats and torsion bars for applications, including electric vehicle (EV) and ICE assembly. As OEMs transition towards lightweight and modular EV design, our capabilities allow for the efficient manufacture of wire-based structural supports, battery compartment reinforcements and vibration-dampening spring assemblies.

Cataphoretic Paint Line (KTL)

William Hughes Bulgaria | Overmoulded Wire Assemblies

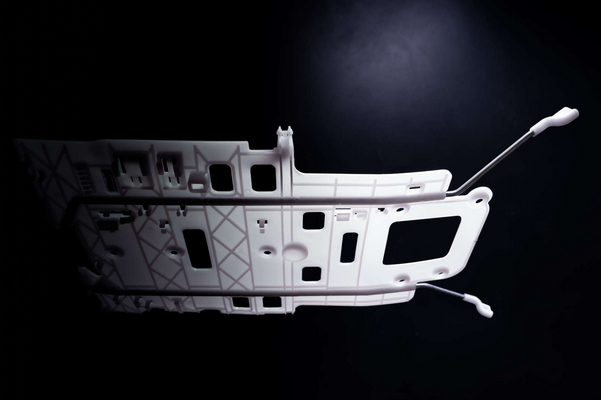

William Hughes Bulgaria supports a purpose-built 7000 square metre factory near Plovdiv which opened for business in 2004 as a centre for high volume production in a mainland Europe location.

In the beginning, the Bulgarian factory was simply involved with wire bending but as demand for its services has grown, so new machinery and processes have been installed. Massive changes inside the factory now include 35 CNC wire bending machines, seven vertical and two horizontal injection moulding machines and two nylon plastic coating lines along with MAG, MIG and spot welding. There are seven robotic welding cells complemented by an Electrophoretic black paint line and Deltatone Finishing.

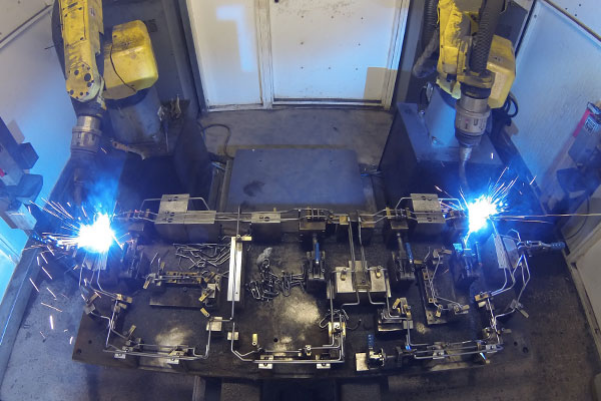

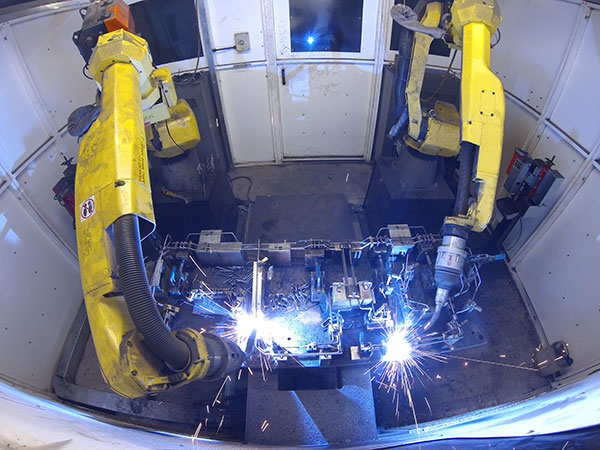

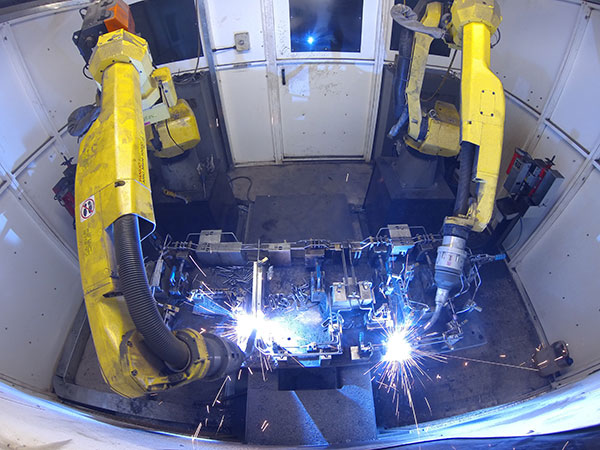

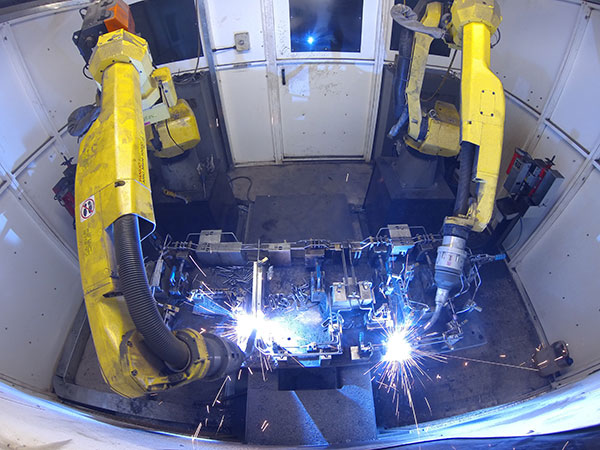

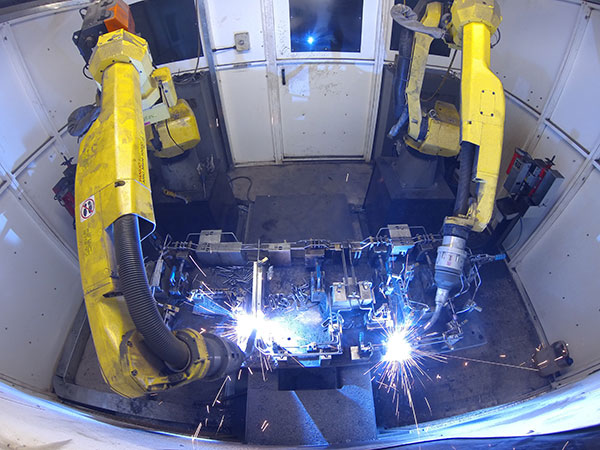

Automation & Engineering Development

We invest significantly in simulation, prototyping and production validation, including finite element analysis (FEA), tolerance stack-up assessment and rapid prototyping using soft tooling or modified jigs. The Stalbridge site features robotic welding machines including 6-axis welding cobots for the repeatable and highly consistent production of complex welded assemblies. These systems are ideal for precision welds, bracket assemblies and other load-bearing components where micro-level consistency in joint strength is essential. Our on-site engineer teams are always available to support customers with:

• Yield improvement and tolerance reduction initiatives

• Prototype-to-production transitions with low-risk scaling

• Design for Manufacture (DfM) and reverse engineering services

This investment in automated welding solutions allows us to guarantee both quality and efficiency, particularly for customers under pressure to meet stringent automotive tolerances and validation criteria.

Secondary Processes in Wire & Spring Assemblies

At William Hughes, we offer a wide range of secondary operations and finishes that enhance the performance, longevity, and appearance of springs and wire components. As specialists in surface treatments across the UK and Europe, we carry out all finishing processes in tightly controlled, quality-assured environments, supported by ISO 9001 and IATF 16949 standards. Every finish is selected to suit the application, load requirements, and customer specifications, ensuring durability, functionality, and regulatory compliance.

Our capabilities include advanced technologies such as Fanuc robotics and a fully automated electrophoretic painting line. We provide finishes and processes including KTL Black, plastic coating, threading, pointing, nibbing, clip fitting, Delta®-Tone and Delta®-Seal coatings, steel and glass shot peening, injection overmoulding, and multiple welding methods. By managing all finishing processes in-house, we maintain quality control, shorten lead times, and deliver consistent results. These services support the demanding requirements of aerospace, medical, and advanced industrial applications.

UK Piano String Manufacturer | William Hughes Since 1790

A Heritage of Precision and Performance

William Hughes has been manufacturing piano strings for over two centuries, a legacy that reinforces the depth of our expertise in wire technology.

We continue to supply specialist string wire to instrument manufacturers and restorers who value not only the quality of the product but have the option to partner with a UK-based piano string manufacturer with expertise in the understanding of material, timbre and tone.

About us

With factories in Stalbridge, Dorset and Plovdiv, Bulgaria, each benefitting from a multi-million pound investment in plant and machinery together with the recent acquisition of Nosag Polska in Poland, William Hughes combines modern technology with traditional skills to bring products to market in the most refined, cost-effective and timely way possible.

These products comprise a broad range of compression, tension and torsion springs, wire forming including simple and complex 2D and 3D wire forms, printed circuit test points and terminals, and specialist wire sales.

Throughout the past two centuries, the success of William Hughes has been based on the traditional virtues of a family firm - commitment to its customers, concern for quality and service - allied to continual improvements in production and technology to meet the precise specification of each individual requirement in the most appropriate way.

The resources provided by William Hughes are amongst the most extensive and sophisticated in Europe, with the capability of fulfilling orders, however large or small, with equal facility, and an established administration and distribution function that ensures continuity of supply, rapid delivery and competitive prices on every single item.

The variety of springs and wire forms available is almost infinite in a choice of metals which is nearly as wide including stainless steel, brass phosphor bronze, beryllium copper and nickel-chrome alloys.

PROTOTYPING

William Hughes has many years of design and manufacturing experience and can offer its customers a rapid design and prototyping service in a range of materials. This service is particularly suited to the aerospace and automotive industries where small quantities are required for test and evaluation with the capability to move to volume production once a final design is agreed.

SUB-ASSEMBLIES

Through the 90’s the company expanded to includes the manufacture of sub-assemblies. These sub-assemblies are still based on wire but techniques have been developed such as welding, punching, pointing, chamfering, nibbing, threading, clipping and many more that add value to the product for our customer. Through the next decade we expanded our range of in-house surface treatments to include shot peening, ultra-sonic cleaning, KTL black coating, painting, Delta-Tone™ and nylon coating.

OUR EUROPEAN OPERATION

In 2004, William Hughes set up a purpose-built factory near Plovdiv in Bulgaria, the better to compete in an increasingly cost-conscious market and also to facilitate speedy delivery into its many customers in mainland Europe. Today our Plovdiv factory has twice doubled in size and is currently around 7,000 square metres.

Our work force has more than trebled to 200 skilled employees even allowing for the fact that we have added automation-handling robots for secondary processes and collaborative robots for packing and repetitive tasks.

The Plovdiv factory now houses 35 CNC wire bending machines along with 9 injection moulding machines, both vertical and horizontal, for over-moulding projects utilising rotary and fixed platens along with MAG, MIG and Spot welding.

There are also seven robotic welding cells complemented by an Electrophoretic black paint line and Deltatone Finishing.

UK EXPANSION

Further expansion took place in 2008 with the acquisition of the springs and wire form business of Baumann Springs and Pressings (UK) Ltd.

NOSAG POLSKA

Nosag Polska, previously part of the DEFTA Group, was acquired by William Hughes in the autumn of 2017.

Based in Tychy in southern Poland, Nosag Polska is a major manufacturer of seat mats, wire frames and bent wire parts, predominantly for the automotive industry. This makes the Company a perfect fit for William Hughes with our complementary manufacturing facilities in Dorset and Bulgaria but providing us with a manufacturing hub with easy access to mainland Europe and the Baltic States.

Nosag is a leading supplier to all the major car interior and car seat manufacturers in Europe. The Company enjoys a reputation for service and quality similar to our own which has led to a smooth transition of ownership and opportunities for both operations to benefit from the experience and expertise of the other.

PRECISION SPRINGS FOR THE AEROSPACE INDUSTRY

William Hughes specialises in the manufacture of precision, high specification springs and its modern manufacturing facilities, together with state of the art spring measurement systems, are ideally matched to the exacting requirements of the aerospace industry.

Springs manufactured by William Hughes are used in vital items of aerospace equipment including oxygen systems, access hatches and the solenoid valves used to control the hydraulic and cabin pressure systems.

William Hughes is an approved supplier to many leading companies in the aerospace industry and is an audited and approved supplier to Honeywell. Other customers include BAE, Eaton Aerospace, Lockheed Martin, Meggit and M.E.L. Aviation.

To meet the specifications for high temperature performance, many springs for the aerospace industry are manufactured in exotic materials such as Nimonic, Inconel and Ni-span. These expensive materials are more difficult to work than conventional materials and William Hughes has the machinery and expertise to use these materials with high accuracy and minimum wastage.

For critical applications it is essential that any lubricants and debris from the manufacturing process are removed from the spring before it is despatched to the customer and William Hughes offers an ultrasonic cleaning process to meet aerospace standards for cleanliness.

William Hughes Ltd is Nadcap accredited for heat treatment, room temperature tensile testing (materials testing laboratory) and chemical processing.

QUALITY ASSURANCE

Our aim at William Hughes is to meet and exceed the expectations of our customers in every way adhering to principles of continuous improvement and zero defect. Quality systems to ISO 9001:2000, ISO/TS 16949:2002 the latest automotive standard and AS9100 for aerospace ensure consistency and accuracy of supply.

A SECURE FUTURE

Each year the company invests in new plant and equipment to the tune of 10-15% of turnover with the medium and long term strategy of positioning itself as a volume supplier of quality products to demanding customers for generations to come.

Images

Videos

Articles / Press Releases

Brochures

Trade Associations