Company details for:

Aerocomponents Ltd

Unit 3B, Headley Park 10,

Headley Road East,

Woodley,

Reading,

Berkshire,

RG5 4SW,

United Kingdom

Quick Links:

Products / Services

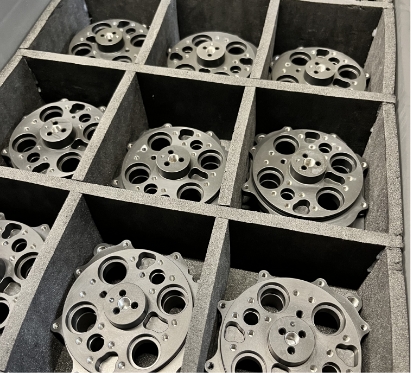

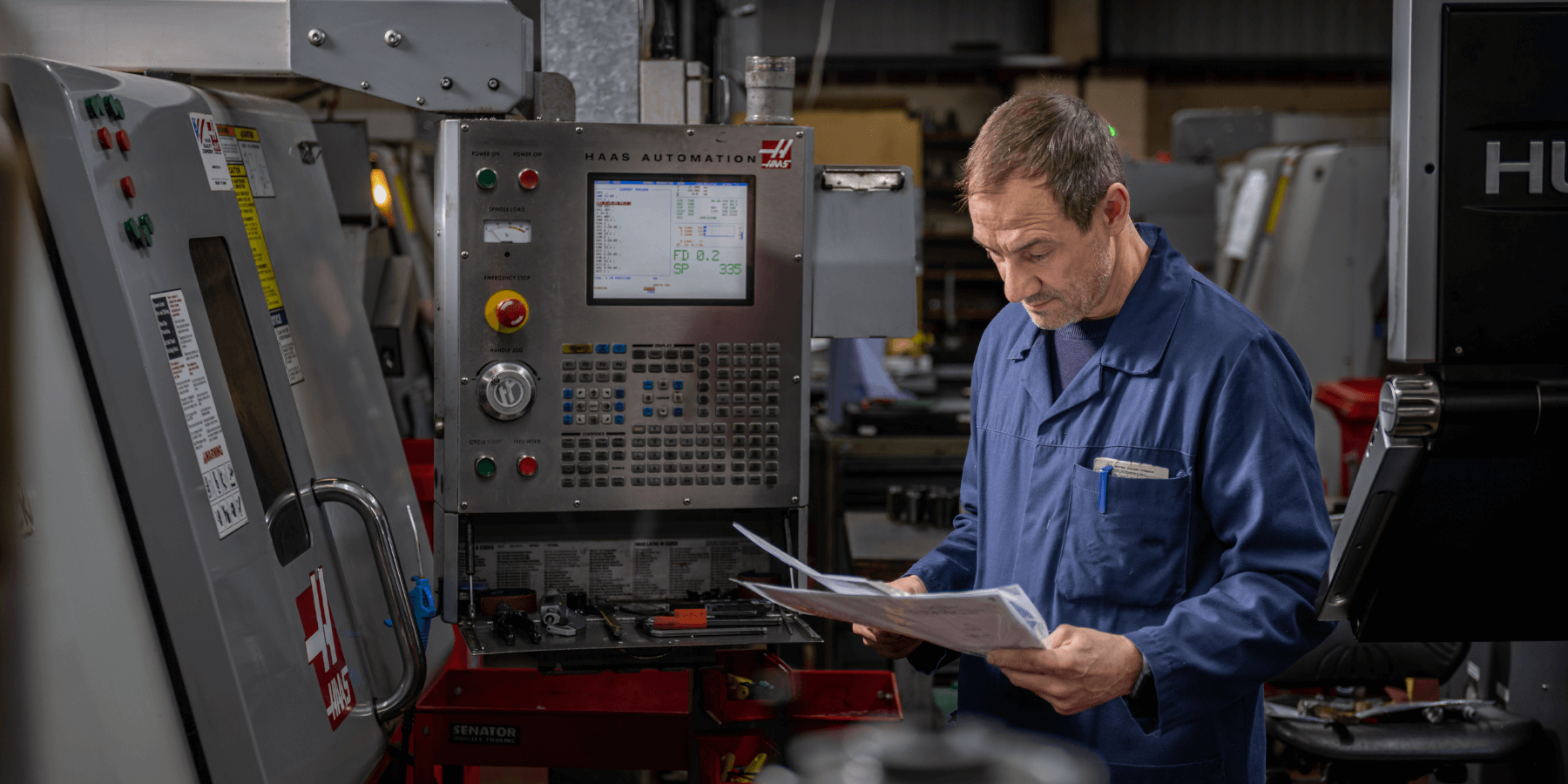

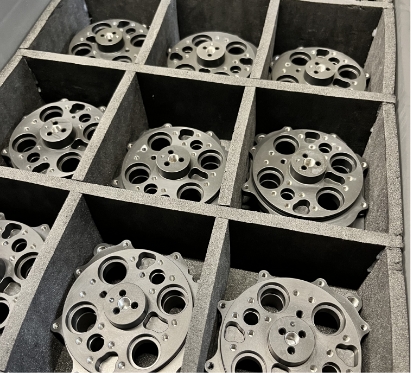

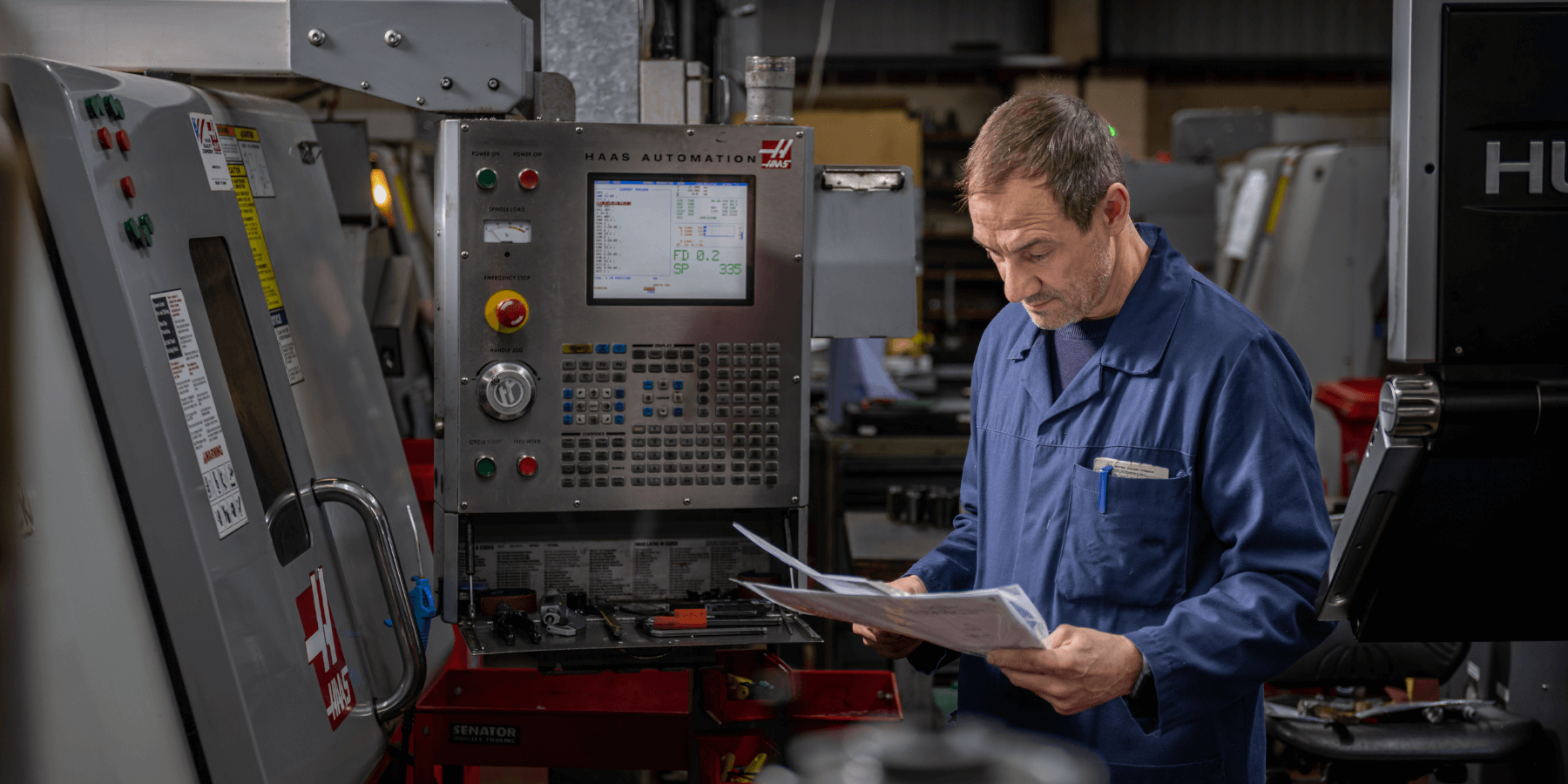

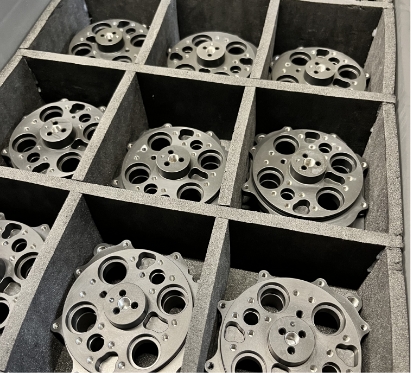

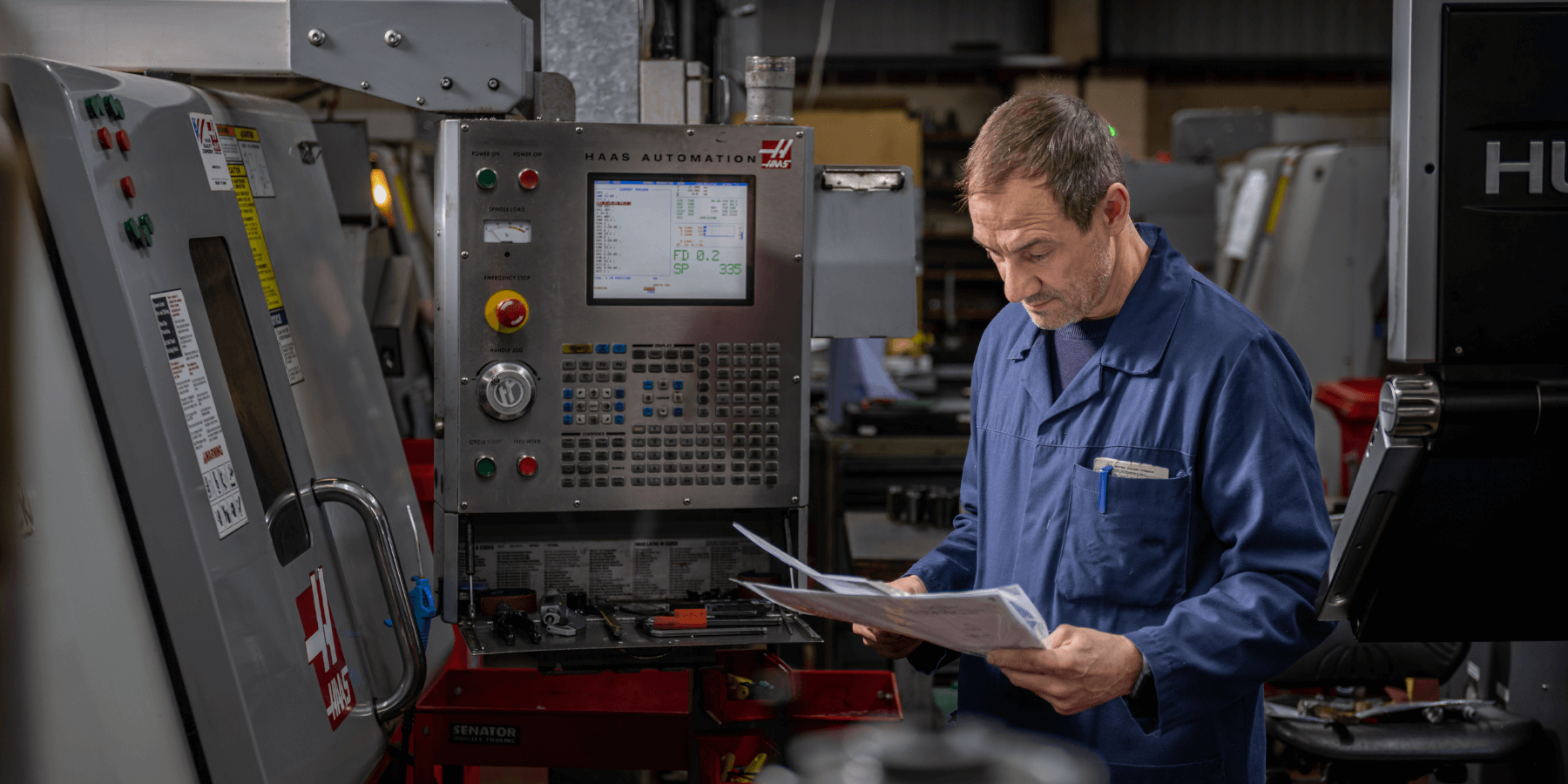

CNC Turning

Our CNC turning service delivers precision, high-volume components with consistent quality, efficiency, and cost-effective solutions across a wide range of products.

Based at our Reading facility in the UK, we operate 10 CNC turning centres, providing 1,200 man-hours per week, handling sizes up to 431 x 863 mm, a 254 mm chuck, and bar capacities up to 76 mm. With over 70 years of experience, our skilled engineering team ensures first-class service from start to finish.

CNC turning is a subtractive manufacturing process where bars of material are rotated in a lathe while a cutting tool removes material to achieve the required shape. This method enables fast, high-volume production while maintaining exceptional quality.

CNC Milling

Our CNC milling services produce bespoke, intricate components to the highest standards using advanced Hurco® technology.

Based at our Reading facility in the UK, we run 18 CNC Hurco® VM1 machining centres 24/7, offering 2,160 man-hours of milling capacity per week. With over 70 years of experience, our expert engineering team delivers first-class service from start to finish.

CNC milling is a subtractive process that shapes custom parts by removing material with rotating multi-point cutting tools under computer control. With typically three linear axes, this precise operation is ideal for prototyping and smaller production runs.

4 Axis Milling

We operate three CNC milling centres with 4-axis capability—two vertical and one horizontal—allowing the machining of curved and complex profiles with fewer setups.

4-axis milling adds a rotating axis to a standard 3-axis mill, enabling greater part processing, more detailed engineering, faster production, and higher accuracy—ideal for prototypes and custom components.

Our horizontal Niigata® SPN-50 features twin rotating pallets, spindle speeds of 50–12,000 RPM, helical interpolation, a table probe, tool breakage detection, and automatic tool measurement, making it perfect for high-volume production of small parts.

For vertical milling, we use Hurco® BMC 3017 and Hurco® 30 HT/M machines, which can reach complex surfaces and areas inaccessible on 3-axis machines, including pockets and holes around cylindrical parts, and allow machining on four faces of a component in a single operation.

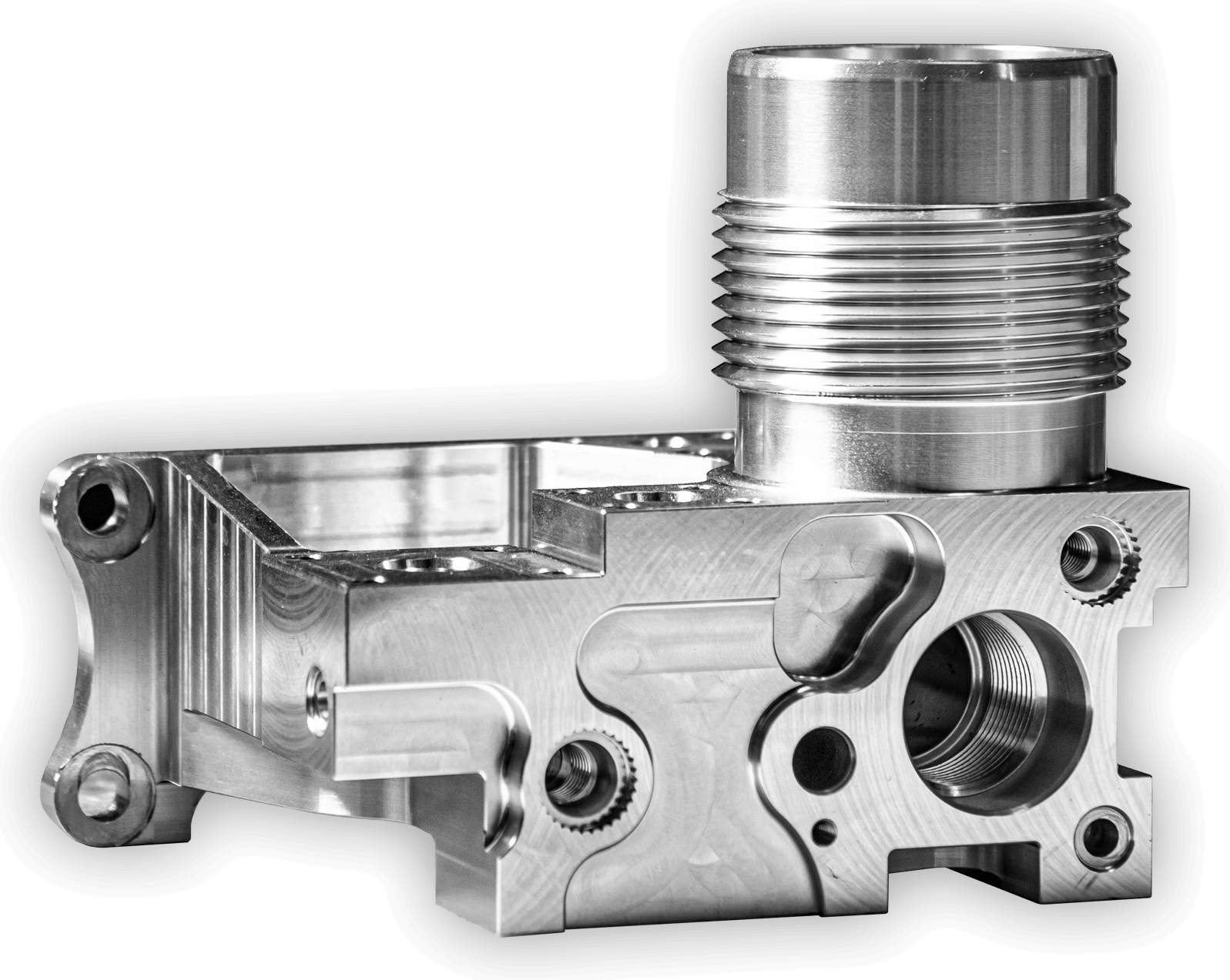

5 Axis Milling

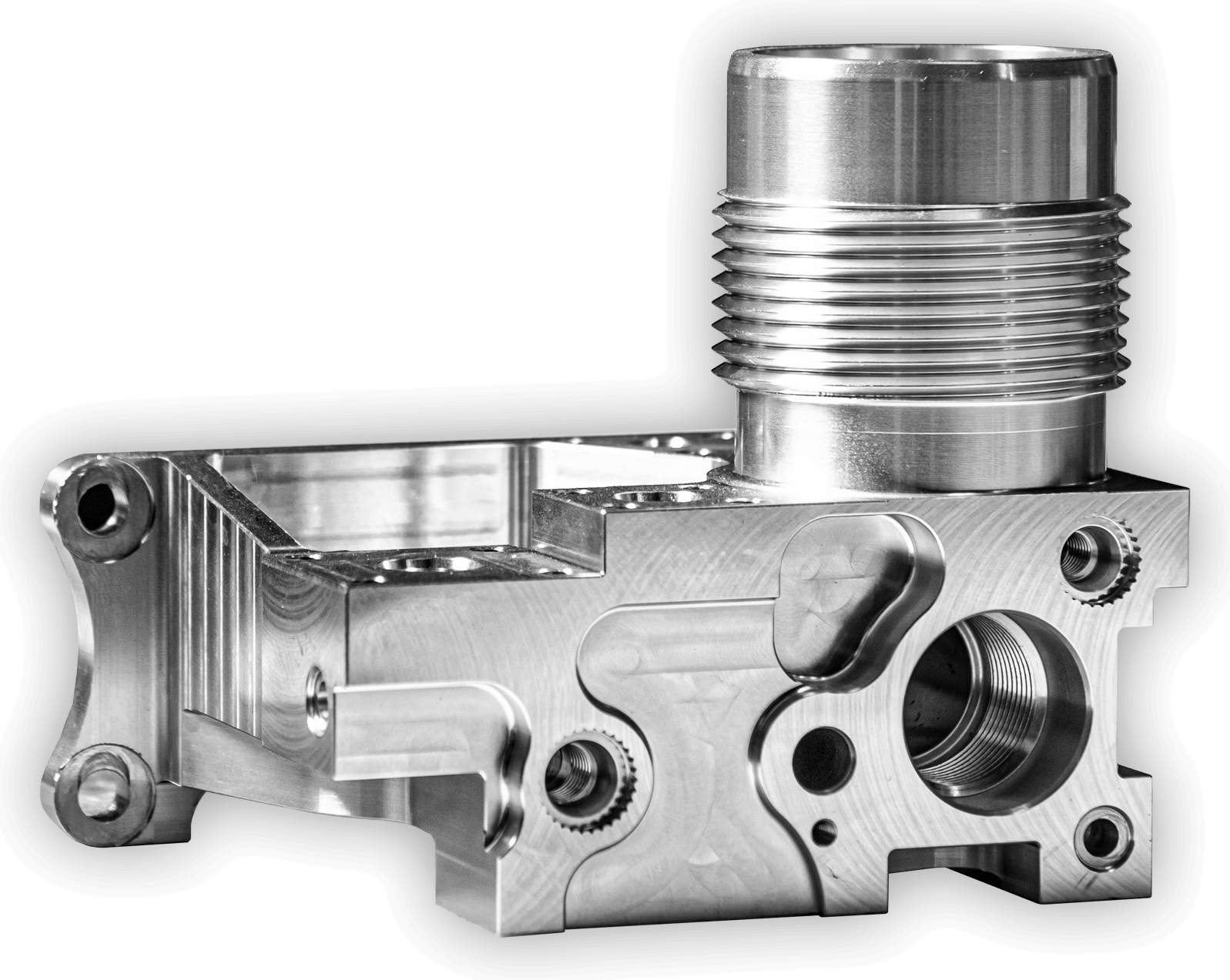

Using Hurco® 5-axis CNC milling centres, we achieve superior consistency, tighter tolerances, continuous surface contouring, fewer setups, and faster material removal, reducing production times for complex, precise components.

5-axis milling enables the creation of highly intricate shapes, with tools moving simultaneously along five axes (X, Y, Z plus A and B), allowing access to five sides of a part without extra setups or turning.

Our expertise in 5-axis milling makes us the choice for aerospace and Formula 1 clients, delivering the highest precision and finish.

We operate 5 Hurco® VMX30U and 2 Hurco® VMX30S 5-axis CNC milling centres, handling the most complex jobs with 762 mm (X), 508 mm (Y), 520 mm (Z) travel, and spindle speeds up to 10,000 RPM.

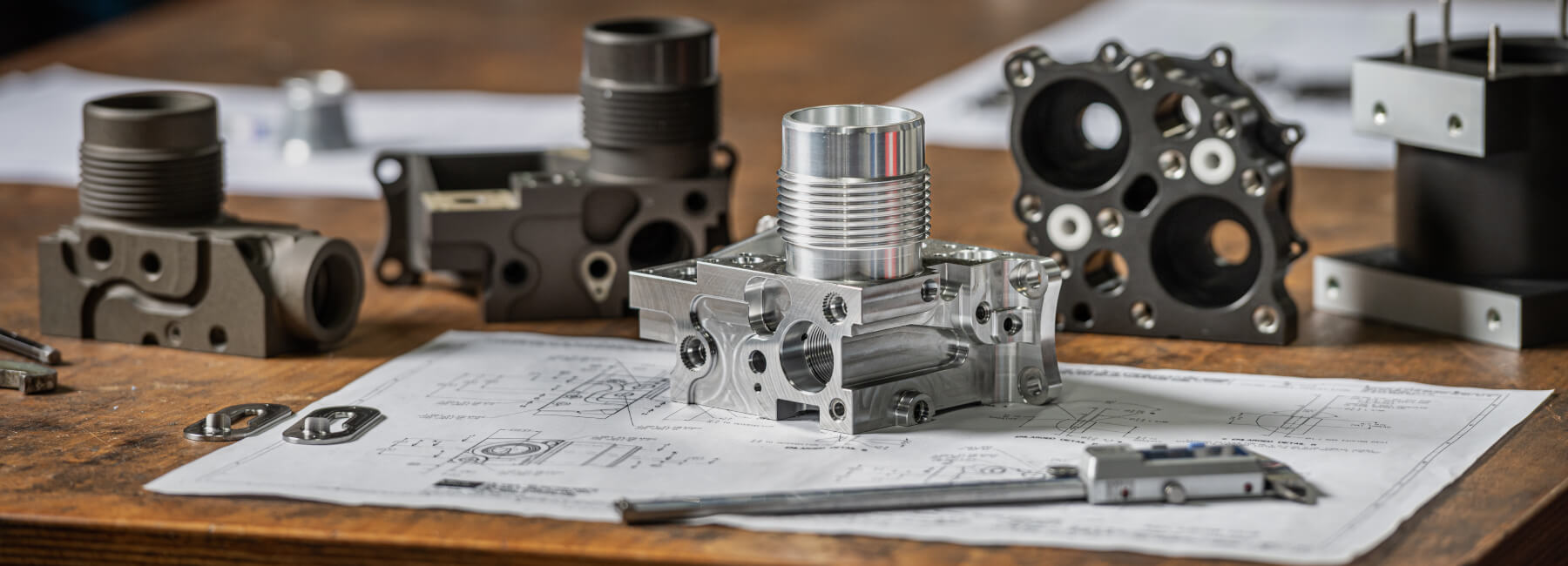

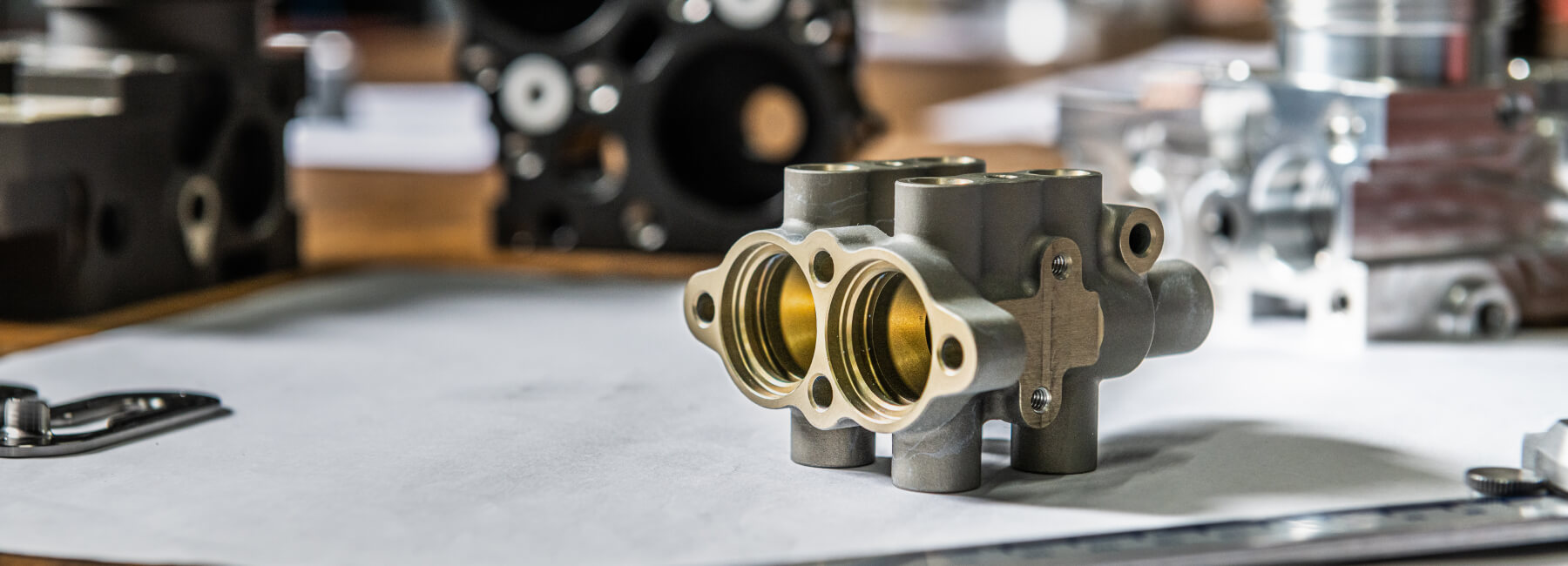

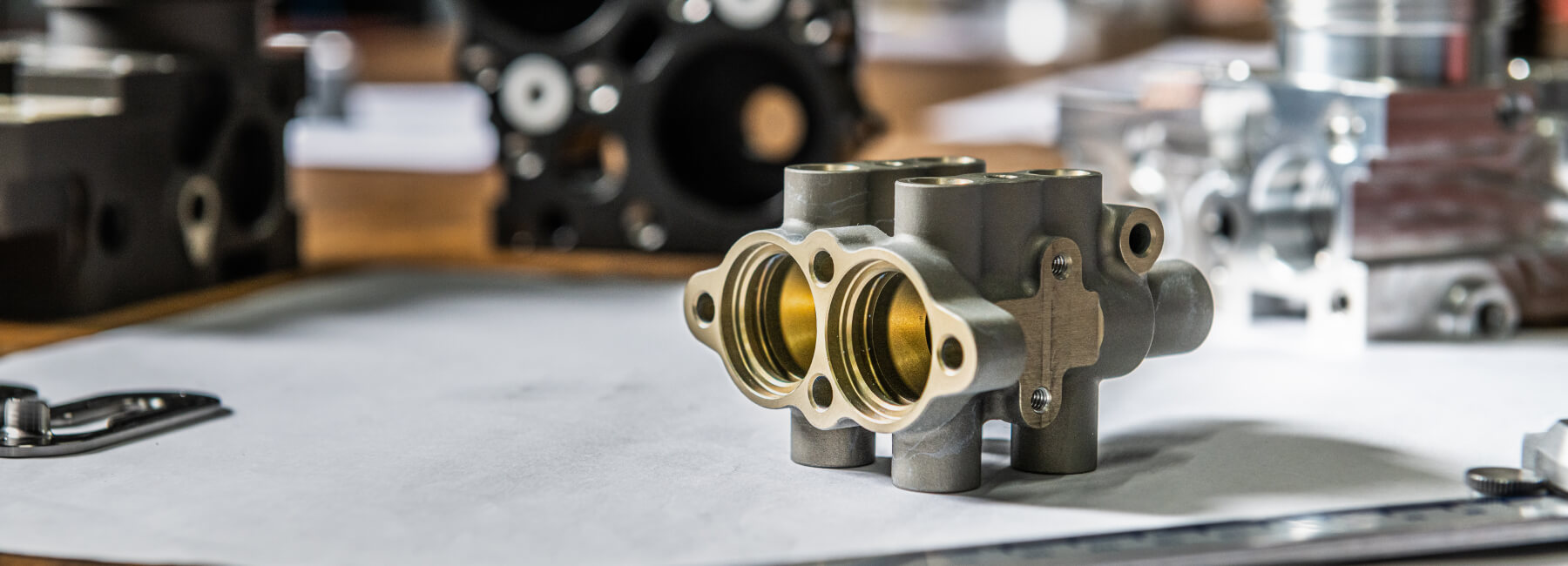

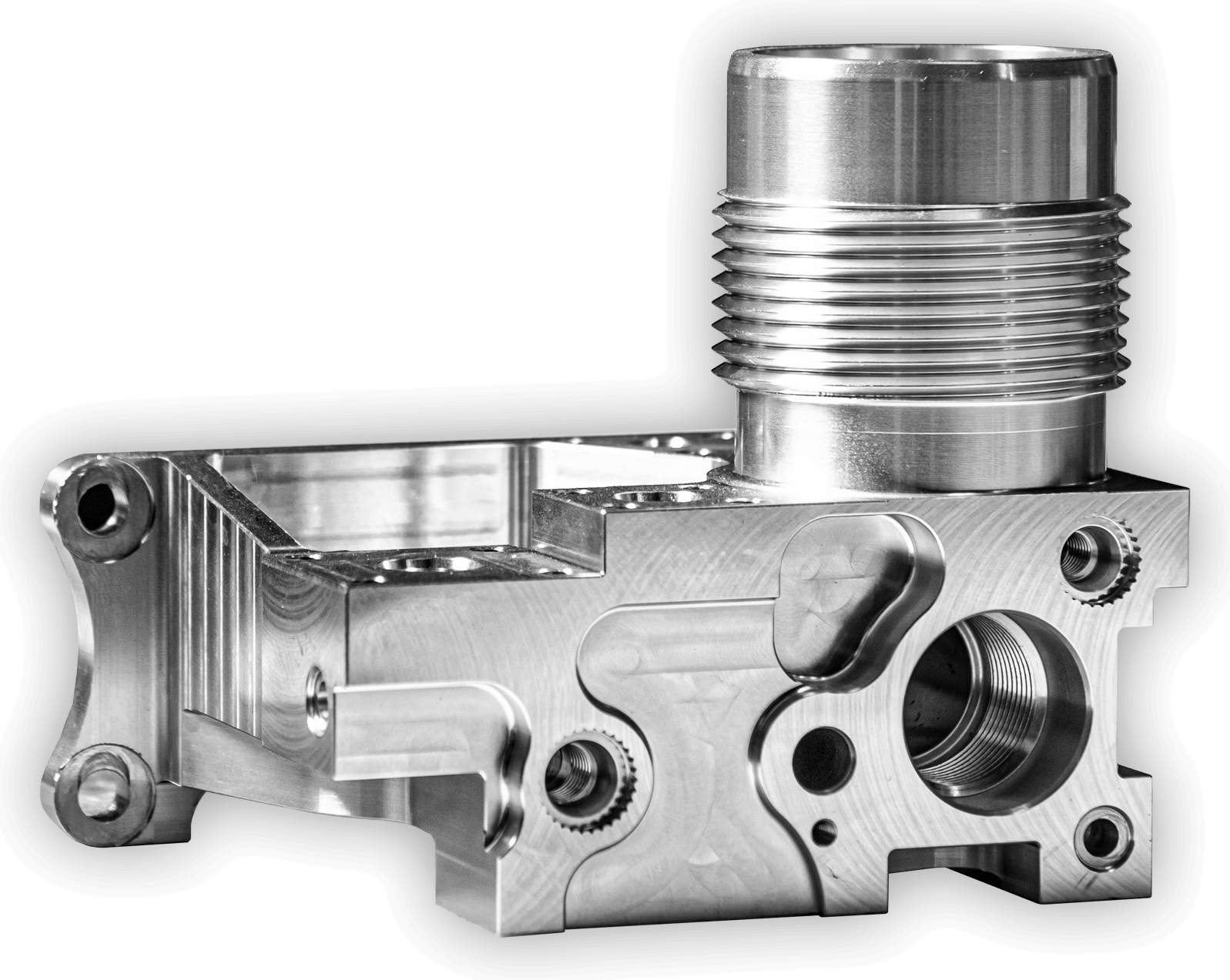

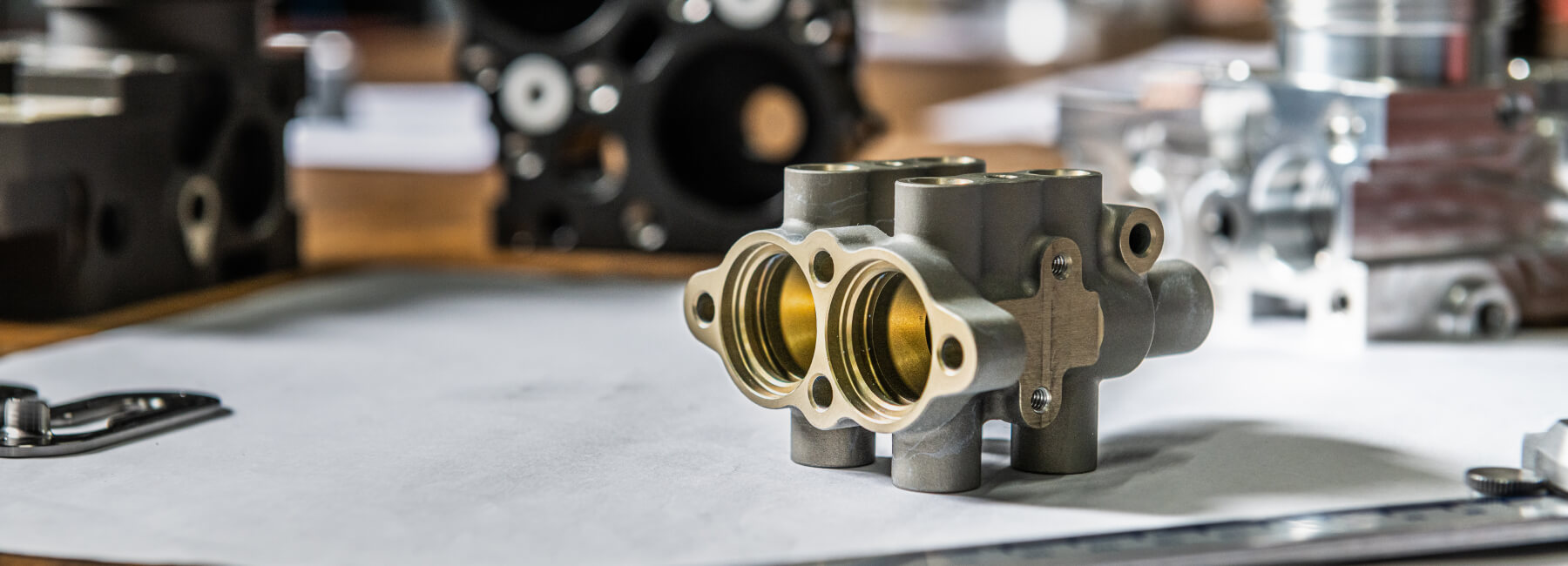

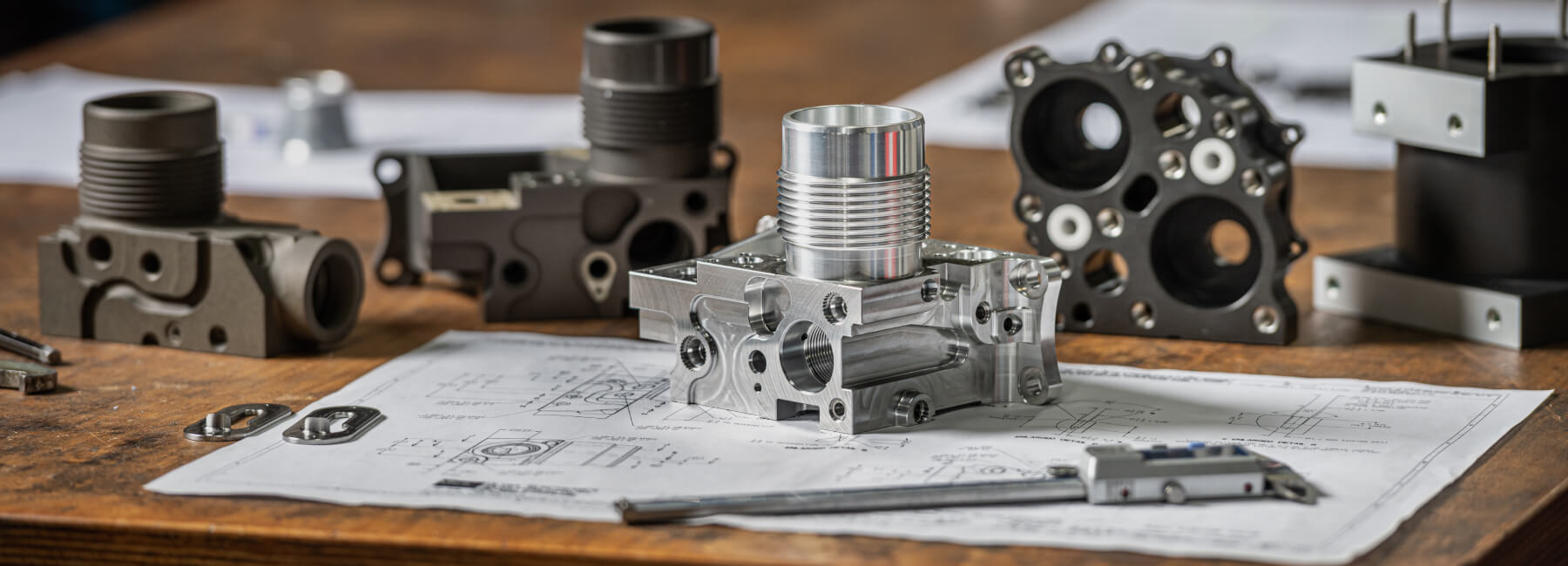

Precision Engineering

We provide a range of specialist precision engineering services, including conventional milling, jig boring, and electrical discharge machining.

Our precision engineering combines advanced techniques and technology to produce components with extremely tight tolerances, often measured in microns or nanometers. The focus is on delivering parts that are not only highly accurate but also reliable and durable.

This level of precision is achieved through technical expertise, cutting-edge equipment, and a thorough understanding of each application’s unique requirements and challenges, supported by our full range of complementary services.

Assembly

We manufacture mechanical and electromechanical components and assemblies to customer specifications.

Using our 3,203 ft² mezzanine area, we allocate skilled manpower across a variety of tasks, including fixtures, soldering, riveting, helicoiling, lead wire cutting, connector assembly, drilling, grinding, tapping, and bench work. For larger contracts, we can also install dedicated manufacturing equipment to create specialized production cells.

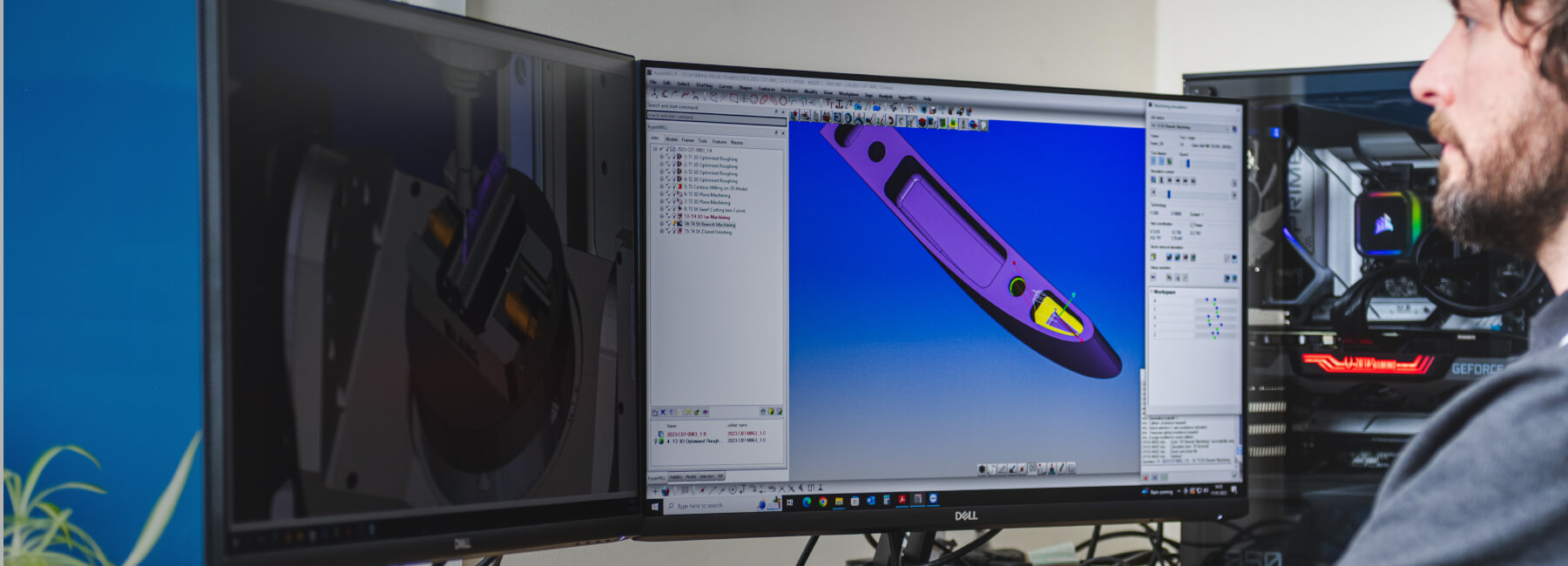

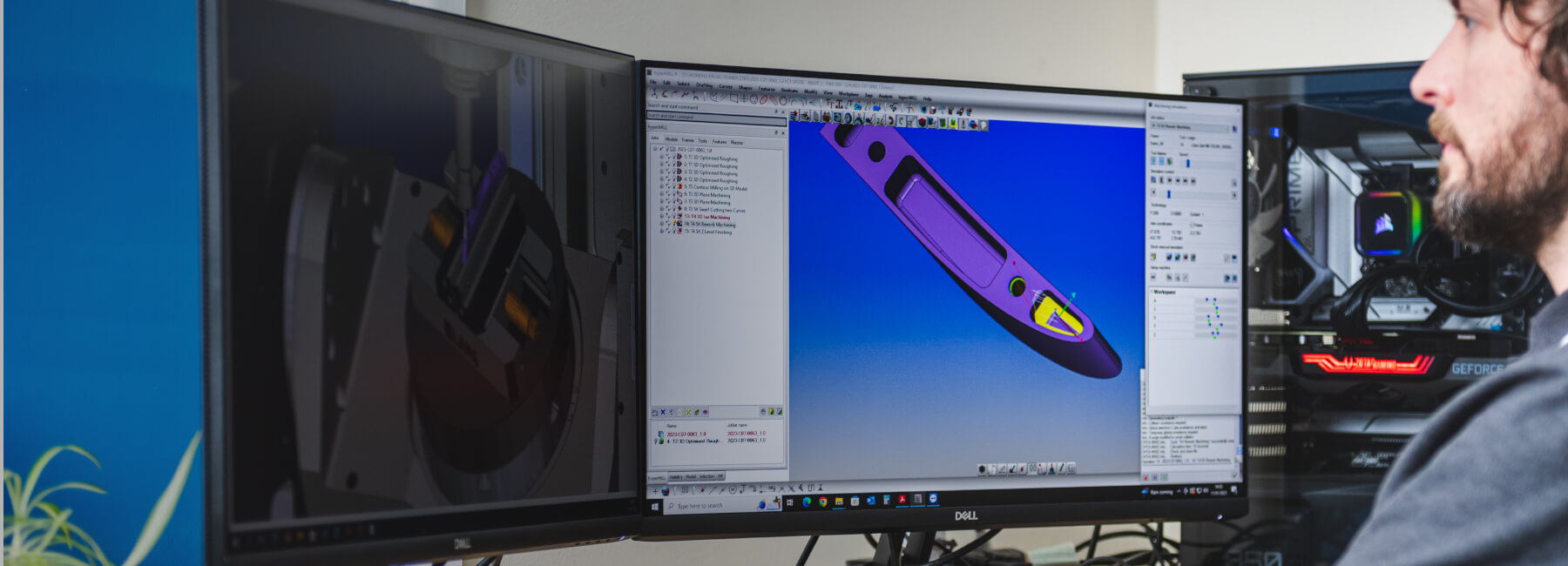

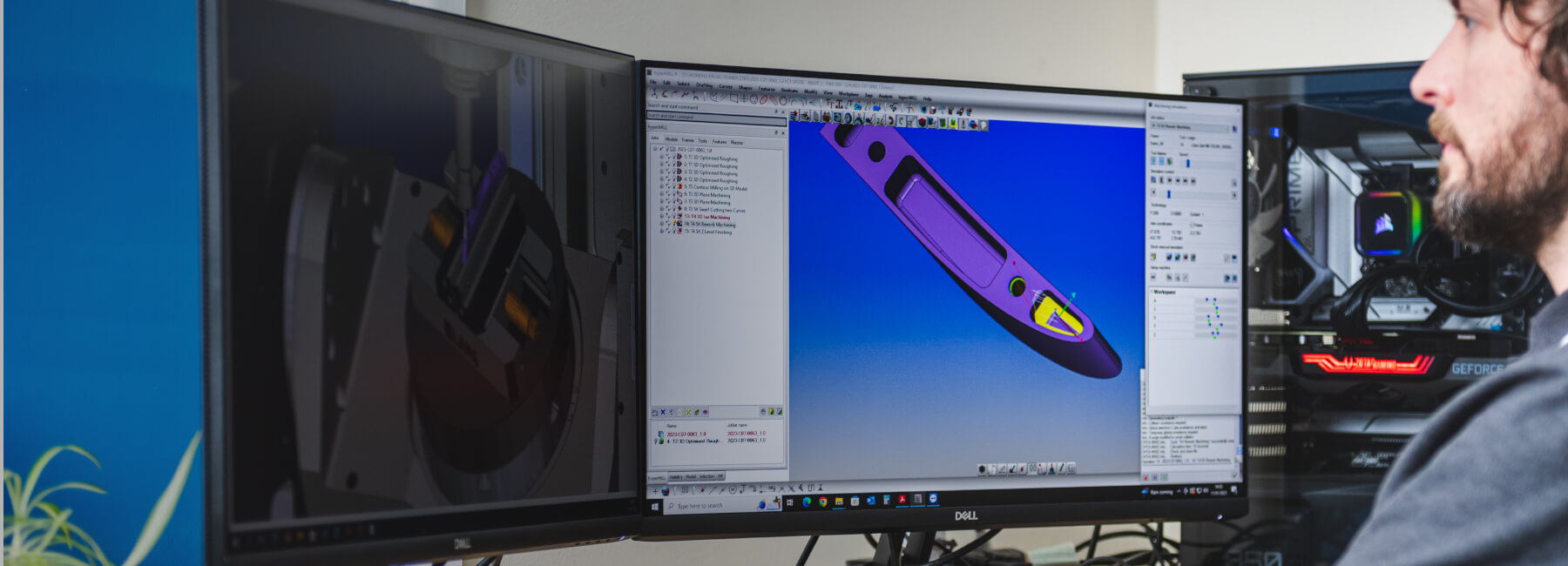

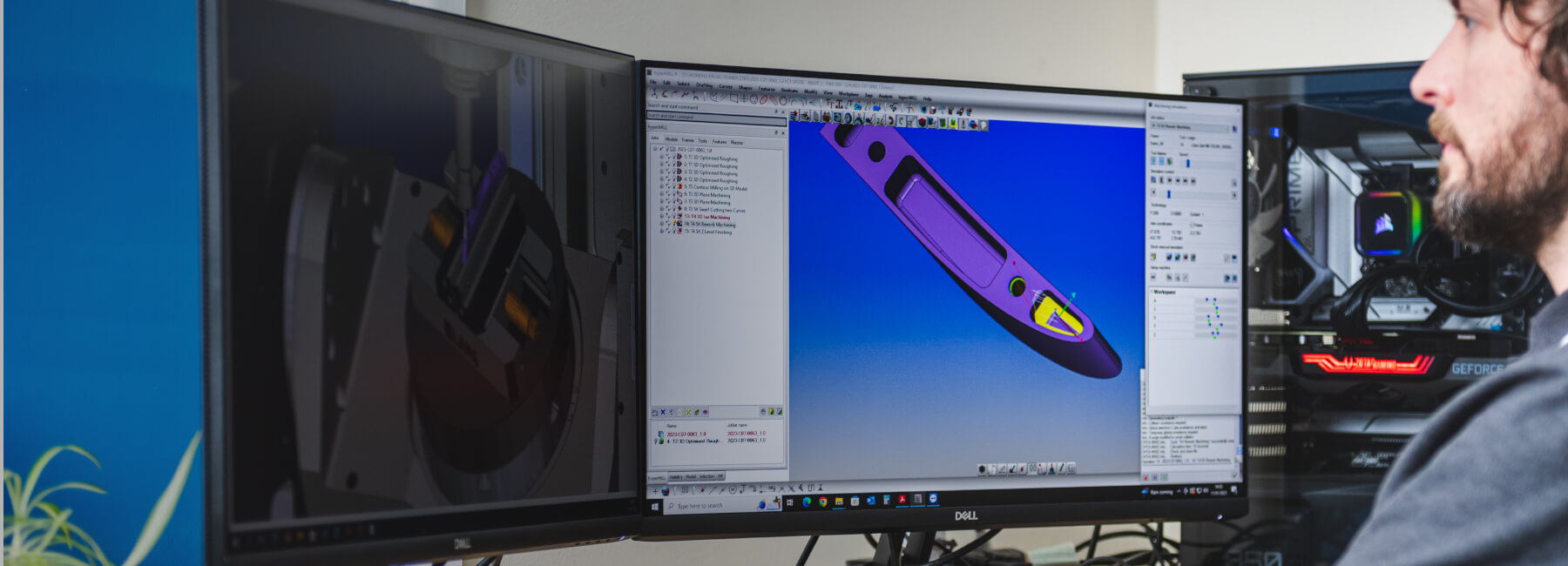

CAD & CAM

Our CAD & CAM services support the design and manufacture of prototypes and finished products, providing reliable scheduling and fast turnaround. Using advanced hyperMILL® Open Mind software, we can produce components ranging from simple to highly complex. Our in-house programmers ensure consistently high-quality, precise designs.

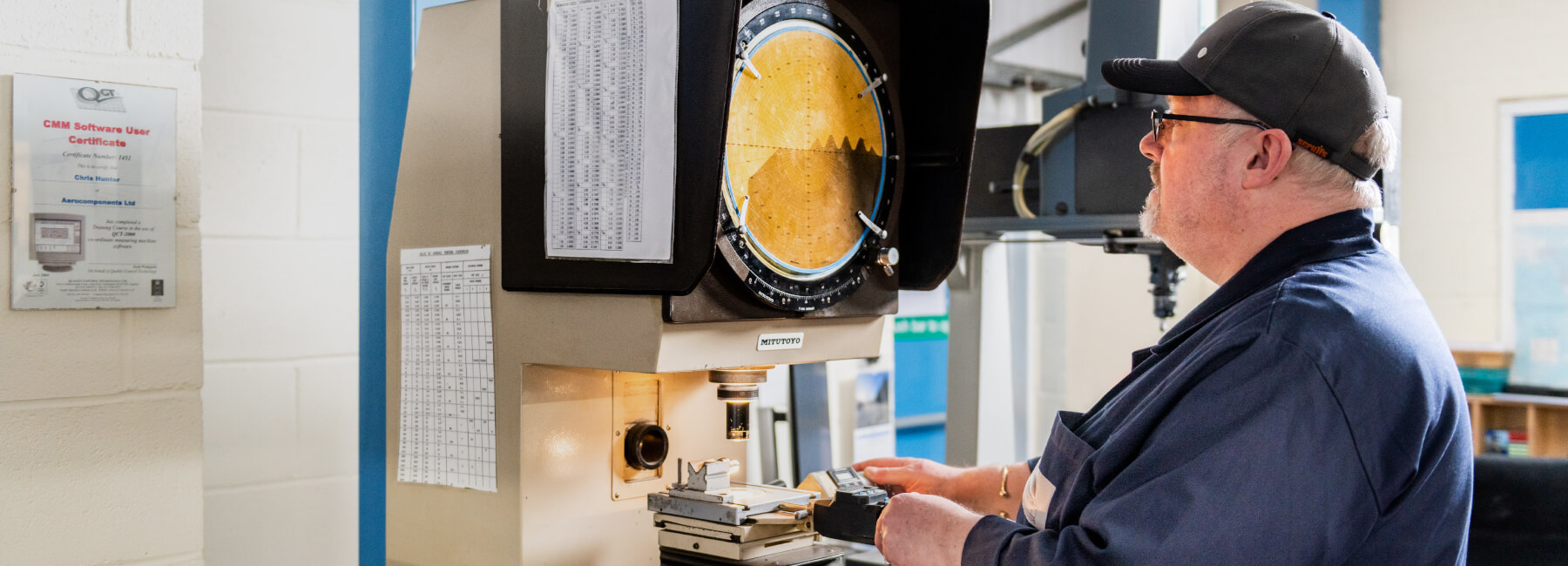

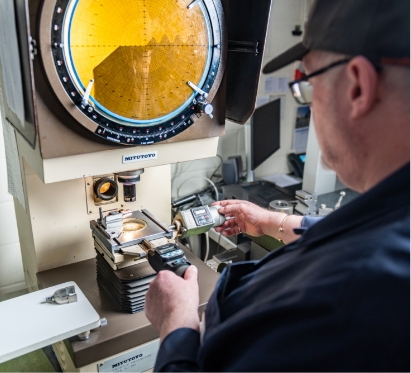

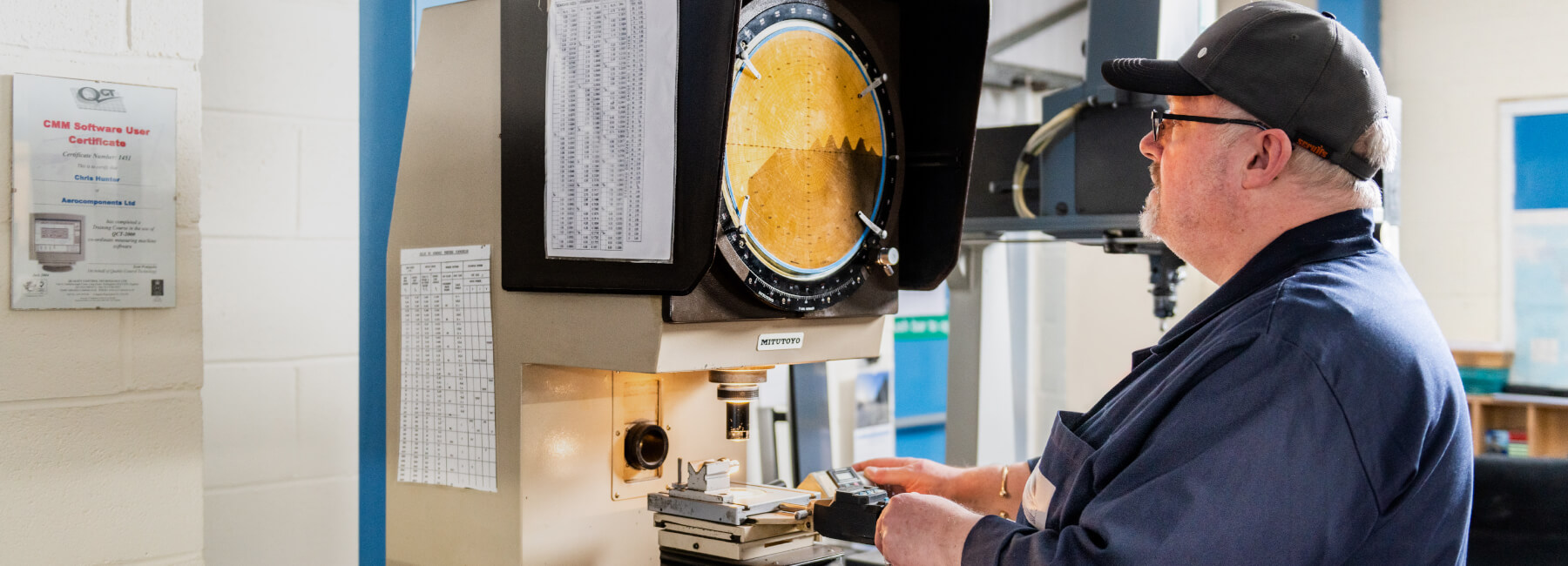

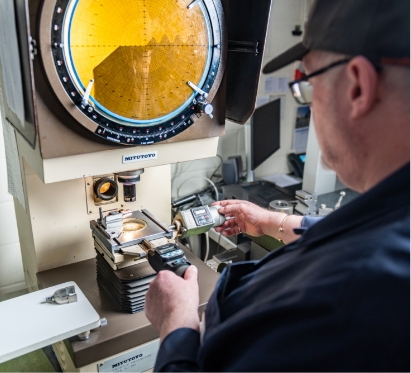

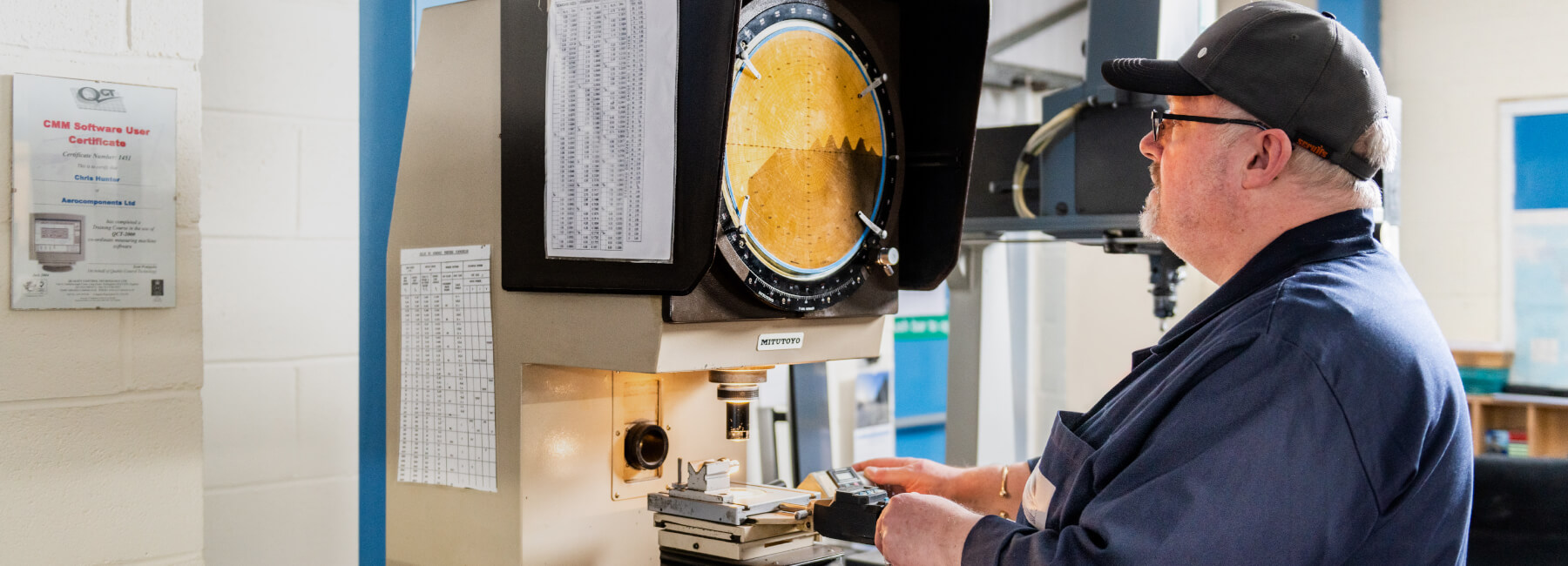

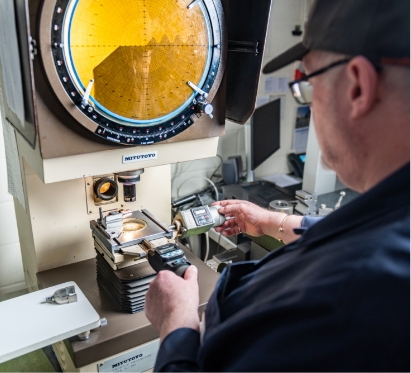

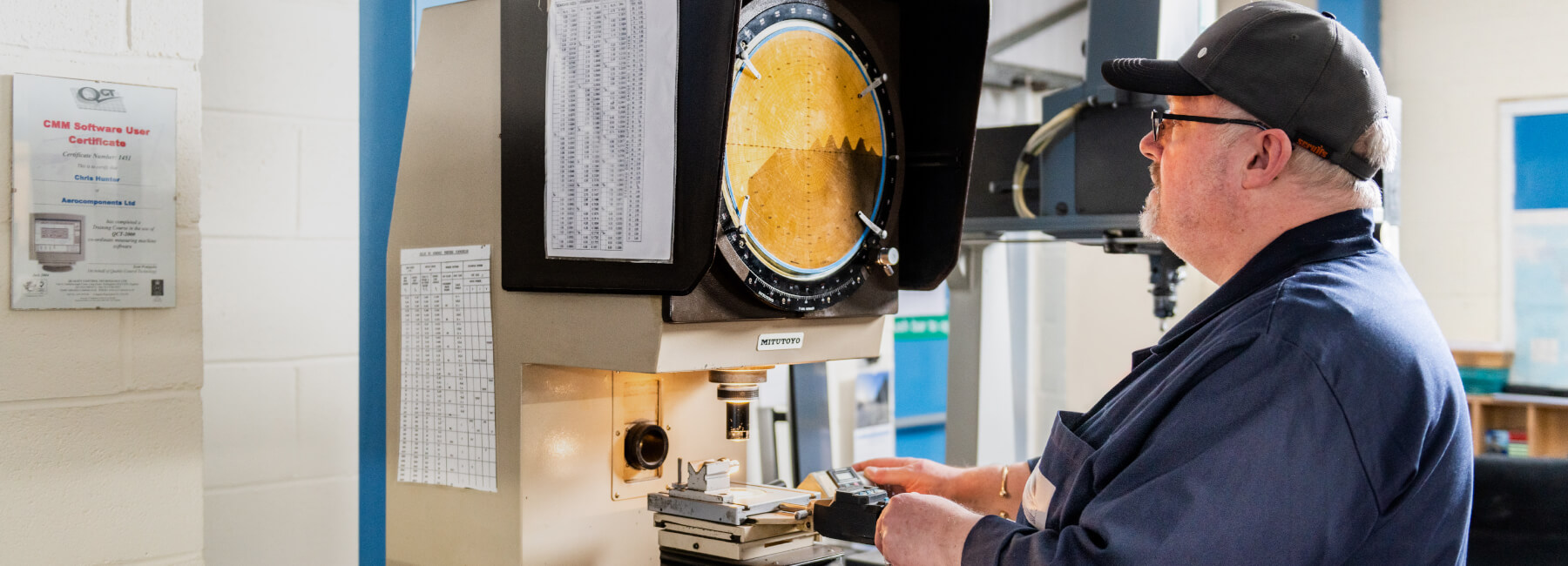

Quality Control

With a long-standing track record in the aerospace and defence sectors, we understand the importance of quality to our customers.

Inspection is a key part of our service. Each machine centre is equipped with online CAD stations and measuring gauges, and we also have a dedicated inspection department staffed by two full-time quality control engineers. This department features CMM equipment, profile projectors, toolmaker’s microscopes, hardness testers, and a full range of gauges and measurement tools.

Most components, depending on the contract, pass through the inspection department, which is integrated with our production management system and CAD/CAM department, where parts are inspected and signed off. We provide full certificates of conformity and batch traceability.

Accreditations

We are certified to AS 9100 Revision D (Aerospace Sector) and EN ISO 9001:2015 quality standards, as accredited by NQA Global Assurance. These standards cover the machining of precision components to customer specifications and the manufacture of mechanical and electromechanical assemblies.

All quality procedures are fully documented, enabling improved business efficiency, greater product and service consistency, enhanced traceability, and overall boosts to staff morale and motivation.

Production Management

We use the full Prodman 9000 suite, a system aligned with ISO 9000 standards.

Prodman is a comprehensive production management solution tailored for small to medium manufacturers and subcontractors with assembly operations. It covers all aspects of business management, including sales and works order processing, stock and inventory control, MRP, route cards, bills of materials, job costing, scheduling, capacity planning, shop floor documentation, and certificates of conformity.

This enables us to manage every stage of production—from quotation and material control to scheduling, manufacturing, delivery, and invoicing—efficiently and accurately.

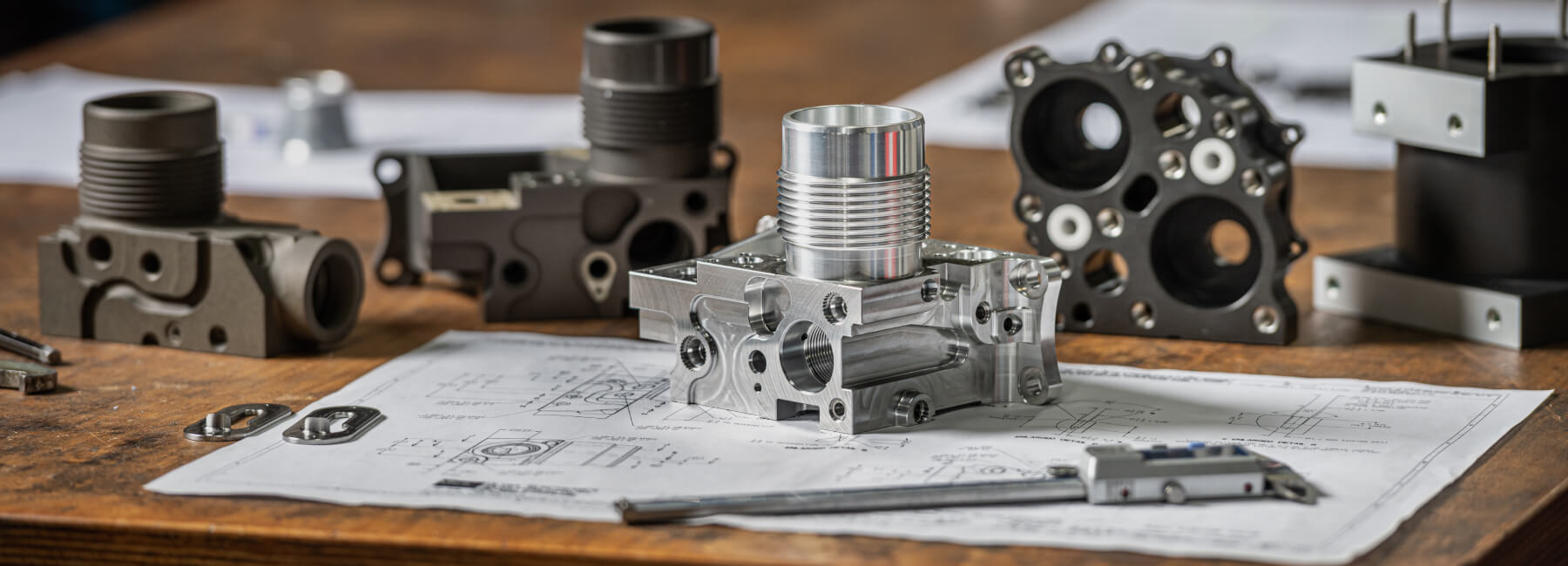

About us

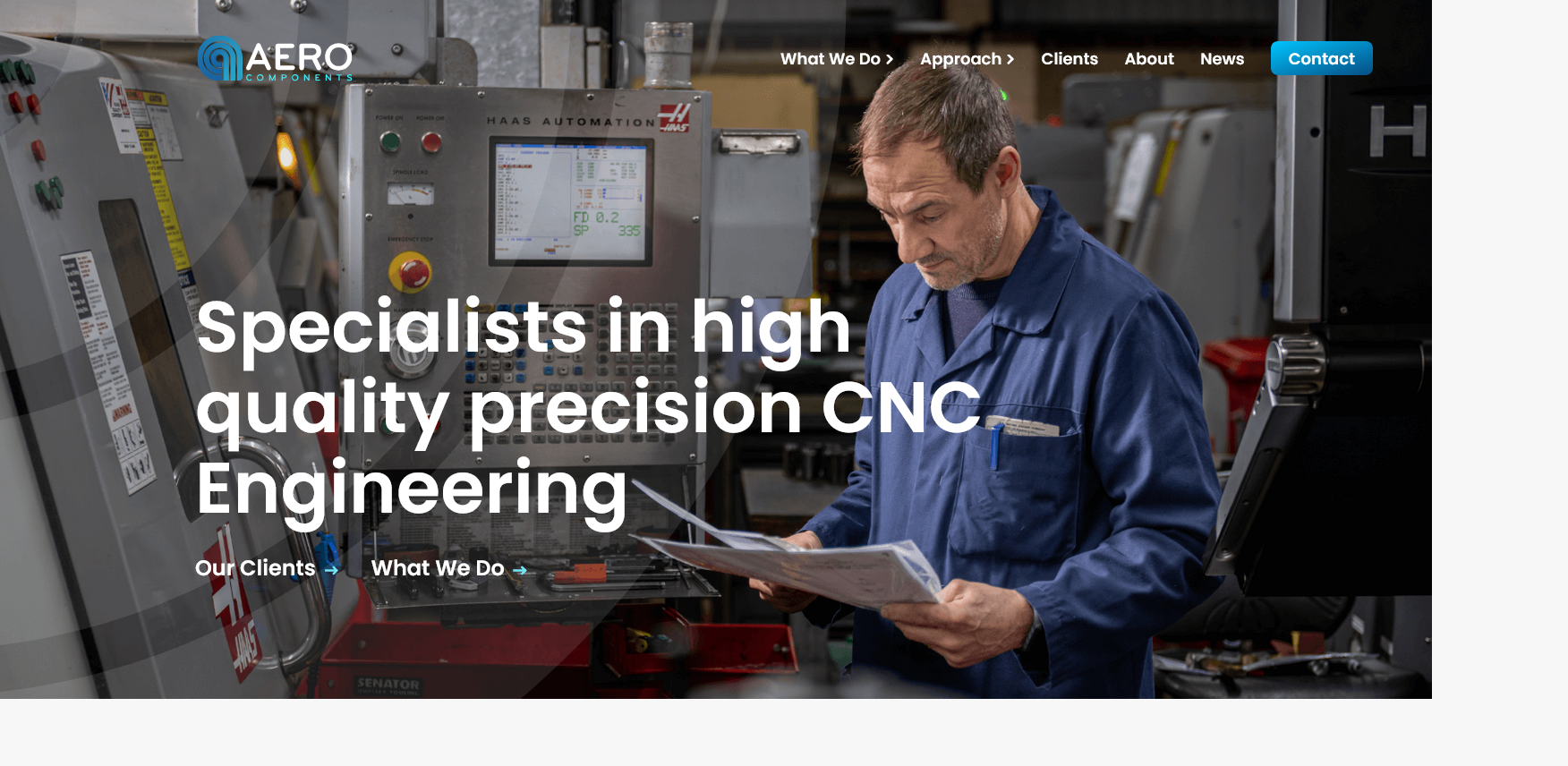

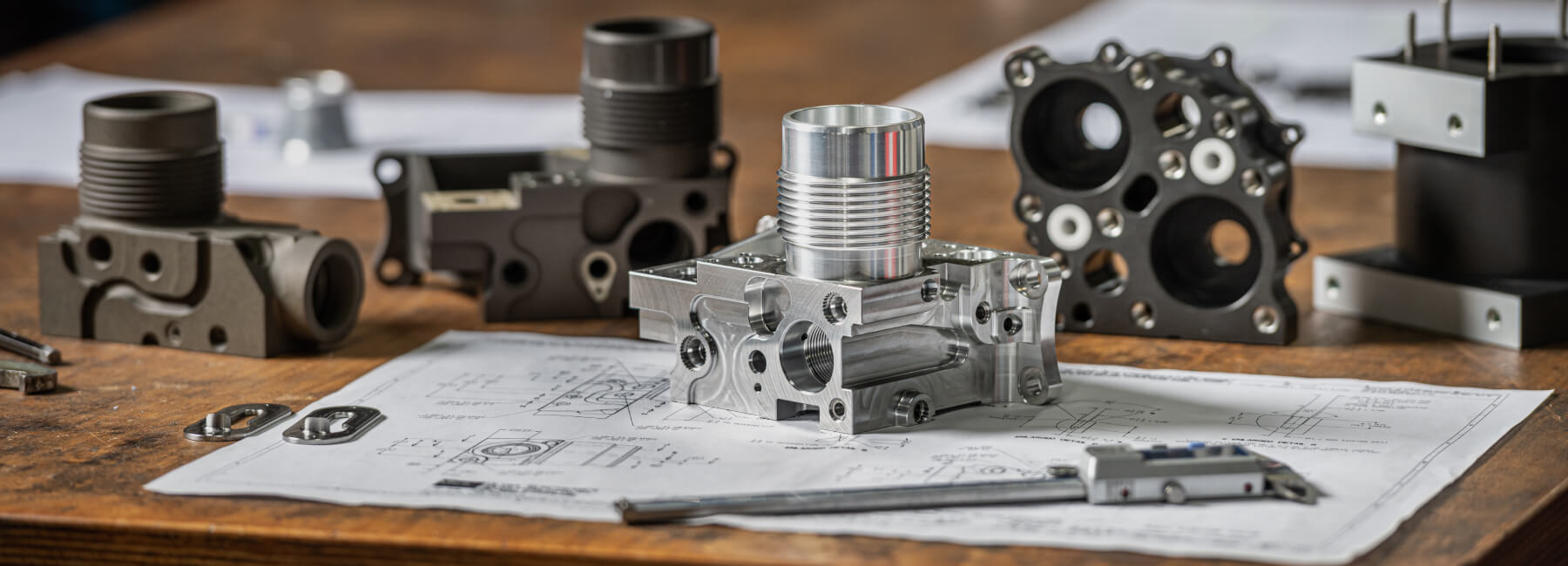

Aerocomponents Ltd designs and manufactures complex, high-specification components using advanced CNC technology and over 70 years of expertise. Our UK-based facilities and expert engineering team deliver exceptional precision and a consistently high-quality finish for every client.

From initial enquiry to final product, we uphold the highest standards using processes refined over 70 years. All our products are quality assured, and our fully documented procedures ensure consistent results and full traceability.

As a key provider in the precision engineering sector serving numerous Tier 1 clients, we take pride in consistently delivering first-class service.

Our Services Include:

CNC Turning

We run 10 CNC turning centres, producing high-volume engineered components with a focus on quality, efficiency, and cost-effective solutions.

CNC Milling

Our CNC milling services produce bespoke, intricate components to the highest specifications using advanced Hurco® technology.

4-Axis Milling

We run three CNC milling centres with 4-axis capability, enabling the machining of curved and complex profiles with reduced setup requirements.

5-Axis Milling

With Hurco® 5-axis CNC milling centres, we achieve improved surface contouring, fewer setups, and faster material removal, resulting in quicker production of complex, high-precision components.

Engineering

We provide a variety of specialist precision engineering services, including conventional milling, jig boring, and electrical discharge machining.

Assembly

We manufacture mechanical and electromechanical components and assemblies to customer specifications, covering fixtures, soldering, riveting, helicoiling, lead wire cutting, connector assembly, drilling, grinding, tapping, and bench work.

We are proud to be leading experts in producing bespoke CNC components for Formula 1, aerospace, military, and other industries, using the latest CNC machining and CAD/CAM technology, supported by comprehensive online CMM inspection facilities in the UK.

We have been trusted to manufacture highly complex and critical components for some of the world’s most prestigious companies. By investing in our skilled team and advanced machinery, we ensure first-class service and the highest-quality finishes for our clients.

For expert precision engineering and top-quality service, get in touch with us today.

Images

Reviews

Trade Associations