Company details for:

Canning Conveyor

Quick Links:

Products / Services

Conveyor Belts & Belting

Total Conveyor Confidence

Canning Conveyor is a trusted name with a long-standing reputation for delivering complete conveyor solutions you can rely on.

At the heart of our conveying excellence is the Cannoflex™ brand — engineered for demanding applications involving heavy, sharp-edged, or abrasive materials such as gravel, crushed stone, limestone, iron pellets, glass, coal, sand, and fertilisers.

Backed by over 60 years of belt manufacturing expertise, Cannoflex™ conveyor belts are renowned for their exceptional reliability and performance. Each belt undergoes rigorous testing to ensure it meets the highest standards in chemical composition, technology, structure, and manufacturing quality — guaranteeing only first-class products reach our customers.

Standard Flat Conveyor Belt

Engineered for Excellence

The Cannoflex™ Standard Conveyor Belt is manufactured to the highest standards of chemical, technological, structural, and production quality.

Constructed with E.P. (Polyester/Polyamide) fabric plies, the belt features abrasion-resistant rubber covers that comply with DIN 22102 and BS 409 specifications. The E.P. fabric is made from a synthetic woven blend — Polyester fibres in the warp and Polyamide (Nylon) fibres in the weft — ensuring superior strength, flexibility, and durability in demanding conveying applications.

Chevron Conveyor Belting

Versatile Sizes and Patterns

Cannoflex™ chevron belts are available in a comprehensive range of widths and pattern designs to suit virtually any application — including sizes beyond standard specifications. Each belt features integrally moulded cleats, formed as part of the top cover during manufacture, ensuring exceptional durability, strength, and performance.

Heat Resistant Conveyor Belting

Heat Resistant Conveyor Belts – Available in Three Grades

Canning Conveyor stocks three grades of heat-resistant conveyor belts, each designed for specific temperature ranges and applications:

CHR-100

Material temperature: up to 200°C | Belt surface: 80–100°C

Cover rubber: SBR

Features: Premium SBR rubber compound offering excellent abrasion and heat resistance. Suitable for handling hot materials such as iron ore pellets, sand, castings, coke, and limestone.

CHR-150

Material temperature: 150–350°C | Belt surface: 100–150°C

Cover rubber: EPDM

Features: Ethylene propylene (EPDM) compound provides superior heat resistance and prevents cracking. Ideal for powdery materials such as cement, fine limestone, clay, slag, and steel millings.

CHR-200

Material temperature: 150–450°C | Belt surface: 120–180°C

Cover rubber: EPR

Features: Highest-grade heat-resistant belting, formulated with EPR (ethylene propylene rubber) for maximum heat resistance and ply adhesion. Perfect for hot cement clinker, phosphate, sintered ore, and hot chemical fertilisers.

Oil Resistant Conveyor Belting

Oil Resistant Conveyor Belting – Two Grades

Canning Conveyor stocks two grades of oil-resistant conveyor belts designed for different applications:

COR-100

Material temperature range: -25°C to +60°C

Features: Moderately oil-resistant compound suitable for conditions involving light oily chemicals. Ideal for minerals, heavy oil, Barbolin rust preventative oil, light oils, rolling oil, grease, machine oil, and sewage.

COR-200

Material temperature range: -25°C to +60°C

Features: Resistant to grain and vegetable oils and electrically conductive to dissipate static electricity. Suitable for animal and vegetable oils, palm, lard, fish, soya, sesame, cotton, rice oils, frying, catering, dust, excreta, and sewage.

Conveyor Parts

Trusted Conveyor Solutions

Canning Conveyor is a well-established name, recognised for its outstanding reputation and commitment to delivering complete conveyor reliability.

We supply an extensive range of conveyor components, including:

Drums

Impact Bars

Fasteners

Scrapers

Tracking Devices

Conveyor Parts - Drums

Custom-Built Conveyor Drums

Canning Conveyor manufactures a wide range of conveyor drums tailored to individual customer specifications. We offer competitive pricing and fast turnaround times to meet practical delivery requirements.

Each drum is constructed from high-quality steel shells with closed steel end plates and fitted shafts. Available configurations include bossed and welded, bossed and keyed, weld-on hub/taper lock bush, Ringfeeder, or designs incorporating flanged bearings on the end plates.

Conveyor Parts - Fasteners

Comprehensive Conveyor Belt Solutions

We offer a wide range of belt conveyor products, including the Alligator® Staple Fastening System, Flexco® Bolt Solid Plate fasteners, and the Flexco® SR™ Scalloped Edge™ fasteners.

Conveyor Parts - Scrapers

Comprehensive Conveyor Belt Solutions

We supply a wide range of Flexco® belt conveyor products along with our own belt cleaning systems, including:

Canning single and multi-blade belt scrapers

Canning chevron belt scraper

Canning V-Plough

Tangential scraper

Rockline® conveyor products

Eliminator® conveyor products

Conveyor Parts - Tracking Devices

Canning Belt Tracking Discs – Key Features

Compatible with standard field conveyor flexing/suspended idlers and return rollers, fitting 102 mm and 127 mm diameter rollers

Easy to install and available ex-stock

Highly competitive pricing

Trusted by leading customers, including:

Cemex – Aylesbury, Cardiff, Brentwood, North Quay, Newark, Grantham

Tarmac – Guilford Quarry, Kingsley, Bow, Hoggs Back Sandpit

Bardon Aggregates – Uttoxeter

Hanson Premix – Ashford

Brett Aggregates – Charring

Ibstock Brick

Civil and Marine and Waterside Maintenance sectors

Conveyor Rollers

Trusted Supplier of Idlers, Rollers & Accessories

Canning Conveyor has been a leading supplier of idlers, rollers, and accessories in both steel and polymer for over 40 years. We maintain an extensive stock of idlers, rollers, replacement rollers for major brands, and related accessories, offering unmatched off-the-shelf availability.

We also manufacture custom replacement rollers to your specifications. To ensure accuracy, we ask customers to complete our roller order form, detailing shaft types and roller dimensions, enabling us to provide prompt pricing and delivery.

All products are manufactured using advanced technology and high-quality raw materials, ensuring precision and exceptional durability. Our experienced sales team is on hand to advise on product availability, suitability, and any technical queries regarding steel, polymer, or related ancillary products.

Adjustable Trough Sets & Returns

Extensive Range of Idlers & Rollers

Canning Conveyor stocks a wide variety of troughing idler sets and return rollers in both steel and polymer. Our range includes adjustable, fixed-angle, cast-bracket, impact, and suspended idler sets, as well as flat, disc, and impact return rollers with compatible brackets.

We maintain standard replacement rollers in stock for immediate availability. Additionally, we can manufacture custom replacement rollers to your specifications. For convenience, a roller order form is provided to capture shaft types and full roller dimensions, ensuring accurate pricing and delivery.

Our updated roller brochure showcases the full range of idlers, rollers, and accessories, including Canning belt tracking discs, belt guide rollers, steering idlers, and return rollers in both steel and polymer. It also highlights our polymer ground conveyor suspended idlers, featuring unique safety handles, along with polymer return rollers, complete with all standard sizes and dimensions.

Fixed Angle Trough Sets & Returns

Fixed Angle Idler Sets

Fixed-angle idler sets feature end-supported wings for added strength, and all rollers are fully interchangeable. The range offers two frame options:

Folded construction – ideal when cost efficiency is a priority

Tubular construction – designed for optimal self-cleaning performance

Cast Bracket Trough Sets & Returns

Extensive Range of Idlers & Rollers

Canning Conveyor stocks a wide variety of troughing idler sets and return rollers in both steel and polymer. Our range includes adjustable and fixed-angle, cast bracket, impact, and suspended idlers, as well as flat and disc rollers with compatible brackets. Many standard replacement rollers are available off the shelf for immediate delivery.

We also manufacture custom replacement rollers to meet your specific requirements. To simplify ordering, we provide a roller order form to capture shaft types and full roller dimensions.

Our updated roller brochure showcases our full range of idlers, rollers, and accessories in steel and polymer, including belt tracking discs, belt guide rollers, steering idlers, and return rollers. It also highlights our polymer ground conveyor suspended idlers with unique safety handles and polymer return rollers, with all standard sizes and dimensions provided.

For any queries or specific requirements, please contact our roller sales department.

Why Choose Canning Conveyor:

Excellent Service

Fast Delivery

Competitive Prices

Impact Troughing Sets & Disc Returns

Impact Idlers – Belt Protection at Loading Points

Impact idlers are engineered to protect conveyor belts by absorbing impact at loading points.

Canning Conveyor supplies a range of heavy-duty impact idler sets, featuring:

Rubber discs compressed onto heavy-gauge steel tubes

Sealed-for-life bearings for low maintenance

Heavy-duty fabricated steel frames, side-supported for maximum strength

We also offer custom-made replacement impact rollers, manufactured to your specific requirements.

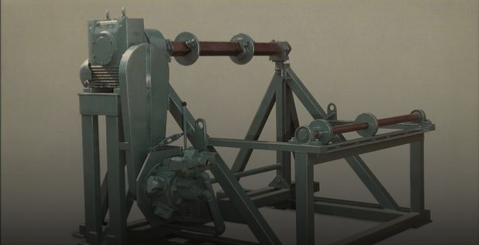

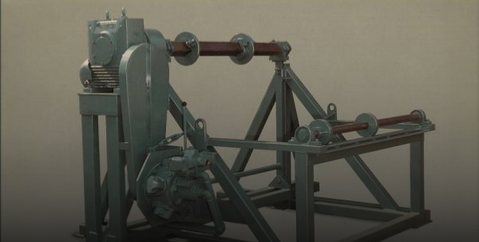

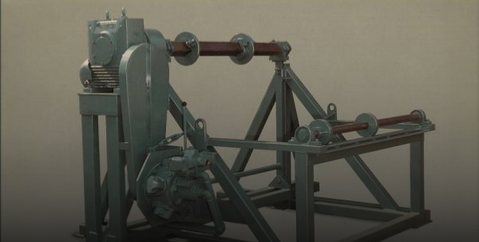

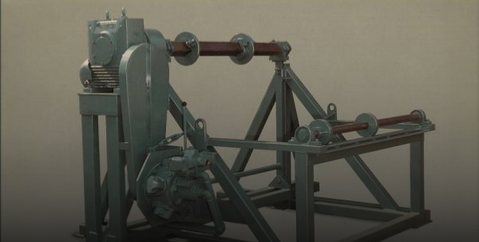

Belt Reeling & Cutting Machines

Belt Reeling Machines – Hire or Purchase

The Canning Belt Reeling Machine provides an economical and efficient solution for handling and reeling conveyor belts.

Standard Models:

Model C36 – for belt widths up to 1000 mm (36”)

Model C72 – for belt widths up to 1800 mm (72”)

Both models can reel approximately 200 metres of 12.5 mm (1/2”) thick belt. Portable for on-site use, they are available with diesel or electric drive and can be transported by a 35cwt pick-up truck. Widely hired across British Coal and quarries throughout the UK, the machines feature the unique ‘Roll Releasing Mechanism’.

Technical Details (C72):

Overall weight: 1.5 tonnes

Engine: Lister Diesel ST2, 15 bhp, with clutch drive via vee belts to Radicon worm reduction gearbox

Custom Machines:We also manufacture machines for alternative sizes and specifications to order.

Belt Cutting Machines

The Canning Belt Cutting Machine is a cost-effective solution for cutting conveyor belting. Available in diesel or electric drive, models are tailored to suit individual applications.

Custom Machines:All belt cutting machines are made to order to meet specific requirements. For further details, contact our engineering department.

Vulcanising

Trusted Conveyor Solutions

Canning Conveyor is a well-established name, renowned for delivering complete conveyor reliability. We provide a comprehensive vulcanising service, available on-site or in-house, to ensure your belts perform at their best.

In-House & On-Site Vulcanising

Canning provides a full vulcanising service, available both on-site and in-house.

Used Equipment Plant List

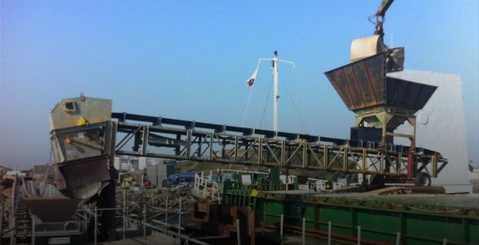

Refurbished & Second-Hand Bulk Handling Equipment

Canning Conveyor offers a wide range of bulk handling and materials processing equipment, available fully refurbished or second-hand, depending on availability, to suit customer needs.

Our range includes crushers, screens, conveyors, feeders, and complete static or mobile plants with diesel or electric drives.

We also supply associated plant and components, including magnets, drums, bearings, motorised drums, motors, and gearboxes, and are happy to accommodate specific equipment requests.

1 (One) – Fully Refurbished Mobile Conveyor, 750mm Wide Belt x 9.2m Long

EX STOCK! Fully Refurbished Mobile Conveyor

Width: 750 mm | Length: 9.2 m

Equipped with Chevron belting

Electric/hydraulic adjustable height: 1.3 m (closed) to 3.4 m (extended)

Includes: Tow bar, feedboot (1 m × 900 mm)

Mobility: Under-chassis with 750 mm rubber-tyred wheels; approx. 3 m wide over wheels

Finish: Painted orange

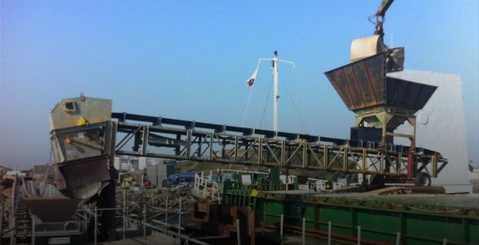

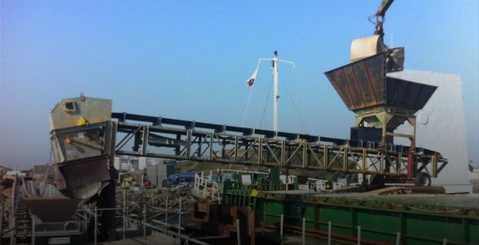

1 (One) – USED MOBILE CONVEYOR - 1m Wide x 15.64M Drum Centres

AVAILABLE EX STOCK

Layout and dimensions as shown

ATEX compliant

Chevron belt: EP315/3 ANTIFLAME

Drive: 22 kW shaft-mounted gearbox, belt speed 1.6 m/sec

Capacity: Approx. 350 TPH @ 1.5 t/m³

Features: Primary scraper, emergency pull wire (both sides), full-length belt covers and deck plates, screw tension at tail

Frame: Galvanised finish

Discharge height: 3,425 mm (fully lowered) to 6,872 mm (fully raised)

Weight: Approx. 7.5 tonnes

Conveyor Drums & Motors

All unused, in-stock items! Ex-works – now at reduced prices!

Skako Vibration Vibratory Feeder

Vibratory Feeder – Excellent Condition

The vibratory feeder is constructed in mild steel with spring-mounted footplates and necessary shock dampers.

Cassette design with manually adjustable gate and stainless steel wear liner in the trough bottom; sides made of Hardox 450

Surface finish: Hot-dip galvanised

Drive: 2 vibrator motors, IP66 protection, Insulation Class F

Power supply: 220–240V / 380–415V

Material handling specifications:

Designed for materials with densities: Steel Slag 3.1–3.6 g/cm³, Ballast mixture (Concrete & Slag) ~2.4 g/cm³, Desulph of steel 7.85 g/cm³

Maximum material temperature: 50°C

Maximum capacity: Steel Slag – 380 t/hr, Ballast – 220 t/hr, Desulph – 220 t/hr

Maximum product size: up to 300 mm

Condition: Excellent

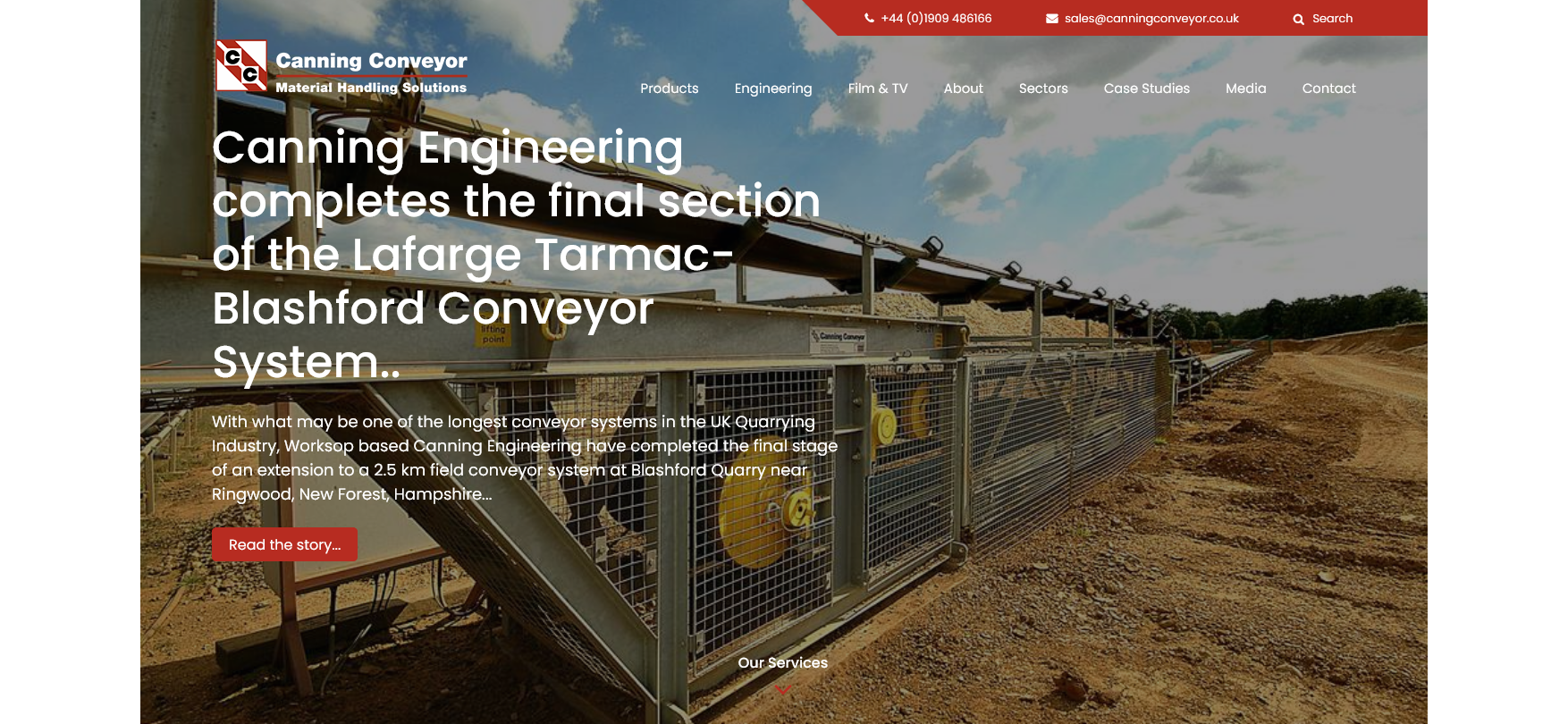

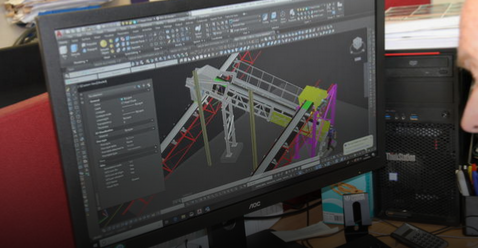

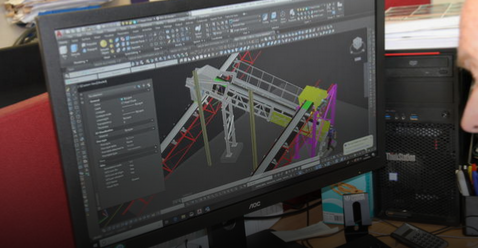

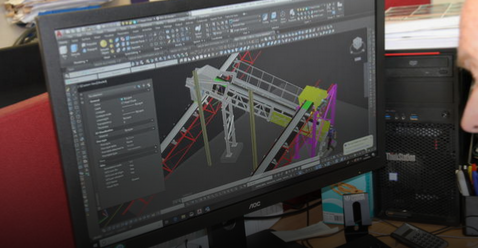

Canning Engineering

Global Engineering Expertise

Canning Engineering, a division of Canning Conveyor, operates from two purpose-built facilities in Worksop, Nottinghamshire.

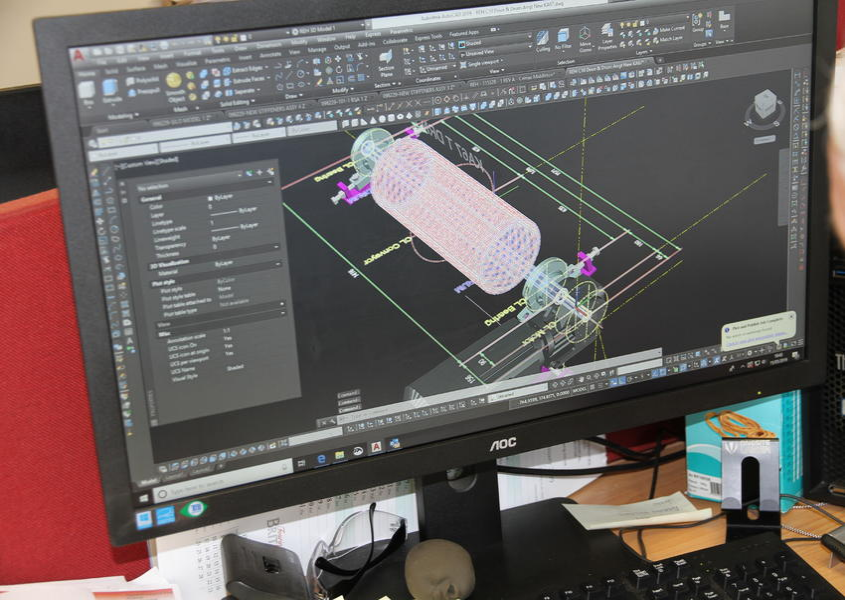

Manufacturing Facilities

Our Worksop engineering site houses a fully equipped machine and fabrication workshop for manufacturing, assembly, and testing. Supported by skilled installation teams, we provide full commissioning, spare parts, and maintenance services — all while maintaining competitive pricing.

Our second facility, located on the Claylands Avenue Industrial Estate, spans over 4,000 m². Equipped with full-length, 5-tonne overhead cranes, this site accommodates additional fabrication, machining, and assembly areas and serves as the home of the Tumbleator.

Project Installation & Commissioning

Canning Engineering delivers complete solutions across all market sectors — from design, manufacture, and supply to installation and commissioning.Our strength lies in our highly skilled engineering team, whose technical expertise and project management capabilities enable us to design, develop, and deliver innovative solutions to complex engineering challenges.

We offer a comprehensive, professionally managed service covering:

Consultancy, design, and manufacture

Electrical design and installation

Skilled labour for off-loading and erection

Full commissioning and craneage supply

Civil works to client drawings

Site fitting and vulcanising

Tailored maintenance and service packages

Our Mission

To be your engineering contractor of choice — delivering quality, reliability, and innovation in every project.

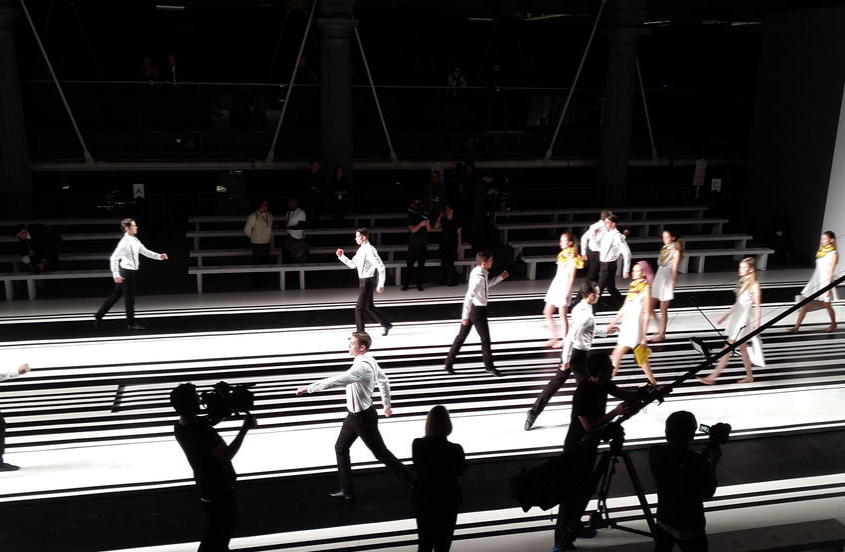

Film & TV Industry Specialist Supplier

Over 40 Years of Industry Experience

With more than four decades of expertise, Canning Conveyor has become a trusted specialist supplier to the film and TV industry. Today, we’re recognised as the leading provider of conveyors, treadmills, travelators, and our innovative, world-renowned Tumbleator™.

About us

Founded in September 1965, Canning Conveyor has grown from modest beginnings to become a leading supplier of custom equipment for the bulk handling and film/TV industries.

Our approach is straightforward: deliver top-quality equipment and services to our customers at the most economical, cost-effective rates.

We continually develop innovative products for the industries we serve. Many of these, such as our high-density polymer replacement rollers, suspended idler sets, return rollers, and belt tracking discs, are now well established and trusted in the market.

Our Products & Services Include:

Products

Canning provides a wide range of conveyor solutions, including belting, parts, rollers, belt vulcanising services, and the supply of belt reeling and cutting machines.

Film & TV

With over 40 years of experience in the film and TV industry, Canning Conveyor is the top choice for conveyors, treadmills, travelators, and our renowned, innovative Tumbleator™.

Canning Engineering

Canning Engineering, a division of Canning Conveyor, operates from two sites in Worksop, Nottinghamshire, including a 4,000 m² facility at Claylands Avenue Industrial Estate, home of the Tumbleator. Our fully equipped workshops support manufacture, assembly, testing, and fabrication, backed by skilled installation teams and comprehensive after-sales service. With extensive experience across all market sectors, our engineers provide consultancy, design, manufacture, installation, commissioning, electrical works, civil works, lifting equipment, site fitting, vulcanising, and full maintenance packages, all professionally project managed. Leveraging technical expertise, project management skills, and state-of-the-art facilities, we deliver innovative, reliable solutions while maintaining competitive pricing.

"Canning’s regularly work on new installation projects on our behalf under both Quarry and CDM regulations on some of our more complicated installations across rough terrain and through tunnelled sections. Currently they are working on behalf of my department on our most critical wharfs to improve and upgrade material supply. They are company we regularly turn to when reliability and performance are key drivers. I have reviewed statistics and note with pleasure that their staff have never been involved in any accident or incident under our projects, their staff operate to and above our expectations in regard to health and safety on site."

David Hakes - Engineering Project Manager - Cemex UK

Canning Conveyor Co. Ltd. is a company registered in England and Wales with company number 858193. VAT number 439 5298 11.

Images

Videos

Articles / Press Releases

Brochures

Reviews

Trade Associations