Company details for:

Linmar Pipework

Quick Links:

Products / Services

Pipe Bending

There is no single tube or pipe bending process that works for every application. The material, size, and complexity of the bend determine the appropriate equipment and method. Common techniques include rotary draw bending, roll bending, compression bending, and freeform bending. Every bend has three radii to consider: the centreline radius (CLR), the inside radius, and the outside radius. The CLR represents the neutral axis of the tube or pipe, where there is no material compression or expansion. Each bending method manipulates various factors to achieve the desired result while maintaining the designated CLR.

Rotary draw bending and compression bending both form the tube around a die, but the way the pipe wraps around the die differs. Rotary draw bending typically requires a mandrel inside the tube to prevent defects—hence it is also called mandrel bending. Mandrel bending is especially effective for creating tight-radius bends in thin-walled tubes and pipes.

In both rotary draw and compression bending, the bend die size sets the CLR. In contrast, for roll bending and freeform bending, the CLR depends on how the tooling moves, not its size. No single method is inherently superior; each has applications best suited to specific materials and bend requirements. A professional with experience can determine the most efficient and cost-effective method for each project.

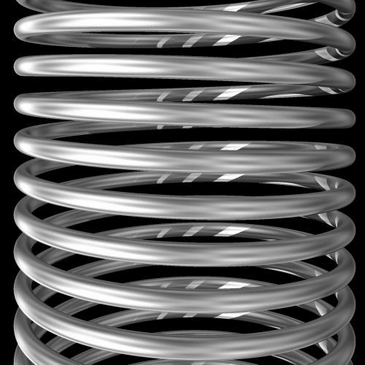

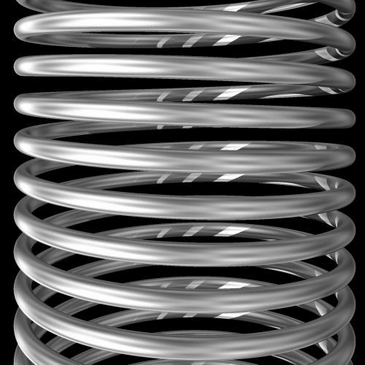

Pipe Coiling

Much of modern pipe bending focuses on pipe coiling, where a tube or pipe is guided through a machine to create a continuous helix or spiral. Used in both industrial and decorative applications, these custom-formed pipes often go unnoticed for the intricate manufacturing process required to produce them.

Section Bending

Linmar Pipework specialises in section bending, delivering precision-formed pipes and tubes tailored to a wide range of industrial applications. With years of expertise, Linmar combines advanced equipment with skilled craftsmanship to produce accurate, reliable bends while maintaining material integrity. Their team works closely with clients to meet specific project requirements, offering flexible solutions for both standard and complex pipework designs.

Coded Welding

Coded welding has long been a core service at Linmar Pipework. Beyond standard pipework installation, the company designs, repairs, and manufactures specialised equipment requiring all types of welding, including coded welding. A coded welder is someone who has successfully completed an industry-recognised examination, demonstrating their skill and competence in a specific welding technique or configuration.

Pipework Installation

With expertise across all aspects of pipework installation and materials, we collaborate closely with each client to achieve the best possible results. From installing new compressed air, gas, or water pipelines to delivering complete factory ring mains, including the renewal or maintenance of existing systems, we provide reliable, tailored solutions to meet every project need.

Steelwork Fabrication

Linmar Pipework offers expert steelwork fabrication, delivering high-quality, precision-engineered structures to meet a wide range of industrial needs. Combining skilled craftsmanship with advanced machinery, Linmar designs, manufactures, and assembles steel components tailored to each client’s specifications. From structural frameworks to bespoke steel assemblies, their team ensures durability, accuracy, and efficiency, providing reliable solutions for both standard projects and complex custom requirements.

About us

Linmar Pipework is a family-owned company with over fifty years of experience. If you’re looking for a pipe bending specialist capable of handling tube manipulation in sizes up to 12 inches in diameter, we may have the solution you need.

You can trust that, whatever your pipe bending needs, we provide competitive pricing and fast turnaround times. Our streamlined structure means you primarily deal directly with the company owners, ensuring efficient and personalised service.

Combined with our extensive experience in fabrication and installation, we offer a one-stop solution capable of handling any challenge. Whether you need a simple, one-off pipe bend or complex multi-helical coils with specialised finishing and installation, we can deliver the right tube manipulation solution for your company.

Our Services Include:

Pipe Bending

Pipe bending available for all materials and wall thicknesses, up to 12 inches in diameter.

Pipe Coiling

Linmar offers pipe and tubing coiling services, producing helical coils, flat coils, serpentine coils, and more.

Section Bending

We handle section bending and plate rolling in-house, ensuring a fast turnaround for orders of any size.

Coded Welding

Coded welding services in MIG, TIG, and Arc for mild steel, stainless steel, and aluminium.

Pipework Installation

More than just a tube bending company, Linmar designs, manufactures, and installs pipework in any material.

Steelwork Fabrication

Linmar Pipework can design, manufacture, and fabricate specialist plant tailored to each client’s specific requirements.

Based in Sheffield, we benefit from convenient access to the motorway network.

We’d love to hear from you! Use the contact form on our website, provide a brief outline of your project if you wish, and we’ll get back to you promptly to discuss it.

Images