Company details for:

Perfect Solutions Group UK Ltd

Quick Links:

Products / Services

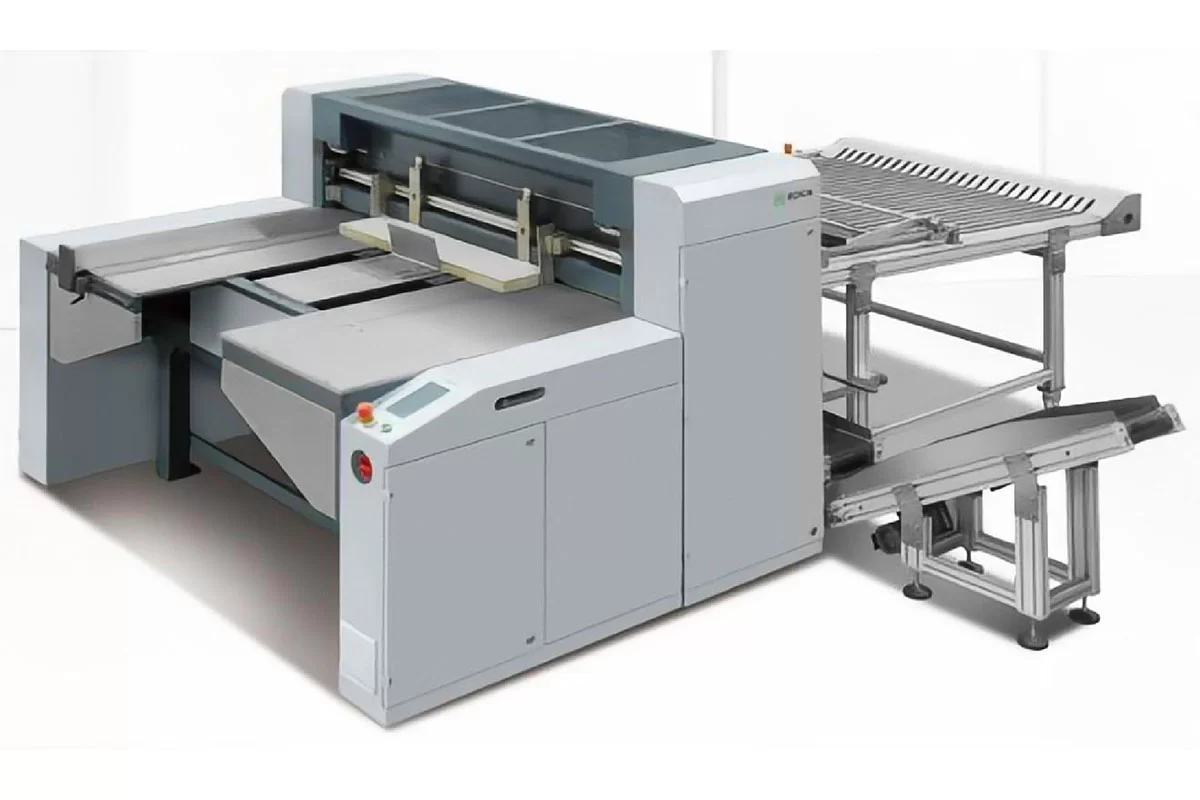

Super D - Automated De-Stacking System

This machine separates pre-glued or sewn book blocks for individual processing in later production stages. Fully automatic and highly flexible, it ensures continuous operation—making it ideal for reel-fed print engines with integrated post-print paper handling systems.

PSG Super Binder

This uniquely designed single-clamp perfect binder is built for on-demand, short-run production of both hard and soft cover books. Featuring touch-screen controls, it allows quick and efficient setup and changeovers.

PBS 096 Spine Strip Cutter

This robust machine produces precise, burr-free strips for all types of casemakers using a shear knife cutting action. By removing the need for a guillotine, it enhances casemaker efficiency and significantly improves overall case quality.

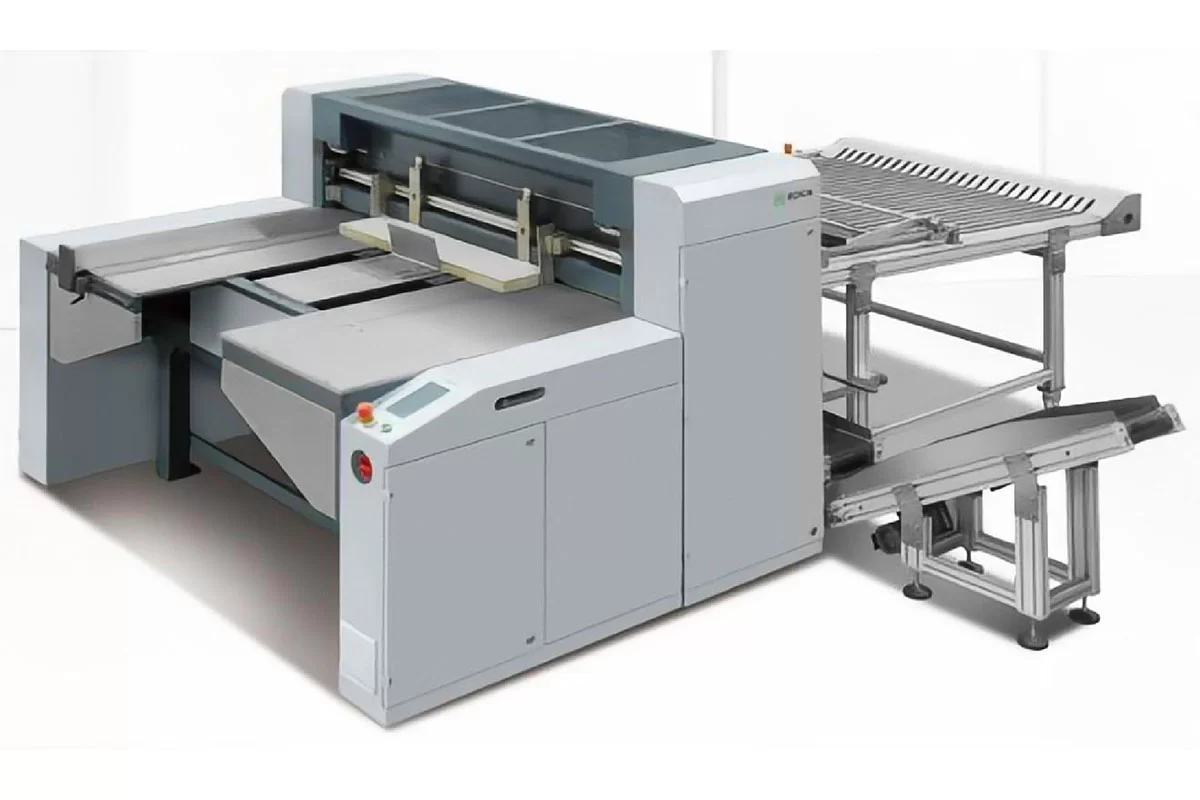

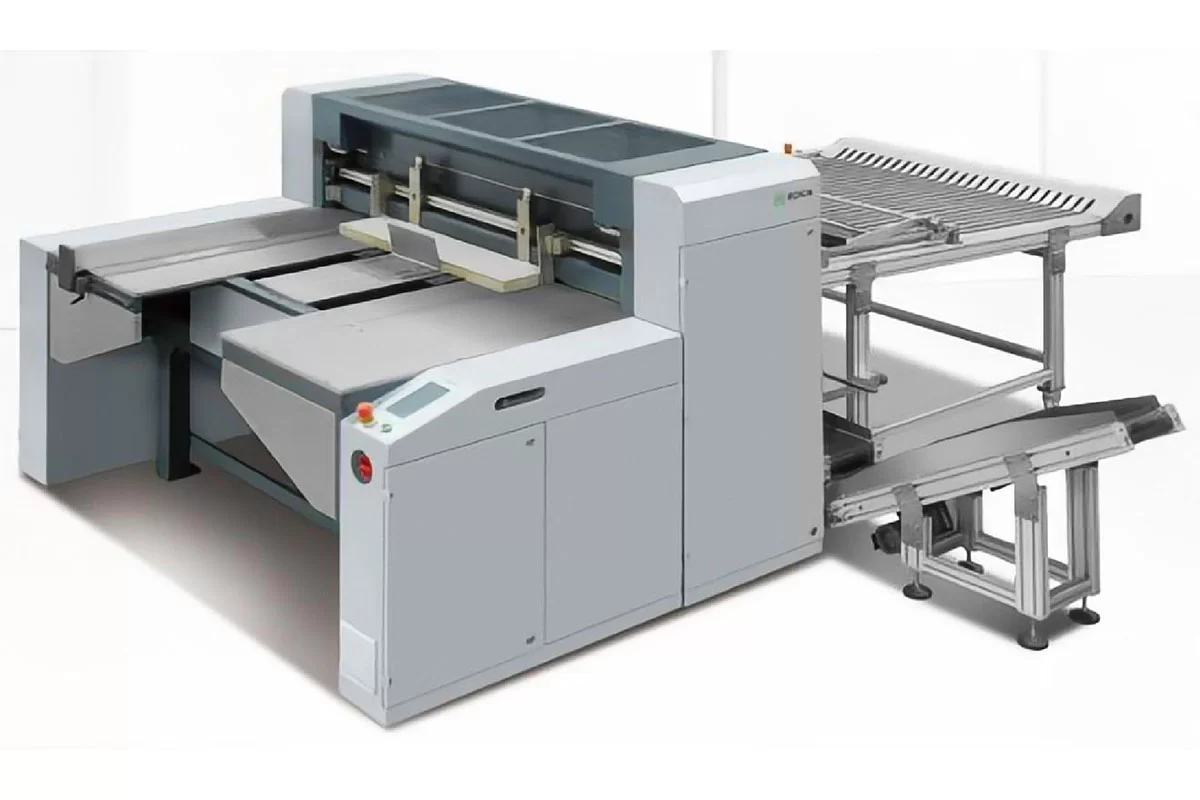

FR-21K Semi-Automatic Board Cutter

This machine is designed to cut large board sheets into precise board pieces. Sheets are automatically fed, sliced into strips, and re-fed for a second cut to achieve the final blank size. Finished pieces are delivered onto a collecting conveyor, while waste is automatically removed via inline conveyors.

Featuring a rotary knife system, it delivers accurate, clean, burr-free cuts on all board types—including industrial cardboard, grey board, and E/F corrugated board. With automatic knife adjustment and simple operation, the machine ensures high productivity with just one operator.

750B Casemaker

We specialise in casemaking machinery, offering an extensive range that includes everything from semi-automatic models for short-run, on-demand production to high-speed, fully automatic systems. Our solutions cover all types of cases—large, curved, shaped, one- to seven-piece, and those with windows or apertures—ensuring we can meet any production need. Our machines are compatible with various adhesive types, including hot animal glue, cold glue, and vegan alternatives.

For tailored advice, we recommend contacting us with your specific production requirements so we can guide you toward the most suitable machine.

As UK agents for leading manufacturers such as Horauf, ODM, Daluiso Machinery, Schmedt, and a selection of reputable Chinese brands, we provide trusted, high-quality casemaking solutions for every application.

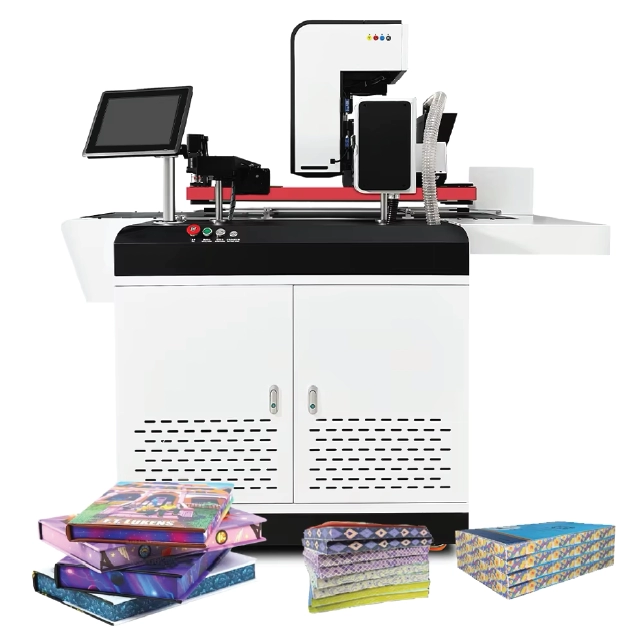

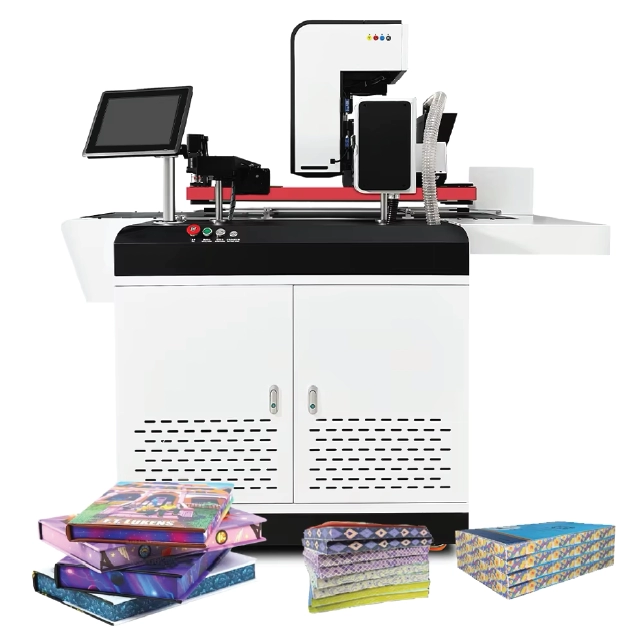

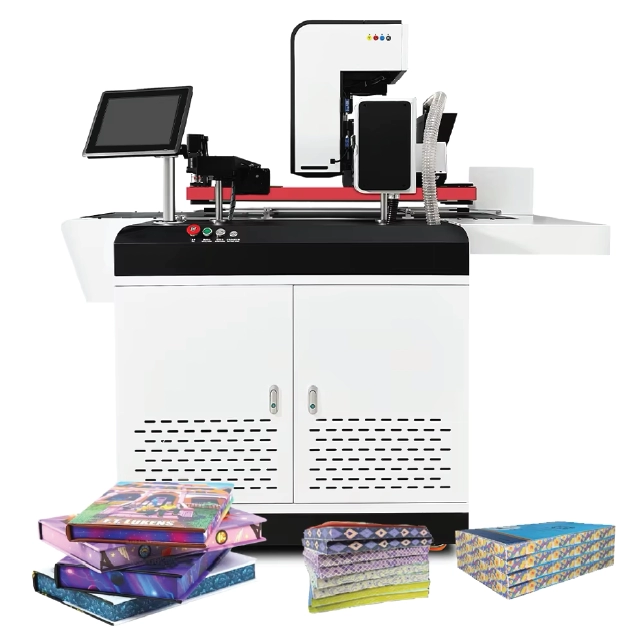

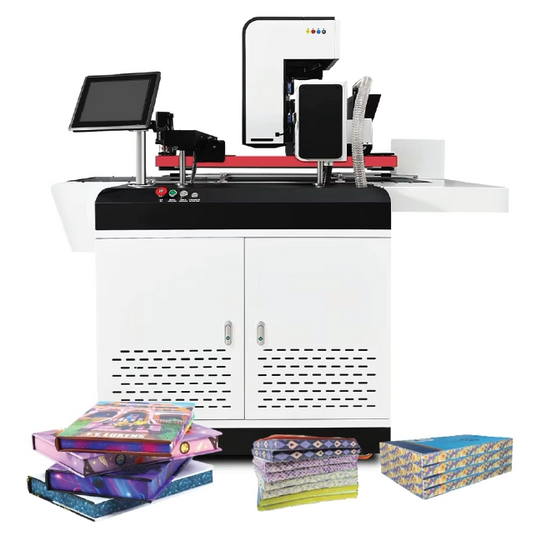

PSG RJ Digital Book Edge Printer

This book edge printing machine is engineered to digitally print text, patterns, motifs, solid colours, and more. Once the design files are loaded, the entire printing process operates automatically, with manual intervention required only for loading and unloading the books.

PBS Elastic Strap Machine

This semi-automatic machine is designed to punch slits or holes into hard cover cases and automatically insert and secure elastic straps using hot melt adhesive on the inner side of the case. The operator is required to manually load and unload the cases from the machine.

CT60 Round Corner Cutting System

This machine is designed to round-cut the corners of soft cover books, card books, and book blocks prior to casing-in. It can function as a stand-alone unit or be integrated in-line with existing binding and trimming systems.

FJ-80 Hot Foil Stamping Machine

This machine is engineered to automatically pick sheets or hardcovers from a stack, position them for stamping, apply foil to the designated artwork, and then neatly stack the finished pieces for quality control or further processing. The stamping pressure is adjustable to suit different artwork sizes and material types.

1246B Fully Automatic Box Production Line – 1 Wrapper

This machine is designed to automatically apply adhesive to cover sheets, which are transported on a vacuum belt to the rigid box application robot. It features automatic inline corner taping, folding the four sides of grooved or die-cut boards to form the box. Once folded, tape is applied to all four corners simultaneously, and the box blank is transferred to the robot’s hopper. The robot then accurately places the box onto the glued sheet with a precision of ±0.1 mm.

The gluing unit includes a high-capacity hopper with a no-sheet detector, hot animal glue, precision rollers, and a circulating pump with viscosity control. After placement, the conveyor moves the box to the pressing station to ensure full contact with the base before entering the box wrapper. The wrapper then automatically takes the box and cover sheet into the forming station, wrapping the cover material around the box to produce a high-quality finished product, which exits via a short conveyor.

STS – Sheet-To-Sheet Digital Laser Finishing

The SmartFinish STS laser processing system is designed for exceptional precision in through-cutting, kiss-cutting, and perforating full-sheet materials. Transform traditional print finishing with this advanced solution that integrates laser cutting, scoring, and perforating capabilities with instant job changeover technology—eliminating the need for costly mechanical dies and lengthy setup times. Easily produce affordable single-run samples or prototypes, or efficiently handle short runs of complex designs on paper, paperboard, plastics, and acrylics at outstanding production speeds.

Equipped with single or dual camera systems and patented material handling technology, the SmartFinish STS ensures precise cut-to-part registration and seamless transfer of finished components. It can be integrated with most commercial and packaging printers to deliver a fully digital, inline workflow from start to finish. A range of optional enhancements is available to expand functionality and maximise your equipment investment.

STP – Sheet-To-Part Digital Laser Finishing with Automated Robotic Part Handling

This system unites the versatility and precision of laser finishing with the efficiency and time-saving advantages of automated robotic part handling. Integrated with a high-speed robotic system, the laser operates dynamically according to stored job parameters and is managed by LasX’s patented LightGuide software. The robot automatically separates processed parts from waste material, then stacks, sorts, rotates, or shingles them as required.

The STP model can be seamlessly integrated into both new and existing digital printing systems, enhancing your printing capabilities and enabling a fully digital, end-to-end workflow.

The Ultimate Solution for Sortation

Perfect Sortation Solutions specialises in automated parcel sortation systems, with numerous successful installations across the UK and Europe. These systems are ideal for distribution centres, manufacturers, and large digital printing operations, enabling the direct delivery of parcels and packages — including books, apparel, cosmetics, and more — straight to end customers.

Active Air Purification

With our Air Purification technology we can neutralise/kill viruses, bacteria, odours, mould spores etc and reduce VOC’s (Volatile Organic Compounds) to ensure a safe working environment for all employees, visitors and patients etc.

Our solutions replicate outdoor fresh air, indoors! We use patented Photohydroionisation (PHI)® / REME® technology.

Please refer to our 'Active vs Passive' brochure to understand the difference between how the two technologies work, and why ours is far superior to other market leaders!

How does it work: The electrostatic positive or negatively charged ions in the air immediately agglomerate (clump together). This ionisation of the particles makes them larger and heavier which allows them to be removed by HVAC filtration or by dropping out of the air/falling to the ground.

Ionised Hydrogen Peroxide (H2O2) is the key active component of this technology for effectively killing viruses, bacteria, mould spores and reducing VOC’s continuously in real time!HALO LED® units utilise proprietary mercury and ozone free LED-UV bulbs. These project UV energy at specific wavelengths onto a proprietary catalyst to promote the conversion of naturally occurring water vapour, into ‘safe to breathe’ outdoor concentrations of ionised Hydrogen Peroxide.The Photohydroionisation process converts water vapour molecules (H2O) that pass through the PHI-CELL into large numbers of ionised Hydrogen Peroxide (H2O2) molecules.

Airborne molecules of ionised Hydrogen Peroxide are effective at deactivating all types of harmful bacteria, viruses, allergens, moulds and odour compounds that may be present both in the air and on surfaces. The concentrations of ionised Hydrogen Peroxide molecules is similar to ambient outdoor concentrations making the treated indoor air perfectly safe to breathe.

1200G High Speed Grooving machine with automatic waste corner removal

This machine is designed to automatically cut up to 8 V grooves in standard board and paper for packaging products. The machine incorporates two hoppers to enable fast change over from the first to the second cut completing the box blank ready for the next process. This model includes automatic waste corner removal and a device for sharpening the blades in house. The blade angle is adjustable (from 90° to 110°approx.) to enable inside lining after grooving, which means when the box is formed, the 90°corner is retained. Dust free, quiet production.

F7 Digital Box Wrapper

This electro-pneumatic box wrapping machine represents the most innovative choice for finishing of high-quality boxes for small and medium runs. The pre-formed box with the glued sheet has to be placed manually by the operator on to the suction head with the tool/mould already in place. A tool/mould is required for every box size, one for the lid and one for the base. The operator then presses 2 push buttons to operate the wrapping process. The vacuum operated system keeps the product in position throughout the complete folding and pressing cycle. When folding is completed, the suction head releases the finished box ready for manual removal or alternatively ejected onto conveyor belt etc. Material must have hot animal glue application or cold vegan glue heated to 30 degrees to ensure efficient, clean production. This model is set automatically using the touch screen simply by inputting the box parameters and the machine will adjust itself. It also has a facility to save jobs/settings for repeat orders.

Speed, pressure and dwell time are all adjustable to suit a wide range of materials ensuring a quality finish.

Destratification Technology

With our Destratification technology we can regulate your air temperature and improve air flow throughout your building ensuring a more manageable working environment both in the Summer and Winter without costly AC installations and alternatives. This will save the amount you pay for your energy and means the temperature is consistent everywhere; ground floor, first floor, offices, factory floor, mezzanine etc

Productivity in the print industry - Controlling the temperature on mezzanine floors assists box and book production when using hot adhesives. Temperature variations throughout the day/shift cause challenges for output and quality as well as staff comfort!

Optimus Prime - Bottle Box/Slip Case production

This machine is designed to automate slip case / bottle box production for consistency, efficiency, and quality. It will automatically wrap the cover sheet around the taped board carcass (slip case or bottle box).

Save on man-power – let OPTIMUS PRIME do all the hard work! A tool/mould will be required for each different box/slip case size. Material must have hot animal glue application or cold vegan glue heated to 30 degrees to ensure efficient, clean production.

Two Machines Required, Depending On Run Length.

Machine 1: Pre-formed boxes are placed onto the pre-glued sheet and then held on the machine with a suction tool. The machine then wraps the material around the slip case / box automatically.

Machine 2 Option: For wrapping inside the slip case / box, this can either be done by hand (short runs), or the second machine can be deployed to finish the box, by tucking in the final part using a different tool.The vacuum suction tooling also enables the forming of the slip case / box from a die / grooved board. The board should be placed on the glued sheet, and suction holds the board on the tool and then let the machine complete the process – automatically!

Ventilation (Mould, damp, dust mite control & radon mitigation)

Did you know that most mould, condensation and dust mite infestation is a direct result of poor ventilation, causing high relative humidity issues? Our systems fix the root cause and eliminate the reoccurrence of these issues. We can also integrate our active air purification technology for adding an extra layer of protection! Mould/damp issues are often misdiagnosed and the ‘solution’ tends to be a costly building structural issue, which is rarely the case, and doesn‘t fix the problem! If these issues are left untreated they can cause many dangerous health and wellbeing conditions, and in some cases death. We’d love to come and survey your building to give you an honest explanation and solution to your issues. Talk to us to find out more!

Radon is a colourless, odourless radioactive gas that comes from the natural decay of uranium in rocks and soil. While outdoors radon levels are very low, it can collect in enclosed spaces like homes and workplaces. The primary health risk of high radon exposure is an increased risk of lung cancer, making it crucial to test for and reduce high levels. We have the expertise and solutions to reduce radon concentrations to below the Action level and ideally below the Target level. These are specialist ventilation systems which include one or both of the following: Positive Pressure Ventilation or Powerful Sump Extraction Ventilation. Major Radon hotspot areas in the UK include South West England (especially Cornwall, Devon, Bristol, Bath, Somerset and Dorset), Wales, Cumbria, Northumberland and parts of the Peak District and Gloucestershire .

About us

Perfect Solutions Group UK Ltd is our new umbrella company for all of our brands, as we keep expanding our products and services! Here's a bit about each brand:

Perfect Bindery Solutions is our core family business which was founded in 2005. We specialise in technology and equipment for Print Finishing, Bookbinding and Stationery production. Our portfolio of machinery has been selected to address many post-press requirements for Digital and Litho production.

Our expertise with paper and board production has led us into the packaging sector, thus enabling us to offer equipment for the production of Luxury Boxes, with a new range of high-tech solutions for short to medium runs and fully automatic lines for large runs. This division is branded Perfect Box Solutions.

Perfect Box Solutions then led us further into the packaging sector, specifically to parcel logistics & sortation. We incorporated another division called Perfect Sortation Solutions to deal with automatic parcel sortation systems and secondary packaging such as labelling etc. Our solutions are designed to improve productivity, quality and efficiency. Our machinery is for materials such as paper and board ensuring a sustainable and eco friendly approach to production.

Since these 3 brands have been so successful, and having been introduced to an Active Air Purification system that is being used by printers, production factories as well as hospitals, care homes and other buildings etc we decided to include this within our portfolio of technology, branded Perfect Air Solutions!

One of our customers installed technology to neutralise odours being produced by the printing and laminating processes and found that it also improved the efficiency and general running of the machinery too! This is the only technology that works in real time, purifying every cubic cm of air in the building, reducing the spread of viruses, bacteria, dust, odours, allergens etc therefore also reducing staff absenteeism.

Perfect Air Solutions also supplies solutions for ventilation to increase air flow and destratification fans, helping to regulate factory temperatures throughout the building, no matter the weather, ensuring your staff have a comfortable working environment from Summer to Winter, whilst saving you energy!

Perfect Technical Solutions is our engineering division which looks after all of our machinery safety upgrades, installation, training and factory moves etc.

Images