Company details for:

TM Specialist Engineers Ltd

Quick Links:

Products / Services

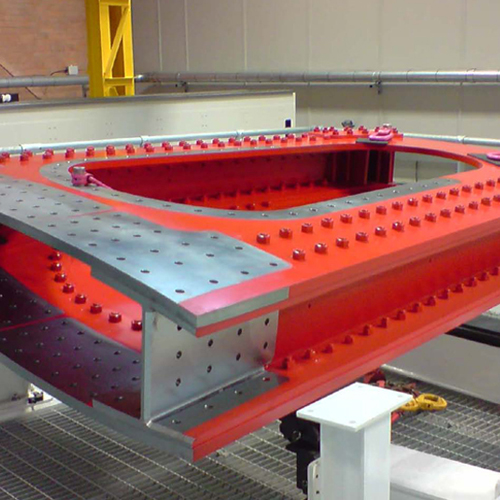

Machine / Mechanical Handling Equipment Assembly

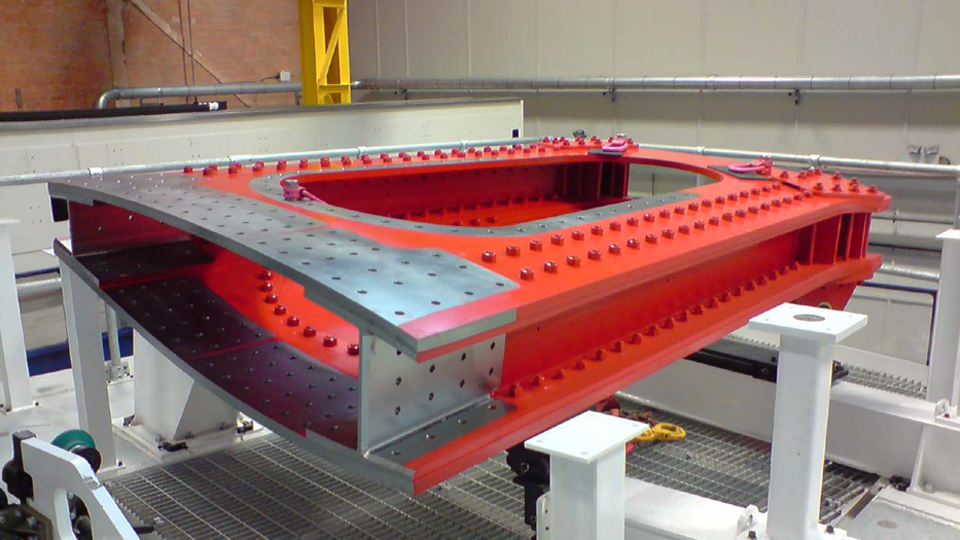

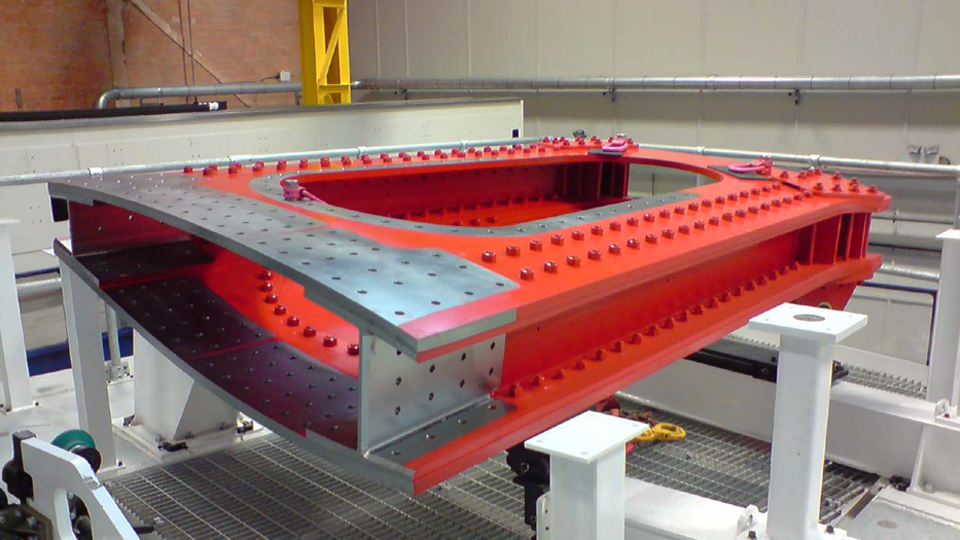

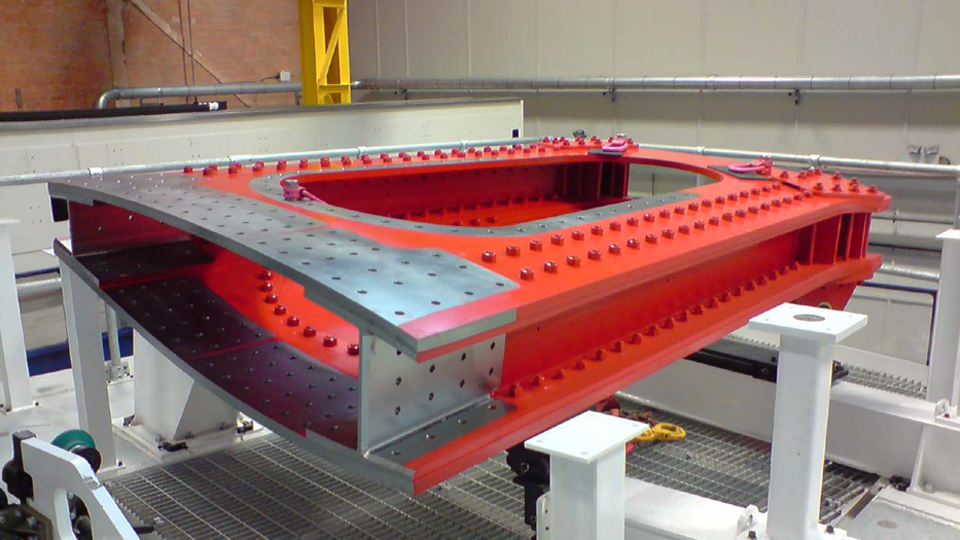

Heavy Steel Fabrication

Our engineers are highly experienced and qualified to work with all grades of Steel, Carbon Steel and Stainless Steel.

Welding operatives’ are fully coded for MMA, MIG and TIG welding with considerable experience of NDT tested welds inspected by Dye Pen, MPI and ultrasonic process.

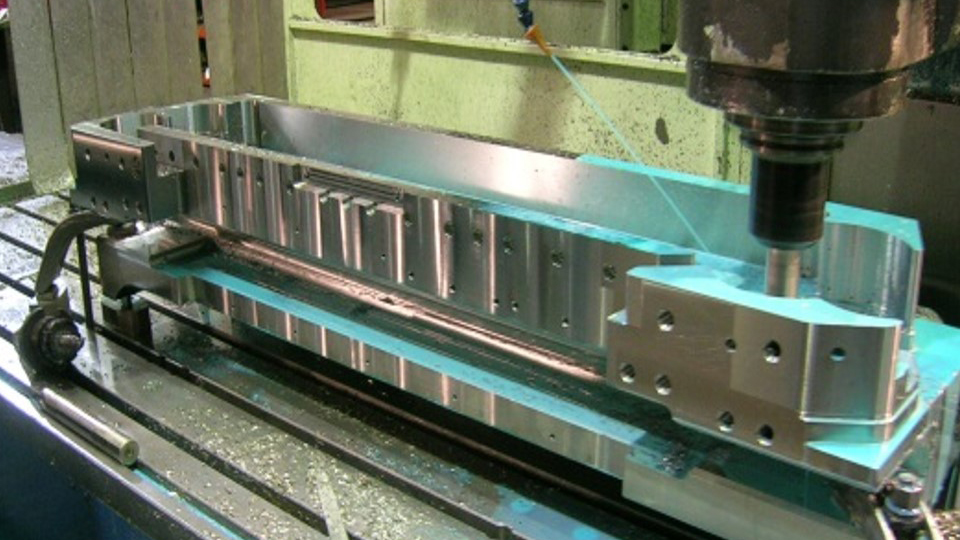

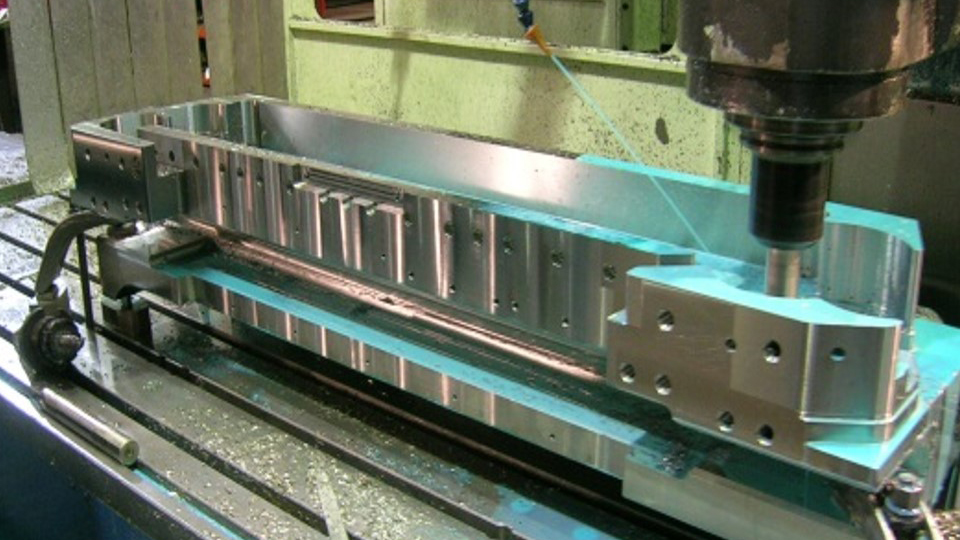

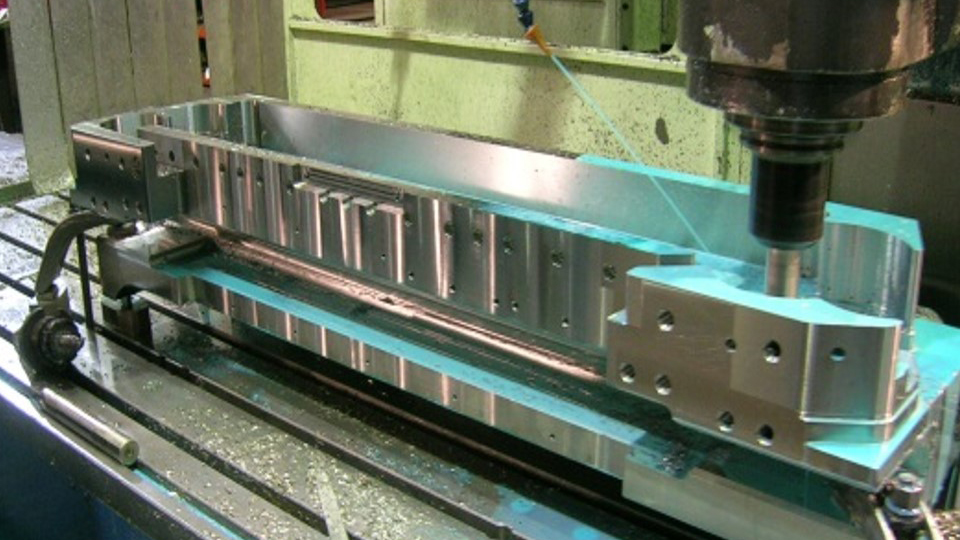

Large Part Precision Machining

TM Specialist Engineers offers an exceptional Large Part Precision Machining service which is promoted on the strength of our machining expertise with the latest CNC machining technology.

We excel in providing cost effective solutions for today’s engineering challenges.

This entails achieving close drawing tolerances and surface finishes on Carbon Steels, Stainless Steel, Aluminium and Titanium.

Large Part Machining Capacity

Our extensive knowledge and experience ensures we meet customers’ large part precision machining requirements; precisely.

The TM Machining Department is fully integrated with TM Fabrication and Machine Building, facilitating a start to finish resource when required. Tolerances are maintained throughout the work cycle, and subjected to In-Process Inspection and Final Inspection on projects varying from clevis pins to 50 tonne base plates. All work complies with appropriate quality standards BS tolerances and customers own stringent specifications.

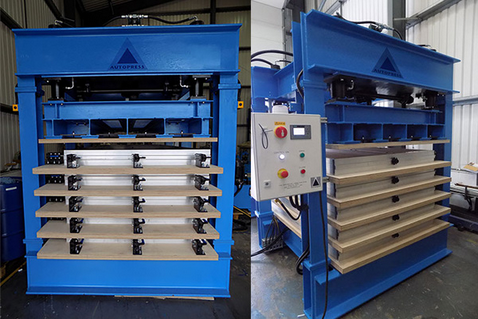

Hydraulic Presses & Shielding

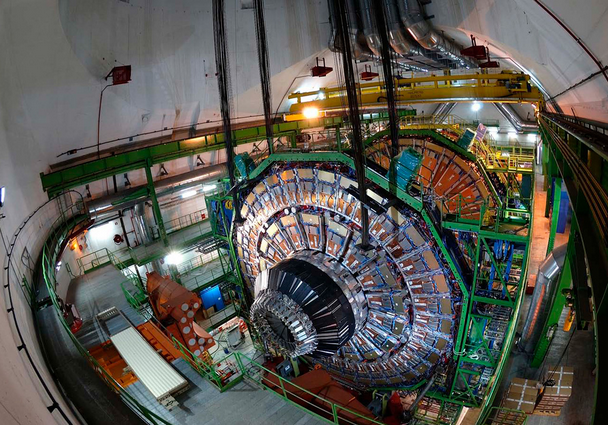

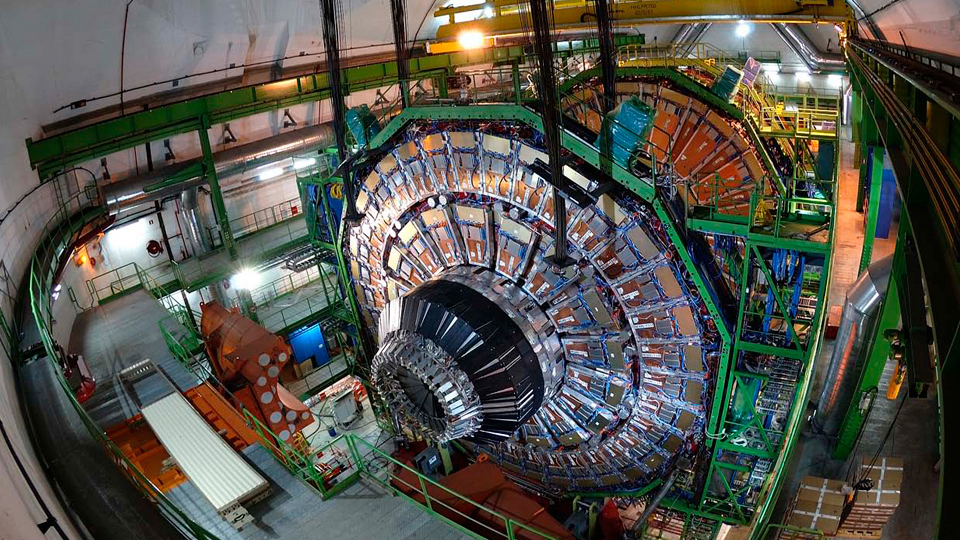

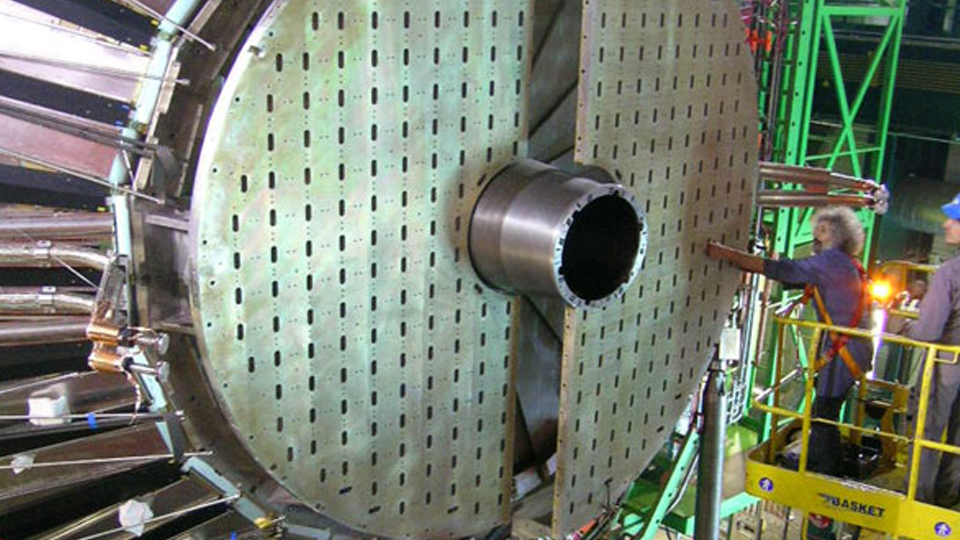

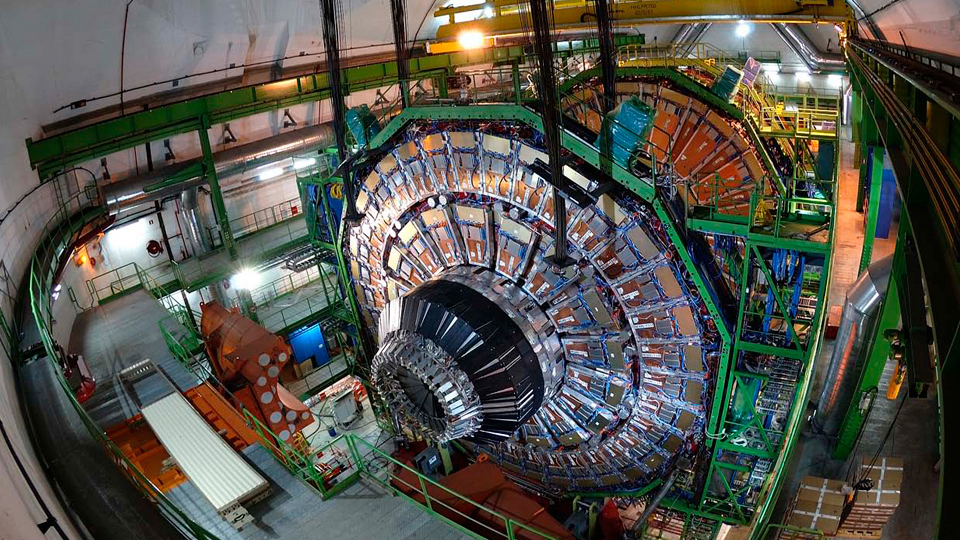

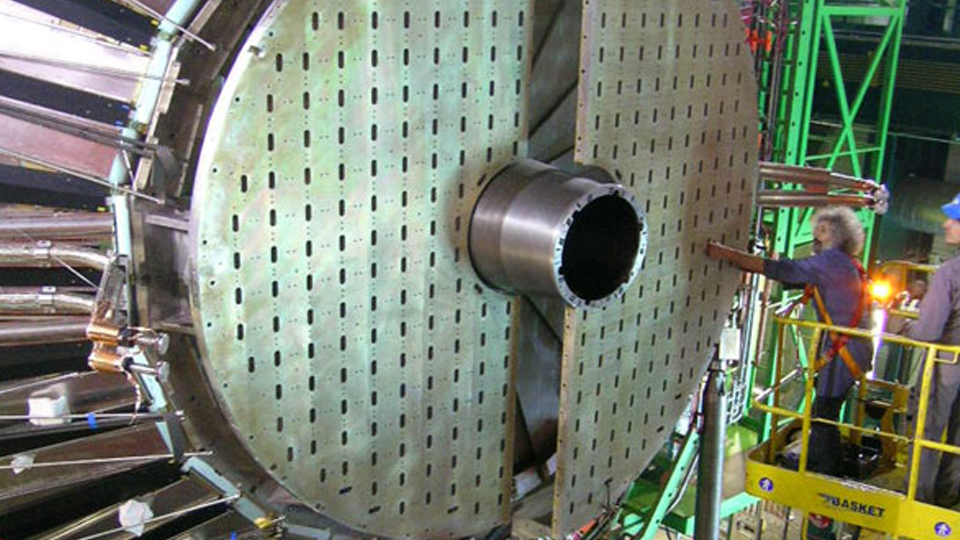

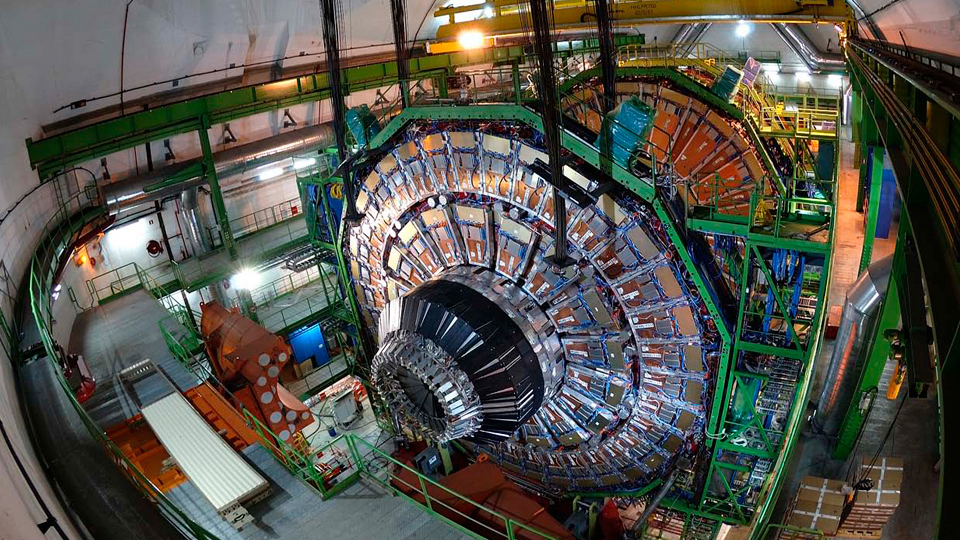

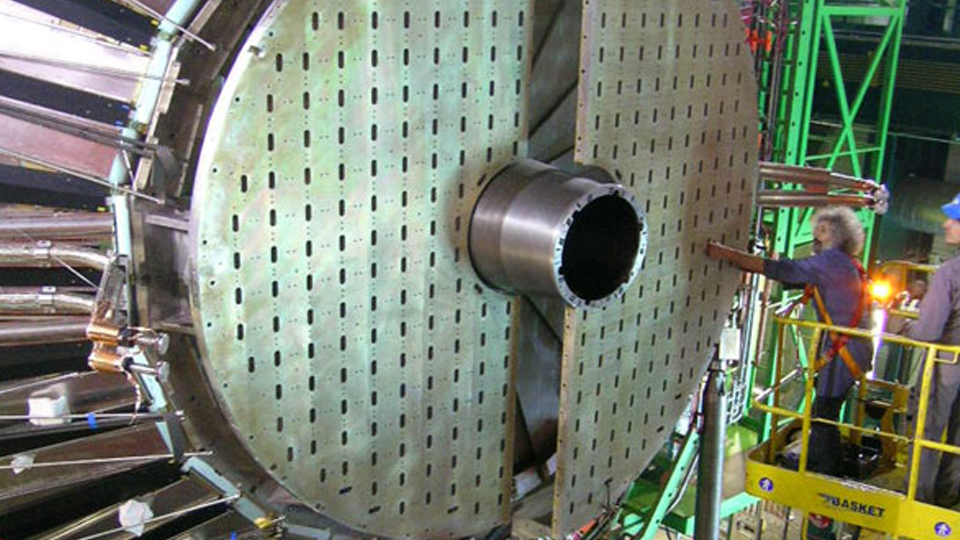

Nuclear Industry Sector

TM has extensive machining and fabrication experience in a wide range of sectors. One sector is the nuclear industry.

About us

Since our formation in 1948, we have focused entirely on meeting our customers’ engineering needs with precision and reliability.

Over the years, TM Specialist Engineers has earned a strong reputation as a trusted provider of high-quality engineering solutions.

We specialise in subcontracting large-part precision machining and heavy steel fabrication for demanding industrial applications.

Our Services:

We provide a variety of services tailored to meet the demands of modern engineering solutions.

Custom Machine Building

Our services encompass a wide array of offerings, ranging from full mechanical assembly to hydraulics, pneumatics, and electrics. Additionally, meticulous testing procedures ensure compliance with both British standards and CE marking requirements, wherever necessary. Furthermore, our comprehensive services extend beyond assembly and testing; we also provide dismantle, pack, and deliver services to any destination. Moreover, for a seamless experience, we offer a complete installation service, ensuring that your equipment operates optimally from the moment it’s set up.

We undertake a diverse range of assignments, spanning from test rig equipment to special purpose handling and machinery, weighing up to 100 tons. Moreover, all our projects adhere strictly to ISO 9001:2015 Quality Accreditation standards.

Large Part Precision CNC Machining

Our machining processes utilise advanced offline programming and a modern operating platform, enabling precise turning, milling, and boring operations in full compliance with ISO 9001:2015 standards.

Benefits

- Large-capacity machining

- Professional, highly customer-focused service

- Operative platform Del Cam, Power shape and feature cam

- Files accepted: DWG, DXF, IGES, STEP, Parasolid (.X_T)

- Fully equipped tool room

- Assembly

Heavy Steel Fabrications

TM Specialist Engineers draws on extensive expertise in all facets of heavy steel fabrication, boasting a proven history of successfully delivering complex and technically challenging large structures.

Our engineers are highly experienced and qualified to work with all grades of Steel, Carbon Steel and Stainless Steel.

Welding operatives are fully coded for MMA, MIG and TIG welding with considerable experience of NDT tested welds inspected by Dye Pen, MPI and ultrasonic processes.

Fabricating large heavy steel structures requires high levels of knowledge and experience, competence and qualification.

Benefits

- Project management service as standard

- Full material Traceability

- Customer-focused attitude

- Professional, highly customer-focused service

- On-time delivery

- Provide material certification in accordance with EN 10204 : 3.1 or 3.2

- Coded welders—up to class 1 nuclear

- Complementary large-part precision machining

- Undertake stress-relieving and painting processes.

- Working relationships with Lloyds Register of Shipping, American Bureau of Shipping Det Norske Veritas and Bureau Veritas

Machining Capacity

Our state-of-the-art machining facility is operated by a highly skilled and experienced workforce, proficient in both traditional craftsmanship and engineering techniques, as well as the latest CNC technology.

Factory Acceptance Tests

Factory Acceptance Tests (FAT) are a vital step in the manufacturing process, where newly constructed equipment, systems, or machinery undergo thorough testing at the manufacturer's site before being delivered to the customer.

The company employs 55 full-time staff located in the heart of the West Midlands, with easy access to major motorway networks. We have made significant investments in machining technology, project management, ISO 9001:2015 quality procedures, and experienced personnel, allowing us to consistently meet customers' expectations for quality, timely completion, and budget adherence.

At TM Specialist Engineers, we take pride in our expertise in providing outstanding engineering and machinery solutions. By choosing us, you’re not just selecting a supplier; you’re forming a partnership with a reliable ally committed to your success.

Images

Brochures

Trade Associations