Company details for:

Daventry Metal Products

Quick Links:

Products / Services

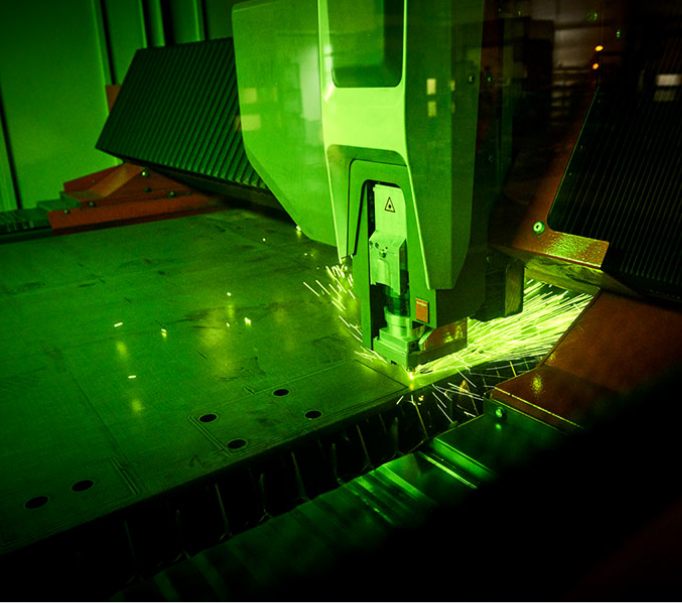

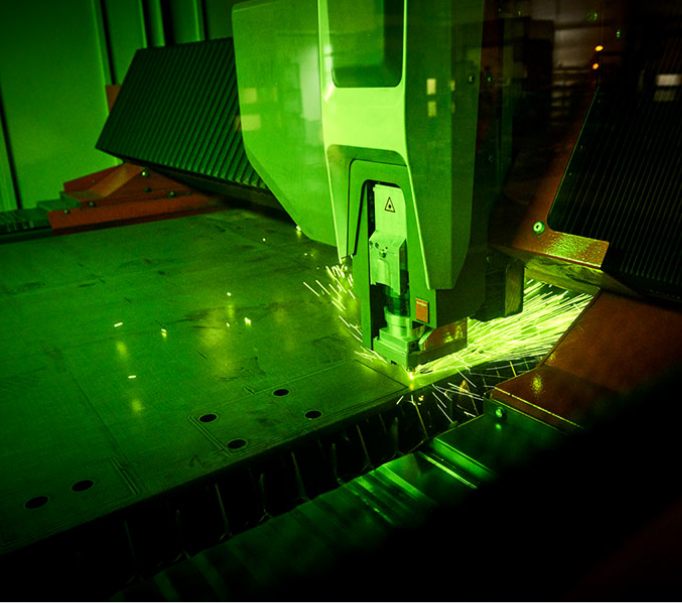

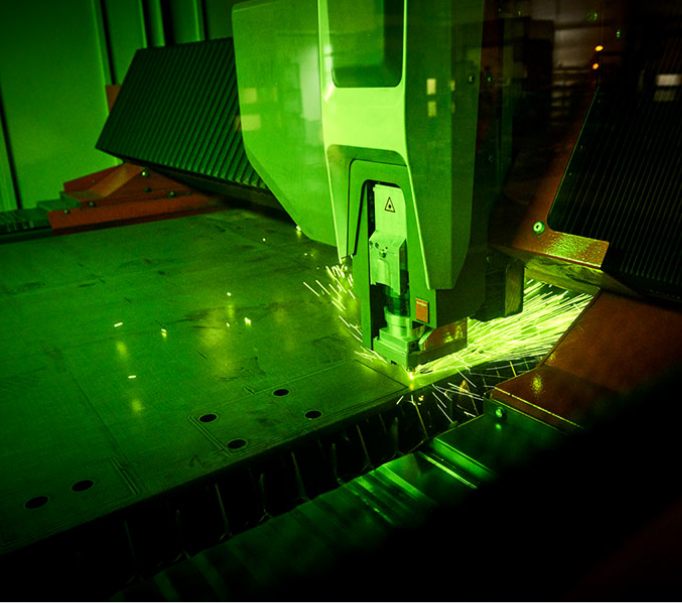

Sheet Metal

DMP have a wealth of experience producing a variety of sheet metal products for industries such as the automotive, medical, power generation, off highway & Marine markets.

DMP maintain a best in class sheet metal processing facility, able to produce products in a short lead time at a commercially competitive level. This level of service means that we are always able to react to any sudden demand charges we see from our customers. It also allows a best in class adaptability to accommodate any engineering changes that may occur as a customer's design progress.

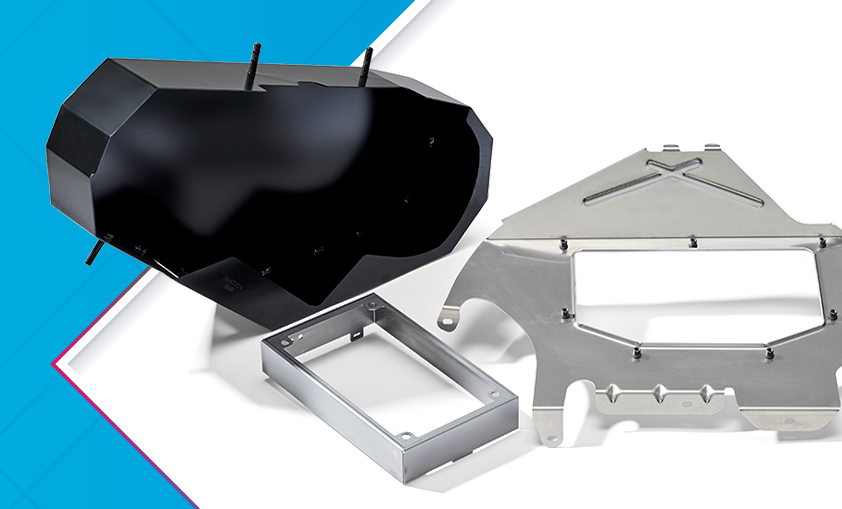

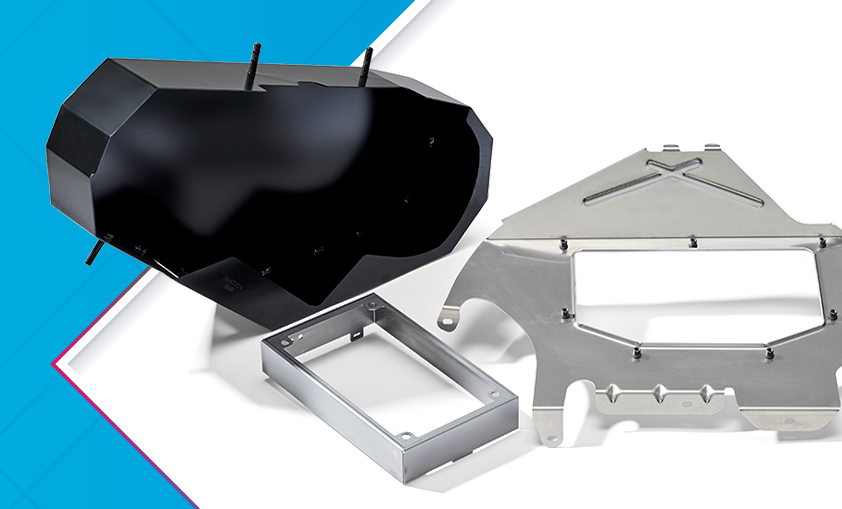

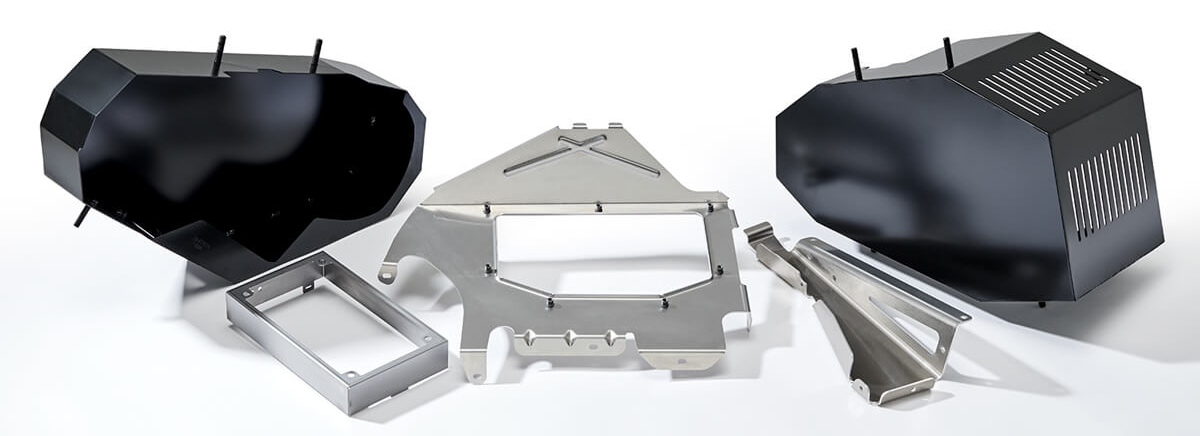

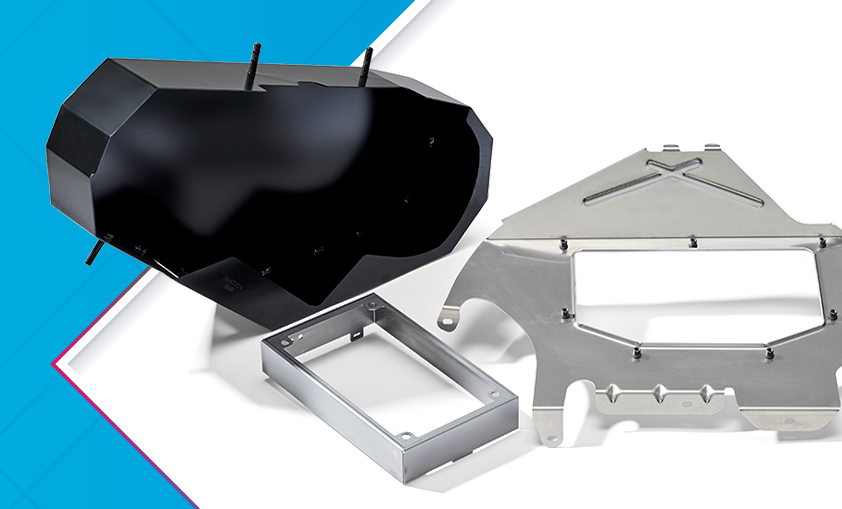

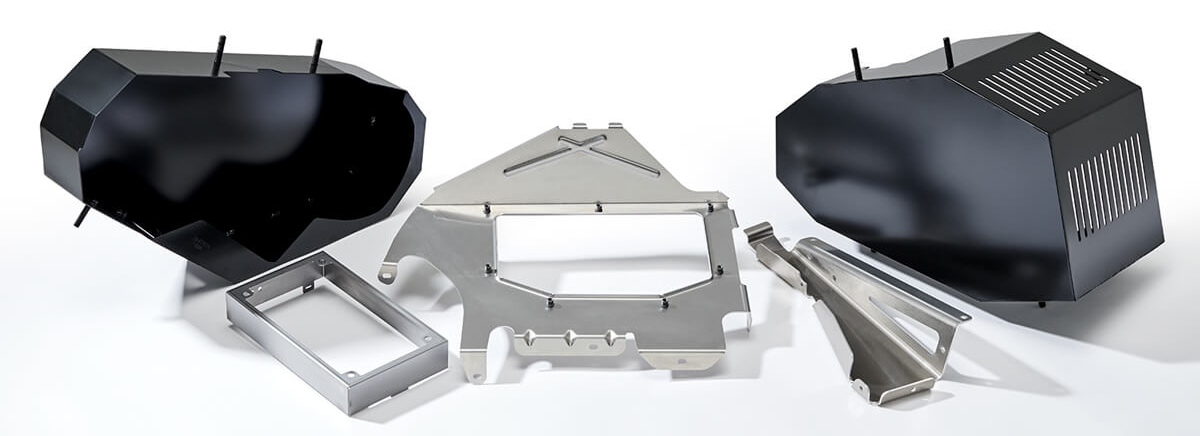

Fabricated Assemblies

DMP offers a capability that is rare to the fabrication sector, in being able to work with a customer to assist in the design phase and carry that through all the way to the series production of a product so that the manufacture phase is optimised to reduce cost and increase quality.

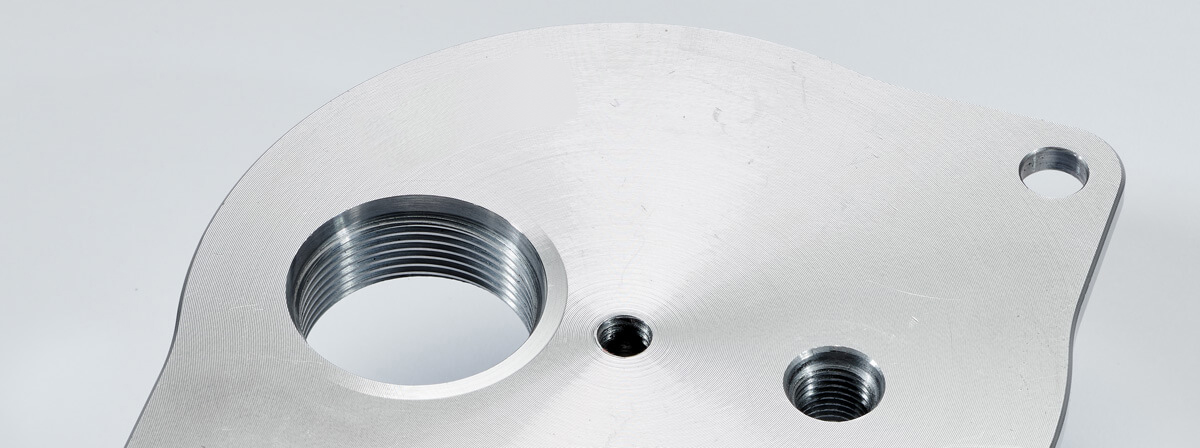

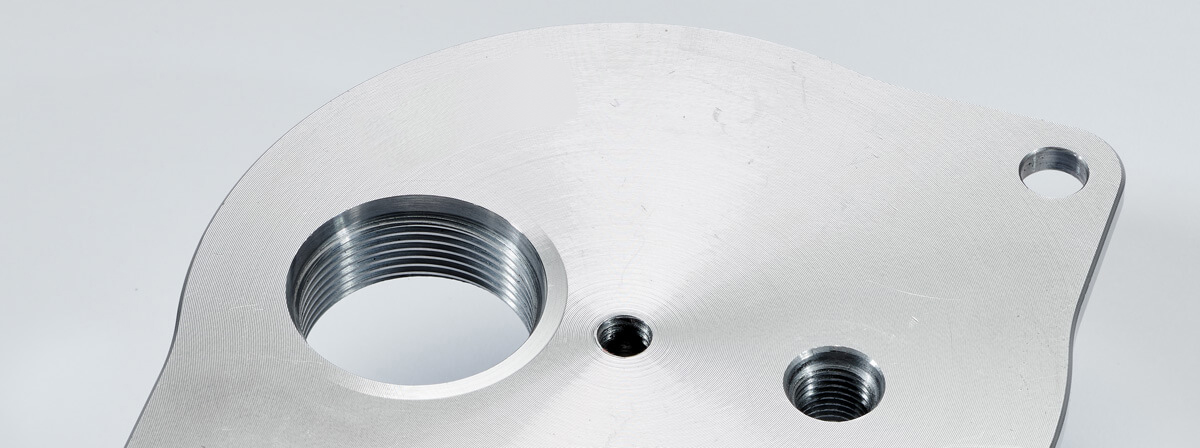

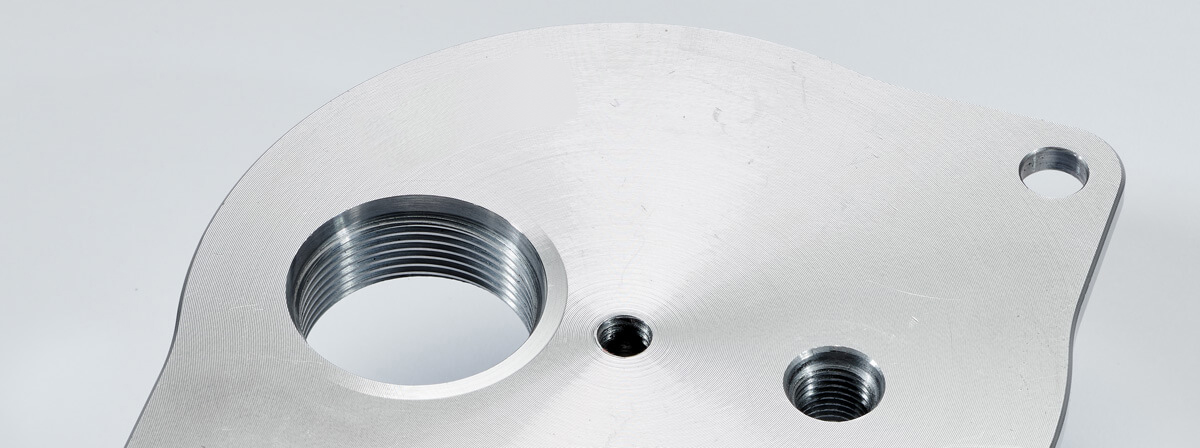

Engineered Products

DMP have a fully equipped CNC Machining facility which is one of the key strategic divisions within the business. The machining facility is capable of accommodating low to high volume turned and milled production parts.

The machining division within DMP supplies both sub assembly products for internal use in a larger assembly and also produces finished parts for shipment direct to customer.

About us

Established in 1974, Daventry Metal Products (DMP) began by producing high-quality engineered components for diverse industries and has continued to grow through strategic acquisitions and ongoing expansion.

DMP started with production and reclamation welding before expanding into the supply of precision-fabricated metal products for industries such as automotive, agriculture, commercial vehicles, power generation, and general engineering.

DMP has transitioned from producing components for its original customer base to becoming a world-class Tier One supplier to leading OEMs.

Our Products & Services Include:

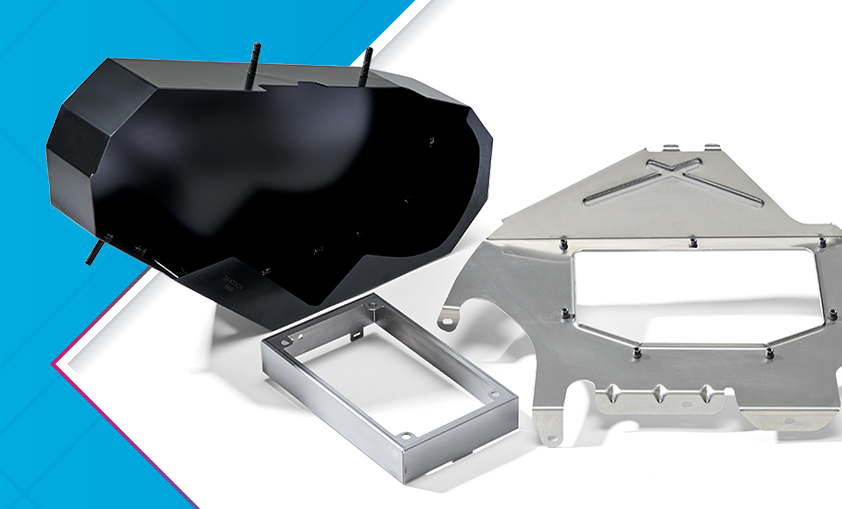

Sheet Metal

DMP have a wealth of experience producing a variety of sheet metal products for industries such as the automotive, medical, power generation, off highway & Marine markets. DMP maintain a best in class sheet metal processing facility, able to produce products in a short lead time at a commercially competitive level. This level of service means that we are always able to react to any sudden demand charges we see from our customers. It also allows a best in class adaptability to accommodate any engineering changes that may occur as a customer's design progress.

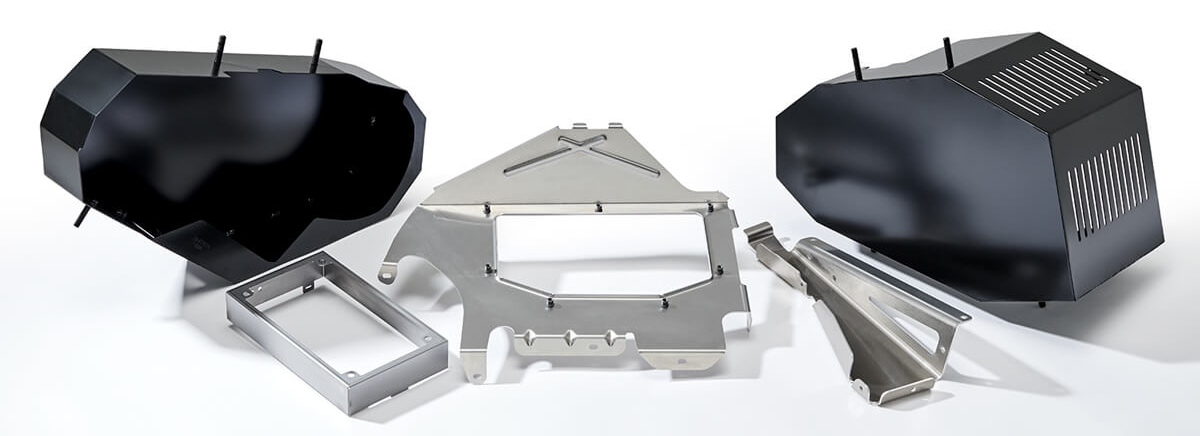

Fabricated Assemblies

DMP provides a unique advantage in the fabrication sector by supporting customers from the design stage through to full-scale production, ensuring manufacturing is optimised for cost efficiency and quality. High-volume precision assemblies are produced using advanced methods including CNC laser cutting, robotic welding, sawing, shearing, rolling, flame profiling, heat treatment, pressure testing, and traditional welding techniques.

Engineered Products

DMP operates a fully equipped CNC machining facility, a vital part of its operations, capable of handling both low and high-volume turning and milling projects. This division produces sub-assembly components for in-house assemblies as well as finished parts ready for direct delivery to customers.

… And more.

DMP runs a comprehensive Quality Assurance System focused on continuous improvement and total quality awareness. Every project undergoes Advanced Quality Planning with Process FMEA to define control measures early on. Using SPC, potential issues are identified in advance, ensuring consistent, zero-defect production.

Driven by continuous improvement, DMP delivers a unique offering in the metal component manufacturing sector—combining full engineering involvement, a skilled and committed team, and cutting-edge technology to provide cost-effective products and services that consistently meet or exceed customer expectations.

Images