Company details for:

GEW (EC) Ltd

Quick Links:

Products / Services

UV LED Curing Systems

GEW’s UV LED curing systems use ultraviolet light-emitting diodes (UV LEDs) as the primary light source. Tens or even hundreds of UV LEDs are built onto GEW’s highly specialised circuit boards − named LED modules. Multiple LED modules are mounted together to create a light array which can vary from 15cm to 250cm in length. GEW offers different UV LED product form factors, power levels and wavelength ranges to satisfy many different application requirements.

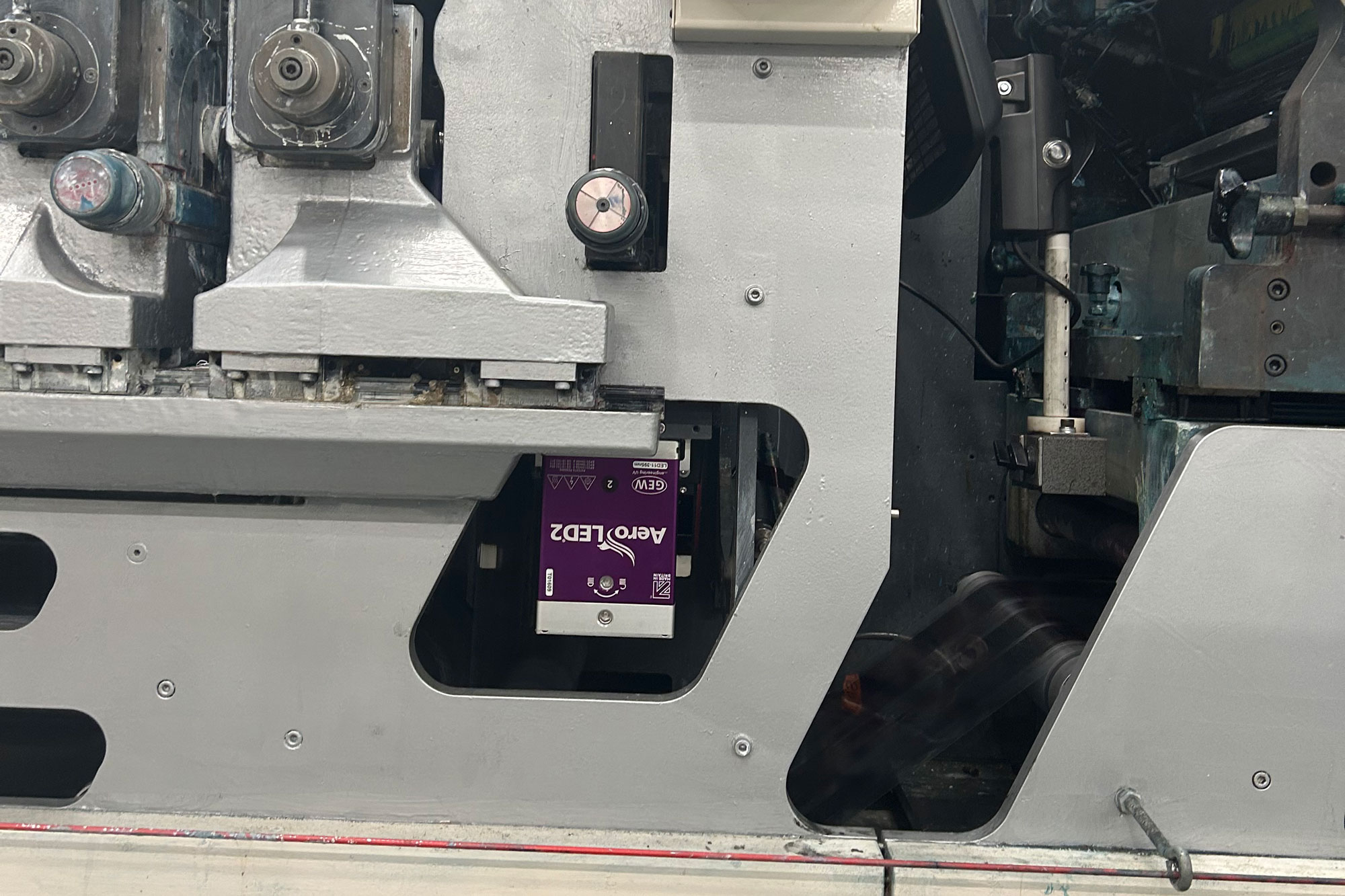

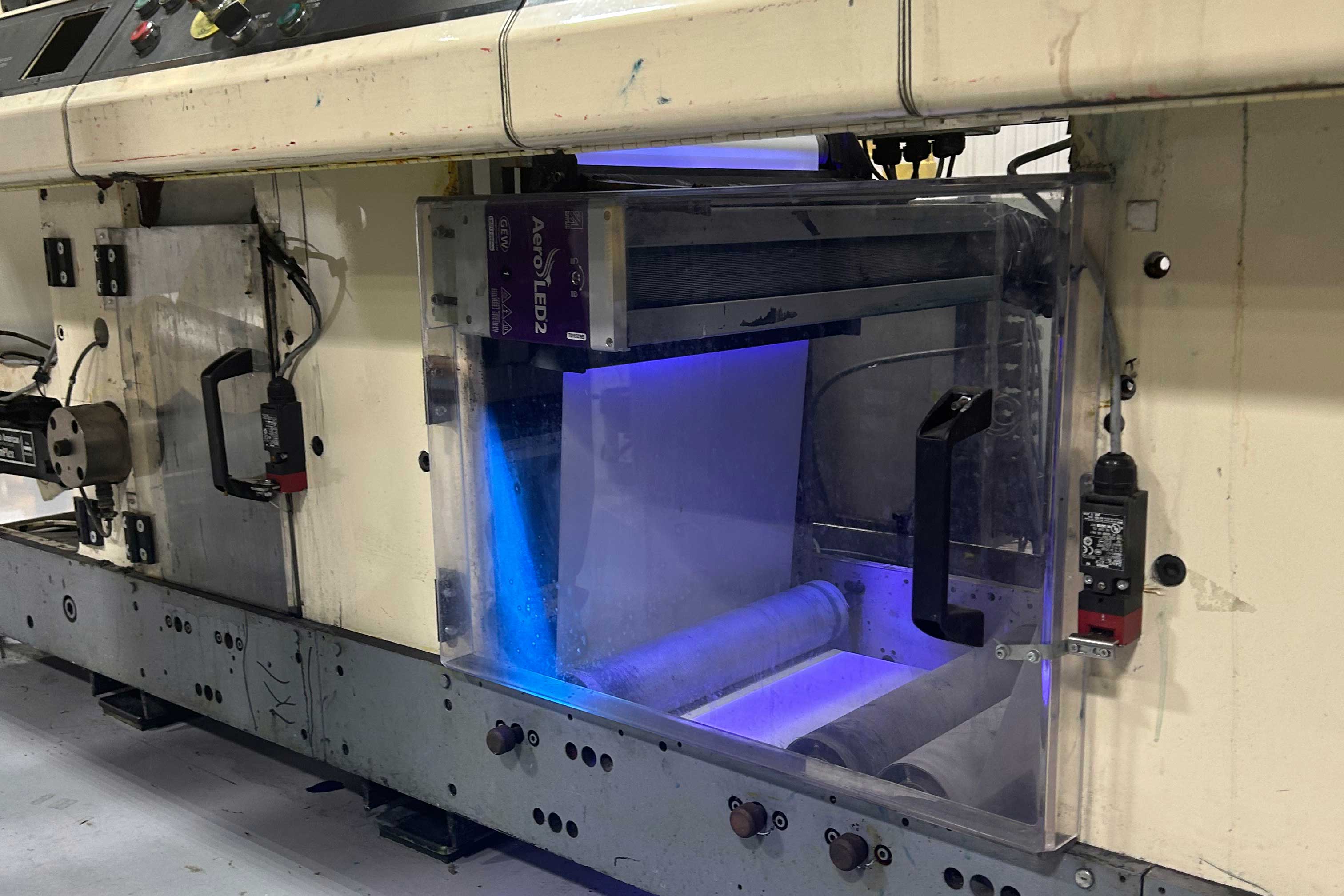

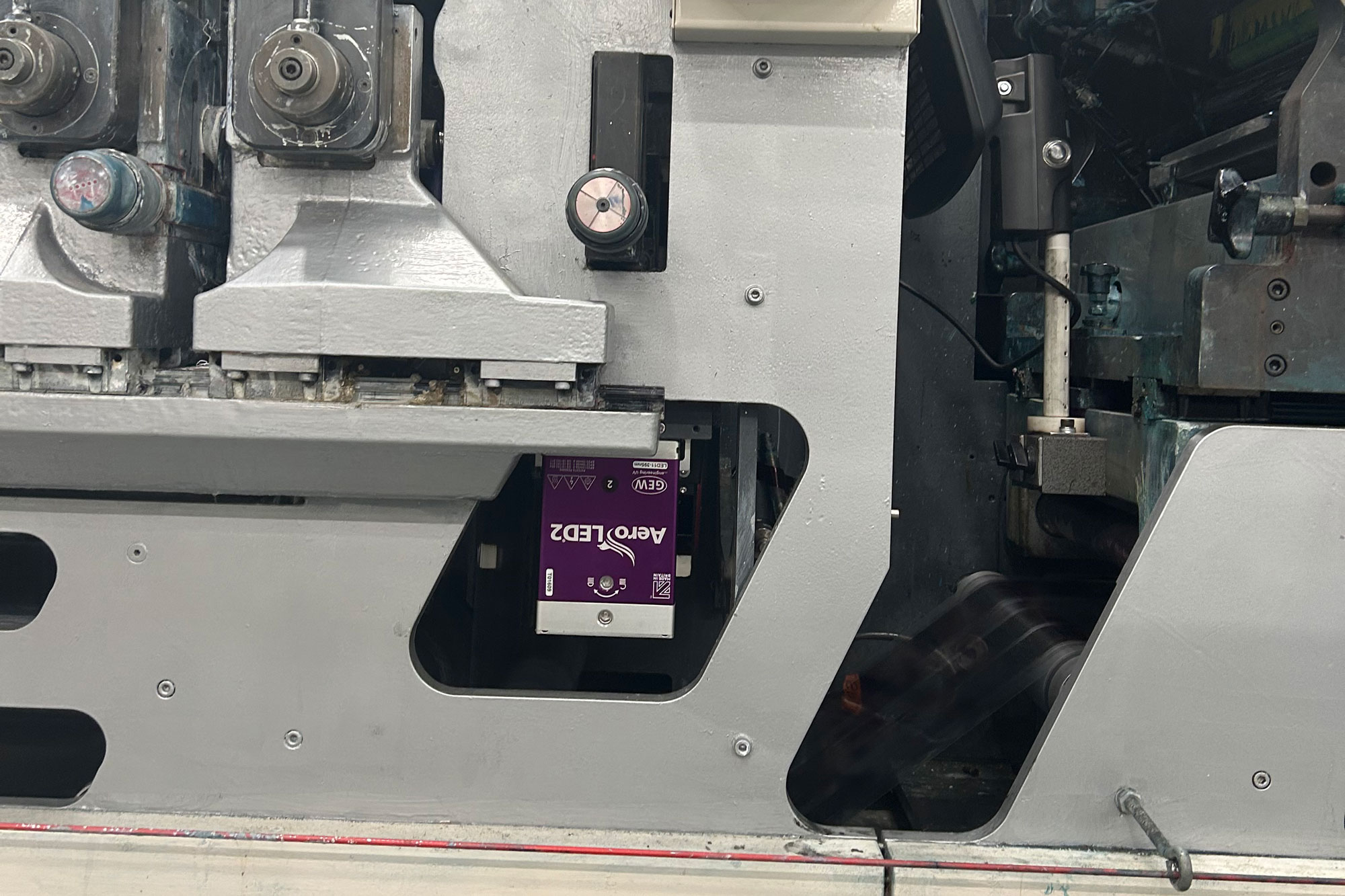

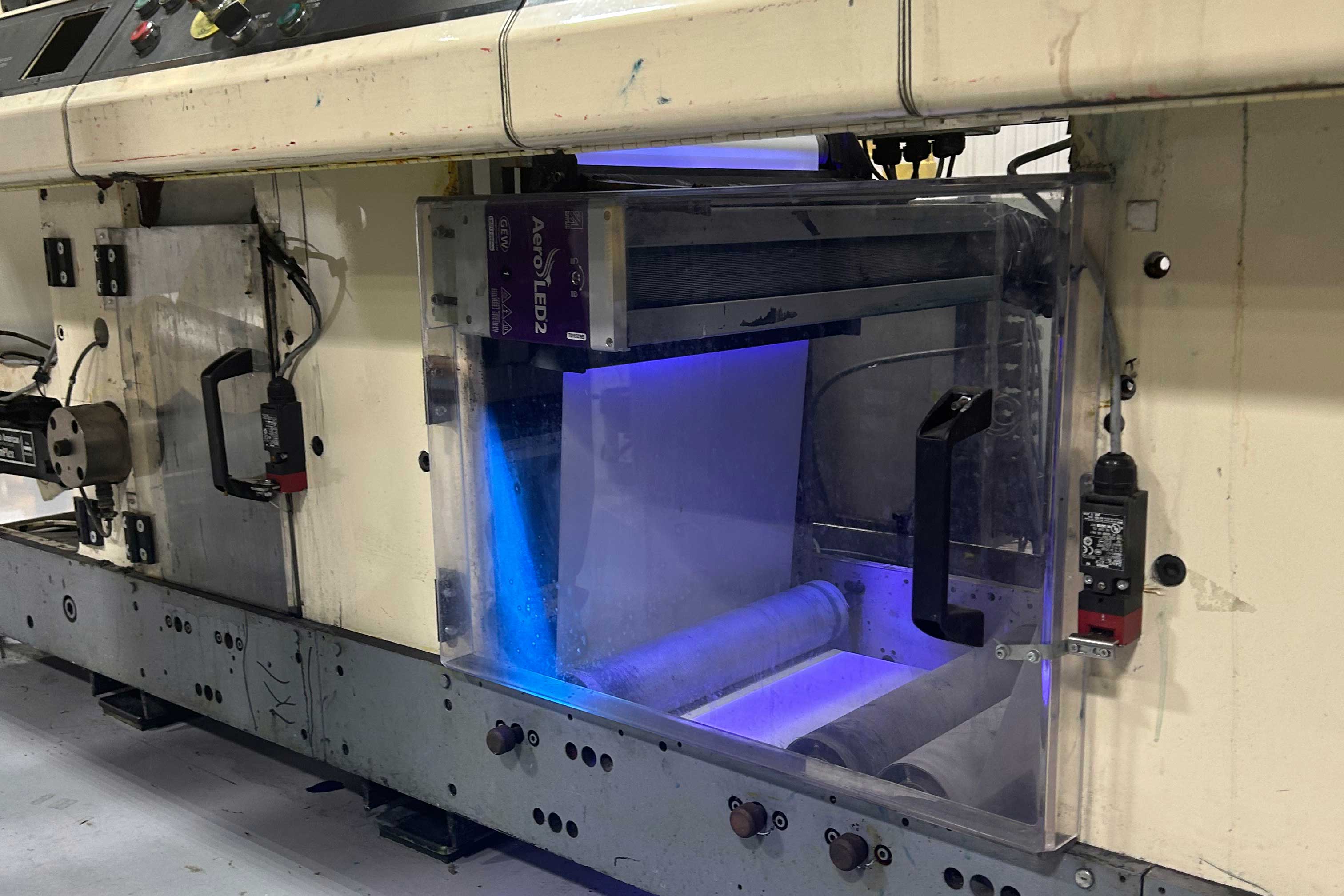

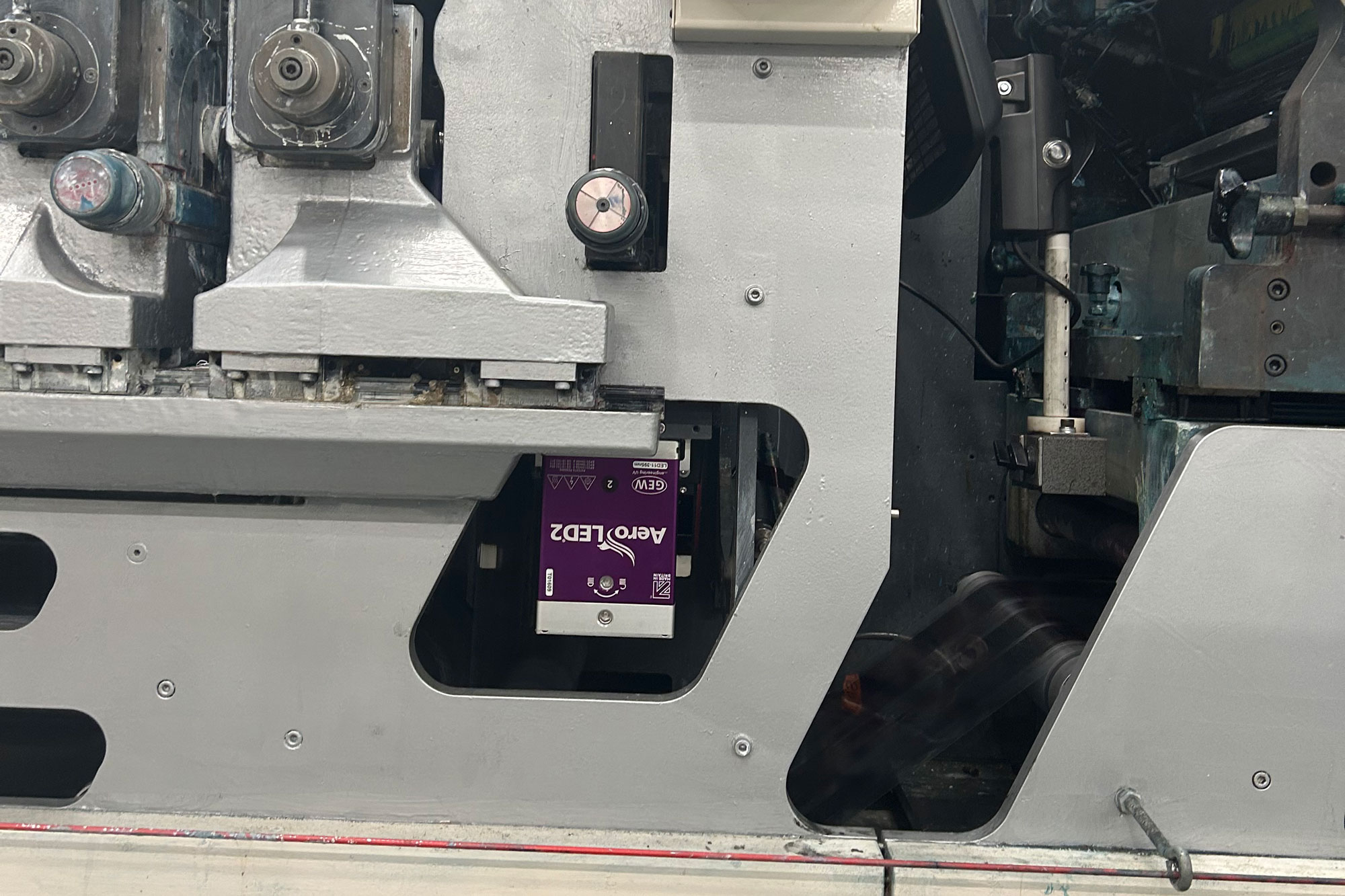

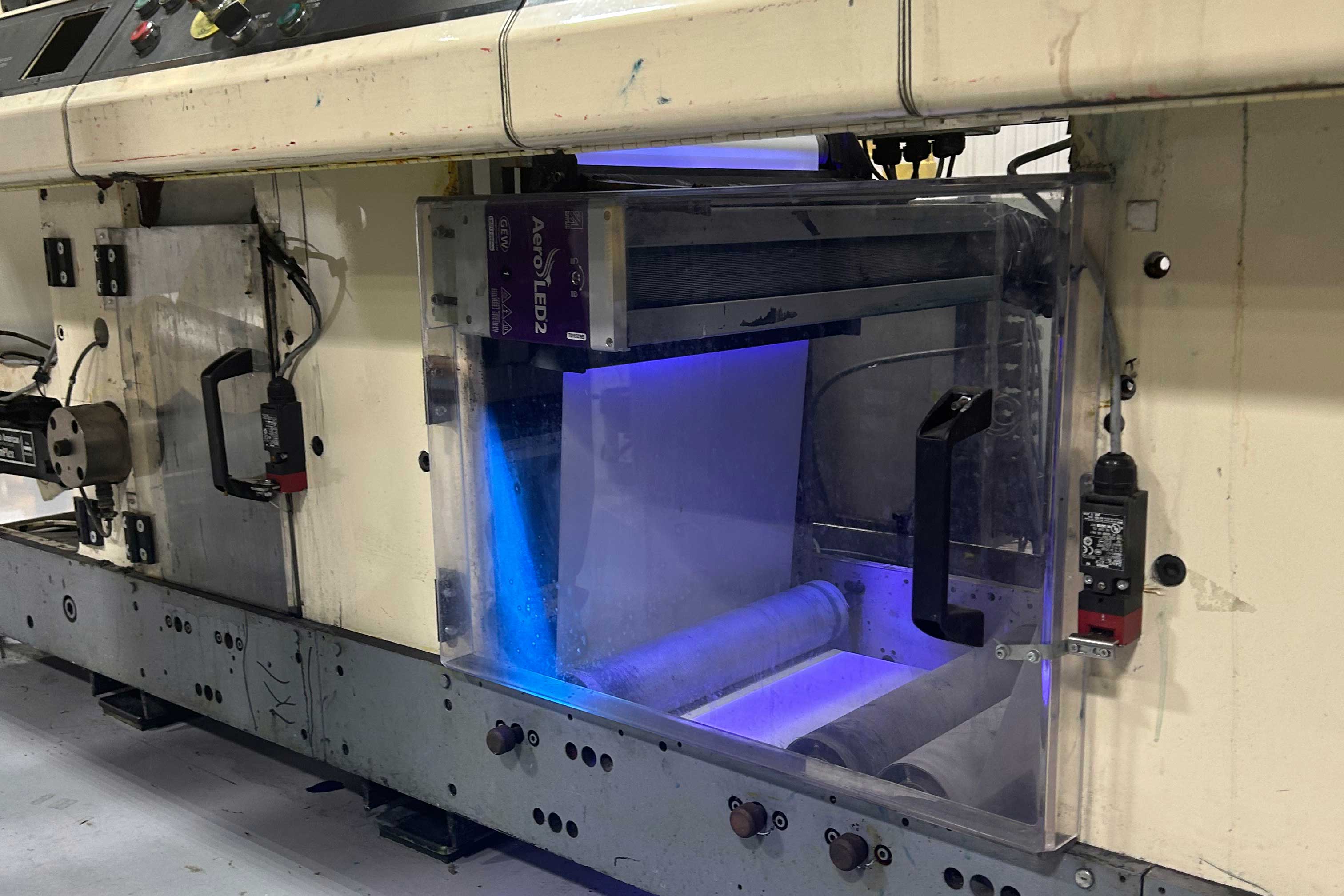

AeroLED2

AeroLED2 is a next generation, higher power UV LED system for full cure, printing, coating and converting applications up to 70cm wide; AeroLED2 offers a 30% increase in electrical power (70W / cm), a 30% increase in UV dose (170mJ / cm2) and a 40% increase in UV irradiance (26W / cm2) compared to its predecessor, AeroLED.

AeroLED2 is also ArcLED compatible. Using the same fan and ducting arrangement as the industry standard E2C, customers have total flexibility to switch between UV arc and AeroLED2 on any station. No filters are required due to the high redundancy, making maintenance a breeze. Moreover any customers with GEW’s RHINO/RLT power supply platform can upgrade to LED within a matter of hours, by simply changing the cassettes and running a software upgrade.

Following its predecessor, in an AeroLED2 system air is extracted by a single centralised fan sited away from the press. There is no need for integrated fans or electronics in the individual lampheads, which eliminates the high pitched noise and risk of failure that these bring. AeroLED2 features the same LED chassis and core components as GEW’s LeoLED2 lamphead, for proven reliability. As with LeoLED2, the lamphead has tough watertight seals to protect the LED modules from ingress and to make cleaning easy and safe. Every aspect of the design has been carefully considered to deliver robust performance and long-term reliability.

AeroLED2’s efficient optical design enables the lowest energy usage of all GEW products. This delivers energy savings of up to 55% when compared to a conventional UV arc system – you can find out your potential energy savings on our ROI calculator. In addition to offering greatly reduced operating costs, printers upgrading to AeroLED2 are able to free up >50% of mains capacity, which can then be used to install new machinery and subsequently increase production capability. Two AeroLED2 systems have a lower electrical supply requirement than just one conventional arc UV system.

A further advantage of LED is its predictability and stability of UV output in the curing process. AeroLED2 delivers improved process control by ensuring stable UV output year after year, and eliminates the uncertainty of conventional UV lamps, reflectors and mechanisms to ensure consistent production quality. As is the case with all new GEW UV products, AeroLED2 uses GEW’s RHINO power supply and control range, for ultimate reliability with Industry 4.0 approved, IoT Remote Monitoring as standard.

LeoLED2

LeoLED2 takes LED performance to new heights over GEW’s already highly-acclaimed, water-cooled LeoLED system. Offering a 55% increase in electrical power (140W / cm), a 50% increase in UV dose (300mJ / cm²) and a 45% increase in UV irradiance (44W / cm²) compared to its predecessor, LeoLED2 is GEW’s next generation UV LED curing system that guarantees the best performance on the market for the most challenging curing applications.

As with the generation 1 model, LeoLED2 is available in both a cassette version and a compact version, depending on the requirements of the customer, their equipment and their application. Both models are designed to interchange with every current arc lamp model in GEW’s range. This patented ArcLED technology gives ultimate flexibility on press, no matter the application.

Like all our UV products, LeoLED2 is powered by GEW’s RHINO power supply for ultimate reliability and controlled by RHINO Control which comes as standard with IoT remote monitoring. This allows our customers the flexibility to go ArcLED without having to invest in a whole new, independent system. For customers with a GEW arc system installed, an upgrade can be as simple as adding a chiller, a UV LED lamphead, and running an upgrade.

LeoLED2 also comes in two power level options, offering ultimate customisability to customers, depending on their application and energy saving needs, whilst providing faster printing speeds alongside GEW’s renowned process reliability.

UV Lamp Curing Systems

GEW’s UV lamp curing systems use medium pressure mercury vapour lamps as the UV light source. Depending on power level, length of lamp and form factor required, GEW have various lamp systems with different cooling methods to meet a vast array of UV irradiation applications.

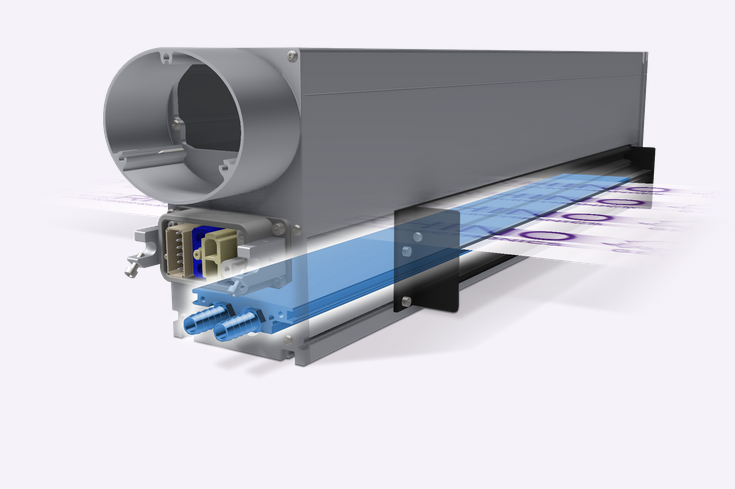

E2C

E2C is GEW’s most popular UV dryer with over 30,000 units installed worldwide. Fully air cooled, it delivers unparalleled curing performance up to 140W/cm due to patented ultra-efficient reflector designs. No similar product delivers more curing performance at this energy level.

Perfect for use on any machine up to 60cm in width, E2C supports printing on the widest range of heat-sensitive materials because our actively air-cooled reflectors reduce heat transfer to the substrate. It also boasts GEW’s renowned quick-change cassette design enabling a new lamp to be fitted in under 2 minutes with only one hex key tool required.

E2C HP

E2C HP comprises a standard E2C UV lamp cassette housed in a larger casing to enable more air cooling and thus higher running power, up to 180W/cm. Perfect for low migration or high speed print applications up to 80cm wide, it boasts the same reliability and patented reflector designs contained in GEW’s most popular E2C product.

E2C HP still supports printing on the widest range of heat-sensitive materials because our actively air-cooled reflectors reduce heat transfer to the substrate. It also boasts GEW’s famous quick-change cassette design enabling a new lamp to be fitted in under 2 minutes with only 1 hex key tool required.

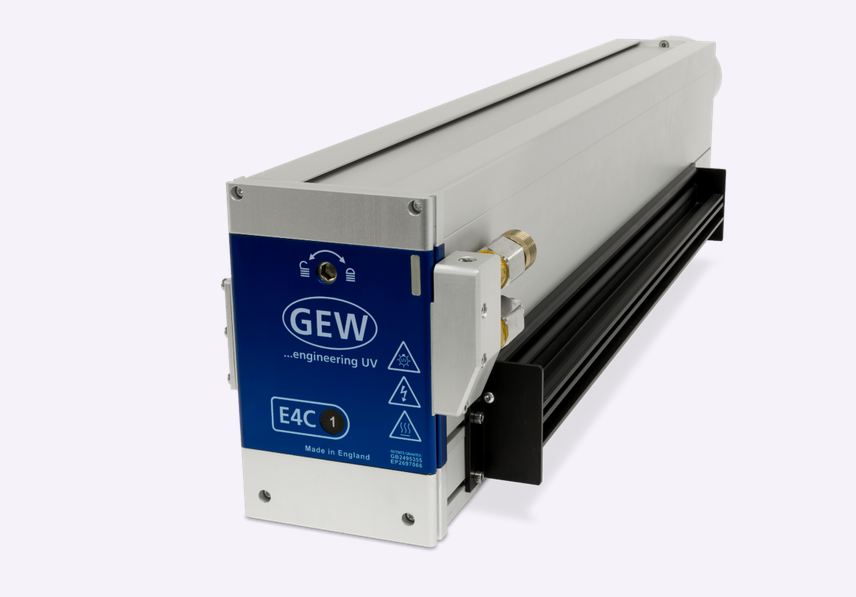

E4C

E4C offers the highest power available from the GEW range, to support the most demanding UV curing applications and the fastest printing speeds on web or sheetfed machines. It performs to the harshest cure test procedures and is suitable for low migration applications.

E4C has optically tuned reflectors to maximise curing power and operates quietly, with minimal air requirements. Water flow monitoring technology ensures water flow at all times, and the E4C’s water-cooled reflectors support the highest UV power whilst limiting heat transfer to the substrate, making it safe for a broad range of heat-sensitive materials.

NUVA2

NUVA2 is the most effective UV curing system for wide web coating and specialist industrial applications. Fully air cooled up to 250cm and available up to 27kW total lamp power, NUVA2 is available with a wide range of customisation and integration options.

GEW’s patented reflectors are actively cooled to ensure that heat transfer to the substrate is minimised, whilst delivering the highest UV intensity and dose available. The quick-change cassette design ensures fast lamp changes with only 1 hex key tool required and the innovative spherical lamp ends prevent breakages on long lamp changes.

NUVA2 HP

NUVA2 HP is the same NUVA2 cassette in a narrower format − the extra cooling available allows running up to 240W/cm, with maximum power decreasing as lamp length increases. Fully air-cooled, NUVA2 HP is available with a wide range of customisation options and is perfect for final cure inkjet applications (with iron-doped lamps) or high-speed web machines.

GEW’s patented reflectors are actively cooled to ensure that heat transfer to the substrate is minimised, whilst delivering the highest UV intensity and dose available. The quick-change cassette design ensures fast lamp changes with only 1 hex key tool required and all replaceable components are plug and play for easiest maintenance.

Excimer Systems

GEW’s ExciRay lamp systems utilise dielectric barrier discharge (DBD) lamps to produce quasi-monochromatic vacuum ultraviolet radiation, typically at 172nm. This radiation is commonly used for mattification of surface coatings, modification of surface tension for improved adhesion or surface cleaning for semiconductor and medical industries.

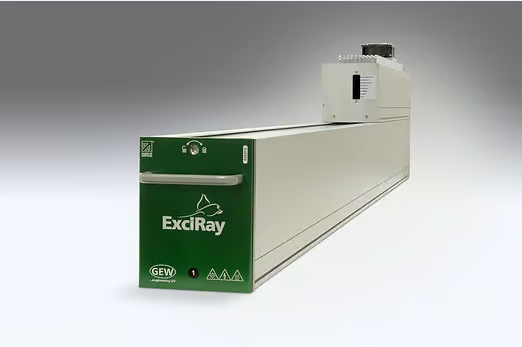

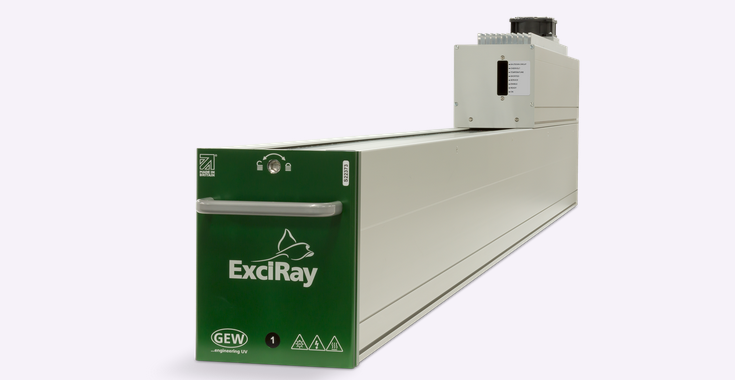

ExciRay Lamps

GEW’s ExciRay lamp systems utilise dielectric barrier discharge (DBD) lamps to produce quasi-monochromatic vacuum ultraviolet radiation, typically at 172nm. This radiation is commonly used for mattification of surface coatings, modification of surface tension for improved adhesion or surface cleaning for semiconductor and medical industries.

GEW ExciRay lamps, which are incorporated into the familiar NUVA2 cassette design, can be produced up to 255cm in length and can be custom integrated for your specific application, including provision for all required nitrogen inerting and control.

UV Lab Units

GEW designs and manufactures UV laboratory equipment, or UV lab units, for use in research & development and press room facilities. LED and mercury arc lamp variants are available immediately from stock while custom laboratory units can be manufactured to meet a wide range of requirements using any combination of GEW’s production UV systems.

UV LED Lab Unit

GEW’s LED lab unit utilises a high precision linear drive to pass a sample tray under the UV LED array.

Variable speed control ensures highly repeatable testing up to 100m/min with UV power adjustable in set increments and LED array height adjustable up to 25mm.

A simple magnetic hinged tray carries print samples or can accommodate an EIT radiometer for precise UV power measurement.

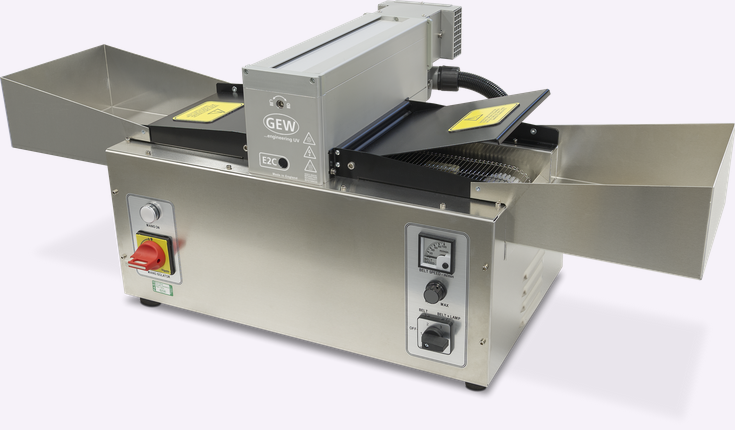

UV Lamp Lab Unit

The UV lamp lab unit utilises a 150mm wide stainless steel conveyor belt to drive samples under the UV lamp at variable speeds up to 70m/min.

The E2C UV lamp contains an ozone-free bulb to prevent the need for duct extraction and an integrated fan controls the lamp at a constant 80W/cm.

A robust, bench-top curing unit incorporating simple feeder/catcher trays, it is a perfect, cost-effective tool for laboratory, press proofing and even low volume production.

UV Control Systems

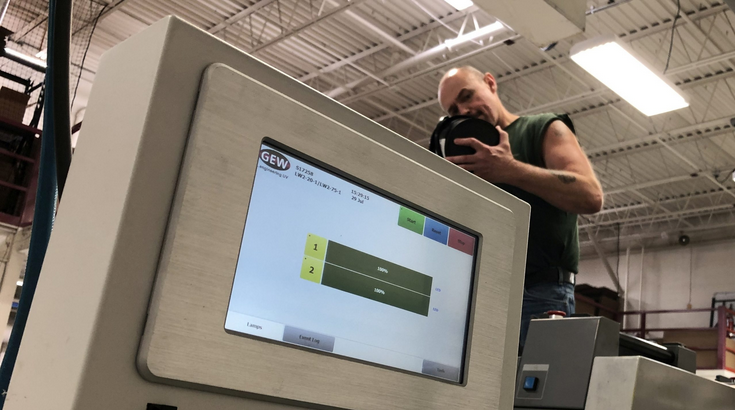

GEW UV systems are controlled by a combination of user commands and settings (entered on a modern industrial touchscreen), as well as machine signals which are either hardwired or electronically communicated to the GEW RHINO power units. GEW’s proprietary RHINO software is able to handle a vast array of common industrial control interfaces from simple relay logic to web-based APIs.

The HMI itself has a simple user interface for operating all key parameters on up to 16 lamps simultaneously, customised for each specific machine configuration. Optional accessories such as GEW’s UV monitoring or inert gas chambers are also controlled through the same user interface. It can be mounted freestanding in any location on or around the press or bevel mounted for seamless integration in machine panels.

UV Cooling Systems

All UV systems produce excess heat which must be efficiently removed to ensure uniform, stable & long-term output of the ultraviolet radiation. GEW utilises air, water and/or nitrogen cooling across the wide variety of products produced. All cooling systems are rigorously designed and tested internally by GEW to ensure perfect compatibility with your UV system.

Air cooling systems typically consist of a central fan connected to a rigid steel ducting manifold which runs the length of the press. Outlets at regular spacing are connected to the lamps via flexible ducting and an automatic damper valve controls the volume of air passing through the lamphead ensuring it remains at constant temperature. The central fan is ducted to atmosphere outside the factory.

UV Power Systems

GEW UV arc and LED systems are powered by the proprietary RHINO and RLT power supplies. Available in a range of sizes up to 27kW, they are custom designed and manufactured by GEW, exclusively to power our UV systems. They meet the highest international safety standards (including ETL listing for all RHINO units), are monitored over the internet 24/7 and can be purchased with up to a 5-year warranty − unparalleled in the industry.

Every power supply is equipped with GEW’s ArcLED technology, enabling both UV arc and LED to be powered interchangeably by the same unit. Every RHINO & RLT system in the field is ready to run LED − only the LED lamp and chiller are required to make this change.

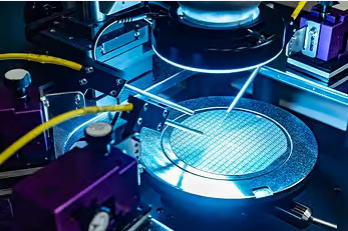

UV LED Modules

The UV spectral output of an LED is relatively monochromatic compared to broadband mercury sources. The material structure of the LED semiconductor determines the exact UV output wavelength, which is fixed and unchanging for each individual diode. Typically, a UV LED module will contain many LEDs with very similar UV spectra and will be specified at a nominal peak wavelength (e.g. 395 ± 5nm).

All GEW LED modules are available with peak wavelengths of 365, 385, 395 or 405nm, with a range of market leading irradiancies to suit many different applications.

Contact us to discuss which option is right for you.

Substrate Cooling

The UV curing process is energy-intensive and causes both direct and indirect heating of the target substrate, which in the majority of cases needs to be controlled. For safety reasons, some form of barrier behind the target substrate to shield off and dissipate stray radiation from the lamp is essential for protecting the machine and its operators. The three most common methods of substrate cooling that meet both of these requirements are:

Air cooled heatsinks

Water cooled heatsinks

Water cooled chill rollers

Where roll material is being processed, the most common solution for this is an extruded aluminium heatsink plate. GEW have a very neat solution for this which is integral to the UV lamphead and can be either air or water cooled, depending on the application. For the majority of processes this method is very effective, unless very heat sensitive materials are being used.

Inert Gas Curing

Under normal atmospheric conditions, oxygen reacts with photoinitiators in the ink after they are exposed to UV light. This renders some of them inactive and limits the extent of polymerisation that can occur. The coating is then poorly cured or the process is forced to run much slower. This is where inert gas curing comes into play.

Curing under an inert atmosphere eliminates oxygen and significantly increases the rate and extent of cross-linking. Curing speeds are greatly improved, migration of harmful materials is reduced and the finished product odour is better.

Quartz Window

In the majority of cases it is best to have a direct path of radiation from the UV lamp to the target area to maximise the curing effect. However, in some cases, the application necessitates a quartz glass filter to be installed in the lamp’s emitting window.

About us

GEW (EC) Ltd designs and manufactures Arc, UV LED and Excimer curing systems used in various applications such as printing, coating, and converting.

GEW are recognised as the primary manufacturer of UV systems specifically designed for label and narrow web printing. Moreover, GEW is rapidly expanding its presence on a global scale in the sheetfed and web offset sectors, catering to the needs of commercial printing and packaging industries. GEW's UV systems are not only available for new machinery but can also be retrofitted onto existing active presses, providing an opportunity for printers to rejuvenate their older printing equipment. The company operates a top-notch production facility at our headquarters in the UK and has subsidiaries located in the USA and Germany. Additionally, GEW has established an extensive network of distributors worldwide.

Recently, GEW's focus has been in the design and installation of UV LED systems, having introduced its latest UV LED products, AeroLED2 and LeoLED2, in early 2024. Representing the next generation for UV LED curing, AeroLED2 and LeoLED2 offer improved electrical power, UV dose and UV irradiance specifications compared to their first-generation predecessors, and both remain compatible with GEW’s patented interchangeable ArcLED system.

AeroLED2 is GEW’s next generation air-cooled offering and eliminates the need for a chiller by air-cooling from a single remote fan, to bring UV LED within affordable reach for all. It is also newly available for wider web widths, to cater for more presses in the narrow web market.

In comparison, LeoLED2 introduces two power level options to GEW’s acclaimed water-cooled system. The regular power option offers modest gains over the original LeoLED, while maintaining backward compatibility. The high-power option, however, brings game-changing increases in UV irradiance and dose over its predecessor, delivering unprecedented performance for the most extreme curing challenges across the most demanding curing applications.

GEW places a strong emphasis on providing long-term support and excellent customer care, ensuring that their UV systems maintain optimal efficiency throughout the entire lifespan of the machines they are installed on. The company's commitment to ongoing assistance and maintenance services guarantees that the UV systems continue to operate smoothly and effectively. By prioritising customer satisfaction and offering comprehensive support, GEW ensures that our UV systems deliver consistent performance and reliability, providing customers with peace of mind.

Our commitment lies in providing effective UV curing solutions that enable our customers to achieve faster and continuous printing operations, minimising energy consumption and eliminating downtime.

Images