Company details for:

J-TEQ EMS Solutions Ltd

Quick Links:

Products / Services

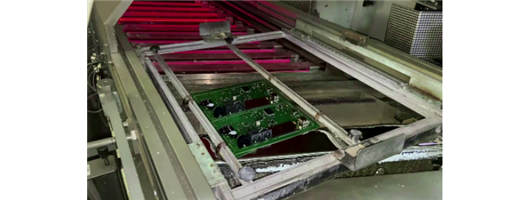

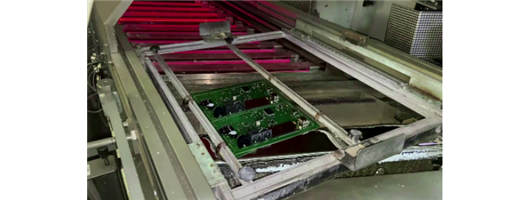

Surface Mount Technology PCB Assembly

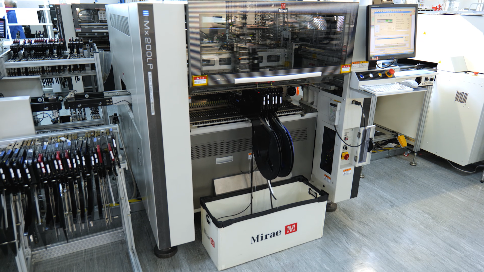

Surface mount technology (SMT) is a method for assembling printed circuit boards (PCBs) where electronic components are soldered directly onto the board’s surface instead of being placed through drilled holes.

SMT is now the most commonly used technique in modern PCB design and assembly.

Through Hole Technology PCB Assembly

Through-hole technology is a PCB assembly method where component leads are inserted into plated holes (vias) and soldered to pads on the opposite side, forming a strong pin-to-pad metallurgical connection.

This technique is preferred for applications requiring high mechanical strength, power capacity, and reliability under thermal or vibration stress, commonly found in aerospace, defense, and industrial sectors.

Box Build Assembly

Box-build assembly refers to all the steps after a bare PCB assembly (PCBA) is completed, transforming the populated board into a fully functional, ready-to-ship product within its enclosure.

It is applied across various industries, including:

Industrial controls & IoT gateways: DIN-rail or IP-rated enclosures with field wiring.

Medical devices: Patient monitors, precision dosing pumps, handheld diagnostics.

Telecom & networking: Rack-mount switches, optical transceivers, small-cell radios.

Consumer & lifestyle electronics: Smart-home hubs, e-mobility chargers, audio equipment.

Rapid Prototyping

Rapid prototyping enables fast production of small-batch, production-quality PCBs and assemblies using agile DFM, quick-turn fabrication, and automated pick-and-place processes. It allows schematics, layouts, component choices, and functional performance to be validated within days.

Benefits of rapid prototyping include:

Accelerated design iteration: Complete build → test → refine cycles within a single sprint, reducing weeks from each board spin.

Early validation: Power-on prototypes confirm circuitry, footprints, and mechanical fit before expensive tooling.

Reduced development costs: Early fault detection minimizes late-stage re-spins, lowering NRE costs and scrap.

Early EMC/EMI insights: Pre-compliance testing identifies radiated and conducted emissions issues before formal certification.

Improved DFM and testability: Real hardware reveals assembly constraints, thermal paths, and test-point access for optimized manufacturability.

Flexible BOM management: Rapid builds allow testing alternative components or second sources to adapt to supply or cost changes.

Enhanced stakeholder confidence: Physical prototypes provide tangible proof for clients, investors, and teams, helping to speed approvals and funding.

PCB Test

Box-build assembly encompasses all steps after a bare PCB assembly (PCBA) is completed, transforming the populated board into a fully operational, ready-to-ship product enclosed in its housing.

This process is applied across multiple industries, including:

Industrial controls & IoT gateways: DIN-rail or IP-rated enclosures with field wiring connections.

Medical devices: Handheld diagnostics, patient monitors, precision dosing pumps.

Telecom & networking: Rack-mounted switches, optical transceivers, small-cell radios.

Consumer & lifestyle electronics: Smart-home hubs, e-mobility chargers, audio equipment.

Value Engineering

Value engineering (VE) is a structured approach aimed at maximizing a product’s value by enhancing functionality or cutting costs, without sacrificing quality, reliability, or performance. This may involve component substitutions, alternative materials, or process adjustments.

Key benefits of VE in electronics manufacturing include:

Cost savings: Reduces bill of materials (BOM) and production expenses.

Greater competitiveness: Lower costs enable more competitive pricing or higher profit margins.

Enhanced quality: Simplified designs often reduce potential failure points.

Faster time-to-market: Streamlined designs and processes shorten development and production timelines.

Component Sourcing, Procurement, & Supply Chain Management

At J-TEQ, we create procurement strategies customised for each client and project, aiming to optimise costs, lead times, and operational flexibility.

We recognise that quality and reliability begin at the source, which is why all our suppliers and partners undergo thorough vetting and audits to ensure they meet our high standards for performance, reliability, and quality.

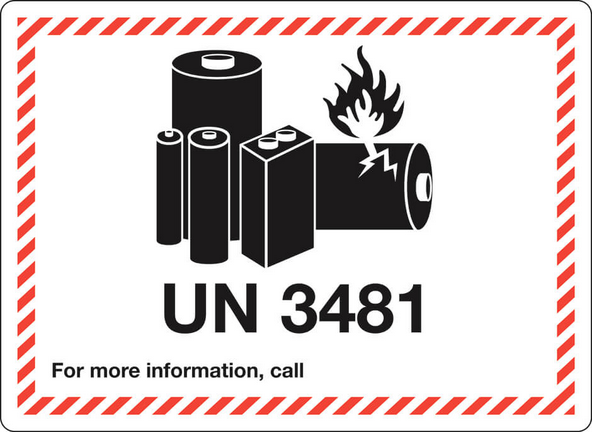

Global Shipping & Logistics

At J-TEQ, we are committed to dependable, on-time delivery and global supply chain reliability. We work with carefully vetted local and international couriers to ensure full compliance with industry standards and regulations.

With real-time tracking, route optimisation, and proactive risk management, our customers receive accurate shipping updates and experience minimal to no disruptions.

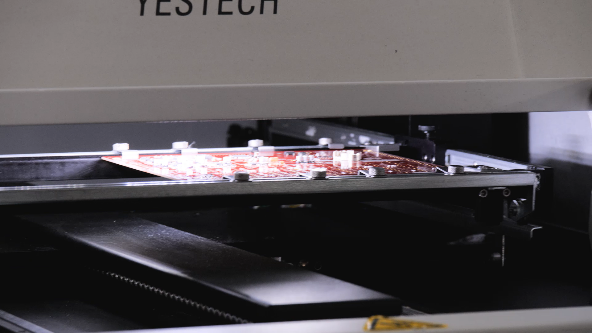

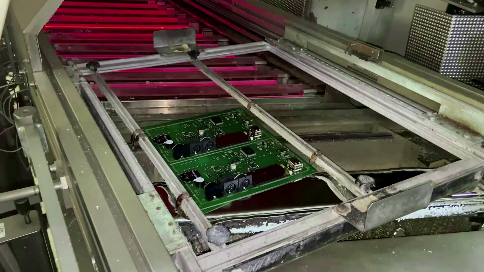

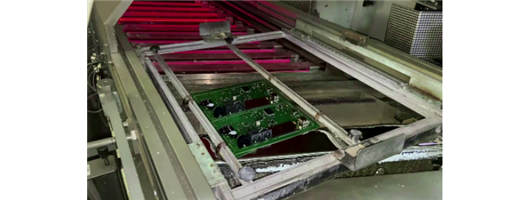

PCBA − SMT & BGA

PCBA − PTH − Mixed Technologies

At J-TEQ, we provide dual capabilities in both RoHS and Non-RoHS processes, which allows us to meet various regulatory requirements, including RoHS compliance for the Restriction of Hazardous Substances. This flexibility is particularly beneficial for customers who need assemblies with both leaded and lead-free components. Our commitment to regulatory compliance ensures that we meet the diverse needs of our clients while adhering to strict environmental standards.

Box Build - Higher Level Assembly

With years of experience, J-TEQ delivers fully assembled, tested, and configured products based on customer specifications. Our capabilities include handling sub-assemblies such as PCBAs integrated into plastic or metal brackets and housings. Our custom-built higher-level assembly and test area allows us to manage complex projects, delivering fully integrated solutions that are ready for deployment. Whether it's a small, intricate component or a large, multi-part assembly, J-TEQ efficiently manages and delivers to meet your requirements.

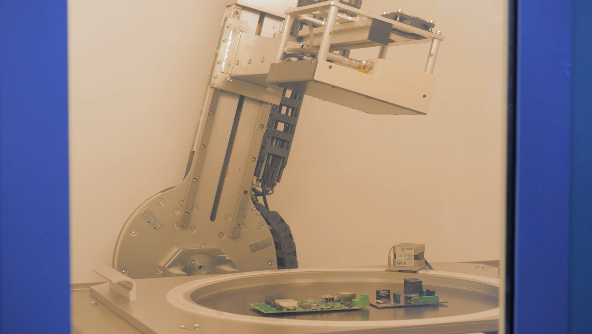

Test, Inspection & Configuration

A key offering at J-TEQ is the development of bespoke test jigs and fixtures tailored to suit various customer applications. This enables us to perform a wide range of testing and inspection processes to ensure the reliability and performance of each product. We utilise advanced testing technologies such as X-Ray inspection, automated optical inspection (AOI), functional testing, and in-circuit testing (ICT) to validate the integrity of the assemblies we produce.

Procurement & Supply Chain Management

Our supplier selection program has been refined over many years, allowing us to confidently source materials from a network of carefully vetted and audited suppliers. These partners undergo rigorous evaluations to ensure they meet our high standards of quality, reliability, and performance. By adhering to these established strategies, J-TEQ delivers significant value to businesses through a consistent supply of quality materials and components.

Rapid Prototyping & Value Engineering

Our rapid electronics prototyping facility ensures a fast turnaround, completing projects in as little as 24 hours to five days, depending on build complexities. Whether you require total free-issue components, full procurement, or a combination, J-TEQ offers the flexibility to adapt to your specific needs. This adaptability accelerates the development and validation of new products. When reduced lead-time purchasing is necessary, our skilled procurement team identifies critical items and efficiently sources essential components by leveraging strong relationships with strategic procurement partners, optimizing lead times, and minimizing delays in the prototyping process.

About us

J-TEQ EMS Solutions Ltd is a UK-based electronics manufacturing service (EMS) provider, offering high-quality and adaptable manufacturing solutions across various industries from our 23,000 square foot facility.

The company specialises in end-to-end services, offering complete solutions from design to delivery, serving industries such as aerospace, space, medical devices, industrial, and telecommunications.

The company is recognised for its precision and efficiency in producing complex electronic assemblies and systems, ensuring strict adherence to quality and regulatory standards at every stage of production. J-TEQ’s expertise spans Surface Mount Technology (SMT), Through-Hole Component Placement (PTH), and High-Level Assembly (HLA)/Box Build Assembly, making it a versatile partner for diverse customer needs. This flexibility is supported by its advanced manufacturing facilities, equipped with cutting-edge machinery and technology to manage both small and large production runs.

Our Services Include:

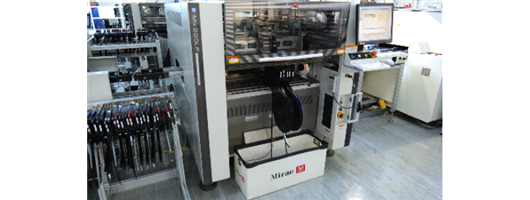

PCBA − SMT & BGA

J-TEQ EMS Solutions Ltd specialises in providing full system integration solutions that meet the diverse electronic assembly needs of our customers. We go beyond traditional services with advanced printed circuit board assembly (PCBA), in-house electromechanical assembly, functional testing, and configuration services. These comprehensive capabilities ensure that we not only assemble products but also rigorously test and configure them to meet exact customer specifications.

PCBA − PTH − Mixed Technologies

J-TEQ EMS Solutions Ltd provides a full range of through-hole assembly (PTH) services, guaranteeing precision and quality throughout the process. Our skilled operators manage the dedicated hand insertion area, expertly handling complex PTH assembly. We select the most efficient method for each project, using hand soldering, wave soldering, selective soldering, or a combination of techniques to achieve top-quality results.

Box Build - Higher Level Assembly

J-TEQ EMS Solutions Ltd delivers complete system integration solutions, customised to meet the unique requirements of electronic assemblies. We specialise in full turnkey assembly services, overseeing each project from start to finish with precision and meticulous attention to detail. In addition to printed circuit board assembly (PCBA), our expertise extends to in-house electromechanical assembly, functional testing, and configuration services, catering to a wide range of electronic manufacturing needs.

Test, Inspection & Configuration

J-TEQ EMS Solutions Ltd provides complete system integration solutions tailored to meet our customers' assembly and testing requirements. In addition to our advanced printed circuit board assembly (PCBA) capabilities, we offer in-house electromechanical assembly, functional testing, and configuration services to ensure products are delivered exactly to customer specifications.

Procurement & Supply Chain Management

At J-TEQ EMS Solutions Ltd, procurement and supply chain management are key aspects of our services. We understand the importance of a reliable and efficient supply chain in meeting customer needs. To ensure optimal results, we create customised procurement strategies for each client, balancing cost-effectiveness, lead-time efficiency, and flexibility.

Rapid Prototyping & Value Engineering

J-TEQ EMS Solutions Ltd offers a complete prototyping and pre-production service, customised to suit our customers' specific needs. Each project is overseen by a dedicated team of professionals from our Purchasing, Engineering, and Manufacturing departments. With over 100 years of combined experience in electronic assembly manufacturing, J-TEQ is fully equipped to manage complex prototyping and pre-production challenges.

J-TEQ takes pride in its customer-centric approach, collaborating closely with clients to create solutions that meet their unique needs, from prototype development to full-scale production. This partnership not only accelerates time to market but also ensures cost-effectiveness and product reliability. Furthermore, the company provides value-added services such as testing, inspection (including in-house X-Ray Inspection and Automated Optical Inspection (AOI)), and supply chain management, further enhancing the overall customer experience.

A key differentiator for J-TEQ is its strong commitment to sustainability and innovation. The company integrates environmentally responsible practices across its operations, such as waste reduction and energy-efficient processes. This progressive approach is further supported by ongoing investment in research and development (R&D) in manufacturing, ensuring J-TEQ stays at the leading edge of technological advancements in the EMS industry.

In summary, J-TEQ EMS Solutions Ltd. is a reliable partner in electronics manufacturing, recognised for its technical expertise, customer-focused services, and dedication to innovation.

Images

Videos

Articles / Press Releases

Brochures

Reviews

Trade Associations