Company details for:

Northpoint Ltd

Quick Links:

Products / Services

Fence Coating

Fencing

Street furniture

Hand rails

Lighting columns

Playground equipment

In fact, most steel surfaces can be coated where a long-term exterior performance is required.

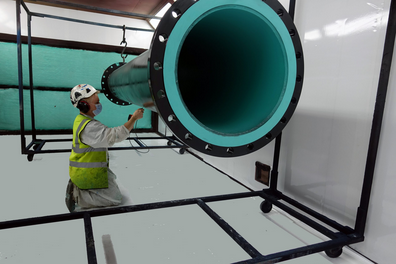

Pipe Coating Specialists

Since the 1980’s Northpoint has been delivering fusion bonded epoxy (FBE) pipe and pipe fittings coatings solutions, servicing a number of industries including water supply and treatment, offshore, and gas and oil pipelines.

Akzo Nobel Resicote is the preferred FBE coating option for these sectors and holds a comprehensive range of approvals combined with a worldwide track record. Resicote can be applied to external and internal surfaces of pipes and fittings and exceeds all industry pipe coating standards.

Sheet Metal Coatings

Northpoint is an expert in sheet metal and metal component powder coatings, providing a vast array of colours, alongside solutions for textured or leatherette finishes. Sheet metal can be finished in a range of coatings including:

Polyester powder coatings, where long lasting colour retention is paramount. Usually applied to parts for outdoor use.

Epoxy powder coatings, which is ideal for corrosion protection on sheet metal and other components. Epoxy’s are used on parts for indoor use and/or aggressive environments.

Epoxy/Polyester, a combination for those environments where both the above points are priority.

PPA 571 a ‘warm to touch’ plastic type coating normally used on handrails and similar high touch products.

Thermal Stripping

Northpoint is a specialist in the removal of powder, paint and other coatings through thermal stripping. This service provides an effective substitute for stripping paint and coatings from metal, which can be very time consuming. Our expertise and in-house facility allow us to ensure strict quality control and provide a complete solution to customers, from stripping to re-coating.

The stripped metal will have a smoother base, meaning the powder coating application will be much more effective; creating a more polished look and ensuring longevity of the new coating. This service ultimately improves the product finish after coating.

For more information on thermal stripping or to speak to a member of our team please contact us today.

Shot Blasting

Located in Dukinfield, Greater Manchester, Northpoint delivers two types of shot blasting services; hanger type and booth. Our dedicated shot blasting booth is ideal for larger parts, fittings and pipes to be treated by our trained professionals. Hanger type shot blasting is a semi automated process, where complete descaling and reconditioning of smaller metal parts is required.

A smooth finish is not the only benefit of shot blasting; after the metal part has been cleaned, the engineer can also identify any structural issues such as compromised weld joints and corrosion. These issues can then be addressed to provide reinforced reliability and longevity of the part before powder coating. In addition, shot blasting provides an environmentally friendly, cost effective solution to the reuse of metal parts.

Northpoint can provide shot blasting services to a commercial grade finish, meeting the ISO 8501-1 Sa 2.5 or ISO 8501-1 Sa 3 standards as per client specification.

Contact us today to discuss your requirements with our team or click here to view our gallery.

Wet Paint Services

Specialist training has been undertaken by key team members to ensure that the requirements of SSPC Train the Painter Scheme and Coatings Inspectors qualified to NACE I, II & III as well as ICorr L2 are met.

The dedicated wet paint booth is set up for the professional application of:

Single layer

Multi-layer

100% Volume solids

Phenolic paints

DWI approved systems

Protective Coating for the Automotive Sector

In the automotive industry, durability and aesthetics are equally important. Components must endure constant exposure to road conditions, temperature changes, and environmental factors while maintaining a flawless, professional finish.

With projects ranging from vehicle trailers to small complex components, it is imperative that we understand the required level of protection that your item needs. ISO 12944 is a good place to start when determining what level of protection you require. You should also think about the thickness of the item, substrate and location where it will be going as these can all influence what the recommended coating specification is.

At Northpoint, we deliver sustainable advanced protective coating for automotives tailored to the specific demands of the automotive sector, ensuring superior protection, longevity, and visual appeal for vehicles and parts.

Protective Coating for the Fencing Sector

Fencing plays a crucial role in providing security, privacy, and aesthetic value across residential, commercial, and industrial applications. Ensuring these structures remain durable and visually appealing requires high-quality protective coating designed to withstand weather exposure, physical wear, and environmental challenges.

At Northpoint, we specialise in delivering sustainable protective coating for fencing that enhance the lifespan and appearance of fencing systems, offering superior resistance to corrosion and wear. Working to BS EN 13438 and BS 1722-16 is crucial to maintaining a high-quality standard on all of our coating work.

Protective Coating for the Marine Sector

Marine environments are among the harshest on the planet, with constant exposure to saltwater, humidity, and extreme weather conditions. Ensuring the durability and performance of marine equipment and structures requires high-quality coatings designed to resist corrosion, abrasion, and environmental wear.

At Northpoint, we provide advanced protective coating for the marine sector including safeguarding vessels, offshore platforms, and other marine assets for long-term reliability.

Our protective coating for the marine sector is engineered to extend the lifespan of marine assets, reduce maintenance needs, and ensure performance in even the most challenging conditions. It is vitally important to understand the function of the coating chosen for protecting anything in the sector as getting it wrong or cutting corners can reduce the life expectancy of items by years.

Protective Coating for the Oil & Gas Sector

Here at Northpoint, we offer protective coating for the oil and gas sector. The oil and gas sector operates in some of the most demanding environments, where durability, safety, and compliance are critical. We deliver advanced coating solutions designed to protect vital infrastructure and ensure long-lasting performance under extreme conditions. With accreditations including National Gas, and processes overseen by NACE Level 3 inspectors, we provide coatings that meet the highest industry standards.

All coating work at Northpoint is overseen by NACE 2 and NACE 3 inspectors and can be coated by Fusion Bonded Epoxy (FBE) or multicomponent liquids (wet paint).

Northpoint holds the following National Gas Specifications

Protective Coating for the Retail Sector

In the fast-paced retail environment, the durability and appearance of fittings are critical. Shelving, racks, and fixtures must endure constant interaction with products, customers, and equipment, all while maintaining a flawless aesthetic. Powder coating for retail is the ideal solution, providing a robust, visually appealing, and long-lasting protective layer.

At Northpoint, our extensive pre-treatment and sustainable coating process is designed to safeguard fittings against damage, rust, and wear at an early stage. This ensures that your retail fixtures remain functional and attractive for years to come, even under heavy use. We also understand the importance of presentation in retail spaces – our process eliminates defects, ensuring a high-quality finish that enhances the overall shopping experience.

We also offer tailored packing solutions to maintain the integrity of your products post-coating. From minimal protection to robust packaging, we ensure your items arrive in pristine condition, ready for immediate use.

Protective Coating for the Urban Infrastructure Sector

Northpoint offering protective coating for urban infrastructure. Urban infrastructure is the backbone of modern cities, encompassing everything from bridges and railings to street furniture and lighting fixtures. These structures not only need to withstand daily wear and tear but also endure harsh environmental conditions.

Left unprotected, urban infrastructure is highly susceptible to corrosion, degradation, and premature failure, leading to safety risks, higher maintenance costs, and shorter lifespans.

At Northpoint, we understand the critical role protective coating for urban infrastructure plays in preservation and enhancement. Our advanced powder coating solutions provide a durable, eco-friendly, sustainable, and aesthetically versatile layer of protection. Designed to resist corrosion, abrasions, and the elements, our coatings ensure long-lasting performance and minimal upkeep, while contributing to the structural integrity and visual appeal of our cities.

Protective Coating for the Water Sector

Ensuring safe and sustainable access to drinking water is a critical priority in the water industry. At Northpoint, we specialise in providing high-quality protective coating for the water sector that meet the stringent requirements of the Drinking Water Inspectorate (DWI) in the UK. Our coatings are designed to enhance the safety, durability, and efficiency of pipe systems, contributing to a reliable water supply infrastructure.

With AMP8 initiatives emphasising sustainability and resilience, we are uniquely positioned to provide protective coating for the water sector, with our extensive experience and industry-leading solutions. Our Fusion Bonded Epoxy (FBE) coatings, including Aqua Green, and Blue EN545, as well as advanced wet paint systems, provide exceptional protection against corrosion and wear, ensuring the longevity and integrity of water systems.

Northpoint holds various approvals for coatings in the water sector.

About us

Founded in 1976, Northpoint Ltd is a leading UK provider of professional powder coating solutions for both decorative and functional applications.

Our dedication to high-quality powder coatings and outstanding customer service has built our strong reputation both in the UK and globally. Based in Dukinfield, Northpoint collaborates closely with customers to meet precise coating needs, offering specialised solutions and ensuring a seamless experience with every project.

Northpoint is a reliable partner in powder coating for diverse industries and applications. Our extensive heritage, experience, and specialised skills distinguish us as a leader in the field.

Our Products Include:

FBE Coating Specialist

Northpoint is a top provider of FBE coatings, offering pipe coating solutions that comply with DWI standards, such as Resicote R4-FB, Scotchkote 206N, and Thixo 468. We also apply Jotaguard VA5001 coatings as needed. For both onshore and offshore pipe and pump applications, Northpoint has the facilities and expertise to apply a full range of NORSOK paint coating systems.

Wet Paint Coatings

Our specialised wet paint facility features a cutting-edge SprayBake Booth. We offer customizable coating solutions to meet NORSOK M-501 standards or other specific customer needs, including Glass-Flake paint, High-Zinc Solids primers, and Novolac Epoxies.

Fence & Architectural Coatings

Northpoint offers expert powder coating solutions for various galvanised steel fencing panels and components, as well as outdoor street furniture, bollards, and architectural elements. Our fence coatings deliver corrosion protection across classes C1 to C5-M and CX.

Metal Part Coatings

Powder coating of sheet metal fabrications and metal components is a central part of our services. We operate a specialised multi-metal coating line that uses advanced automated paint guns to ensure top-quality results.

Northpoint Ltd provides advanced coating solutions to a wide range of industries, ensuring durability and protection across various sectors. Our services cater to fencing, sheet metal, water, oil & gas, metal fabrication, automotive, retail, marine, energy, construction, manufacturing, and furniture. With tailored coatings designed to meet the unique demands of each industry, we help enhance the longevity, performance, and aesthetics of products and infrastructure. Whether it's corrosion resistance for marine equipment, protective coatings for automotive parts, or specialised finishes for retail and furniture, Northpoint Ltd delivers reliable and high-quality solutions.

At Northpoint, the quality of our coatings and services reflects our commitment to tailoring solutions to meet our customers' needs. Our mission is to offer a seamless experience by collaborating closely with clients to understand their goals and delivering exceptional standards throughout the entire process.

At Northpoint Ltd, we are committed to upholding high quality, regulatory, and ethical standards while fostering a collaborative community of suppliers and customers. We ensure that all employees, contractors, and consultants adhere to principles of fair business. We also focus on offering learning and development opportunities for our team and strive to maintain profitability.

Images