Company details for:

Plastic-IT Ltd

Quick Links:

Products / Services

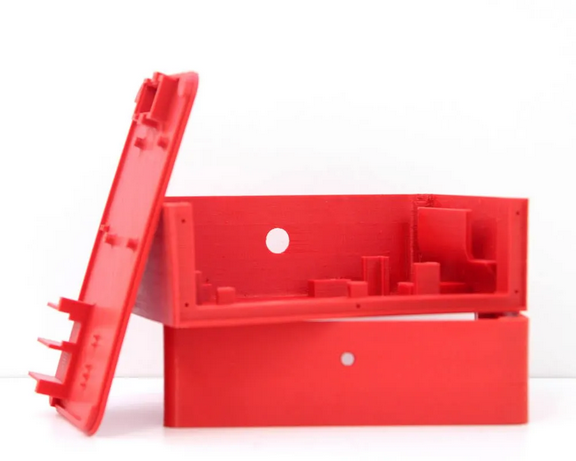

Design for Manufacturing

Getting your plastic product to market in the shortest time possible with the expected quality leads to greater customer satisfaction.

When all aspects of design for manufacturing and assembly (DFMA) have been considered, you will enjoy greater profits too.

If you start the process as early as possible, you can determine much of the final cost of a part at the design stage. Using our expertise in plastics product design and process engineering, you will benefit from the consistency and quality demanded by your customer.

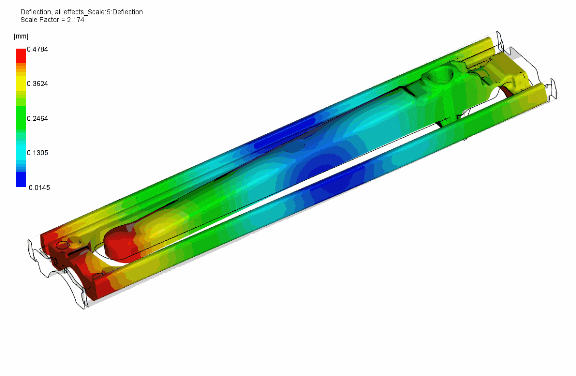

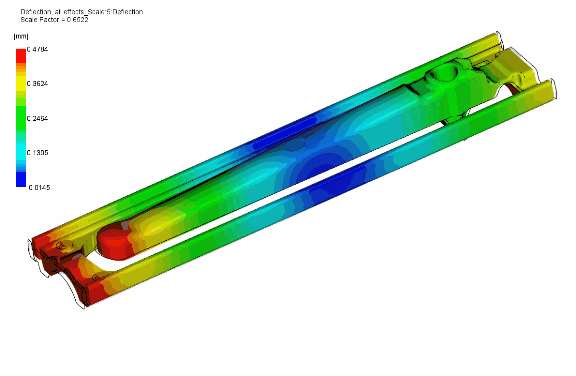

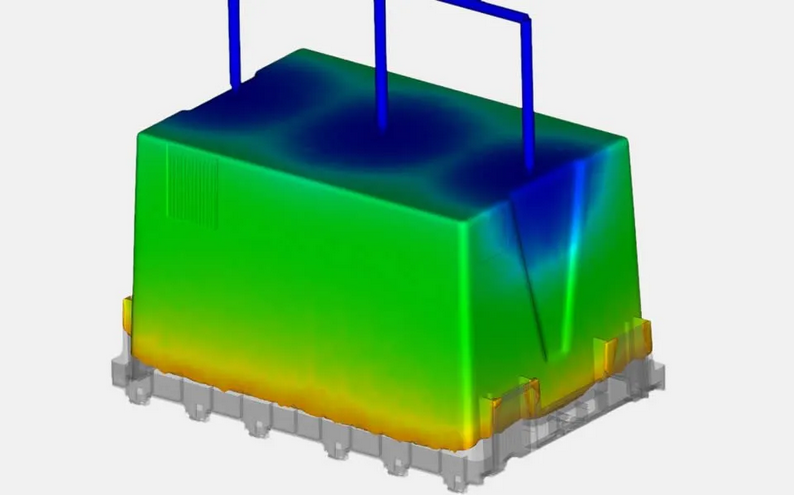

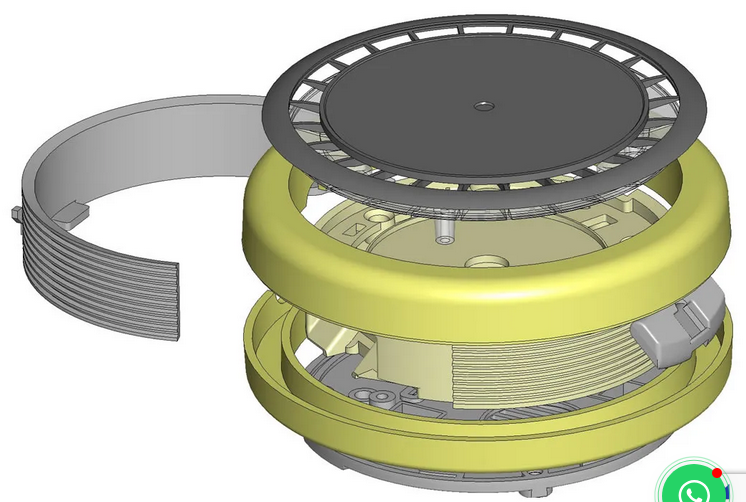

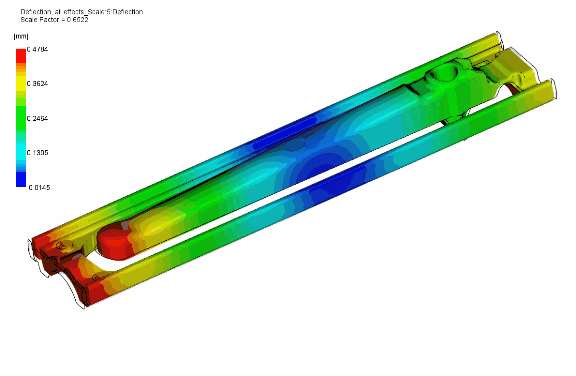

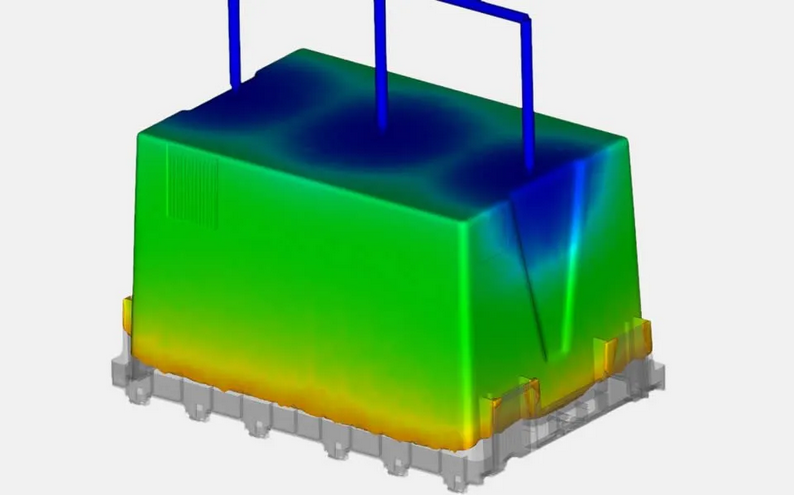

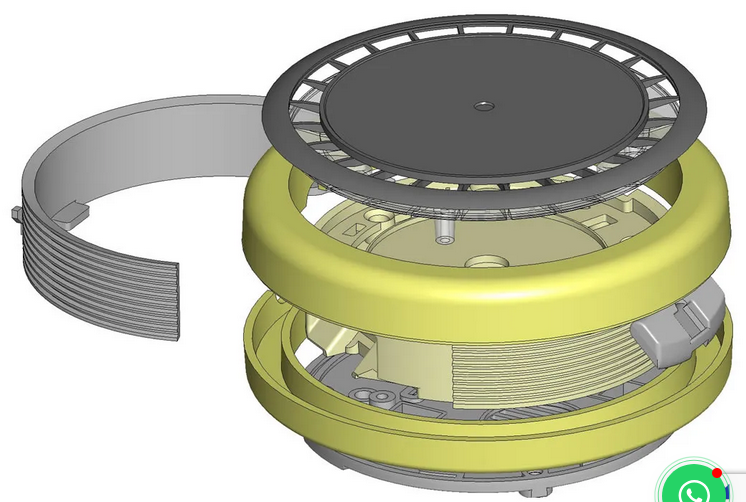

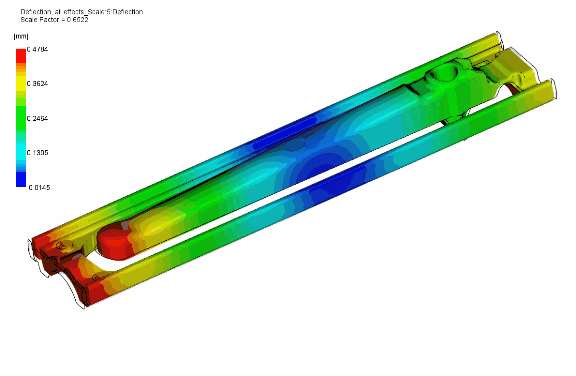

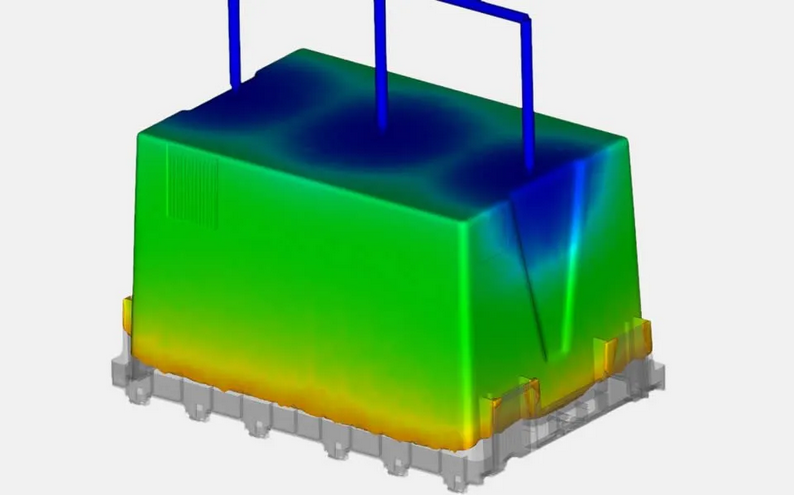

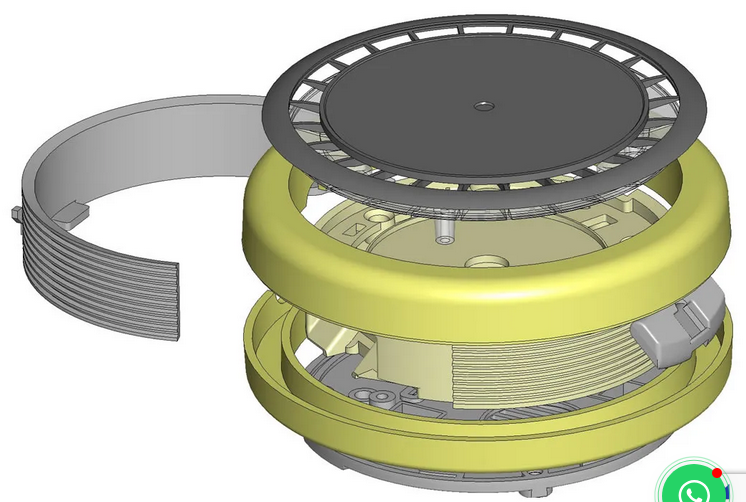

Optimise Your Injection Moulding Process with Autodesk Moldflow Simulation

At Plastic-IT, we provide advanced manufacturing simulation software using Autodesk Moldflow to streamline your injection moulding simulation process. From optimising product design to ensuring efficient mould tool performance, our simulation-driven design solutions help reduce costs, enhance product quality, and accelerate time to market.

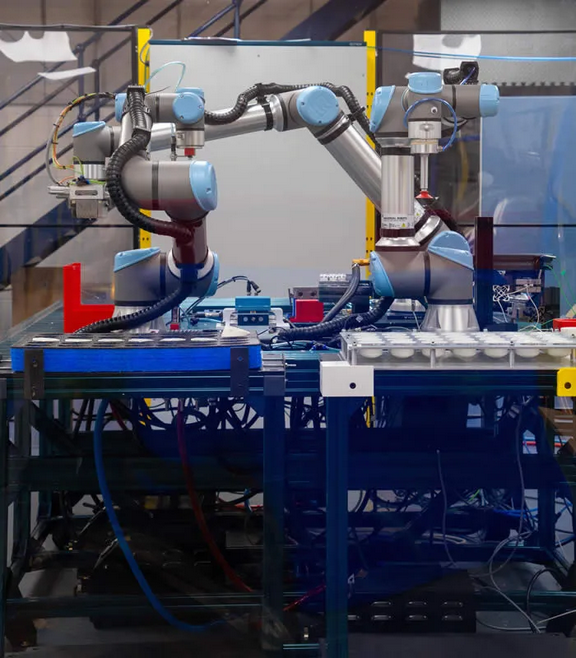

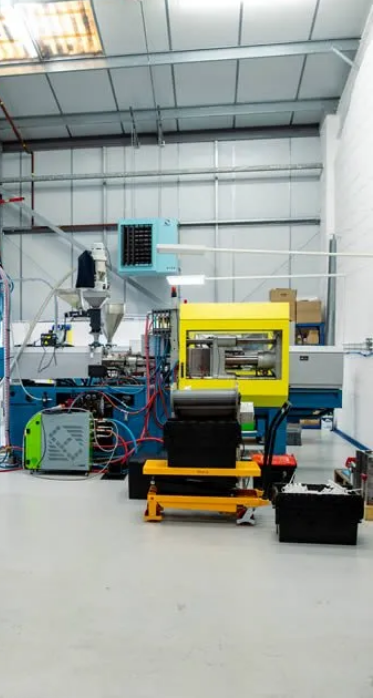

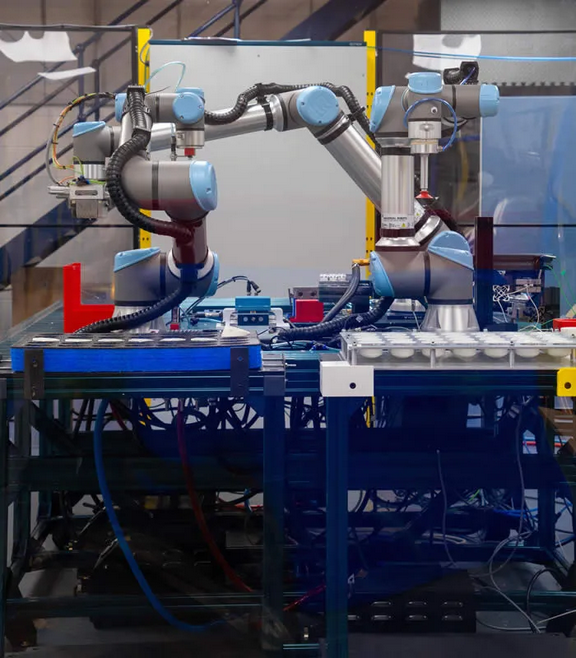

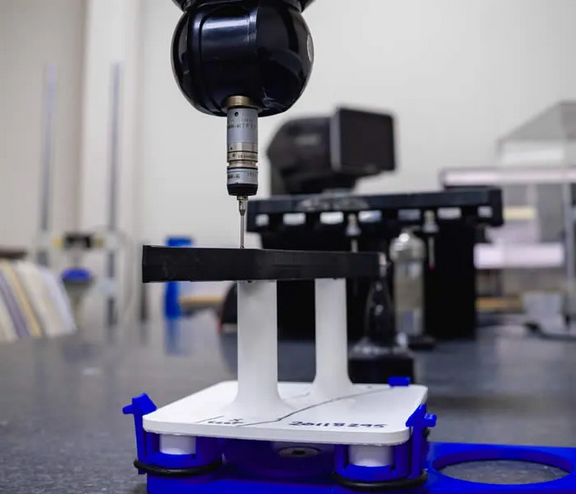

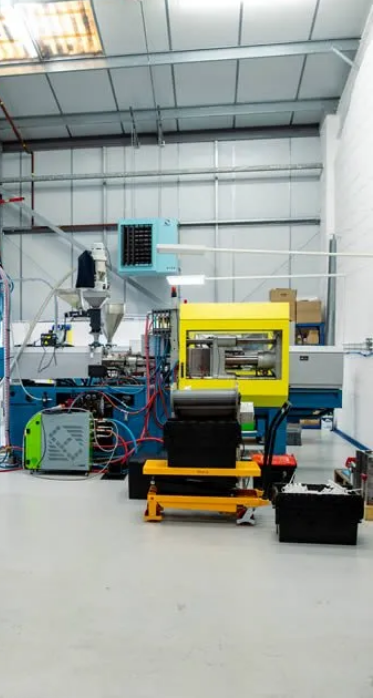

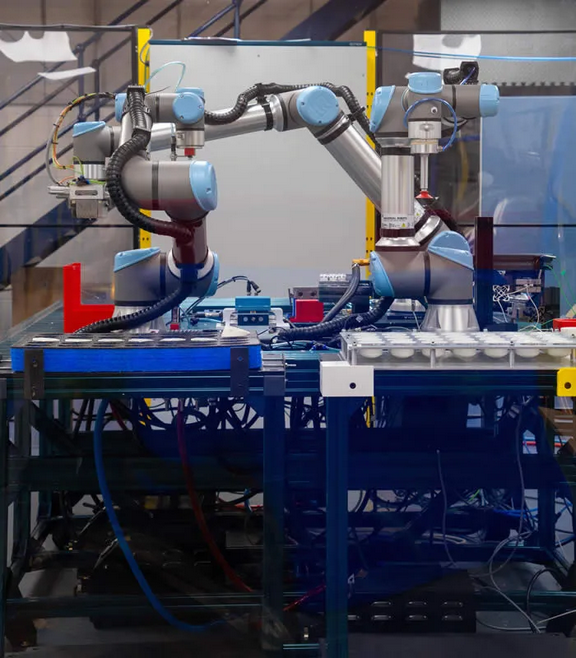

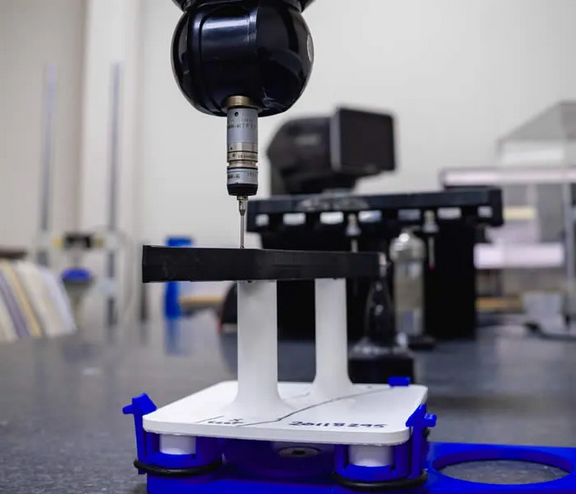

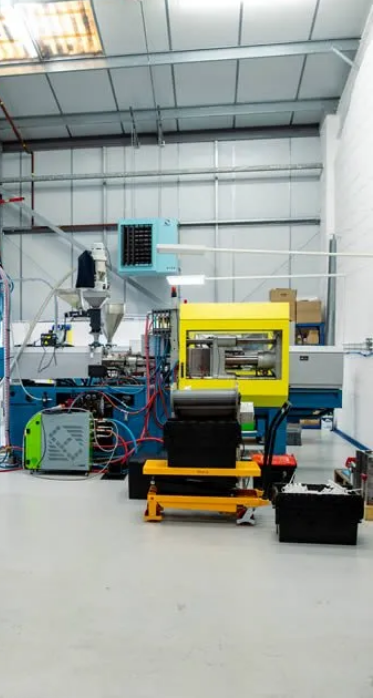

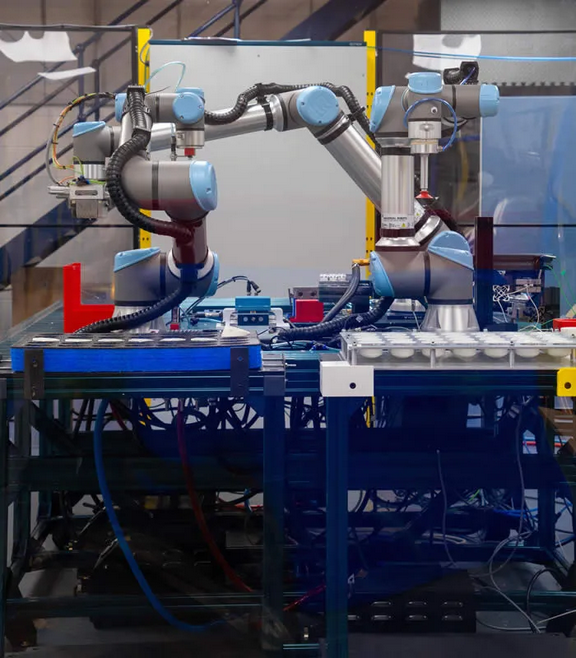

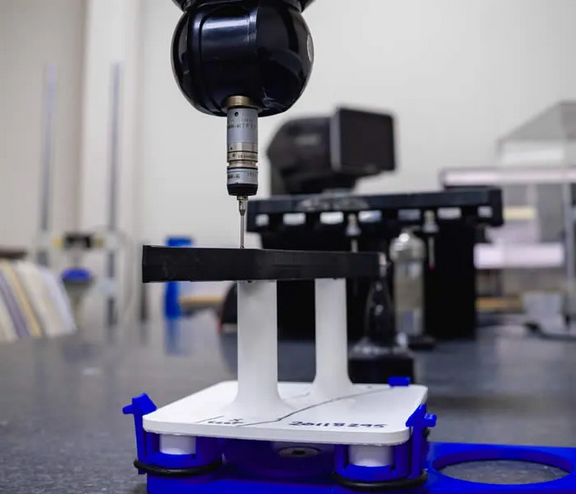

Precision & Innovation with Prototype IT

Whether you need to verify a design, test a component, OR conduct pre-production runs, Plastic-IT Ltd has the expertise and technology to meet your needs.

Where we specialise in delivering cutting-edge prototyping services designed to optimise your plastic injection moulding processes. With our state-of-the-art facilities based in Shrewsbury, Shropshire, and a commitment to excellence, we provide comprehensive solutions that bring your ideas to life with precision, speed, and reliability.

Our prototyping services are not just about creating a model; they are about refining your design, ensuring manufacturability, and accelerating your time to market.

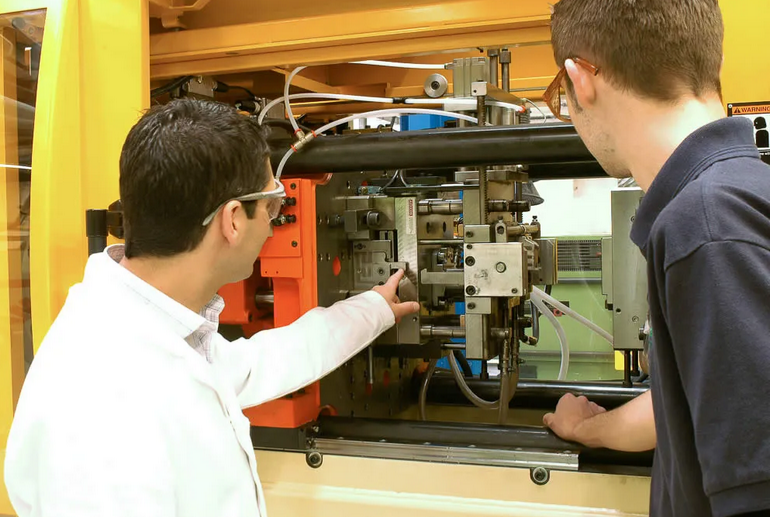

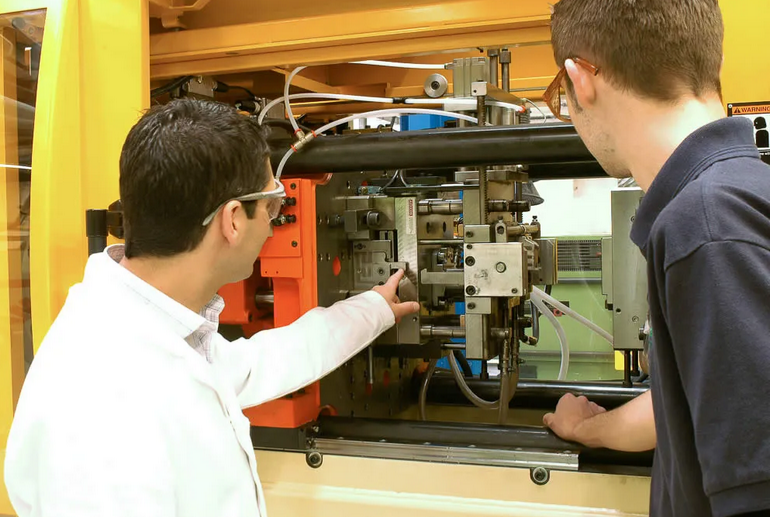

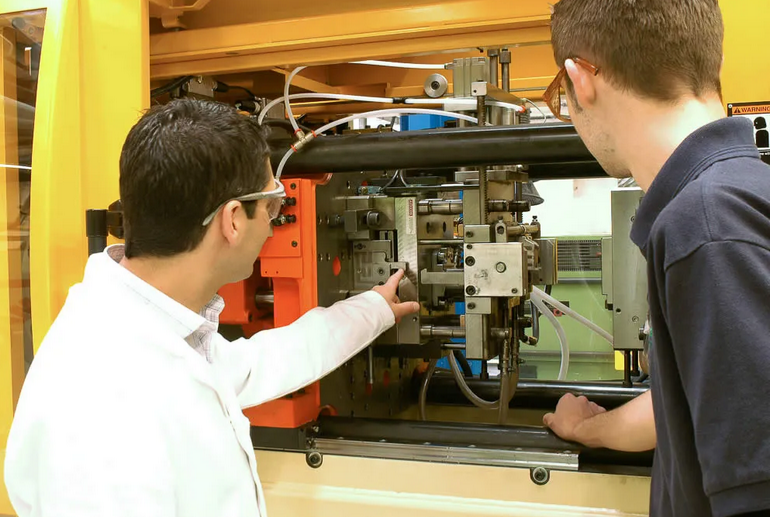

Expert Solutions for Plastic Injection Moulding Optimisation

Plastic injection moulding is a science, not an art

By leveraging the right techniques and technologies, manufacturers can achieve optimal moulding quality and efficiency. At Plastic-IT Ltd, we specialise in injection moulding optimisation that enhances every stage of the process, ensuring superior quality, minimal waste, and reduced production costs.

With expertise across industries – whether consumer products, electronics, aerospace, automotive, or medical devices – our approach to injection moulding optimisation guarantees that your products reach the market on time, on budget, and with excellence.

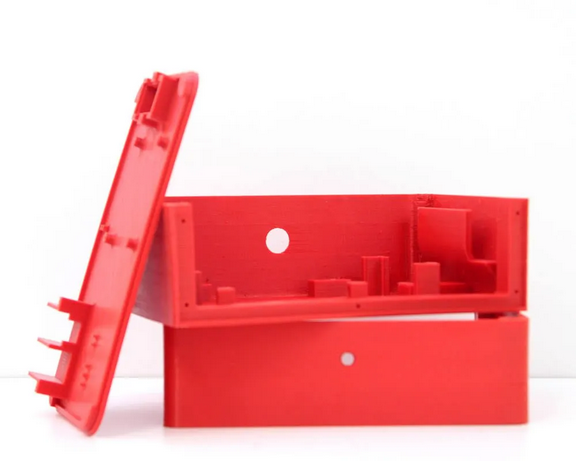

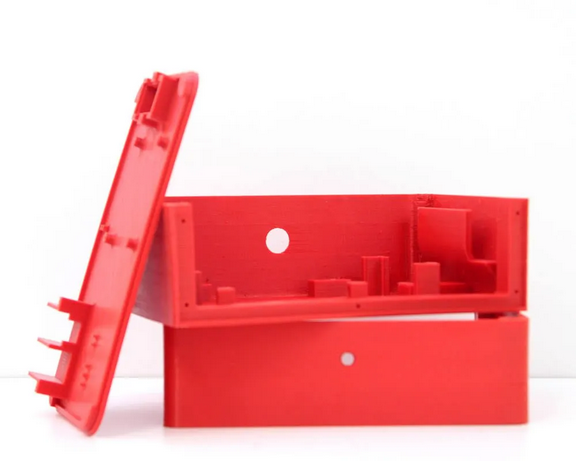

Plastic Injection Moulding

With decades of experience and a commitment to innovation, we provide high-quality, efficient, and cost-effective plastic injection moulding services.

From initial design consultation to full-scale production, we offer comprehensive solutions tailored to meet the unique requirements of various industries, including consumer goods, electronics, medical, agricultural, automotive, telecommunications, building and construction, and education.

Plastic Injection Moulding for Agriculture

The agricultural industry relies on robust and weather-resistant components, that can withstand exposure to moisture, UV and mechanical stress.

Automotive Plastic Injection Moulding

The automotive sector demands scalable, consistent, and high-performance plastic injection moulding solutions, to support today’s fast-paced manufacturing and light weighting goals.

At Plastic-IT, we support both OEMs and Tier 1 suppliers with expert design input, precision component production and independent Moldflow analysis that ensures tooling and parts perform exactly as required.

With deep expertise in design for manufacture, tooling validation and simulation-driven development, we help reduce delays, avoid costly tooling errors and deliver first-time-right outcomes – ensuring plastic parts meet performance and production expectations from concept through to delivery.

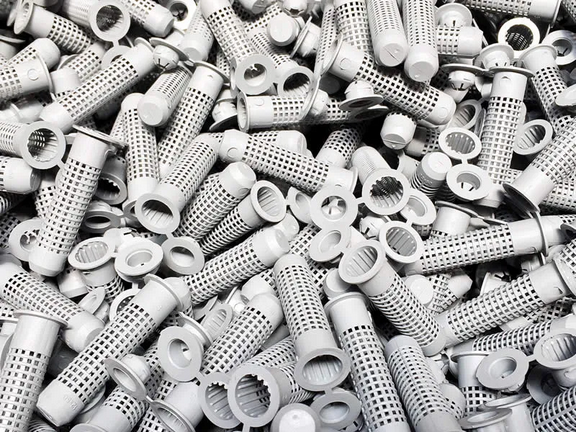

Construction Injection Moulding

At Plastic-IT, we provide high-performance construction injection moulding solutions designed for the harsh conditions and technical requirements of the building industry.

Construction demands materials that are strong, reliable, and cost-efficient. From water-tight pipe fittings to impact-resistant site components, we support architects, contractors and product manufacturers with precision-engineered plastic parts.

Whether you’re building residential, commercial or infrastructure projects, we offer the materials and expertise to deliver.

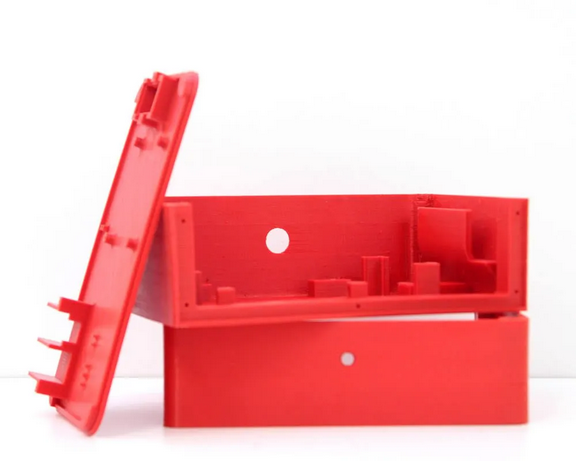

Consumer Goods Plastic Injection Moulding

The consumer goods sector demands highly aesthetic, durable and scalable plastic injection moulding solutions.

At Plastic-IT, we help brands deliver consistent quality while meeting price and timeline pressures in fast-moving markets.

At Plastic-IT, we support product developers, manufacturers and brand owners with custom-moulded plastic parts for a wide variety of consumer goods. From concept to full-scale production, we provide consumer goods plastic injection moulding services that ensure every product meets both your functional and visual requirements.

Whether you need precision fit, strong tactile appeal or custom material performance, our team works with you to get it right the first time.

Plastic Injection Moulding for Electronics

The electronics industry requires compact, durable and precision-engineered plastic components, that deliver performance under demanding conditions.

At Plastic IT, we provide tailored plastic injection moulding solutions for electronic applications, supporting design, tooling and production across consumer electronics, computing, electrical systems and more.

With our advanced engineering expertise, simulation-led approach and flexible manufacturing capabilities, we help electronics manufacturers bring high-performance plastic parts to market faster with reduced waste and maximum reliability.

Industrial Equipment Injection Moulding

At Plastic-IT, we specialise in, industrial injection moulding solutions built for toughness, repeatability and high-performance under load.

Whether you need housings, handles, gears or brackets, we support machinery manufacturers and tooling developers with robust injection-moulded plastic parts.

Our simulation-led approach reduces development time, improves tooling reliability and ensures your parts work in the real world.

Medical Injection Moulding Solutions

The medical sector demands high-precision, fully compliant plastic components

that meet strict quality and regulatory standards.

At Plastic-IT, we specialise in ISO 9001:2015-compliant medical injection moulding, delivering custom-engineered plastic parts for medical devices, diagnostics, and healthcare applications.

With our advanced manufacturing techniques, expert knowledge and commitment to quality, we help medical device manufacturers develop safe, durable, and high-performance components that meet industry regulations.

Telecommunications Injection Moulding

As global telecommunications networks evolve to support 5G, fibre optics and smart infrastructure, precision-engineered plastic components are more vital than ever.

From signal enclosures and antenna housings to cable management systems, we support manufacturers and suppliers with simulation-led design, rapid tooling, and production flexibility. Our solutions meet the challenges of today’s fast-changing digital infrastructure.

About us

Welcome to Plastic-IT Ltd, your reliable partner for cutting-edge injection moulding solutions. We combine state-of-the-art technology with deep industry expertise to improve plastic product design, mould tool creation, and manufacturing processes.

With a strong commitment to quality, efficiency, and innovation, Plastic-IT is a leader in plastic injection moulding, serving diverse industries including consumer goods, electronics, medical, agriculture, automotive, telecommunications, construction, and education.

At Plastic-IT, we know that the key to an optimal injection moulding process lies in combining scientific insight with precise engineering. Our deep expertise and advanced technology enable us to provide high-quality, cost-effective solutions customised to your exact requirements.

Our Services Include:

Design for Manufacturing

The size and complexity of injection moulded parts significantly impact manufacturing costs, with larger, more intricate moulds requiring more resources and machining. However, to achieve the best results, a consistent and thorough process should be applied to both simple and complex designs alike.

Moldflow Analysis

At Plastic-IT, we provide advanced manufacturing simulation software using Autodesk Moldflow to streamline your injection moulding simulation process. From optimising product design to ensuring efficient mould tool performance, our simulation-driven design solutions help reduce costs, enhance product quality, and accelerate time to market.

Prototyping

We specialise in advanced prototyping services that enhance your plastic injection moulding process. From our modern facilities in Shrewsbury, Shropshire, we deliver fast, precise, and dependable solutions—turning your concepts into reality with a strong focus on quality and performance.

Injection Moulding

From early design consultation through to full production, we provide end-to-end solutions customised to suit the specific needs of industries such as consumer goods, electronics, medical, agriculture, automotive, telecoms, construction, and education.

Training

Training is available both online and onsite, tailored to your needs and accessible 24/7. Investing in proper training is far more cost-effective than the potential risks and expenses of an untrained employee.

… And more.

With more than 25 years of expertise, we provide innovative, client-centered injection moulding solutions leveraging advanced Autodesk Moldflow Analysis. From manufacturing design and prototyping to large-scale production, we guarantee precision, efficiency, and top-quality results customized for every client.

Plastic-IT provides customised injection moulding solutions for diverse industries such as consumer goods, electronics, medical, agriculture, automotive, telecommunications, construction, and education, addressing the specific needs of each sector with accuracy, strength, and dependability.

Get in touch with us for plastic injection moulding services that are reliable, efficient, and affordable.

Images

Reviews

Trade Associations