Company details for:

Spectra Packaging

Quick Links:

Products / Services

Extrusion Blow Moulding

bottle manufacturing processes.

One of the most common resins used in the EBM process is HDPE (high density polyethylene). Although semi-opaque in its natural state, a high gloss feel and appearance can be achieved if required. Similarly, a more squeezable feel can be achieved using MDPE (medium density polyethylene), making it ideal for products such as creams and lotions.

Injection Stretch Blow Moulding

high-quality bottles in PET (Polyethylene Terephthalate), which boast a clarity similar to glass. However, the ISB process can also produce less clear materials, such as polypropylene (PP) if required.

Spectra’s state-of-the-art injection stretch blow-moulding machines can produce PET containers in capacity sizes from 50ml up to 500ml. Available in a virtually limitless choice of colours, our PET bottles can

be provided in solid opaque finishes as well as varying stylish translucent shades.

Injection Moulding

Spectra can provide a wide range of off-the-shelf designs or bespoke solutions, tailored to customer needs. Our injection moulded

components are designed to complement our EBM and ISB containers

and offer a total packaging solution.

Decoration

of customers products with a variety of innovative print technologies that include precise four pass silk screen printing as well as timeless sophistication by way of hot foil blocking.

Customers seeking ground-breaking print technologies can also take advantage of our innovative solutions. These include our 360-degree Seamless printing, Chameleon, which changes colour depending on differing lighting conditions and Elevate, our tactile and high build embossed print finish.

Colour Matching

We boast a long heritage in plastic colouring technology and work closely alongside trusted Masterbatch suppliers. It’s this industry expertise that enables us to provide the most appropriate solutions to help give your packaging a real point of difference.

We can provide a range of performance enhancing products from

anti-microbial additives to UV inhibitors, along with an array of stunning colour finishes from frosting and pearlescent to a natural speckled look that emulates card or stone.

Recycled Packaging Solutions

Plastic products that have completed their life cycle as an everyday consumer item and then been recovered from waste are known as post-consumer. The post-consumer recycled (PCR) plastics most commonly used for packaging derive from PET & HDPE products such as clear drinks bottles and more opaque milk bottles.

Bioplastic Packaging Solutions

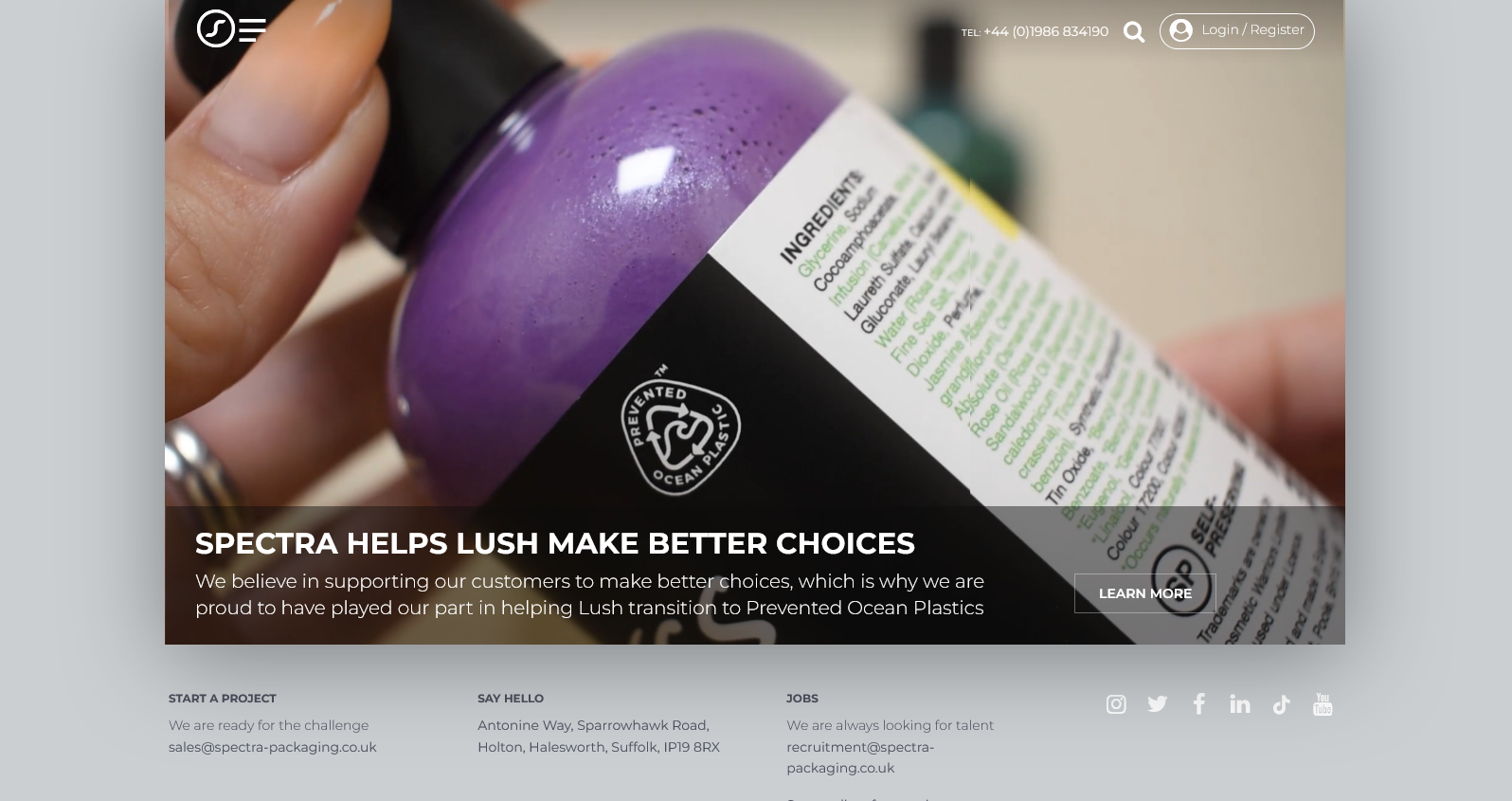

Prevented Ocean Plastic

The programme aligns plastic recycling standards across coastlines at risk from ocean plastic pollution. It offers an ongoing supply of high-quality recycled plastic at industry scale whilst supporting local communities at the forefront of ocean plastic waste in at-risk areas, including Southeast Asia, South America, the Galapagos Islands, the Mediterranean, and Central America & Caribbean.

About us

Spectra Packaging has become a prominent independent producer of high-quality, innovative plastic packaging for the cosmetics, toiletries, and personal care industries.

We manufacture all our products to order at our dedicated, state-of-the-art UK facility. As an independent, privately owned, and self-financed company, we ensure swift, consistently high-quality results for a diverse range of clients, from global corporations to small start-ups, while maintaining full control over quality and lead times.

Since 2008, we have fostered enduring partnerships with many leading cosmetics and personal care brands. By understanding their goals, we enhance the value of their products, helping to strengthen their brand identity, attract more consumers, and effectively convey their core values.

Our Services Include:

Extrusion Blow Moulding

Extrusion blow moulding (EBM) is an exceptionally adaptable process that enables the creation of bottles in diverse shapes, sizes, and neck designs using various plastics, offering significant advantages over other manufacturing methods.

Injection Stretch Blow Moulding

Injection Stretch Blow Moulding (ISB) facilitates the production of premium bottles in PET (Polyethylene Terephthalate), offering glass-like clarity. Additionally, the ISB process can accommodate the use of less transparent materials, such as polypropylene (PP), when needed.

Injection Moulding

Injection moulding (IM) is a precision process used to create plastic components like closures, overcaps, and reducer plugs. Spectra offers an extensive selection of ready-made designs or customised solutions tailored to client requirements. Our injection-moulded components are specifically designed to integrate seamlessly with our EBM and ISB containers, providing a complete packaging solution.

Decoration

Our specialised decoration department enhances the full potential of customers' products through a range of innovative printing techniques, including precise four-pass silk screen printing and the elegant touch of hot foil blocking.

Colour Matching

Spectra recognises the importance of color in enhancing brand packaging within highly competitive markets like personal care and toiletries. With a rich history in plastic colouring technology and strong collaborations with trusted Masterbatch suppliers, we leverage our expertise to deliver tailored solutions that make your packaging stand out.

… And more.

Innovation has always been a core driving force for our business. Beyond the products we create, our commitment to innovation extends to our operational practices, shaping our approach to employees, customers, suppliers, and the environmental impact of our activities.

Despite being a relatively young company, we have industry experts in every department. With over 20 years of experience in masterbatch polymer coloring, we are well-positioned with a strong track record in packaging. Since 2008, we have earned a stellar reputation as the preferred supplier of innovative packaging for a wide range of leading high street brands.

Since 2008, Spectra Packaging has quickly become a leading supplier of bottles and closures to numerous prominent brands. Our approach is straightforward: to consistently deliver excellence, innovation, and sustainability as standard.

Images