Company details for:

CS Simmons Precision Engineering Ltd

Mill Road Trading Estate,

Frome Hill,

Radstock,

Bath,

Somerset,

BA3 5TX,

United Kingdom

Quick Links:

Products / Services

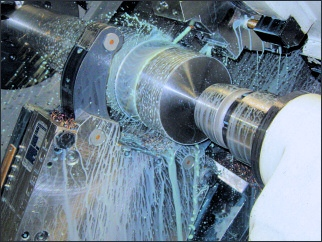

CNC Manufacturing Services

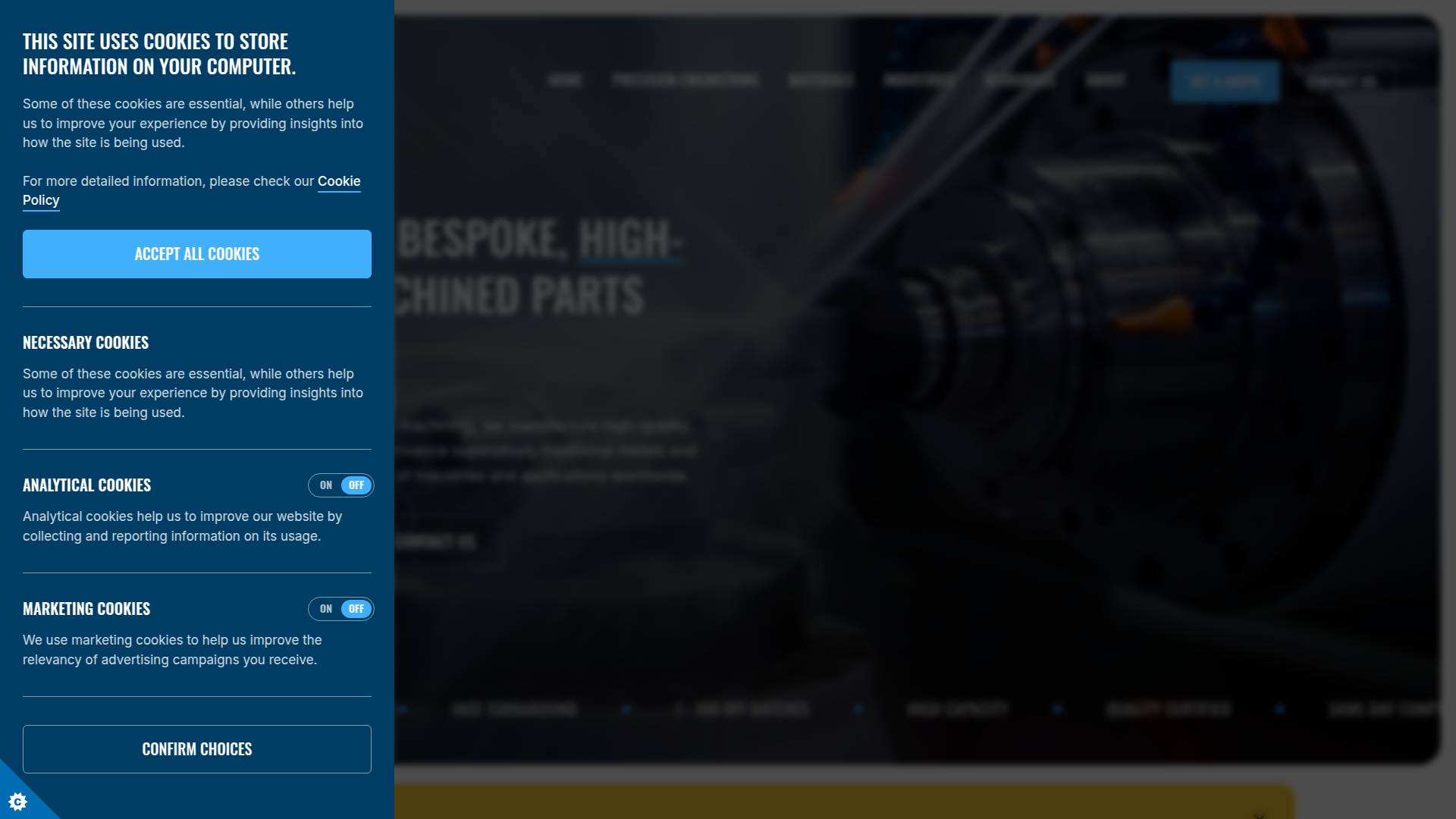

CS Simmons Engineering provide Large Component, Complex Component, Prototype Component, and Reverse Engineering CNC Precision Machining Services in both Regular and Super Alloys.

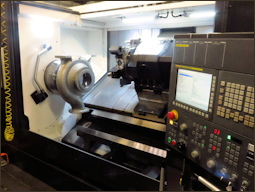

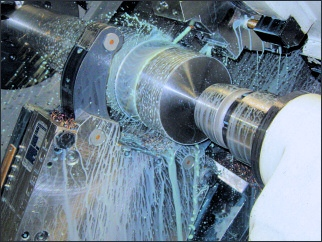

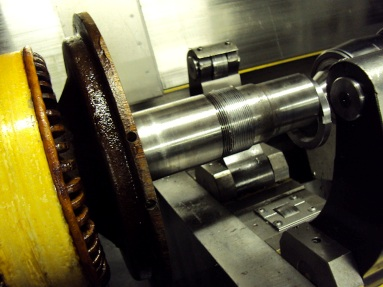

CNC Machining of Specialist Steels

C.S. Simmons Engineering prides itself on its ability to machine the more exotic materials such as Inconel, Hastelloy, Monel, 17-4 PH, S316 Super Duplex, Zeron 100 and Waspalloy.*

In our factory all of these materials have been successfully machined, as well as many other specialist alloys, for oil, defence and many other industry applications.

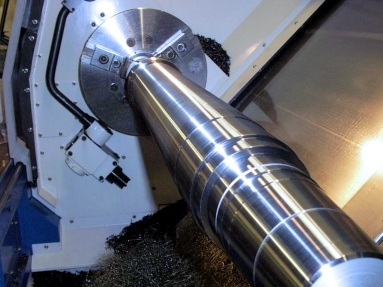

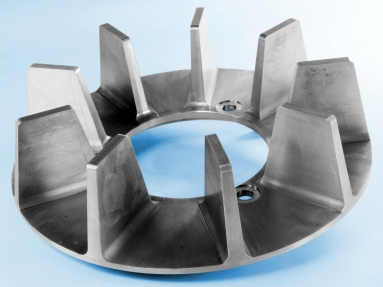

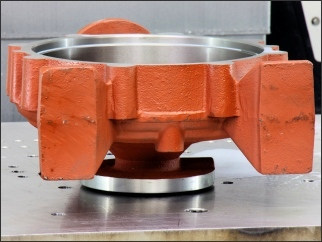

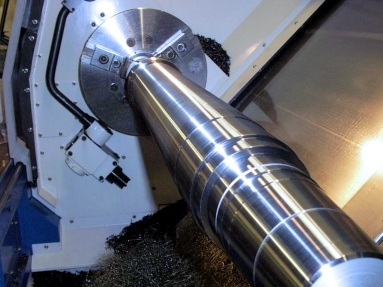

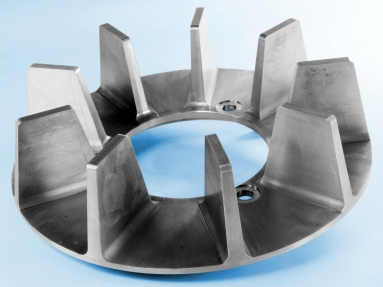

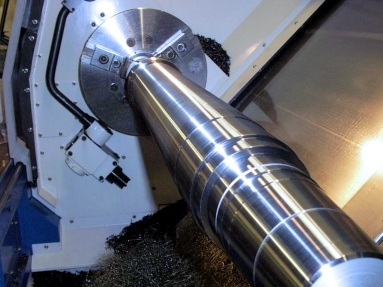

Large Component CNC Machining Services

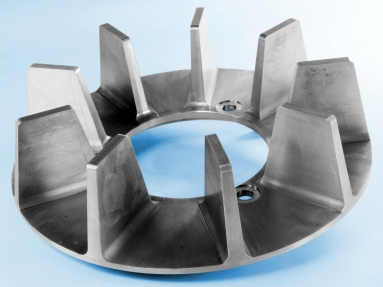

CS Simmons Engineering specialises in CNC machining of large and often complex components in both regular and Super Alloys.

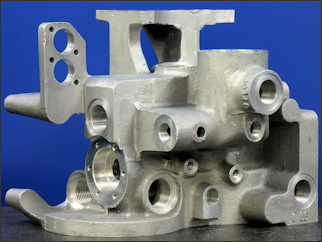

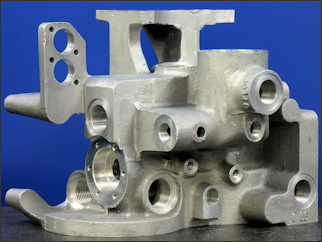

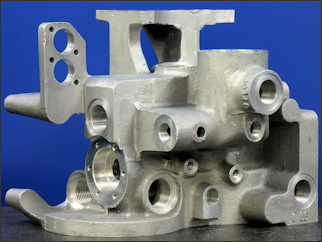

Complex Component CNC Machining Services

CS Simmons Engineering specialises in CNC machining of complex and often large components in both regular and Super Alloys

Prototype CNC Machining Services

CS Simmons Engineering specialises in CNC machining of complex and often large prototype components in both regular and Super Alloys.

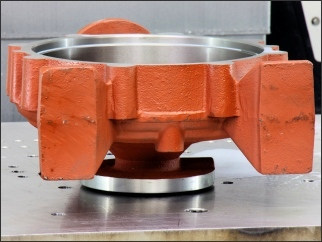

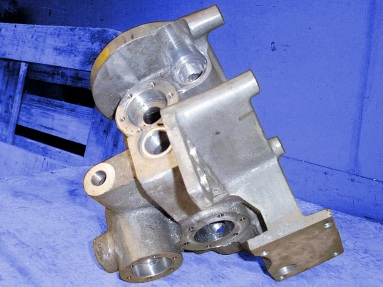

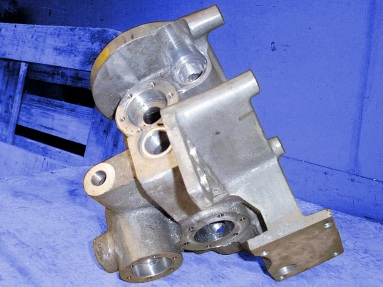

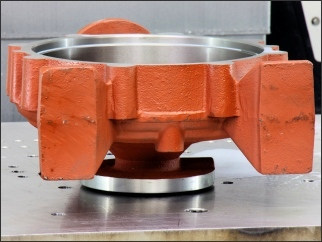

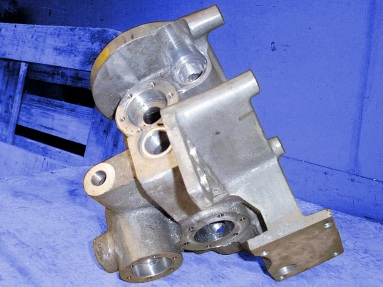

CNC Precision Machined Castings Services

CS Simmons Engineering specialises in CNC machining of complex and often large castings in both regular and Super Alloys.

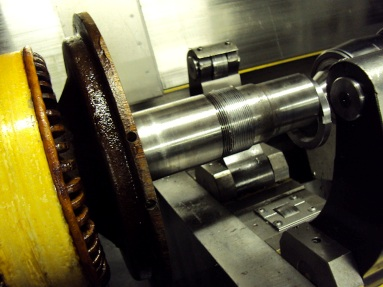

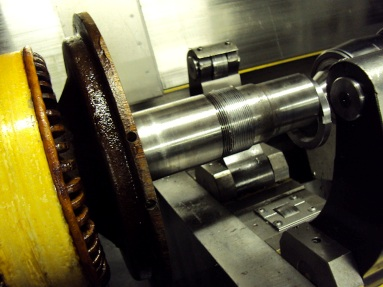

Reverse Engineering CNC Machining Services

CS Simmons Engineering is often asked to re-engineer an existing component that has broken or become so worn as to be no longer functional, and is no longer easily available.

Welding Services

CS Simmons Engineering provides welding services compliant with various ASTM International Standards as well others, such as API 6A, and can provide welding test results such as Dye Penetrant Inspection Reports and Radiographic Inspection Reports if required.

CS Simmons Engineering has worked with Code A Weld, who conveniently have a branch located only a few miles away, to develop Welding Procedure Specifications (WPSs) to comply with various welding standards often requested by its customers. This allows for a one-stop shop approach to both Precision CNC Machining and Standards Compliant Welding for machined components.

CS Simmons Engineering also uses Code A Weld for Dye Penetrant Inspection and Radiographic Inspection, as and when required.

Compliance with such welding standards is often an essential requirement within the oil and gas industry, as well as in many other industries.

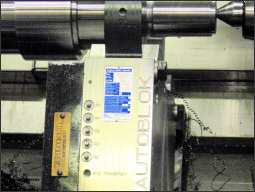

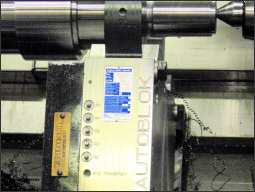

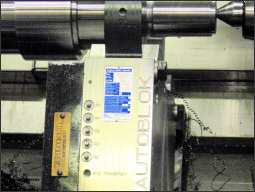

Tricorn Production Control

CS Simmons Engineering uses job processing, scheduling and quality management software from Tricorn Systems for Production Control. This is used from quotations to invoicing, incorporates all ISO 9001:2015/AS9100 quality requirements and allows real-time job scheduling and planning and full material traceability.

BS EN ISO 9001:2015 Quality

CS Simmons Engineering is a BS EN ISO 9001 : 2015 Quality Management Certified Firm, Certificate No. 9835. Working with a local manufacturing association CS Simmons have also employed lean strategies to further improve our quality performance.

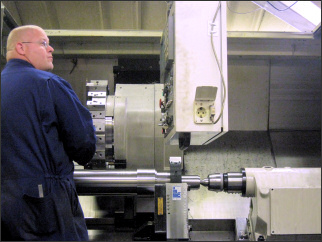

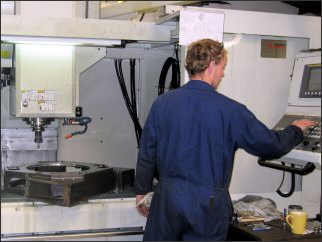

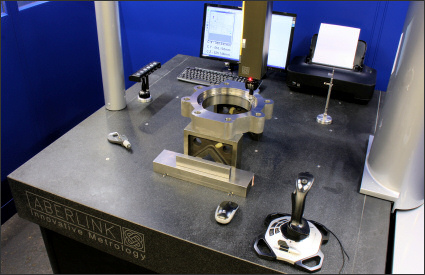

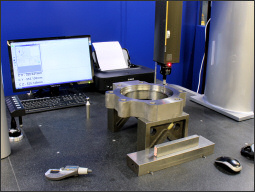

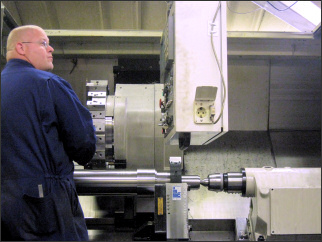

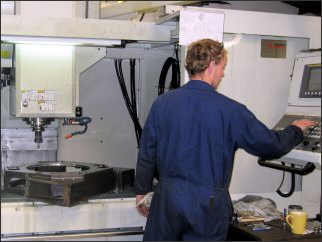

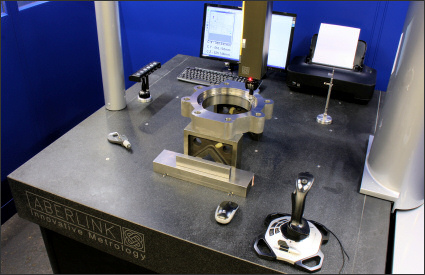

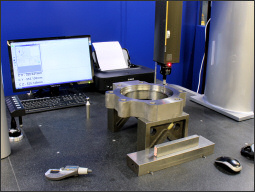

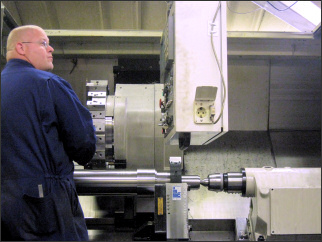

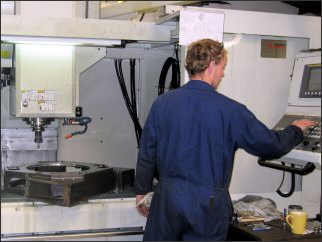

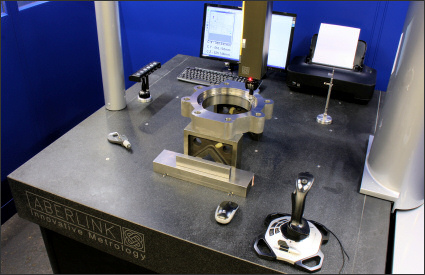

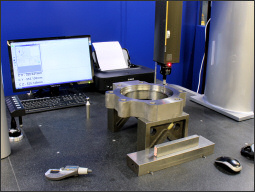

Our Factory

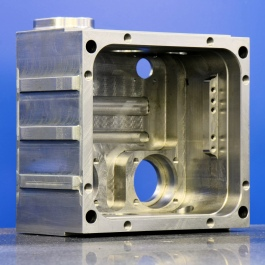

CS Simmons Engineering has a modern, well equipped factory in Radstock, in the heart of Somerset.

Capacity List

CS Simmons Engineering provide a CNC machining service to many industries, including oil, valve and defence. All types of machining are undertaken, including heavy stainless steel machining and machining of exotic materials such as Inconel, Hastelloy, Monel, 17-4 PH, S316 Super Duplex, Zeron 100 and Waspalloy.*

Manufacture and inspection meet the requirements of the updated BS EN ISO 9001 : 2015 certification (Certificate can be provided on request).

Quality and performance are monitored closely with set procedures and with Tricorn Job Processing software that allows unparalleled traceability during the machining process and long after delivery.

CS Simmons Engineering continually invests in the latest CNC precision machining technology available to always remain very competitive and to be able to meet very demanding delivery times without compromising quality.

About us

CS Simmons Precision Engineering Ltd has delivered top-quality CNC machined components for over 45 years.

Founded in 1976 by Clive Simmons, CS Simmons Engineering remains a family-run business, now managed by both Clive and his son, Mark.

CS Simmons Engineering Ltd has extensive expertise in CNC machining a wide range of superalloys, including Inconel, Hastelloy, Monel, 17-4 PH, S316 Super Duplex, Zeron 100, and Waspalloy.

Our Services Include:

CNC Machining Services

CS Simmons Engineering provide Large Component, Complex Component, Prototype Component, and Reverse Engineering CNC Precision Machining Services in both Regular and Super Alloys.

Welding Services

CS Simmons Engineering also offers welding services that meet a range of standards, including ASTM International and API 6A. Upon request, they can supply welding test documentation such as Dye Penetrant and Radiographic Inspection Reports.

… And more.

CS Simmons Engineering Ltd holds BS EN ISO 9001:2015 Quality Management certification (Certificate No. 9835) and is regularly audited by NQA.Quality and performance are rigorously controlled through established procedures and Tricorn Job Processing software, ensuring exceptional traceability throughout machining and beyond delivery.

For more information please contact Mark Simmons, Clive Simmons or Allen Moore on +44 (0)1761 433944. All will be very happy to help you with any request.

Images

Articles / Press Releases

Brochures

Trade Associations