Company details for:

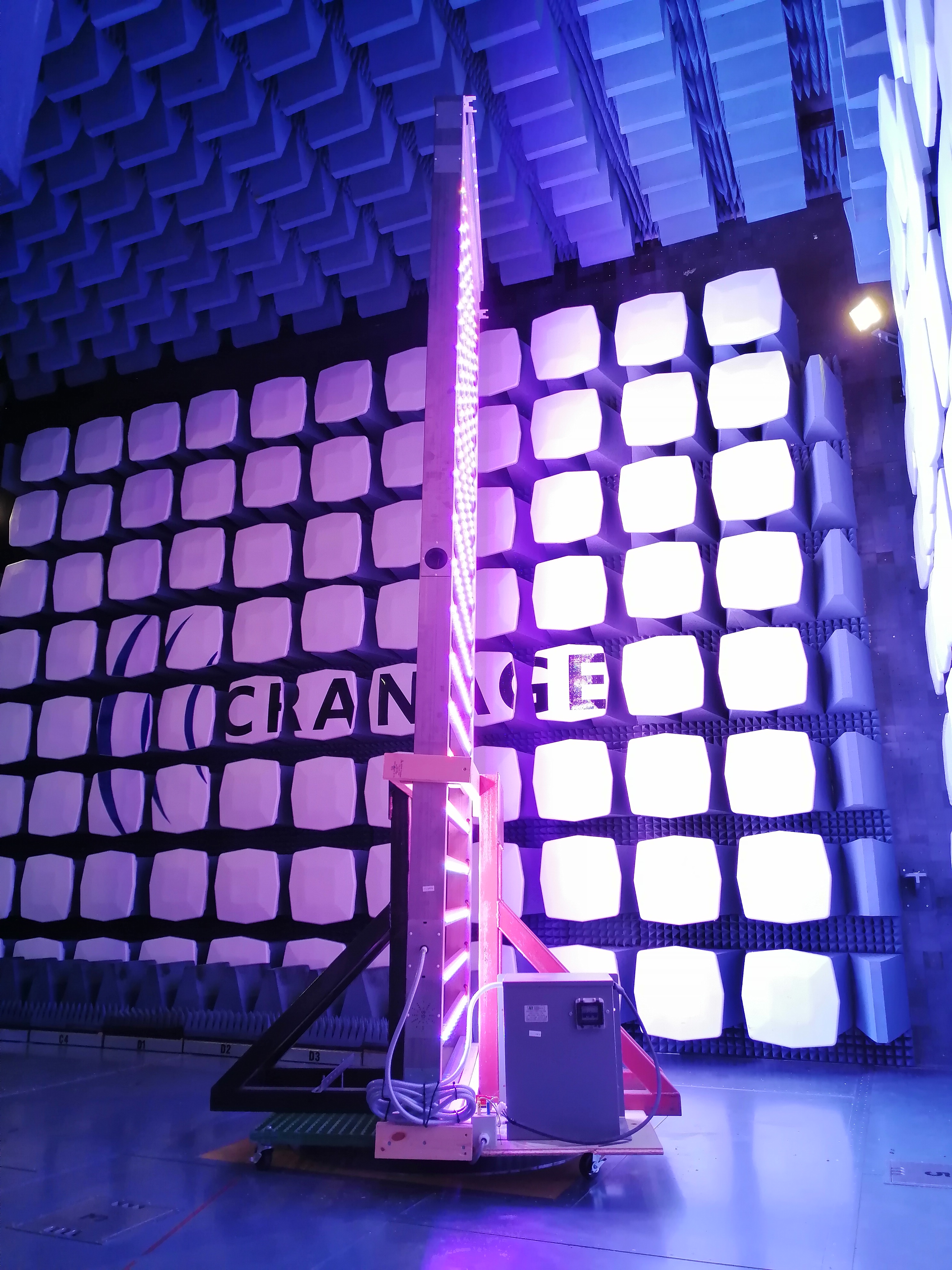

Cranage EMC & Safety Ltd

Quick Links:

Products / Services

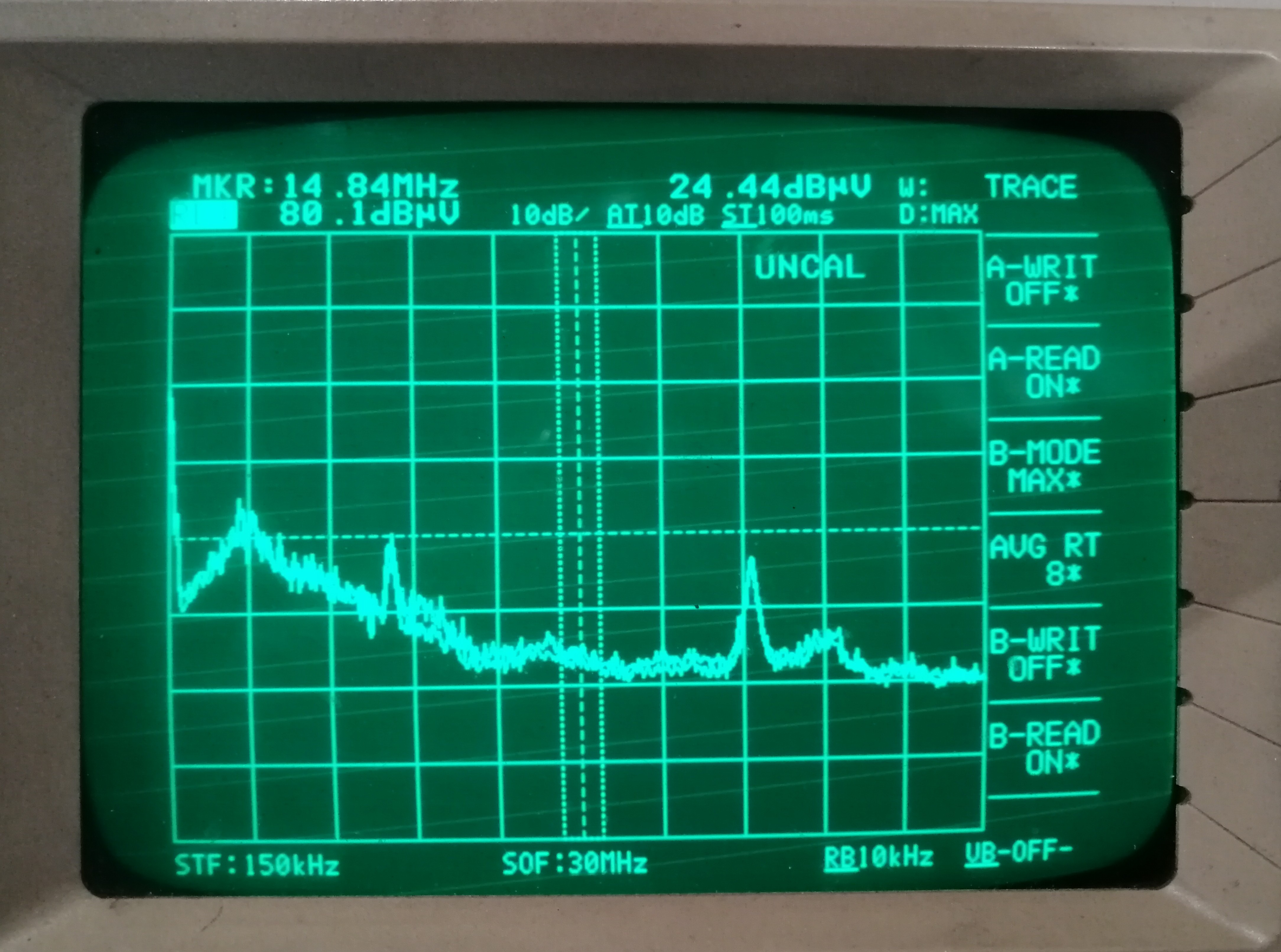

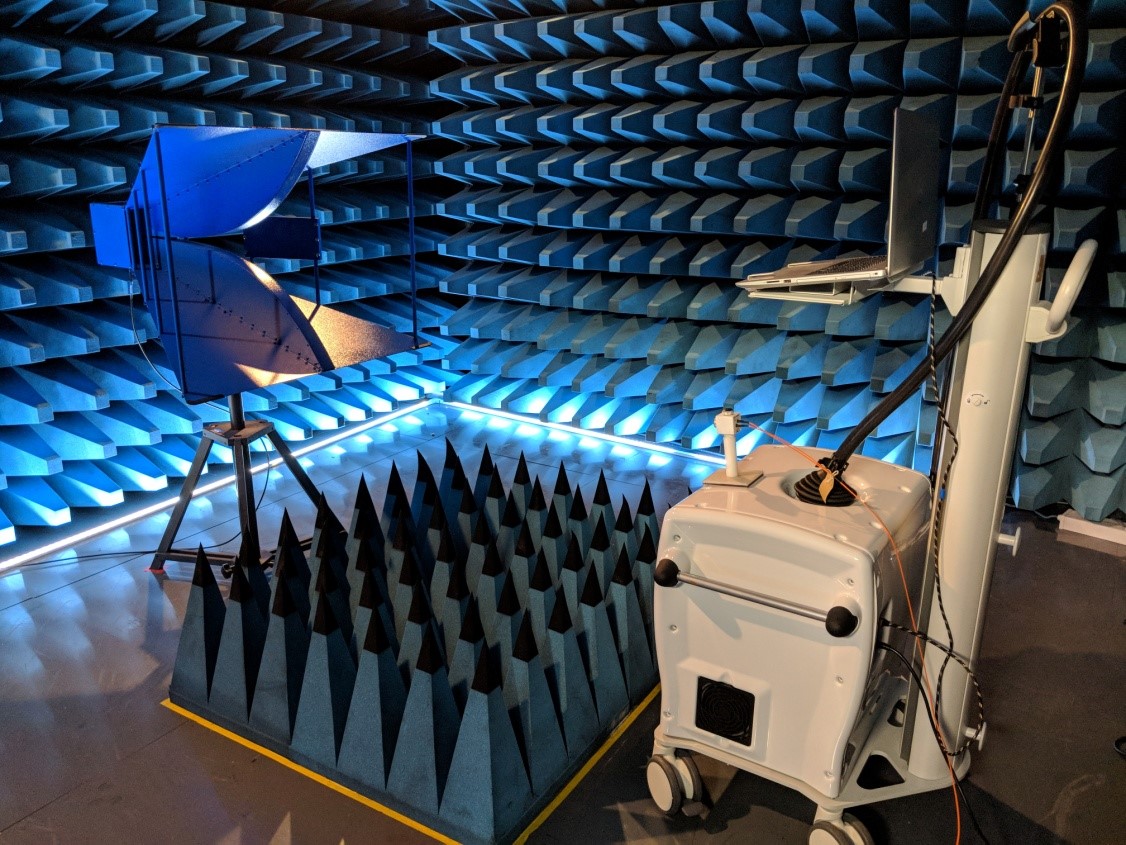

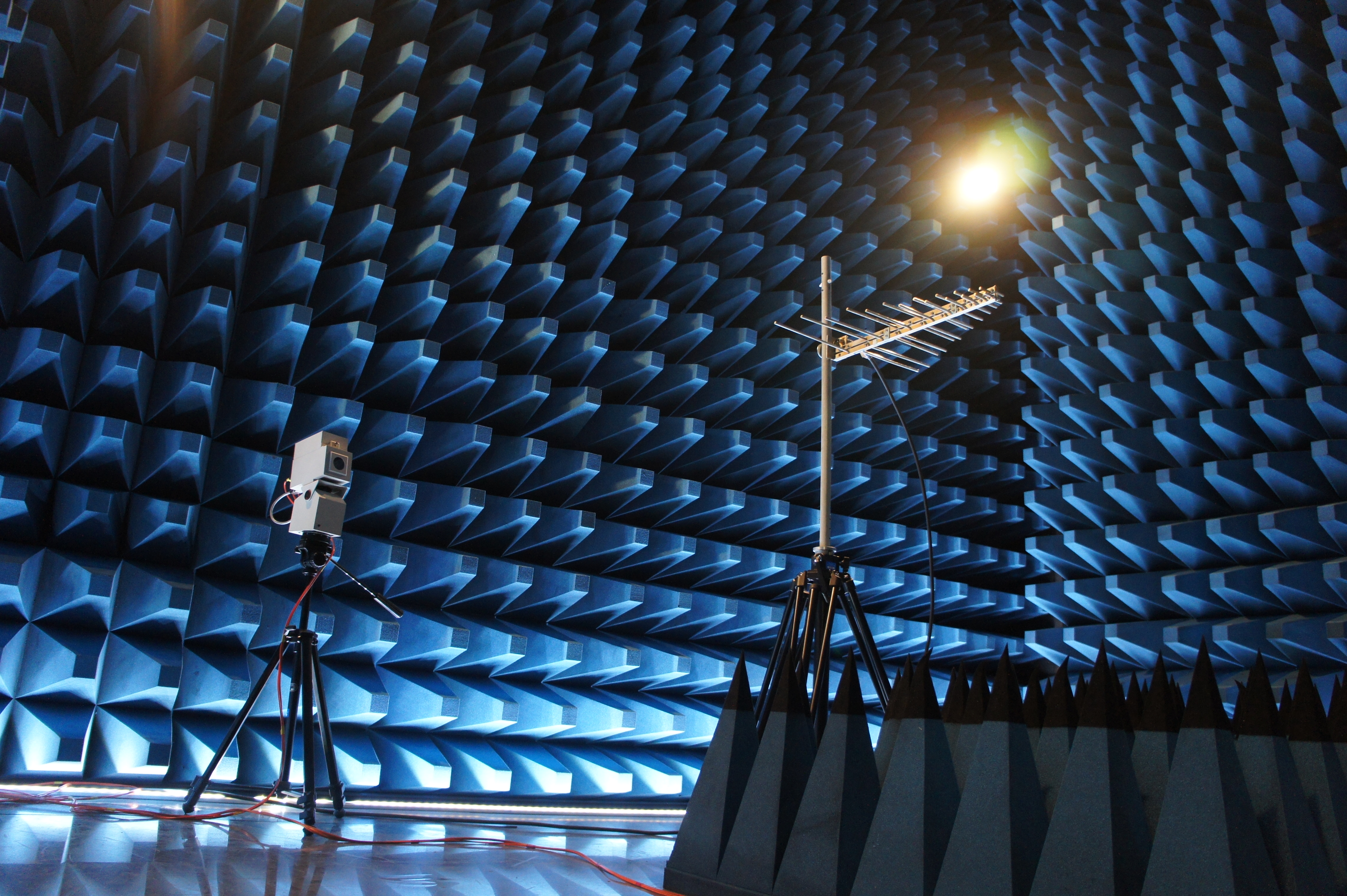

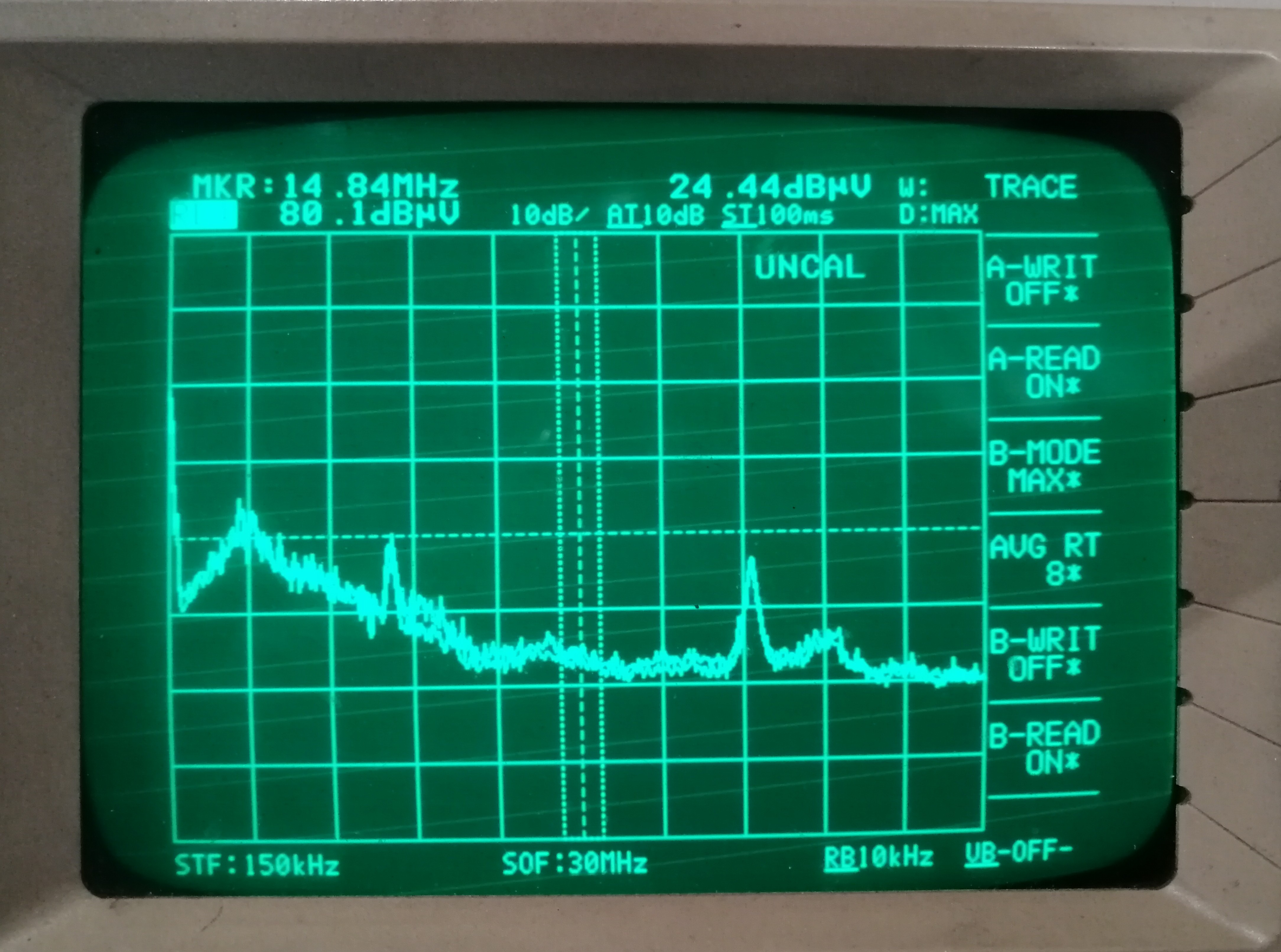

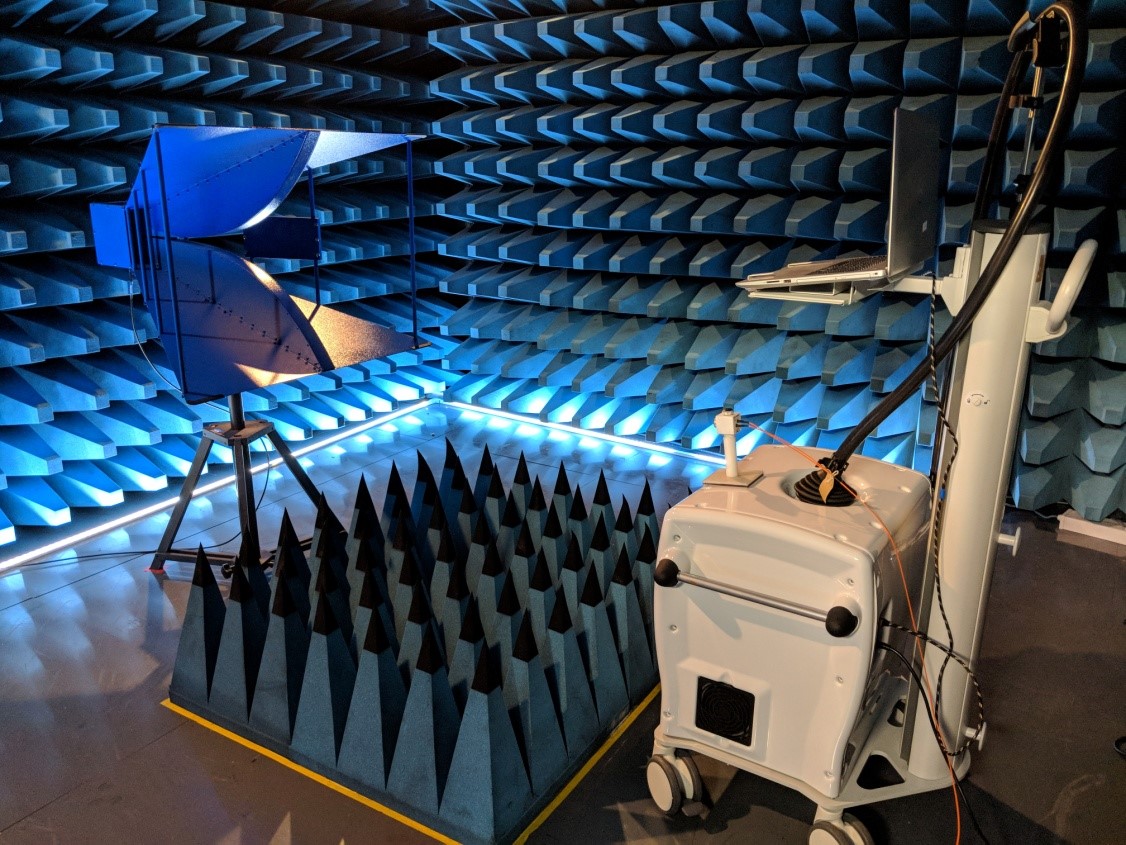

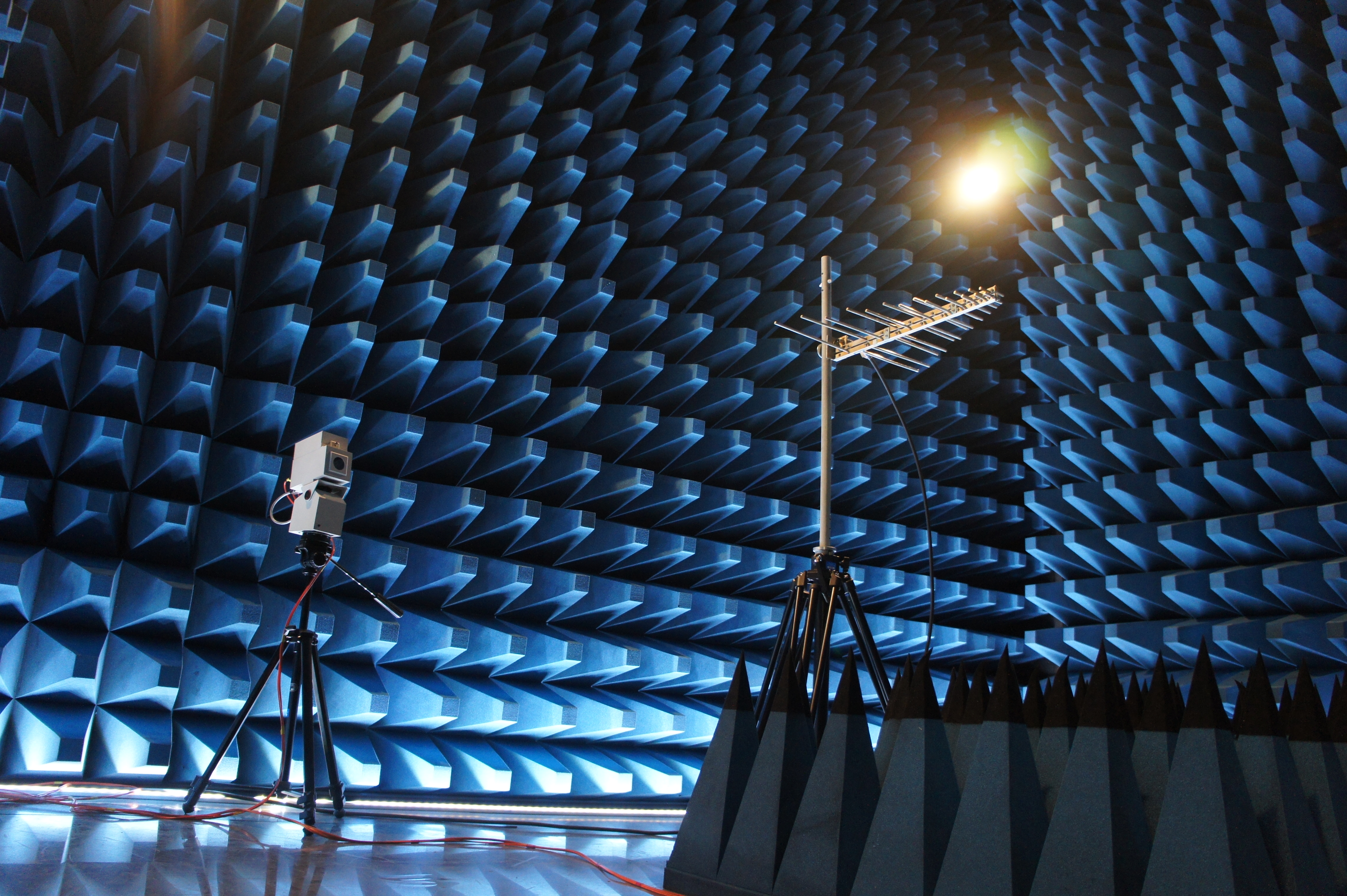

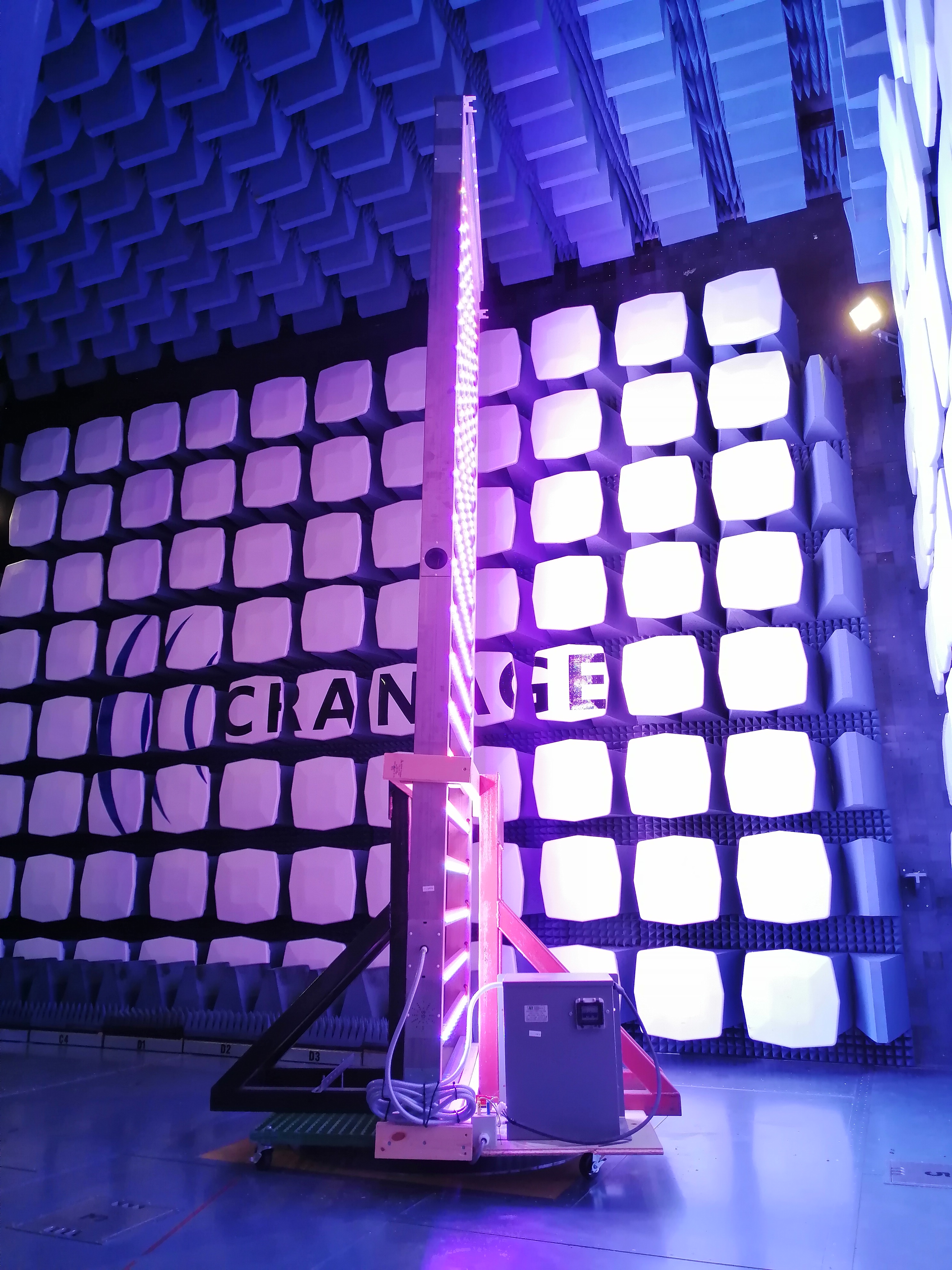

EMC Testing

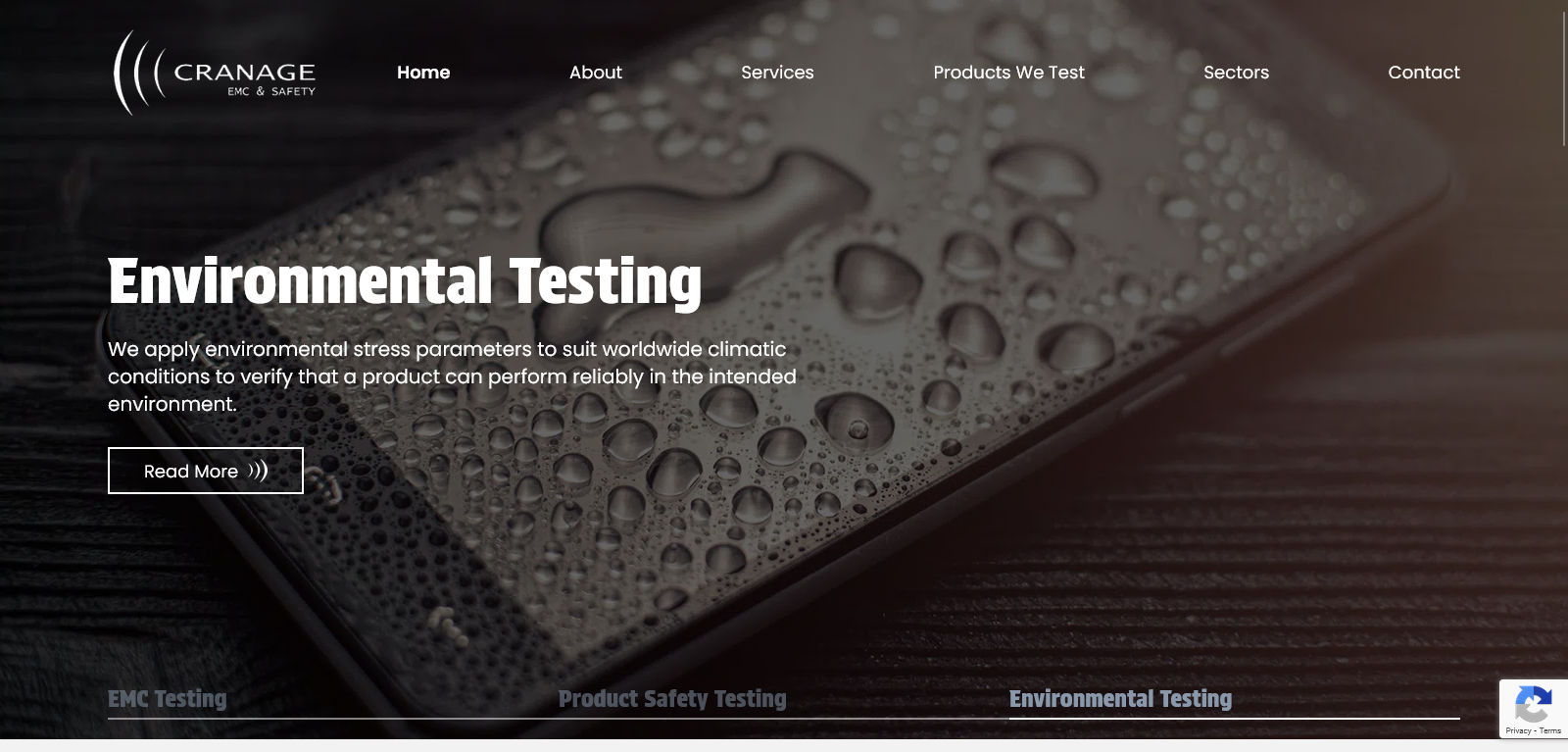

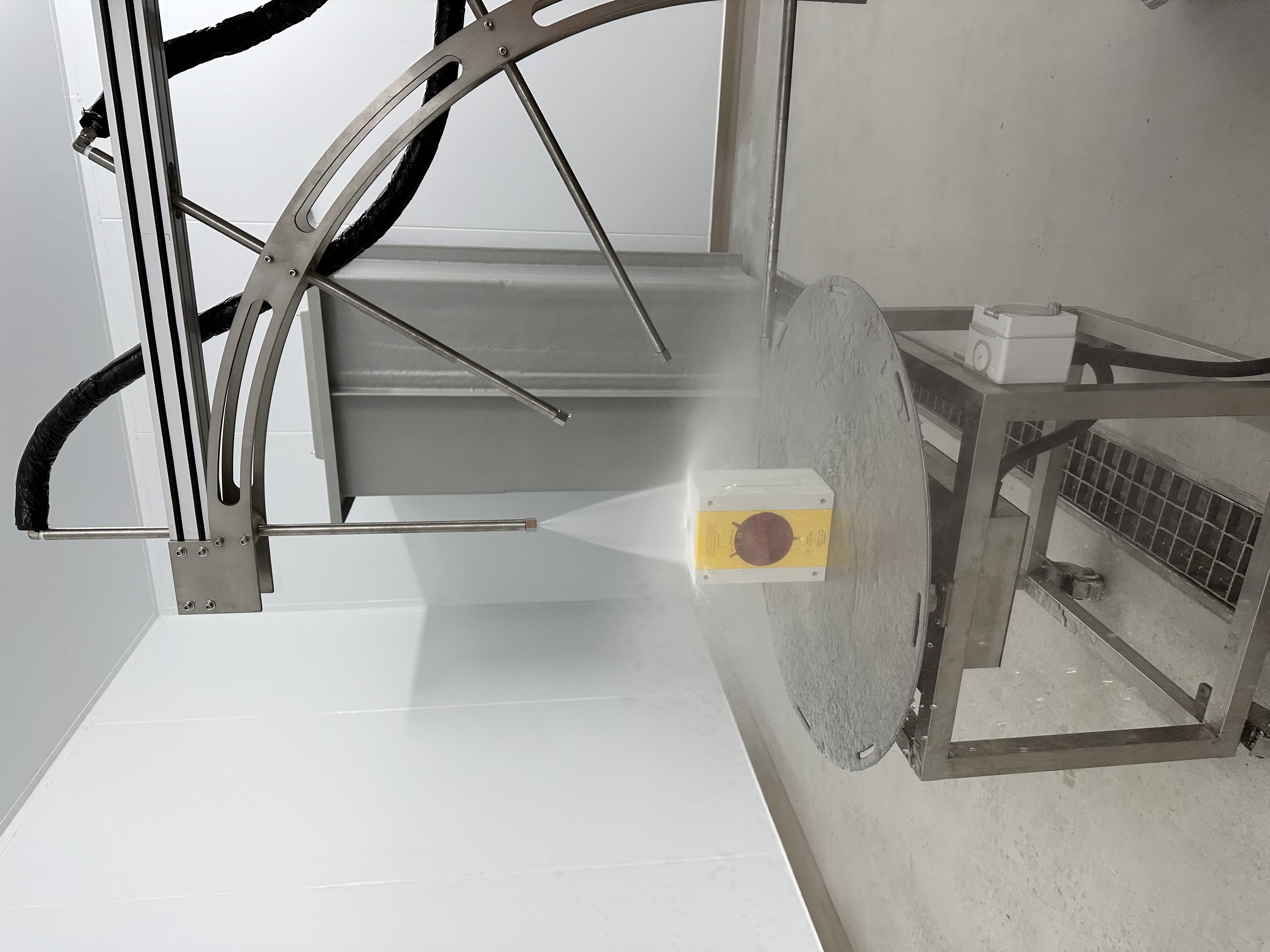

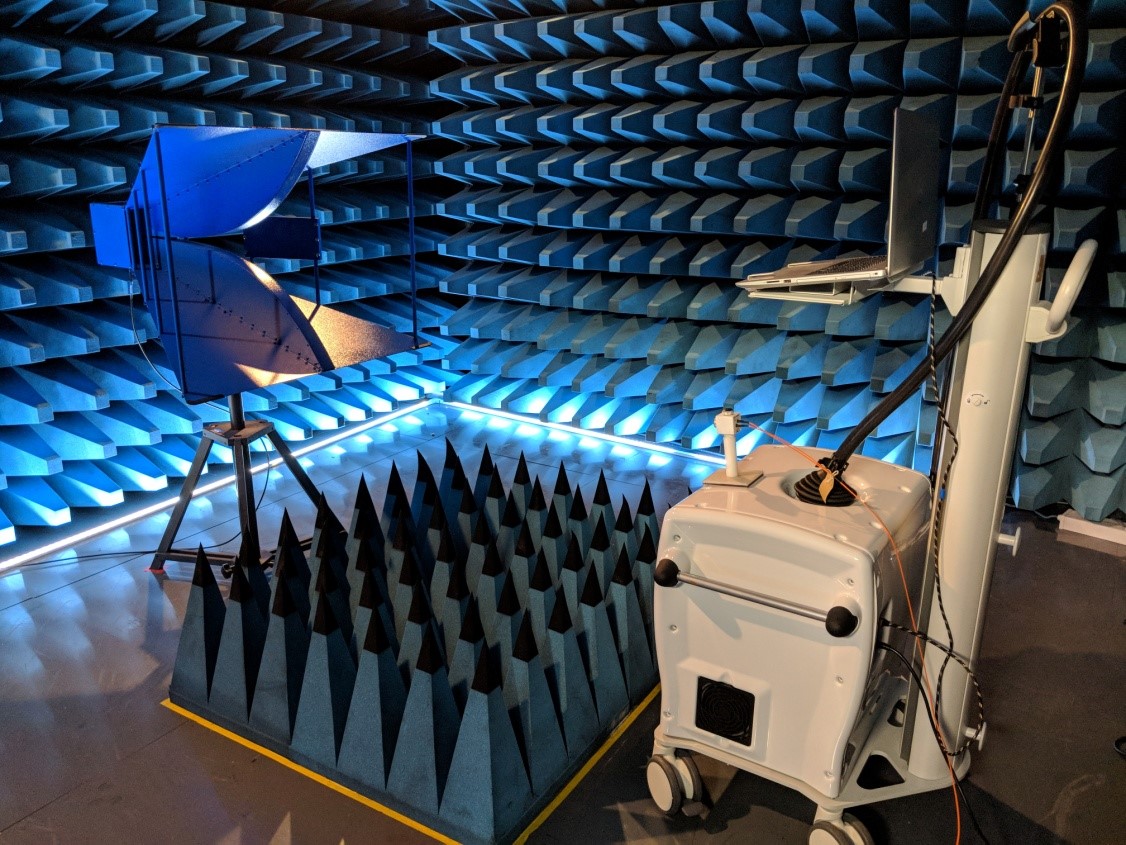

Cranage EMC and Safety, based in Shropshire near Birmingham, offers a complete range of EMC testing throughout the UK, including full compliance, pre-compliance and in-situ testing.

Ensure your electrical equipment performs seamlessly in any environment. Reach out below to explore our comprehensive EMC testing services and safeguard your operations against interference.

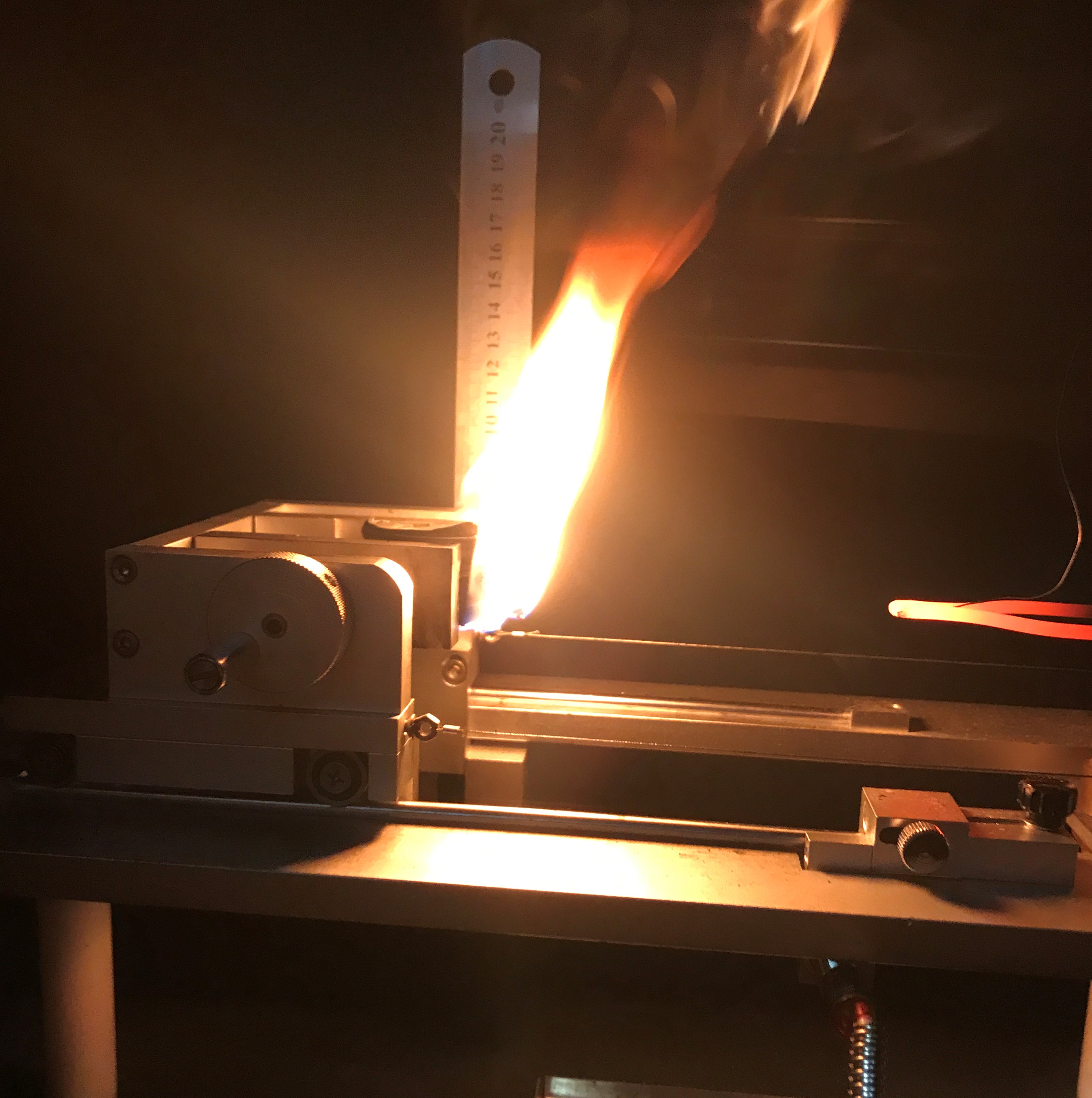

Product Safety Testing

The Cranage EMC and Safety team, based in Shropshire near Birmingham, can assess a wide range of items to ensure they comply with the relevant country regulations. Our UKAS scope includes an extensive range of standards, and using an accredited laboratory for your product safety testing will help mitigate the risk of danger to the consumer.

Cranage EMC and Safety offers a complete range of safety testing for electrical and electronic items to meet the country-specific regulations of your intended market. In Europe, this is the Low Voltage Directive (LVD) 2014/35/EU, and in the UK, it is the Electrical Equipment (Safety) Regulations 2016.

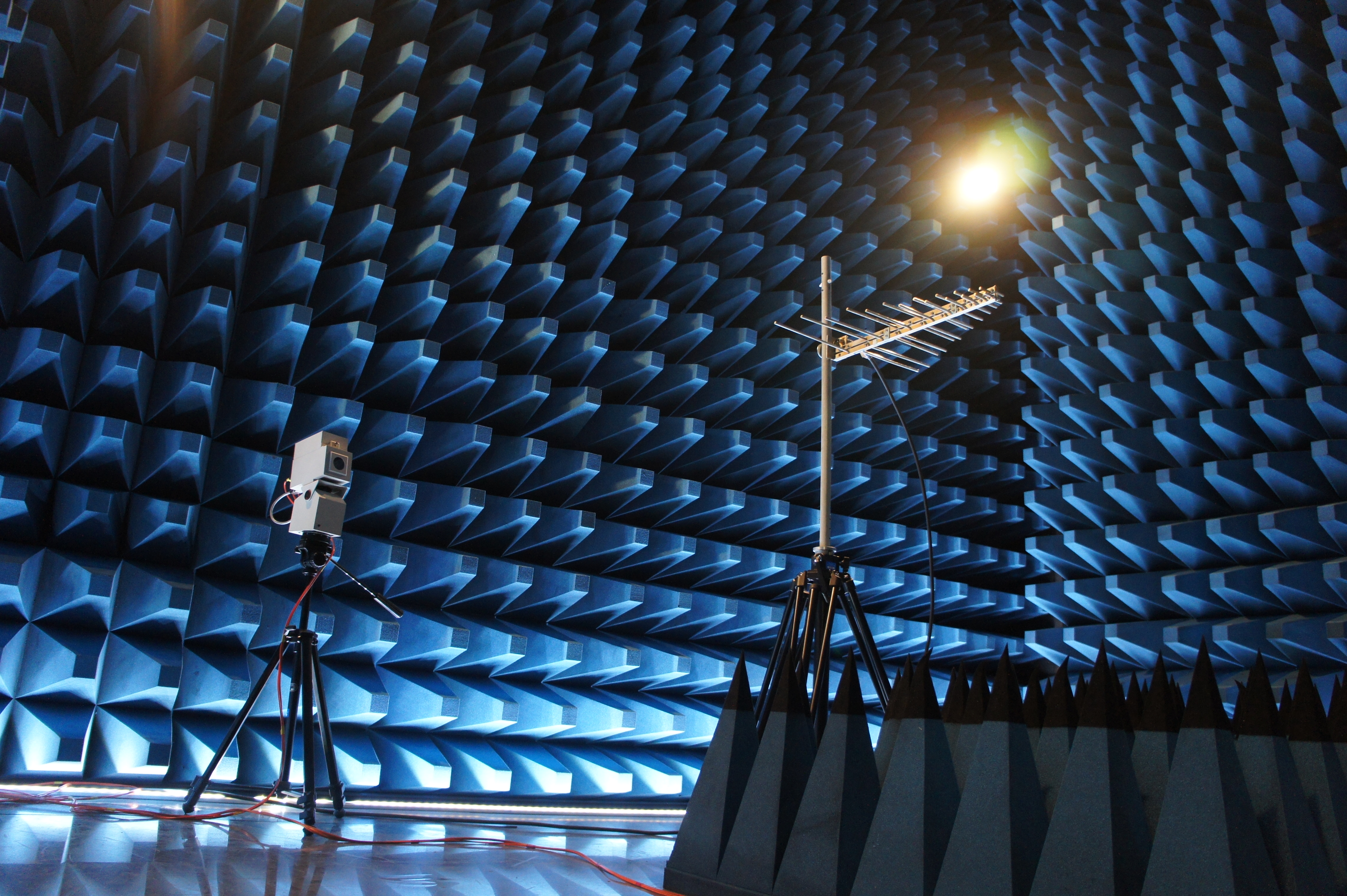

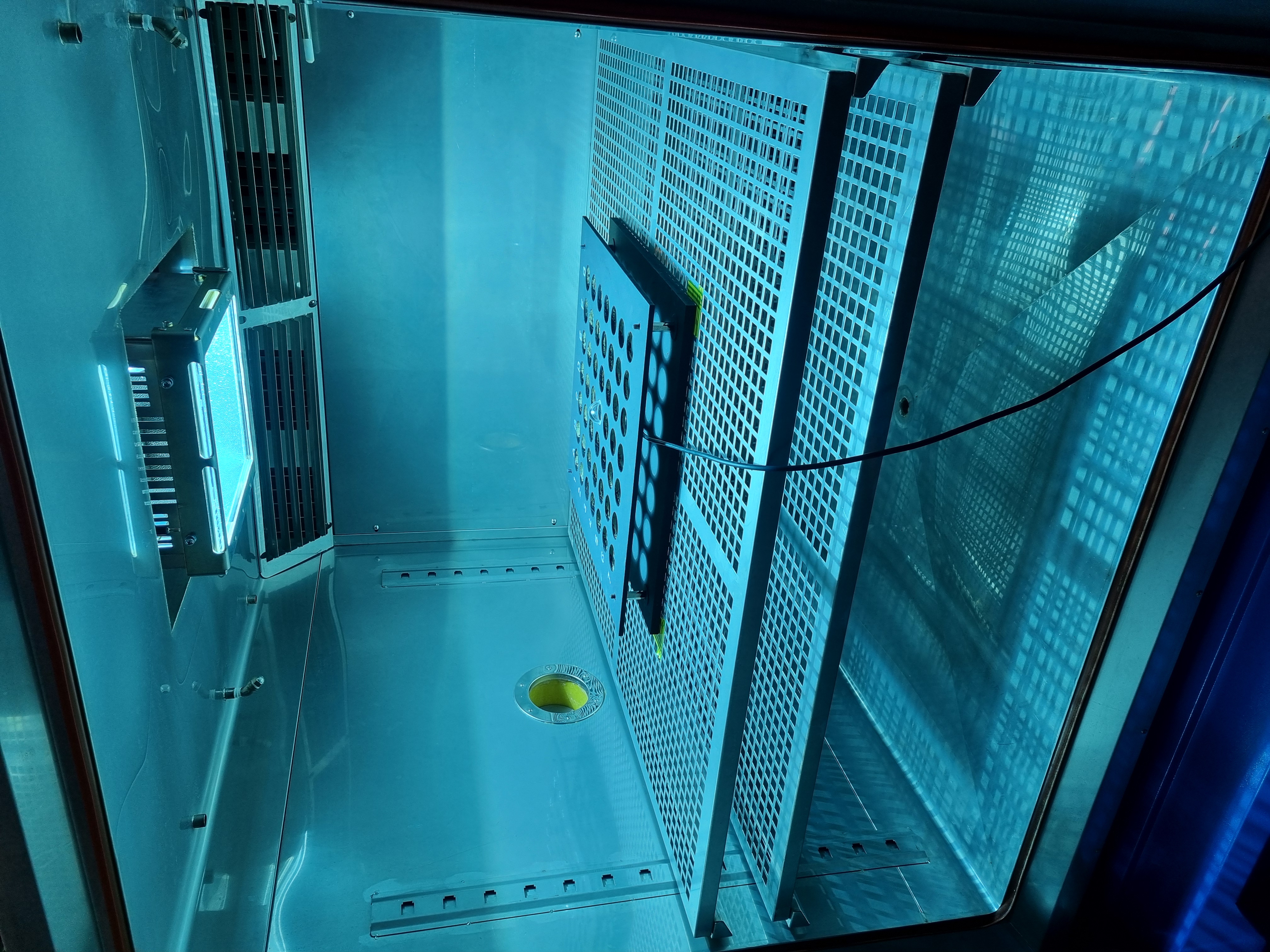

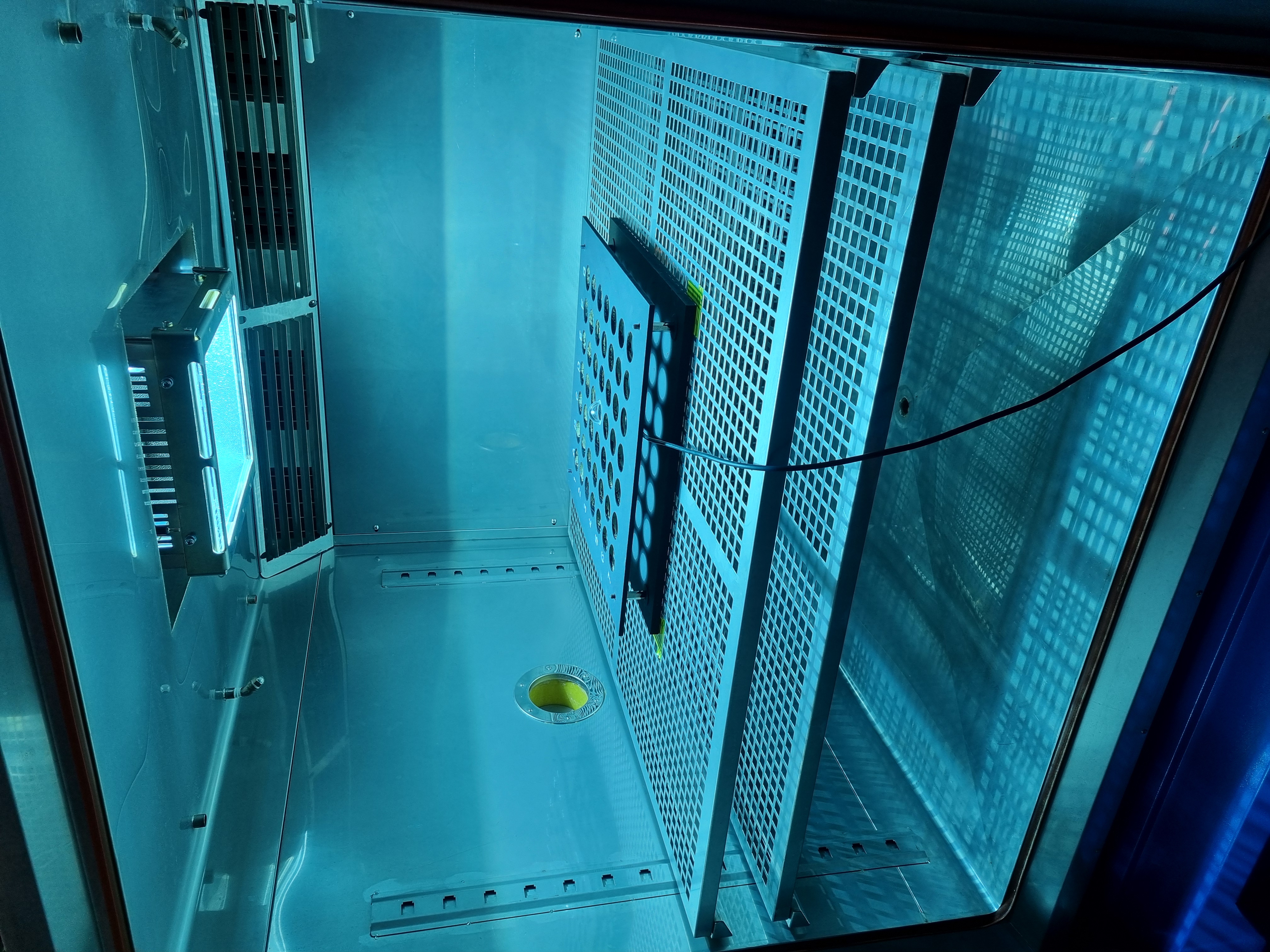

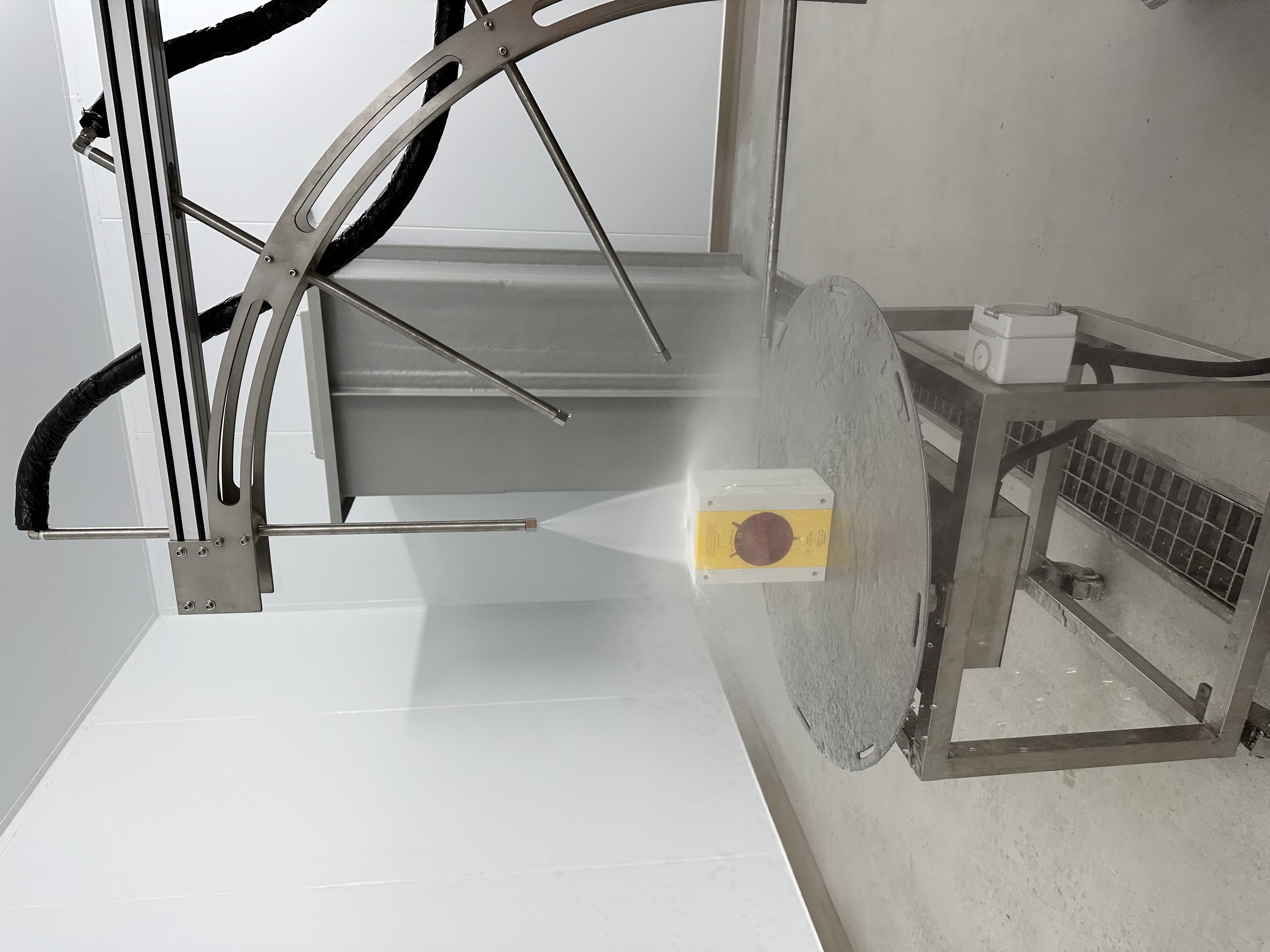

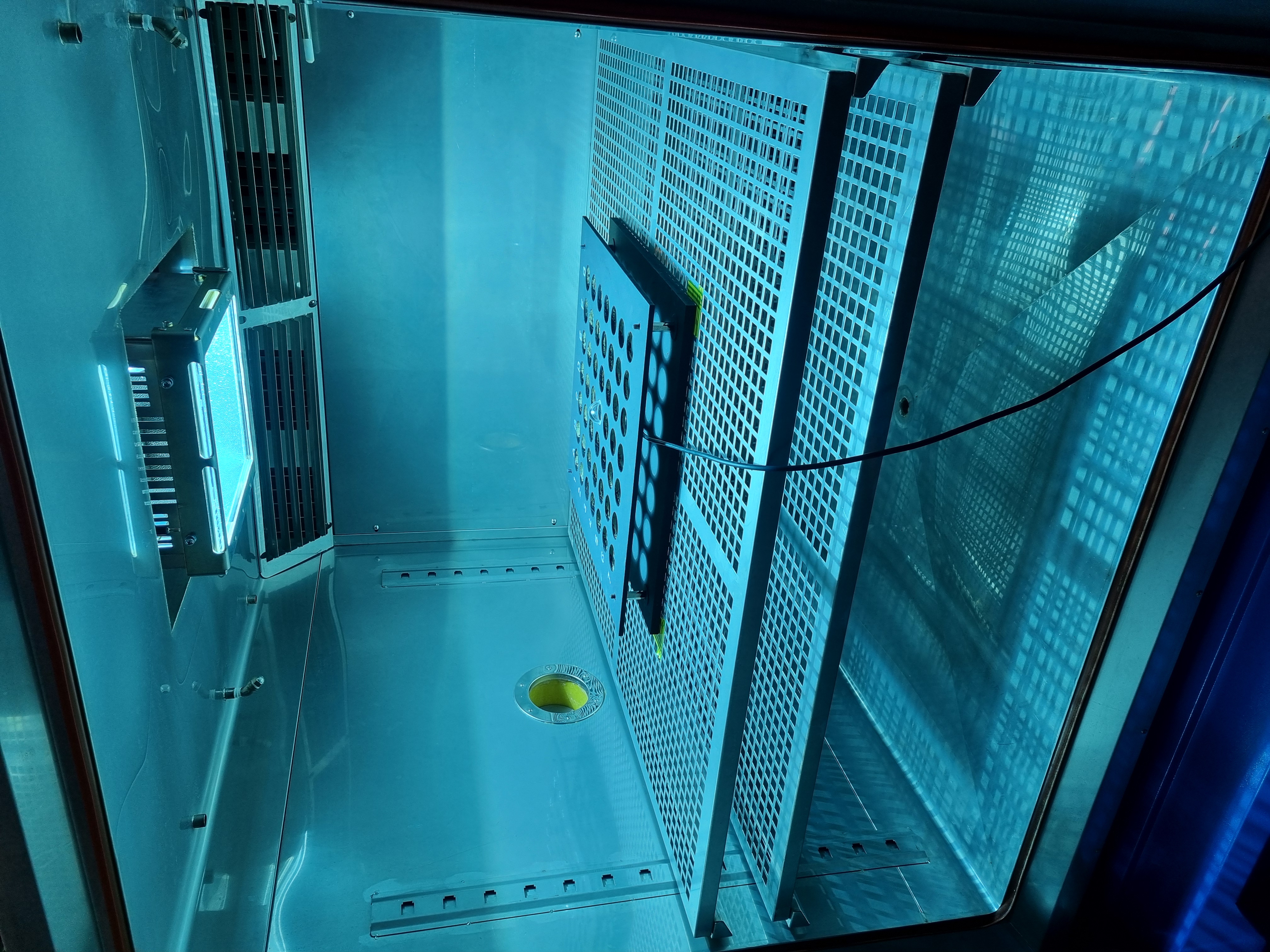

Environmental Testing

Cranage EMC and Safety, based in Shropshire near Birmingham, has an extensive suite of environmental test chambers at our premises. These chambers simulate the majority of environments that your product may be exposed to, either through storage, transport, or operation. We can apply environmental stress parameters to suit worldwide climatic conditions to verify that a product can perform reliably in the intended environment.

We have climatic chambers to cover humidity, RH damp heat, solar radiation, temperature cycling and salt spray.

Don’t leave your product’s reliability to chance. Reach out below to explore our comprehensive environmental testing solutions and ensure your electronics can withstand the toughest conditions they may encounter.

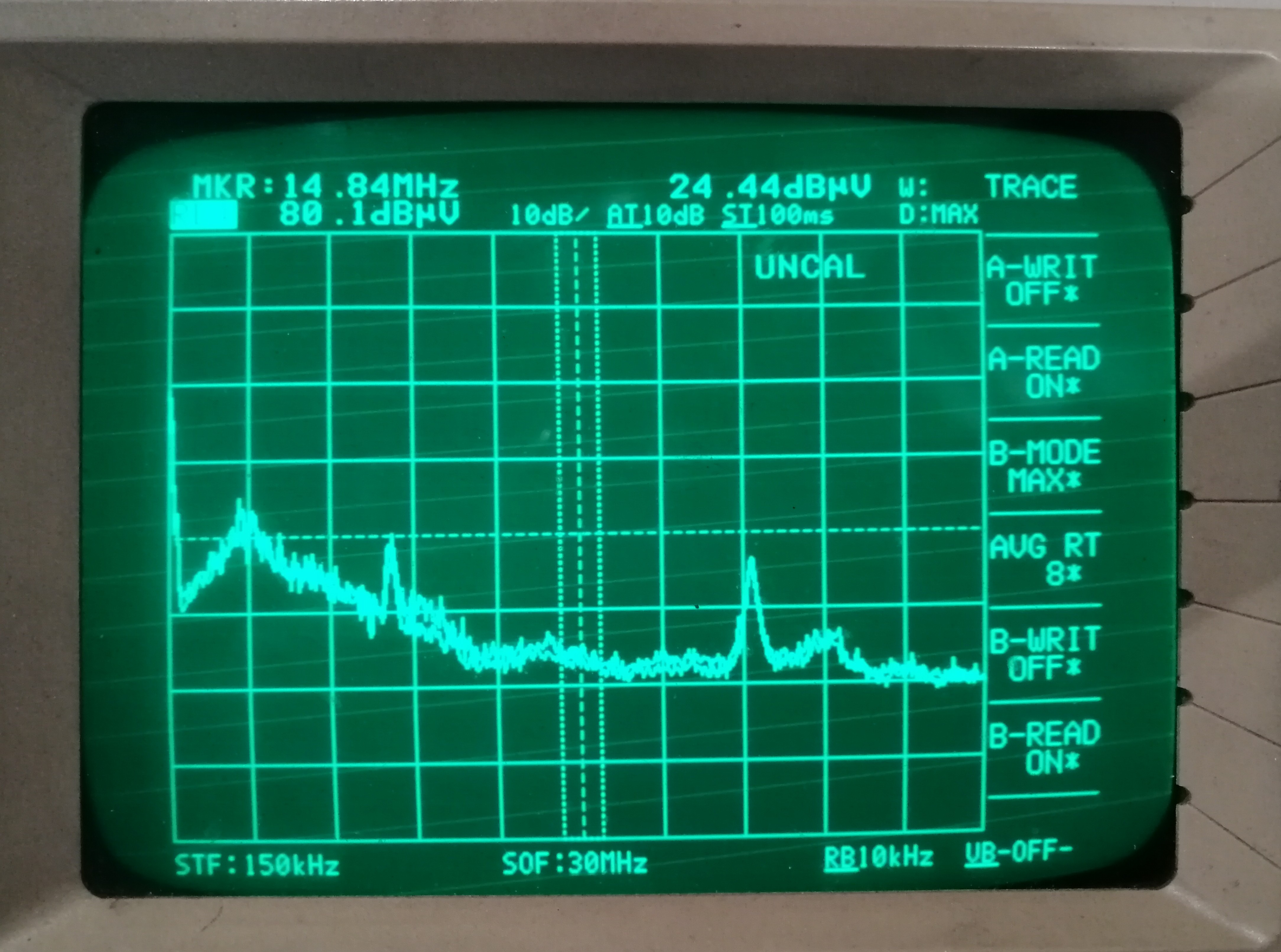

Pre-Compliance Testing

It is not unusual for a product to fail initial full-compliance testing, and this can be due to issues such as failing to apply EMC principles in the product design, the use of non-compliant modules, unpredicted interactions among circuit elements, an assumption that the presence of a declaration of conformity on a sub-assembly is enough and not testing the power supply with the full product. Considering and designing for EMC and safety early in the product lifecycle helps to reduce the chances of product malfunction or product recalls.

EMC Pre-compliance testing can be categorised into two main groups: emissions testing and immunity testing. Within each of these, both radiated and conducted tests are carried out.

On-Site Testing

Although it would not be feasible to perform tests in full accordance with the relevant technical standards, Cranage EMC’s testing methodology and procedures have been assessed and approved for product certification. Testing will be performed to simulate actual operating conditions.

It may be necessary to assess more than one mode of operation to maximise emissions or determine worst-case susceptibility.

Global Services

EMC is not a legal requirement for products sold on the US market. The FCC regulates radio-frequency emissions, but its standards and equipment authorisations do not comply with European or British regulations. Our compliance engineering team can advise on gaps or shortfalls and recommend appropriate action to meet EMC requirements.

Commercial Alarm Testing

Mobility Aids & Stairlifts Testing

At Cranage, we work with manufacturers of this technology, assisting to evaluate their products for adherence to British, European and International Standards, providing independent and impartial testing facilities for demonstrating safety, reliability and performance. We test mechanical safety, EMC and electrical safety and also work with manufacturers to assess user manuals.

Household Appliance Testing

We offer pre-compliance and compliance testing to help customers gain UKCA / CE Marking or global certification, and where products are large or in-situ we can even test at your premises.

In a fast-paced, competitive environment where manufacturers are continually developing their products, it is vital that the appropriate tests are carried out to ensure not only consumer safety but also product quality.

Light Testing

-CE Marking Directive

-Low Voltage Directive (LVD)

-Electromagnetic Compatibility Directive (EMC)

-Electromagnetic Fields Directive (EMF)

-Artificial Optical Radiation Hazard Directive (AOR)

-General Product Safety Directive (GPSD)

-Energy Related Products Directive (ErP)

-Restriction of Hazardous Substances Directive (RoHS)

-Waste Electrical and Electronic Equipment Directive (WEEE)

-Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH)

-Substances of Very High Concern (SVHC)

-Ecodesign and Energy Labelling Directive

-UK Electrical Equipment Safety Regulations

Type Testing & Screening

These are products which contain components (other than a fuse link, switch or indicator light) and are considered to be electrical equipment covered in the UK by the Electrical Equipment (Safety) Regulations 1994 (SI 1994 No. 3260). These types of products are also defined in The Plugs and Sockets etc. (Safety) Regulations 1994 (SI 1994 No. 1768) as electrical appliances.

Road & Rail Testing

Equipment intended for use in safety related systems is particularly scrutinised for its immunity to electromagnetic disturbances, continuous and transient, derived from airborne and conducted sources.

Cranage has specialist knowledge and facilities to investigate and measure the screening performance of cables, connectors, materials, assemblies and electronic modules. We work with clients to investigate the sources of electromagnetic leakage and have developed application specific shielding solutions to achieve EMC. Our experience ranges from testing rolling stock apparatus to vehicle messaging signs and this aspect of our business is under constant development as new technologies and products continue to push boundaries.

Lab Equipment Testing

Medical Equipment Testing

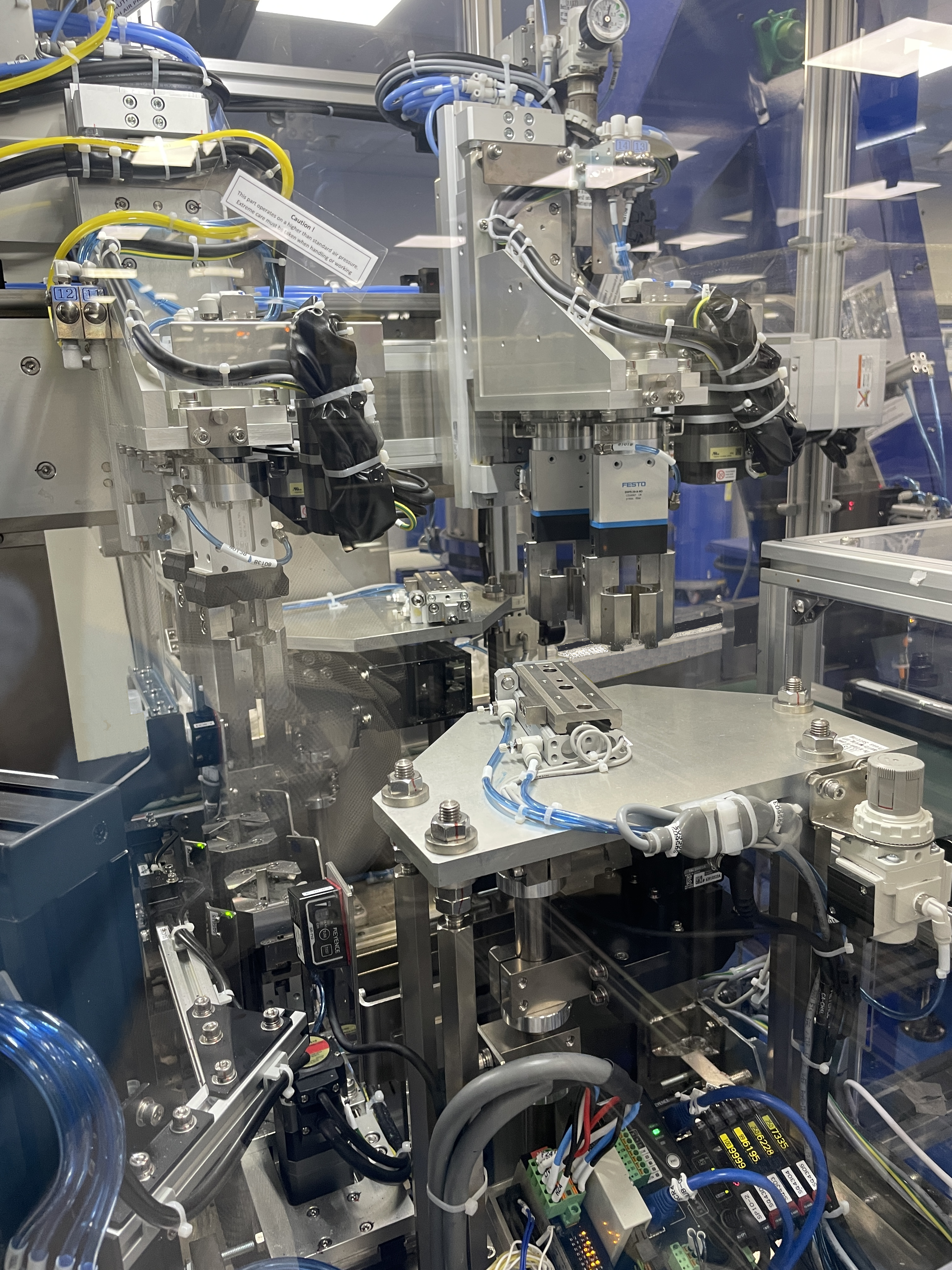

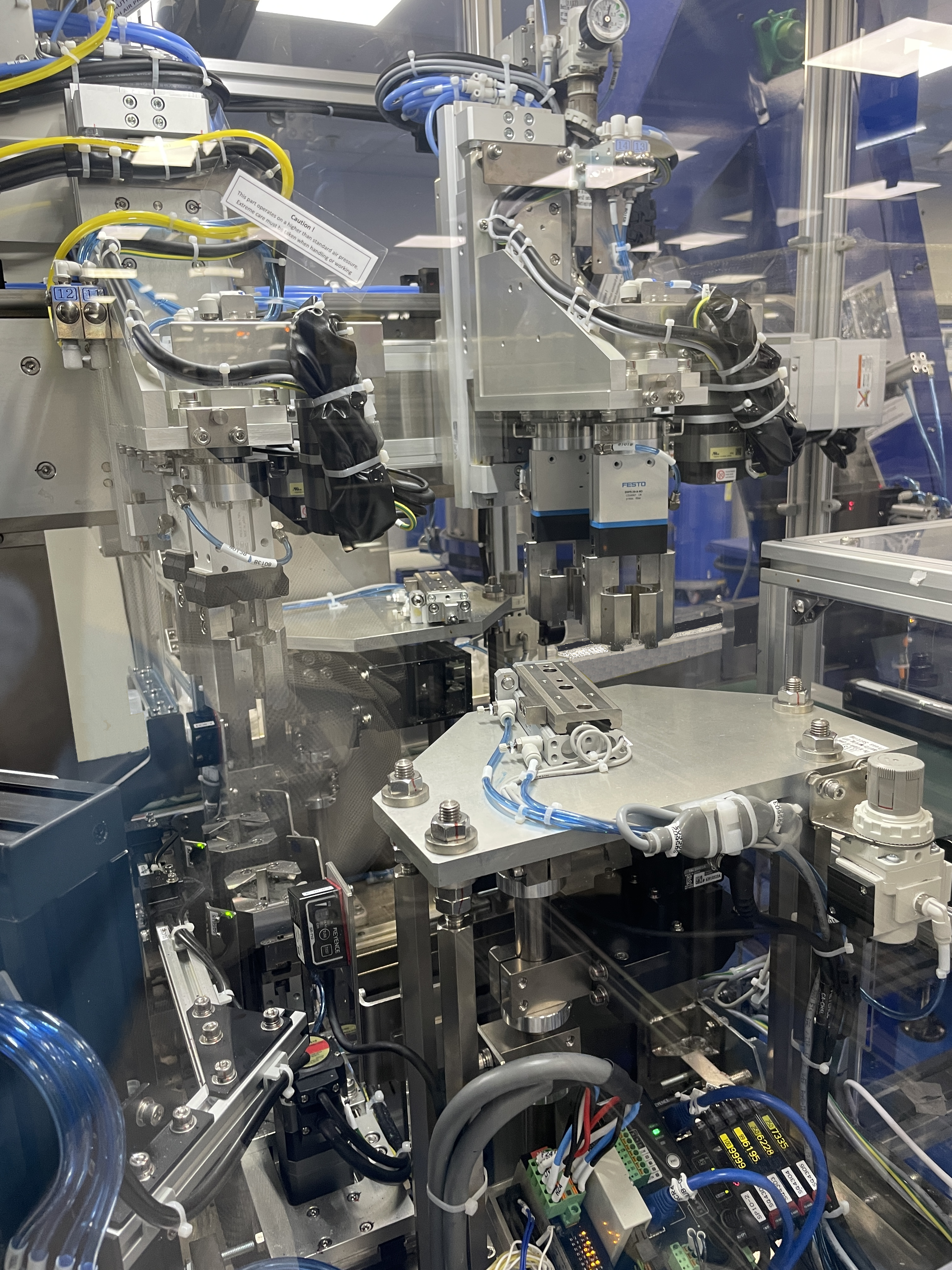

Industrial Machinery Testing

Industrial equipment and electrical machines have all got one thing in common- the utilisation of electrical energy. The electrical wiring which makes this possible conducts and radiates electromagnetic energy much like the workings of a radio antenna which is capable of receiving and transmitting electromagnetic waves according to what it is connected to and the electrical charges contained within it. Therefore, unless a machine is a self-contained stand-alone product it doesn’t necessarily follow that it is incapable of producing harmful disturbances when installed on the users’ premises. To accommodate this possibility, conformity assessment procedures for EMC have been developed for ‘apparatus’ and ‘fixed installations’. It also enables the viability of Certificates of Incorporation in lieu of a CE Mark.

IT Equipment Testing

IT applies to many products, audio-visual equipment and multi-media equipment, but some products that do not contain IT may not be subject to the same rules and regulations.

In the last decade, IT has had a phenomenal impact on productivity, education, society and our personal lives and to maintain this development, it is important to make sure that IT equipment is safe to use and characterised according to where it is used.

Most products with IT and Audio-Visual will require EMC and electrical safety testing.

Accreditations & Credentials

We are proud of our long standing UKAS accreditation as it serves as a reminder that we are continually assessed as technically competent, with accurate, consistent and reliable test methods and results.

We have a comprehensive UKAS scope at Cranage EMC and Safety and this can be seen on our website, or the UKAS website.

If you would like to discuss your UKAS testing requirements, please get in touch with our expert team, who would be happy to talk through your project.

About us

Established in 1992, Cranage EMC & Safety Ltd offer a substantial range of UKAS accredited EMC, Safety and Environmental testing services to industrial and commercial clients. Based in Shropshire, our company provides an innovative approach to EMC, Safety and Environmental testing, PTI Testing and CTI Testing, ensuring that all applications meet the relevant standards for the appropriate market.

We specialise primarily in medical and laboratory testing and deliver outstanding customer service at all times and pride ourselves on our ability to solve problems using a knowledgeable, expert approach.

Here at Cranage EMC & Safety, we cater for a variety of industries and sectors, some of which include medical and therapeutic, scientific and laboratory, lighting, household appliances, industrial equipment and machinery, information technology and audio visual, security, fire and smoke, electrical fittings and surge protection, mobility aids and assistive technologies, road and rail, energy and environmental, electronic toys and games and many more. We are the UK’s one-stop shop for export compliance and offer specialist advice on electrical products and solutions.

Our staff at Cranage are fully trained to deliver exceptional service from start to finish. We are fully equipped for both compliance testing and engineering analysis, ensuring that each client receives the perfect solution for their application. We specialise in the overall evaluation of EMC, electrical safety and mechanical and environmental performance. We offer a fast and efficient service which has resulted in numerous product approval timescales being reduced from months to weeks.

We at Cranage EMC and Safety Testing offer testing for a vast array of medical devices, some of which include hospital beds, lifting devices, prosthetic limbs, blood pressure monitors, ultrasound devices, anaesthetic machines and ventilators, patient monitors, imaging system displays, pulse oximetry, TENS machines and more.

We have many years' experience of evaluating electrical equipment used in the diagnosis, treatment or monitoring of a patient, resulting in thousands of satisfied customers across the UK. We strive to ensure that all medical devices do not negatively affect the clinical condition or safety of users or patients.

EMC Testing

Cranage EMC and Safety, based in Shropshire near Birmingham, offers a complete range of EMC testing throughout the UK, including full compliance, pre-compliance and in-situ testing.

Product Safety Testing

Cranage EMC and Safety offers a complete range of safety testing for electrical and electronic items to meet the country-specific regulations of your intended market. In Europe, this is the Low Voltage Directive (LVD) 2014/35/EU, and in the UK, it is the Electrical Equipment (Safety) Regulations 2016.

Environmental Testing

We have an extensive suite of environmental test chambers at our premises. These chambers simulate the majority of environments that your product may be exposed to, either through storage, transport, or operation. We can apply environmental stress parameters to suit worldwide climatic conditions to verify that a product can perform reliably in the intended environment.

We have climatic chambers to cover humidity, RH damp heat, solar radiation, temperature cycling and salt spray.

Pre-Compliance Testing

Our EMC and safety pre-compliance testing assists in identifying any potential issues early in the design stage, allowing for a more efficient resolution. Pre-compliance testing can help to save money, as modifications can be implemented earlier in the design phase, following prompt testing feedback before full-compliance testing.

On-Site Testing

We can offer testing at your premises if your equipment is large or in situ. In-situ EMC tests and measurements are usually undertaken to support a Technical Construction File (TCF) for the tested equipment.

Global Services

If you want to import a product from the USA into the UK, we can assess the components to ensure they comply with UK regulations. Our service also includes advice on construction and regulatory requirements to sell your product to the UK market. Product documentation will be reviewed to ensure it is by UK requirements.

Commercial Alarm Testing

A test plan is usually combined with a risk assessment to facilitate a pragmatic approach to monitoring equipment under test, as it may only sometimes be practical to test all functions within a reasonable time frame. The test report is, therefore, a record of test results and measurements and a synopsis of the risk involved if testing deviates from standard procedures or operating conditions of the equipment under test.

Mobility Aids & Stairlift Testing

Mobility aids play a vital role in helping disabled people and the elderly live more independently and can reduce the risk of injury or accident related to restricted mobility. Therefore, equipment designed for this purpose must avoid introducing additional safety hazards.

At Cranage, we work with manufacturers of electric wheelchairs and mobility scooters to evaluate their products comprehensively to ensure adherence to British, European, and international standards. Our UKAS accreditation shows that we provide independent and impartial tests with accurate results.

Household Appliance Testing

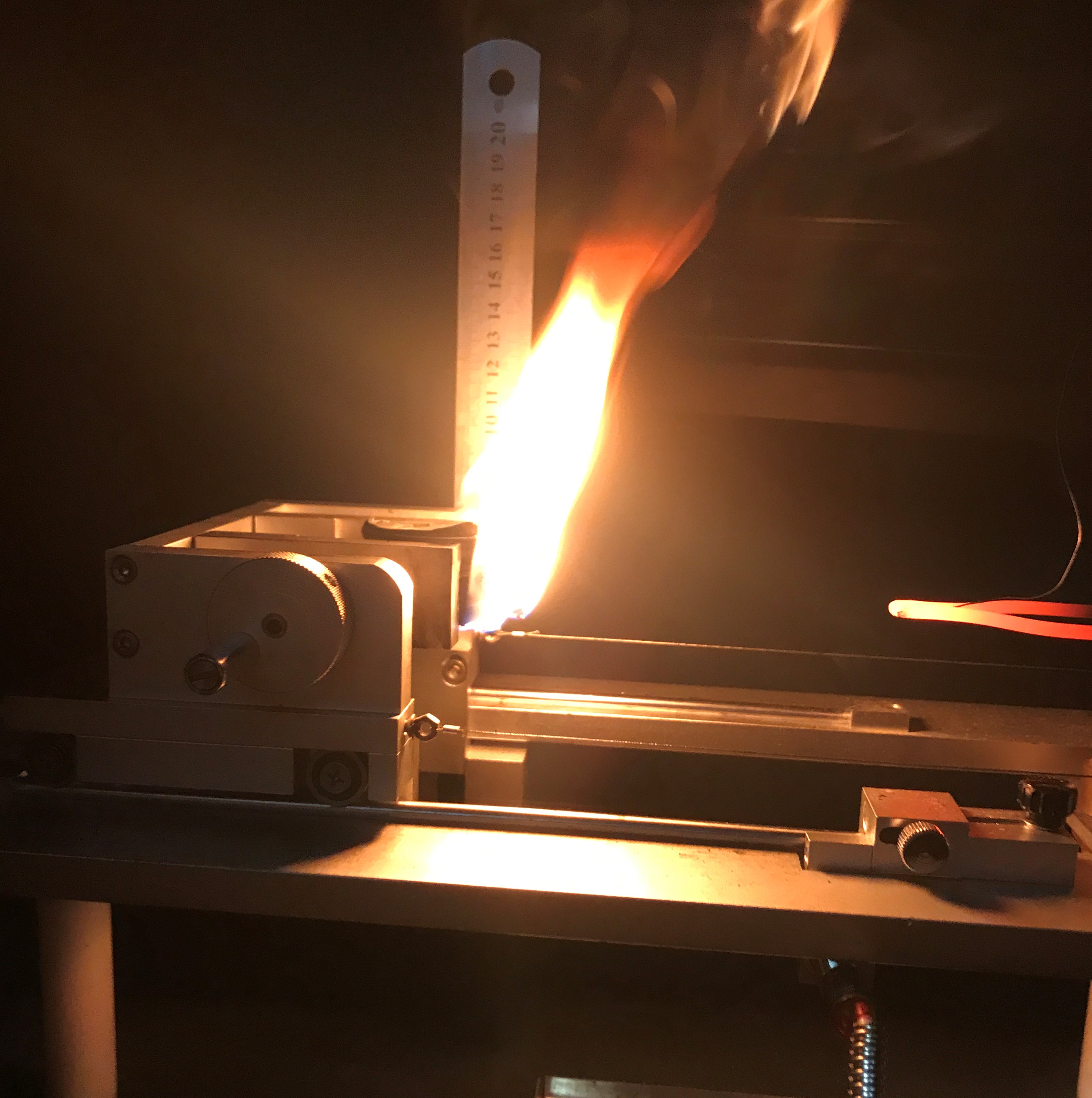

This is to ensure product safety and user protection. Some common tests conducted by IEC 60335-1 include:

- Insulation resistance test: This test measures the appliance’s insulation resistance to ensure that it can withstand the electrical voltages present during normal operation.

- Dielectric strength test: This test determines the ability of the appliance to withstand high voltage without breaking down.

- Ground continuity test: This test checks the integrity of the appliance’s grounding system to ensure proper protection against electric shock.

- Heating test: This test evaluates the temperature rise of components during operation, ensuring that they do not overheat and pose a fire hazard.

- Mechanical strength test: This test assesses the durability and robustness of the appliance under normal use conditions.

- Leakage current test: This test measures the amount of current that leaks from the appliance, ensuring that it remains within acceptable limits to prevent electric shock.

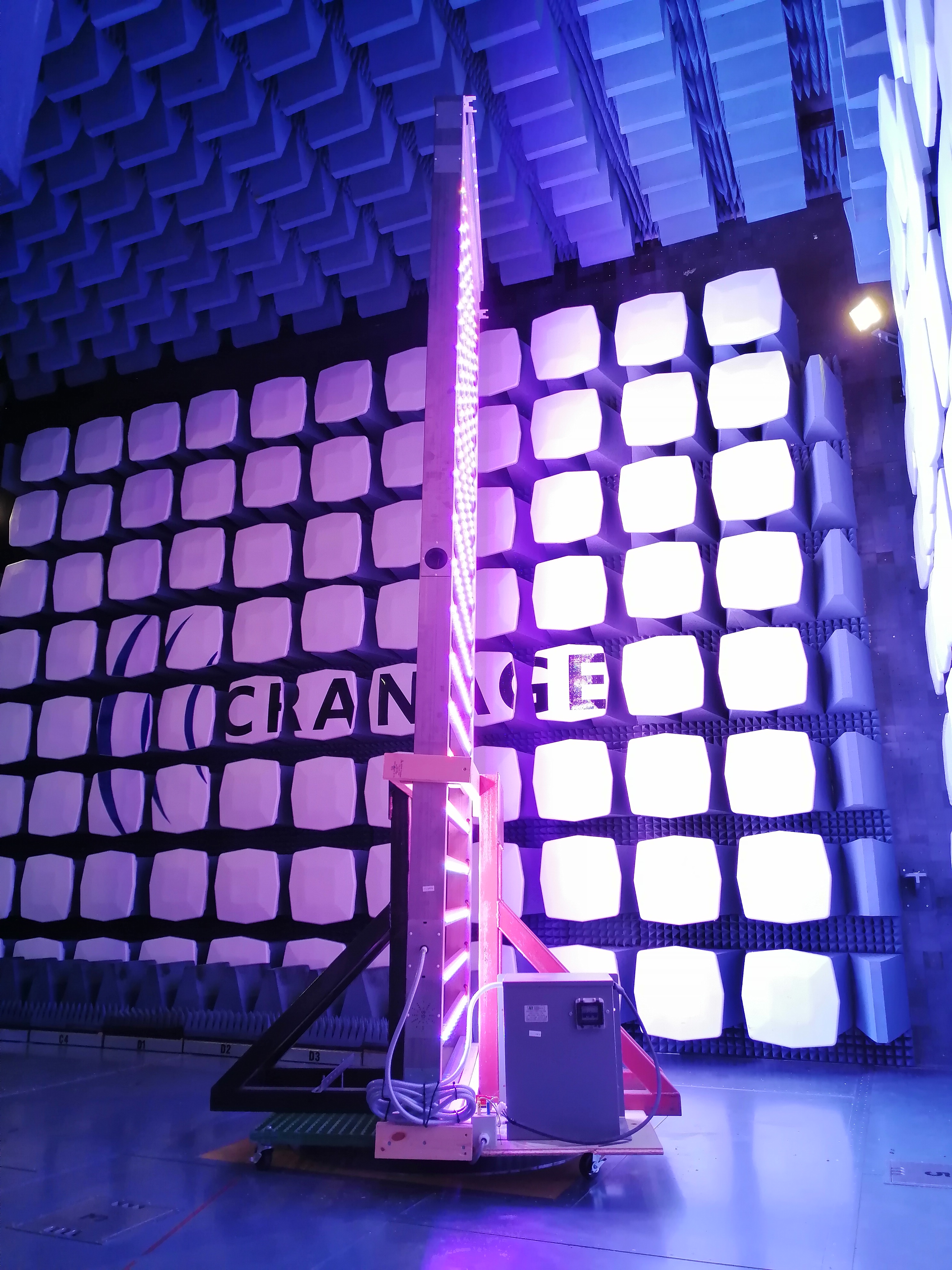

Light Testing

LED lighting can produce electromagnetic emissions, so EMC testing is increasingly important to show that your product will not affect or be affected by other products in the same environment. Cranage can offer testing and certification for all types of lighting products, as per Regional and International requirements.

Road & Rail Testing

Cranage has specialist knowledge and facilities to investigate and measure the screening performance of cables, connectors, materials, assemblies and electronic modules. We work with clients to investigate the sources of electromagnetic leakage and have developed application-specific shielding solutions to achieve EMC.

Our experience ranges from testing rolling stock apparatuses to vehicle messaging signs, and this aspect of our business is constantly developing as new technologies and products continue to push boundaries.

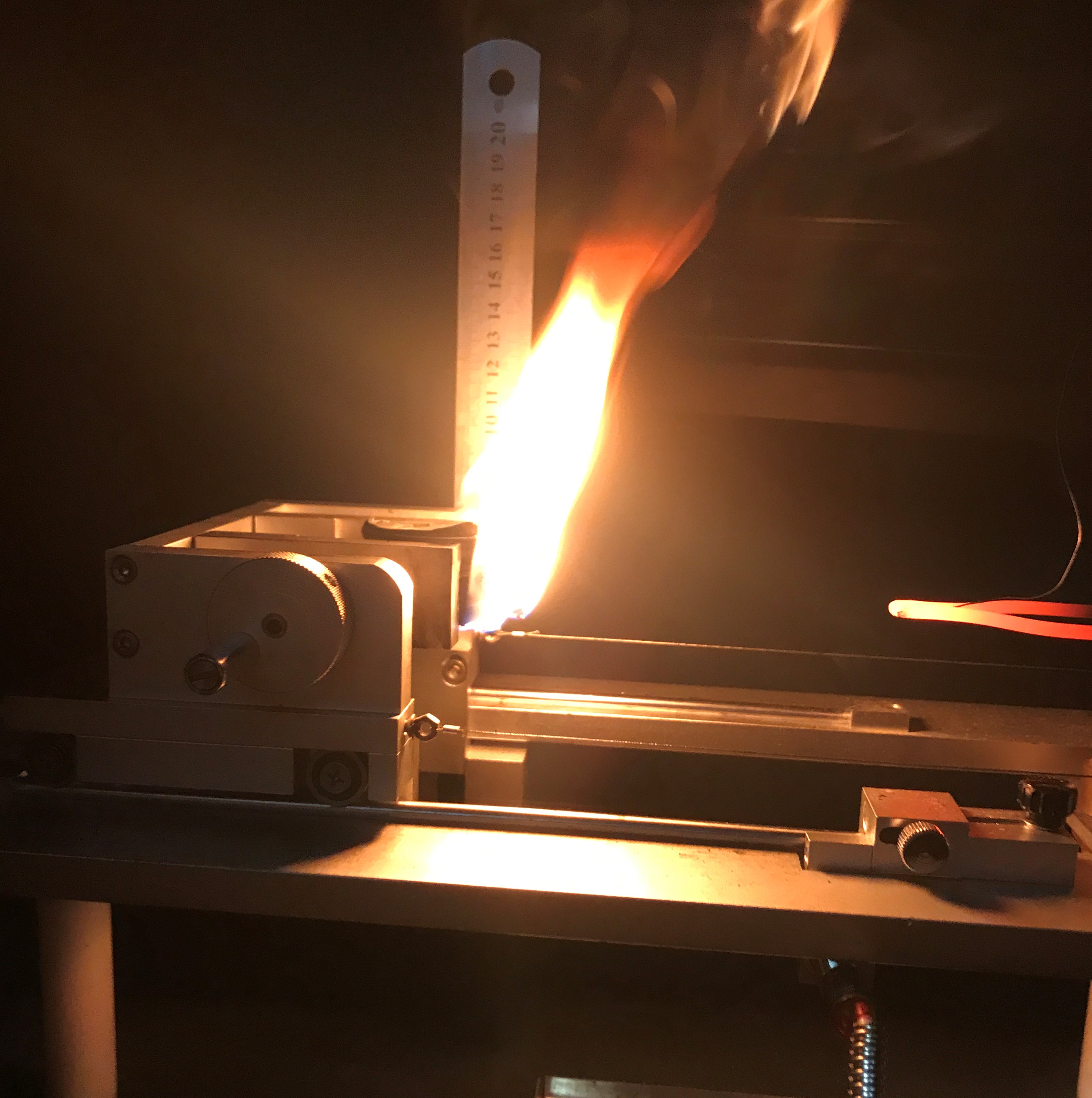

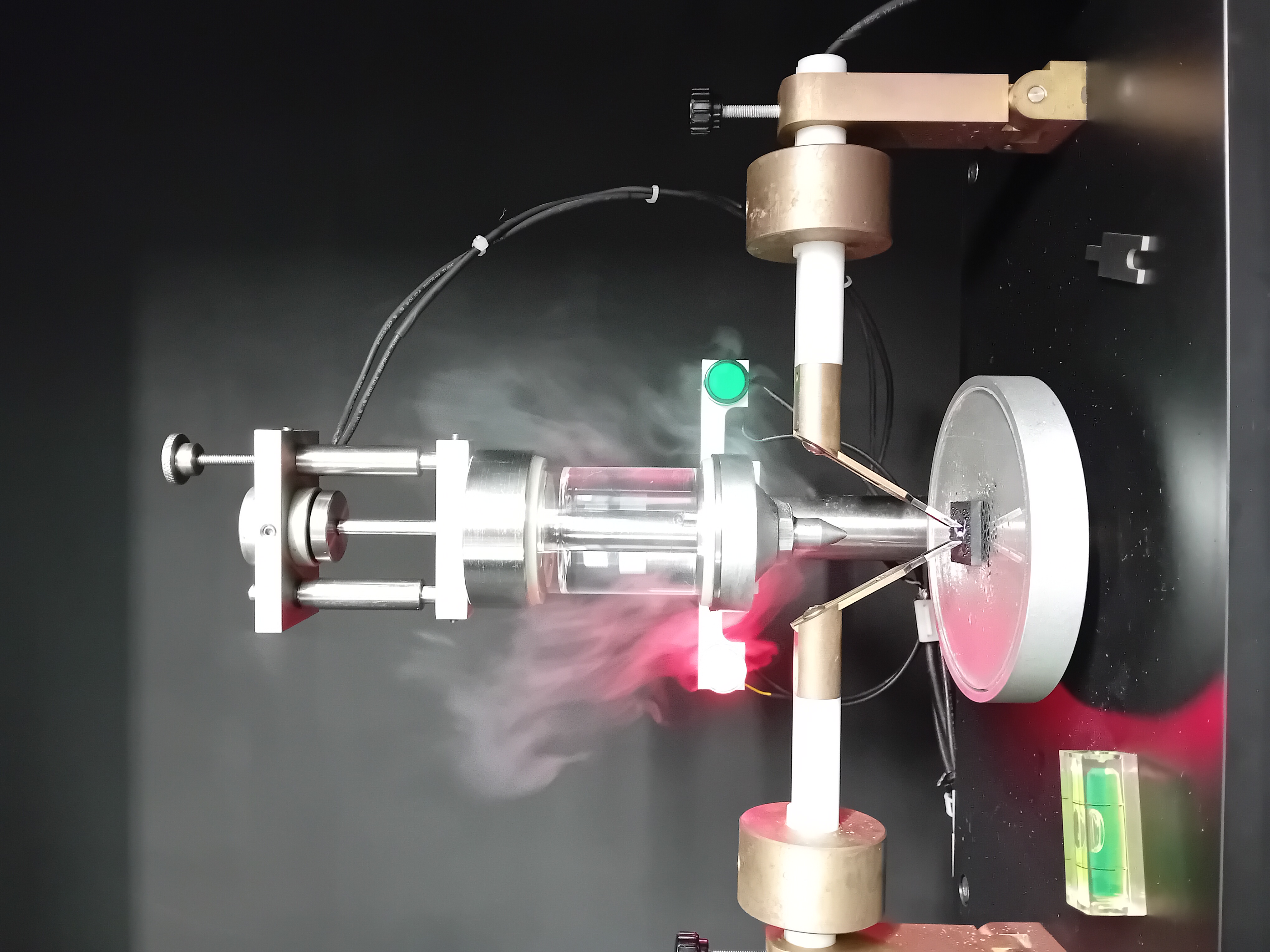

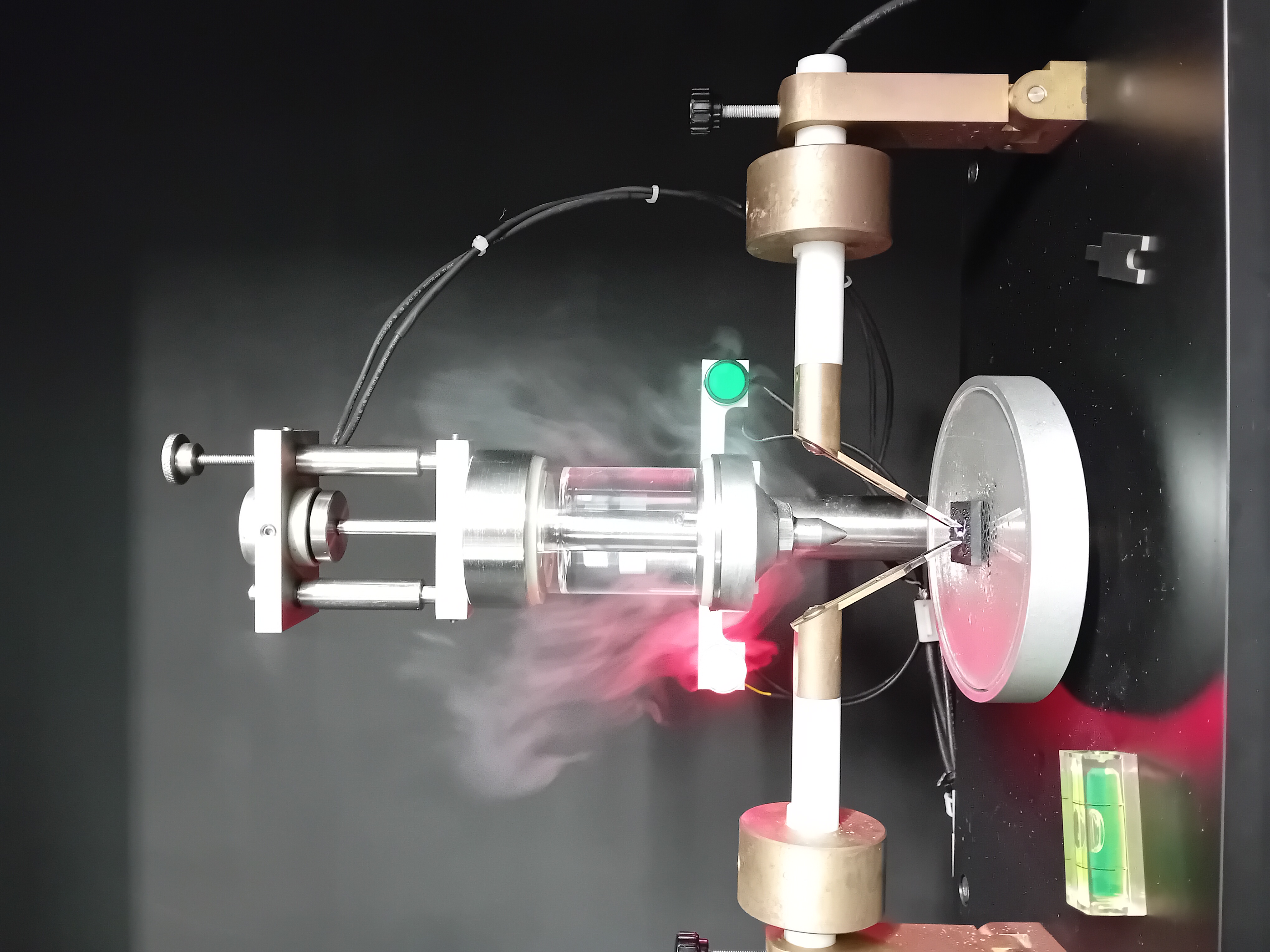

Lab Equipment Testing

The team at Cranage has specialist knowledge and experience in lab and science equipment testing, such as high-precision mass spectrometers using gas and plasma sources. Our engineers also provide technical support for manufacturers of semiconductors and general laboratory electrical equipment.

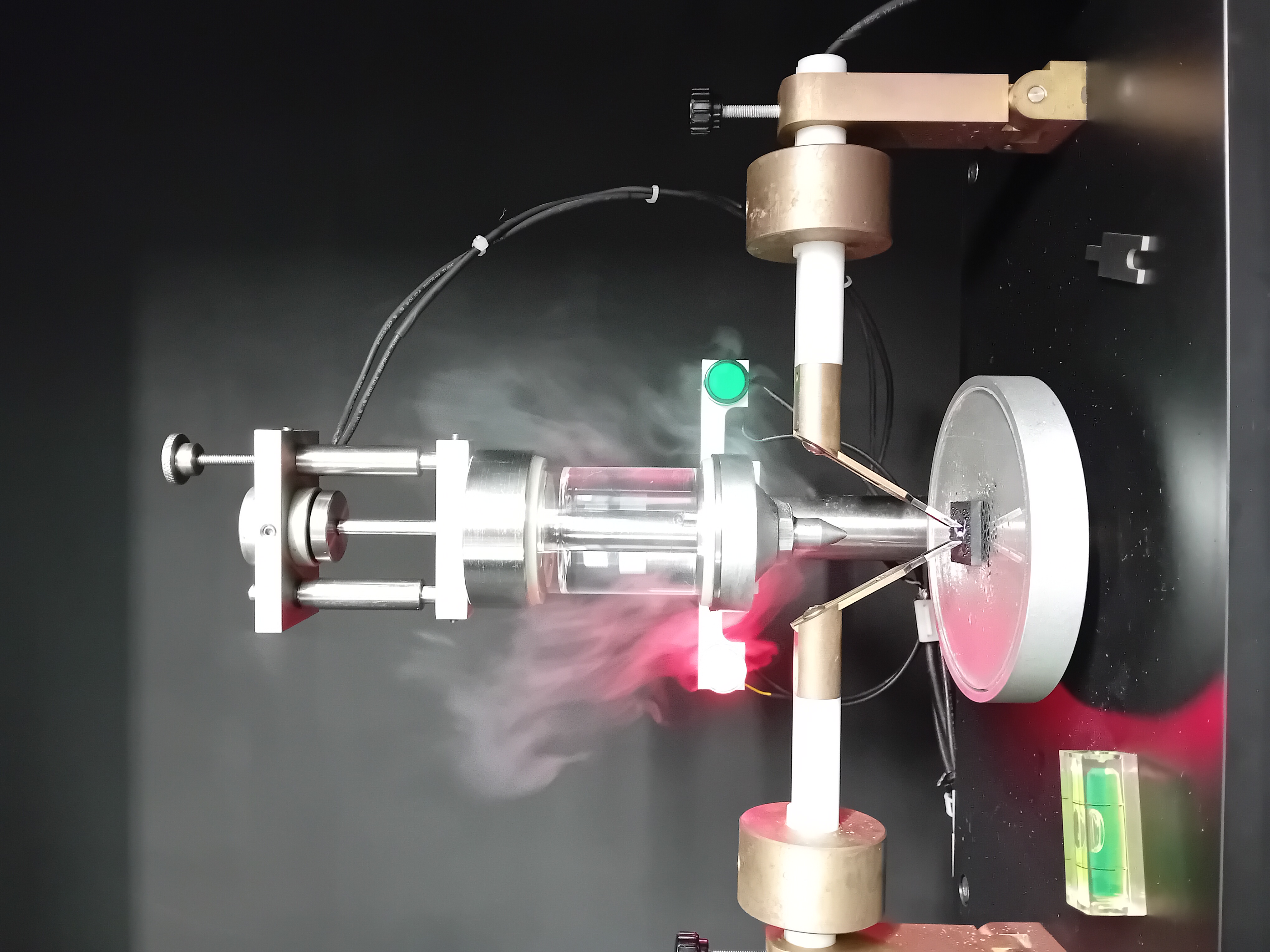

Medical Equipment Testing

Medical devices are heavily regulated due to the type of environment in which they are used and the potential severity of product failure. They must not compromise the clinical condition or safety of users or patients. Cranage EMC and Safety, based in North Shropshire near Birmingham, have experience evaluating medical equipment intended to be used in the diagnosis, treatment, or monitoring of a patient or for compensation or alleviation of disease, injury, or disability within a medical or home healthcare environment.

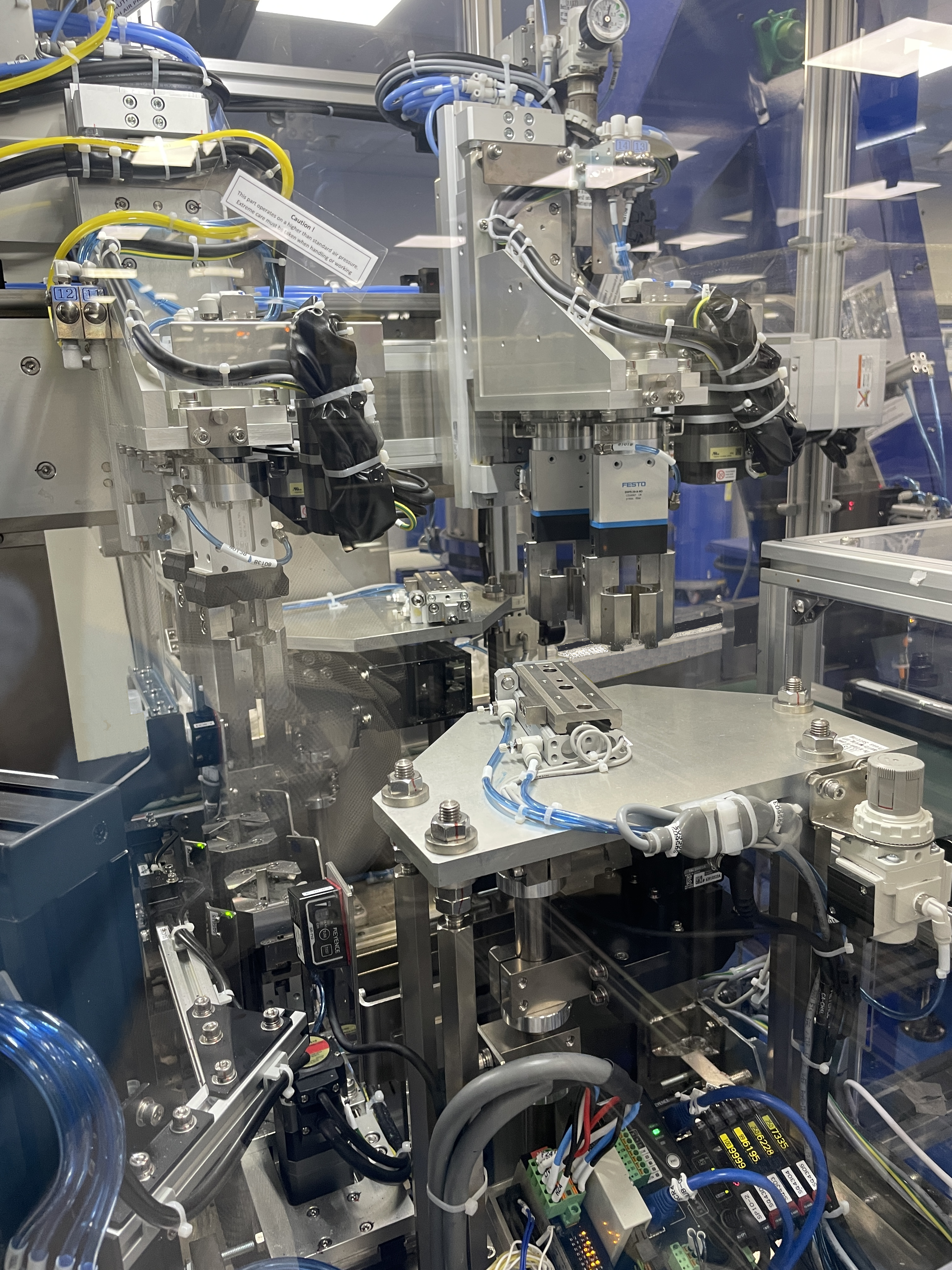

Industrial Machinery Testing

Industrial equipment and electrical machines have all got one thing in common- the utilisation of electrical energy. The electrical wiring that makes this possible conducts and radiates electromagnetic energy, much like a radio antenna, which can receive and transmit electromagnetic waves according to what it is connected to and the electrical charges contained within it. Therefore, unless a machine is a self-contained stand-alone product, it doesn’t necessarily follow that it cannot produce harmful disturbances when installed on the user’s premises.

IT Equipment Testing

IT equipment testing applies to many products, including audiovisual and multi-media equipment, but some products that do not contain IT may be subject to the same rules and regulations. Cranage EMC and Safety, based in North Shropshire near Birmingham, provides an extensive IT and Audiovisual testing service throughout the UK.

Images

Videos

Articles / Press Releases

Brochures

Reviews

Trade Associations