Company details for:

Essex Injection Mouldings

Unit 12-15,

Craftsman Square,

Temple Farm Industrial Estate,

Southend-on-Sea,

Essex,

SS2 5RH,

United Kingdom

Quick Links:

Products / Services

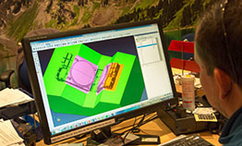

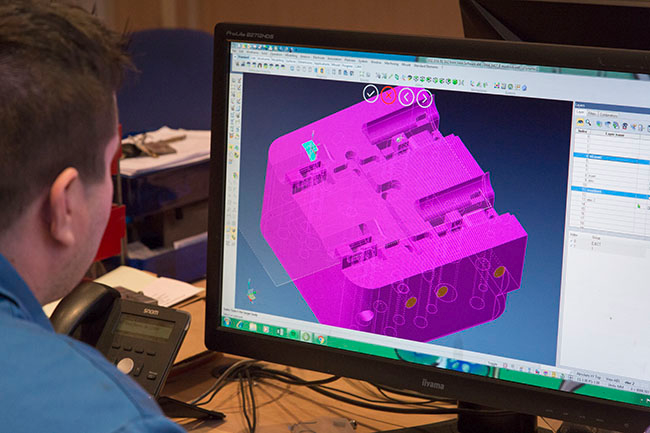

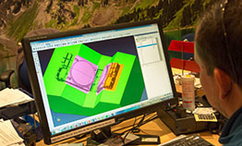

Product Design

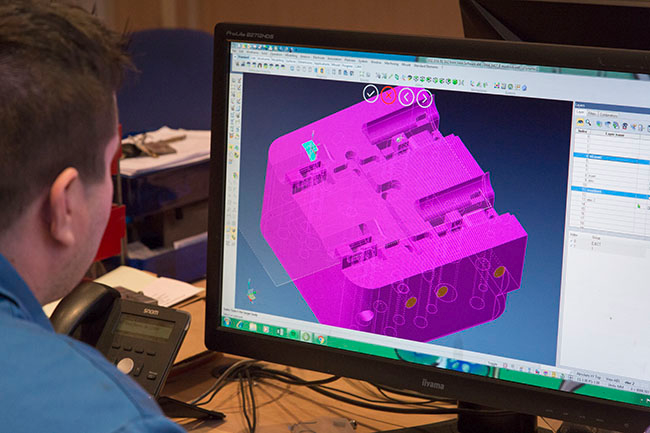

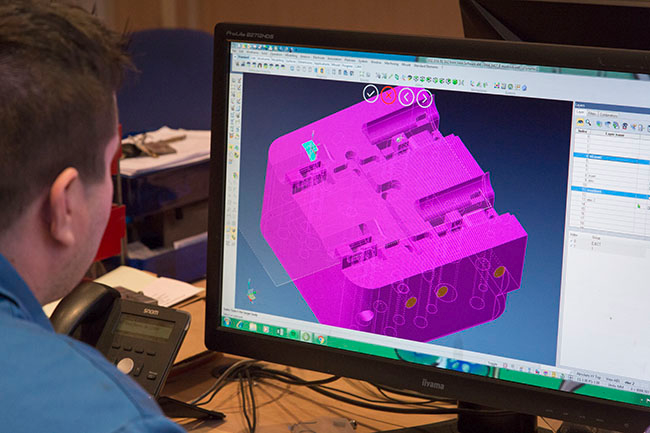

Using our four seats of the latest Visi, Inventor and Hypermill software we are able to deal with most aspects of 3d cad cam design.

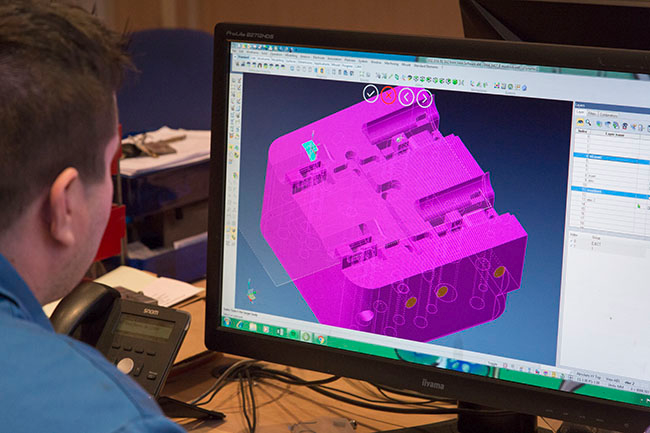

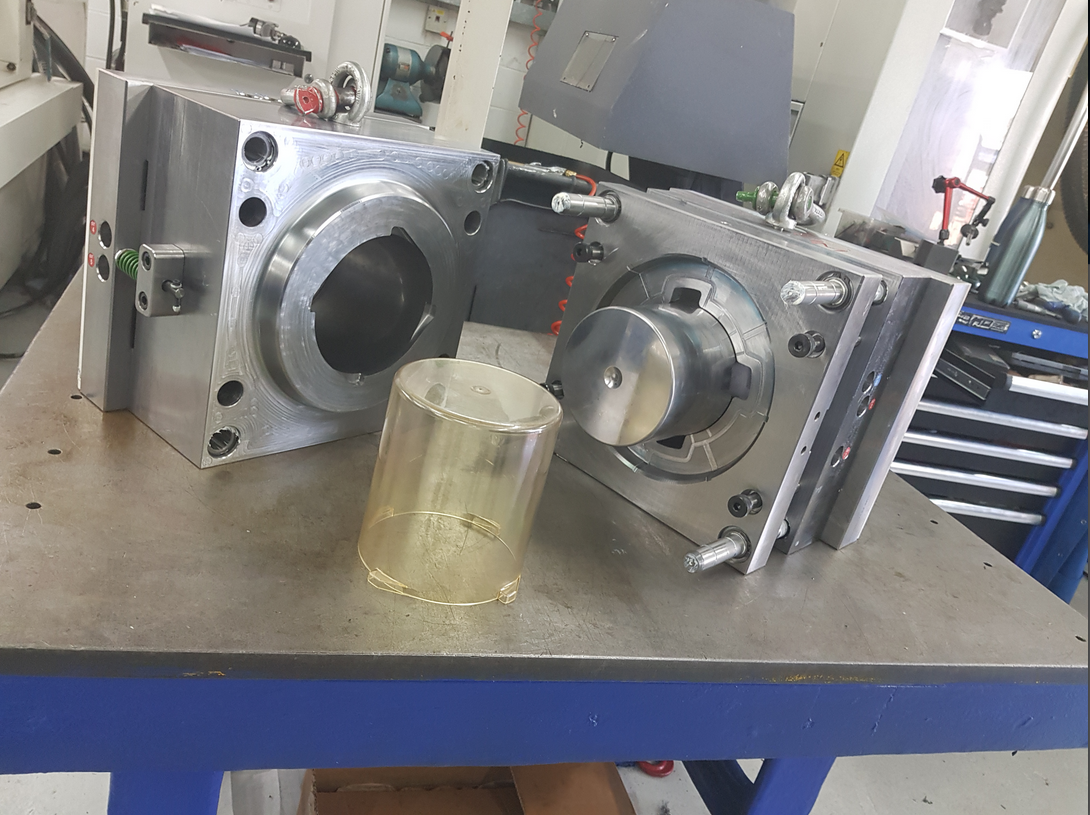

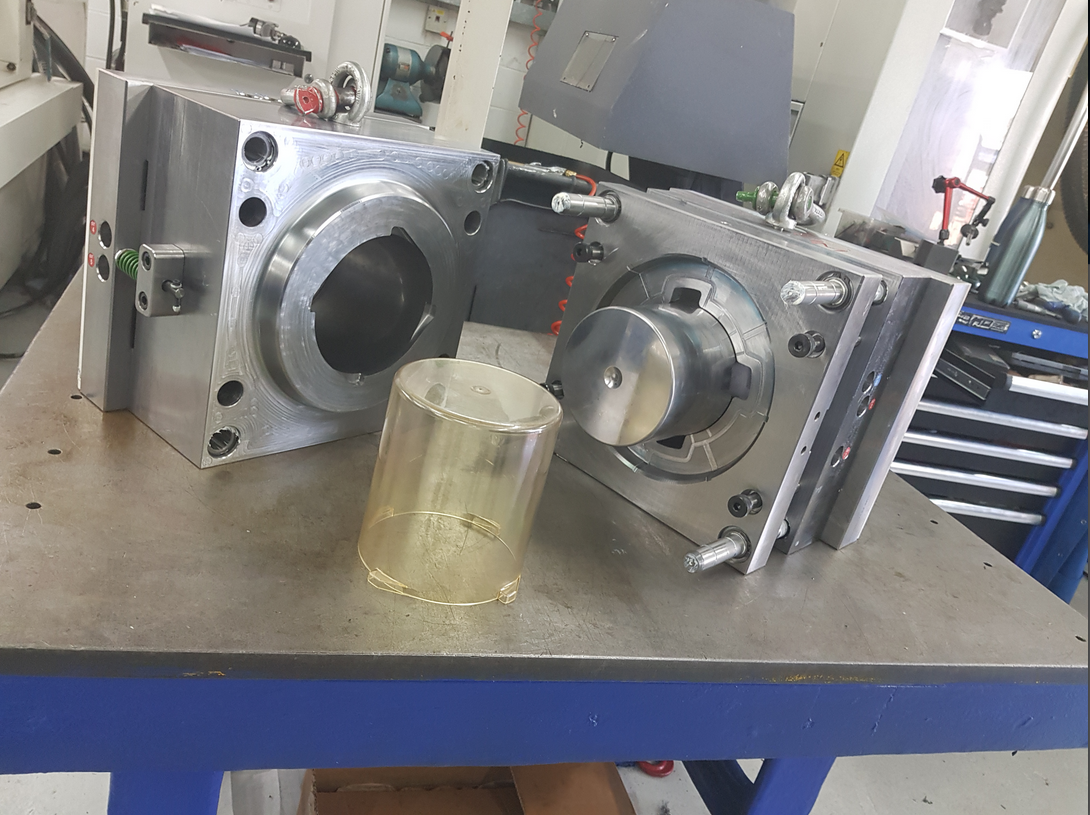

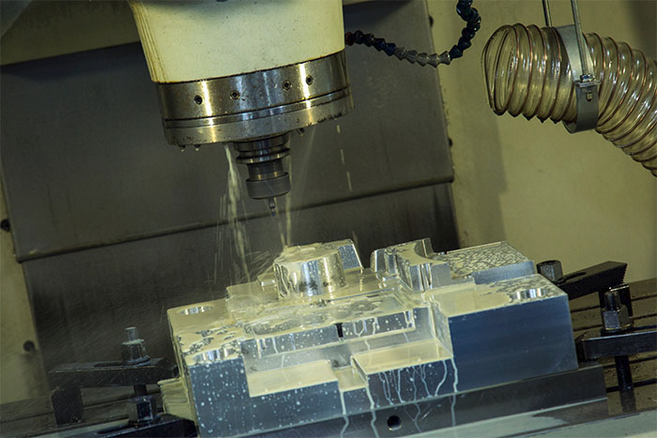

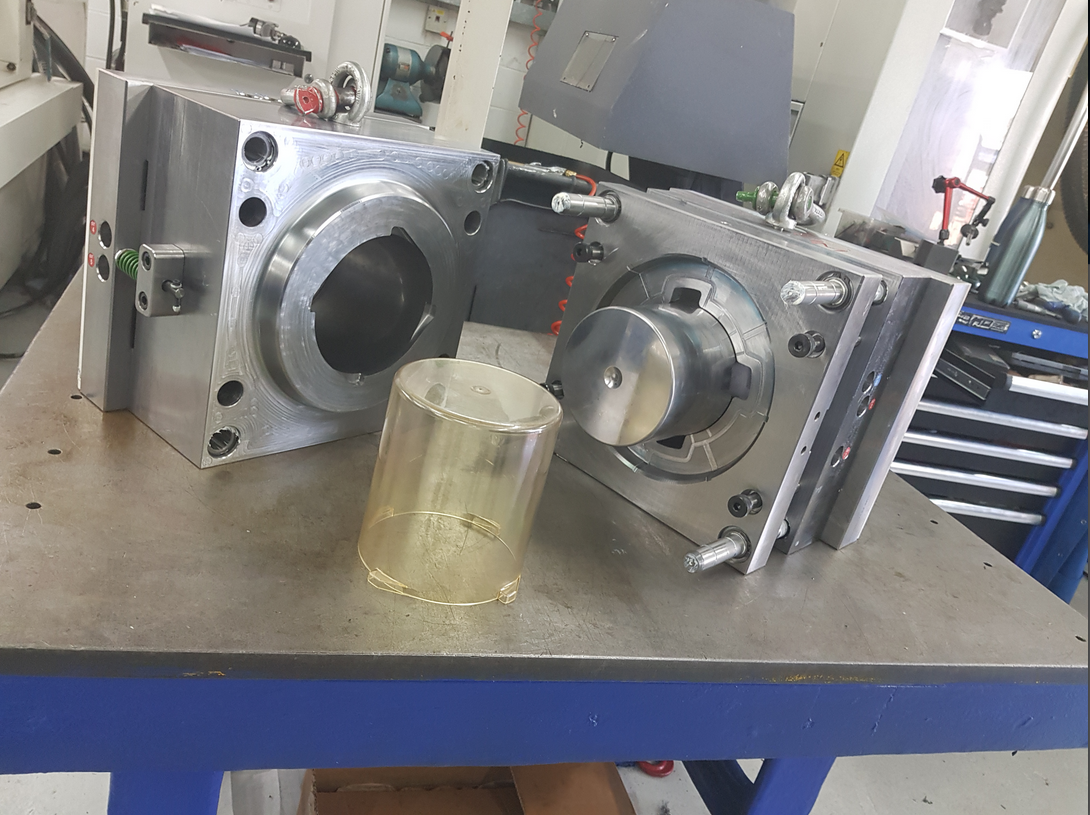

Tool Making

Essex Injection Mouldings are able to offer a complete tool making solution from our in house toolroom. All new tooling is designed on site using our 3d cad cam software and manufactured using modern tool room equipment and procedures utilizing quality European mould components.

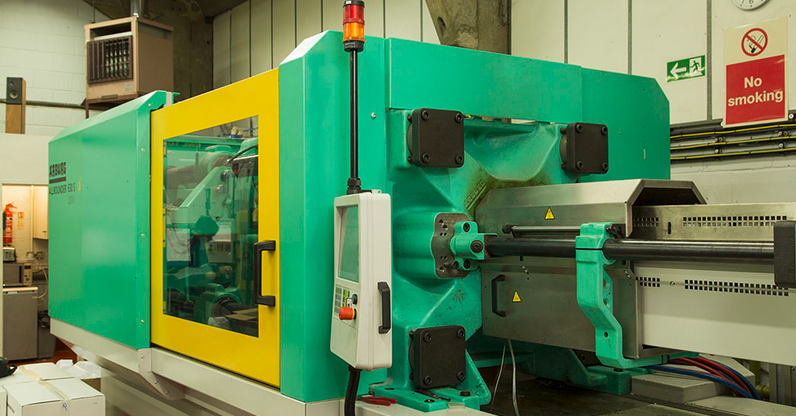

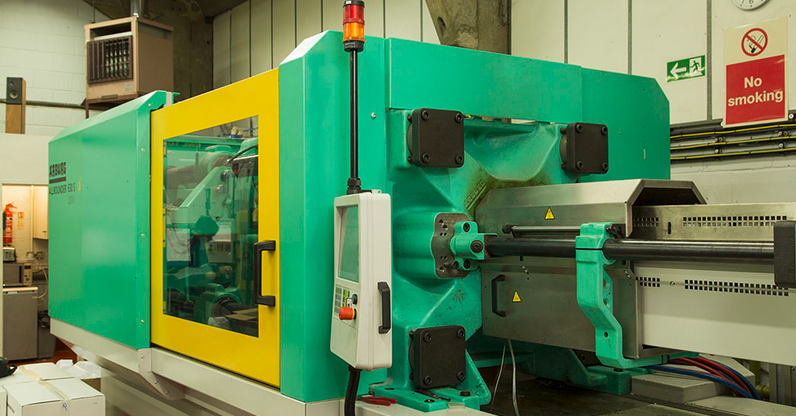

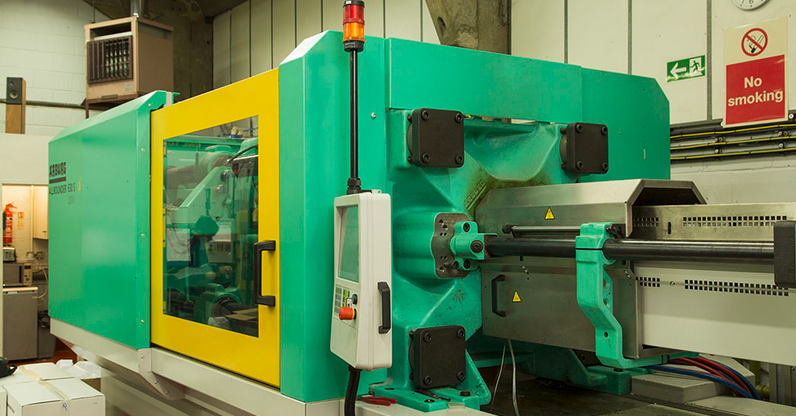

Injection Moulding Shop

Essex Injection Mouldings specialise in the manufacture of injection moulded plastic components. Using the latest technologies, our modern moulding machines range from 25ton – 250 ton. We can cater for all customer requirements from a tool trial to high volume production. At Essex Injection Mouldings we can offer a range of moulding services including, insert moulding, in mould labelling and over moulding. We process a wide variety of materials from polyolefins to engineering grades.

Packing Department

Essex Injection Mouldings understands customer needs for a total value added solution, hence our packing department can provide a number of added services including:

- Heat inserting

- Pad printing

- Assembly work

- Hand Finishing

- Heat sealing

- Limited Storage to meet Call Off Order requirements

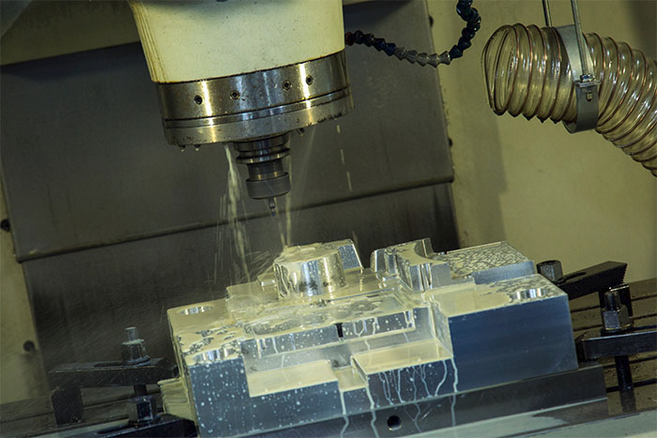

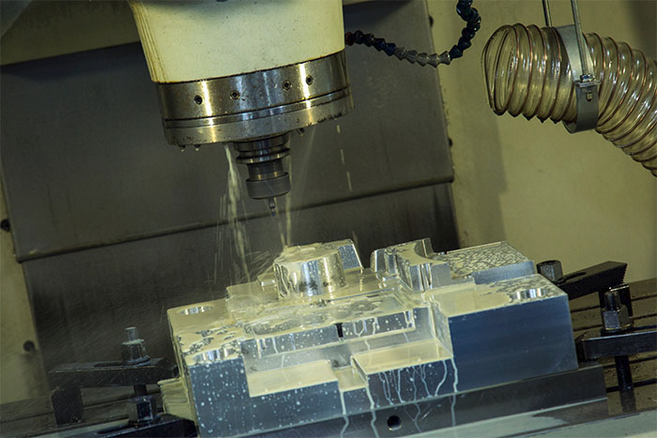

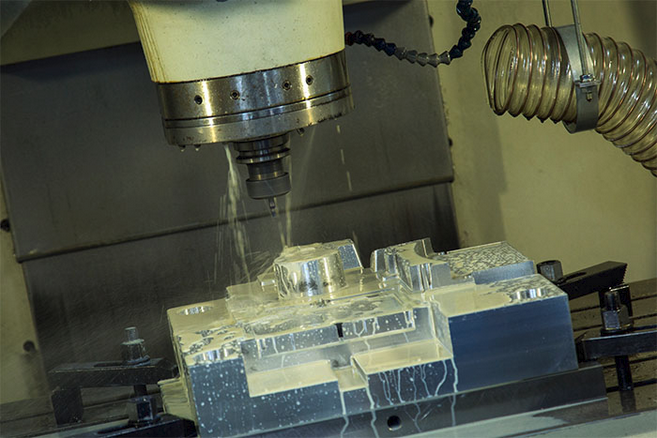

CNC Milling

Depending on work load we also offer a complete 2d and 3d cnc milling service producing small batch and bespoke components.

About us

Essex Injection Mouldings is a comprehensive provider of injection moulding and toolmaking services based in Essex.

Founded in 1987, the company was created to provide a complete, all-in-one service that supports clients from initial concept through to the final product, all handled in-house.

With a fully equipped tool room and skilled team, we handle everything in-house—from product design and full CAD data creation to tool design and mould tool manufacturing.

Our Services Include:

CAD & CAM Design

Equipped with four licenses of the latest Visi, Inventor, and Hypermill software, we can manage a wide range of 3D CAD/CAM design tasks.

Tool Making

Essex Injection Mouldings provides a complete toolmaking service from our in-house toolroom, where all new tooling is designed using advanced 3D CAD/CAM software and produced with modern equipment and high-quality European mould components.

Mould Making

Essex Injection Mouldings delivers end-to-end toolmaking solutions from our in-house toolroom, where new tools are designed on-site with advanced 3D CAD/CAM software and built using state-of-the-art equipment and premium European mould components.

Packaging

Essex Injection Mouldings is committed to delivering comprehensive, value-added solutions tailored to customer needs. Our packing department offers a range of additional services, including heat inserting, pad printing, assembly, hand finishing, heat sealing, and limited storage to support call-off orders.

Utilising advanced technology and modern moulding machines (25–250 tons), our Mould Shop can produce everything from basic washers to complex multi-insert technical mouldings. We support mould trials, short runs, and high-volume production across a wide range of materials.

All secondary processes, such as tampo printing, assembly insertion, and packing, are handled by our Packing Department.

The company has expanded to become one of Essex’s largest independent trade moulding firms, serving a diverse range of industries such as automotive, aviation, electrical, environmental, and medical.

Images