Company details for:

Tatra Rotalac Ltd

Quick Links:

Products / Services

Service & Expertise

We offer initial design and material specification to help turn your plastic projects into real life. We offer a range of in-line, out of line and secondary finishing processes and can provide cost-effective processes to deliver your products.

We offer support every step of the way, with our aftercare services we cover all of your needs with fast in house support.

Aftercare

As a plastic manufacturer we can help take your plastic project from an idea to real life, we are here to help throughout your plastic journey.

From initial design and material specification, to full production and beyond, at Tatra Rotalac we take pride in making sure your plastic products are fit for purpose and stand the test of time.

Start your plastic project journey today with Tatra Rotalac.

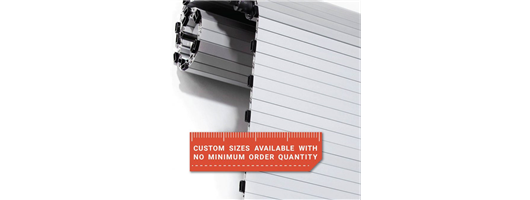

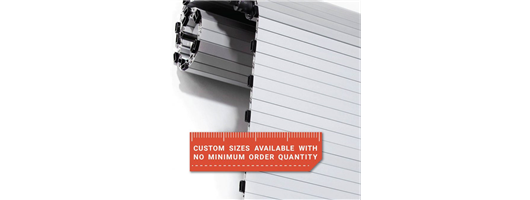

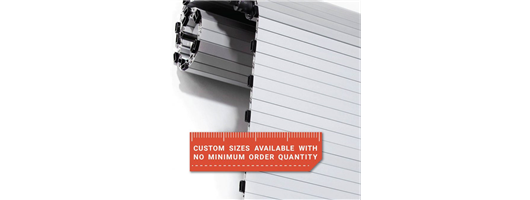

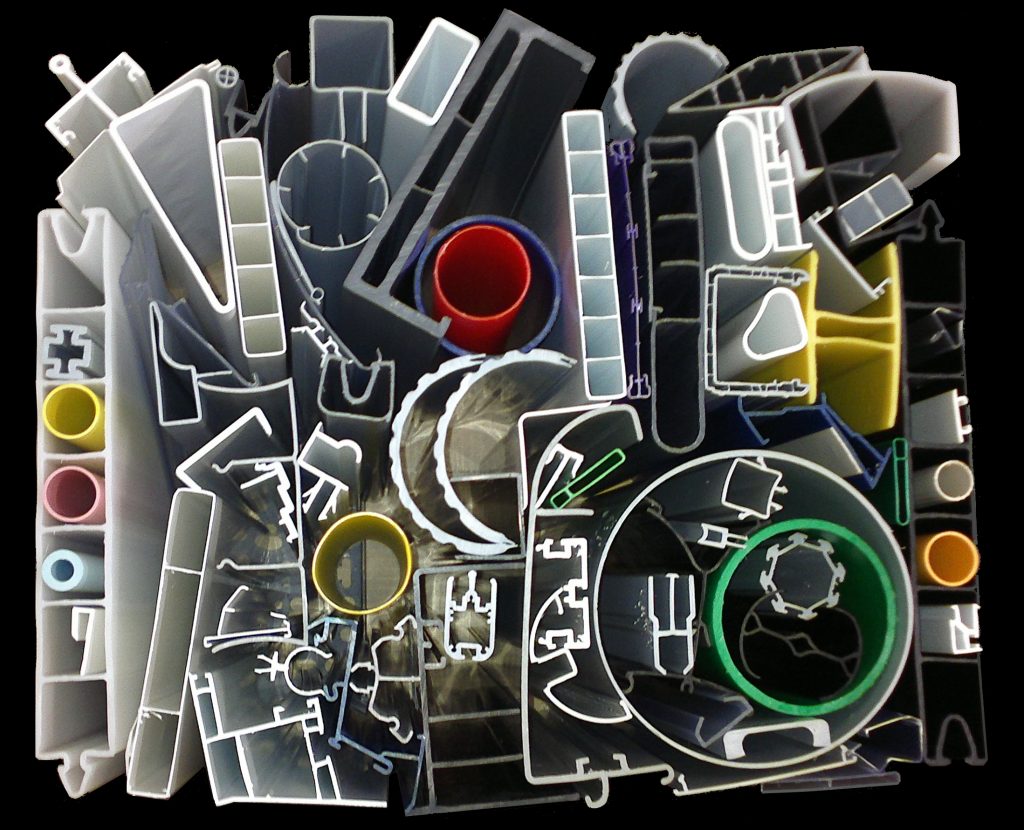

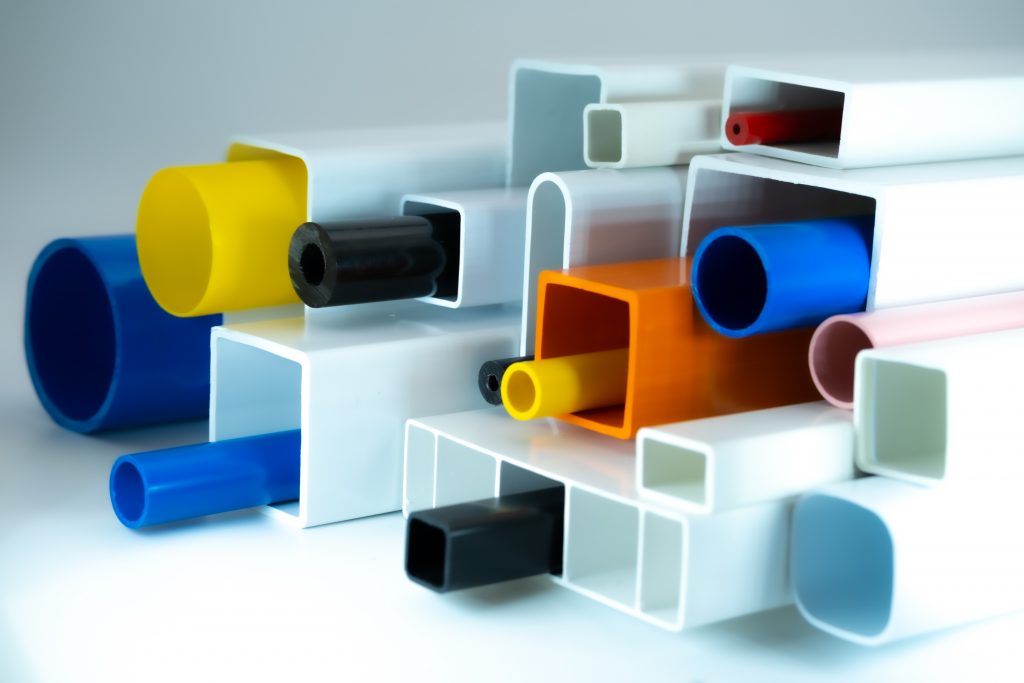

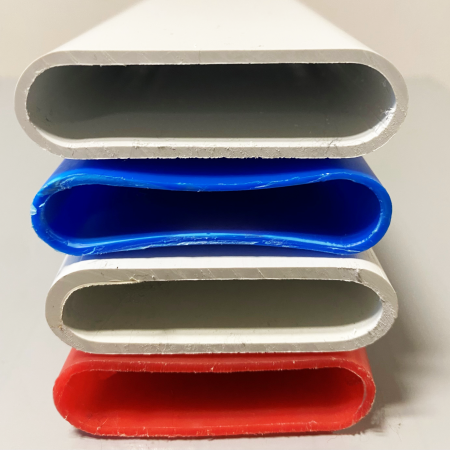

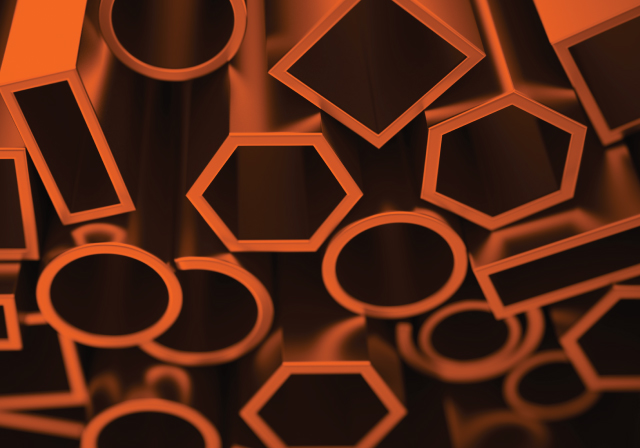

Custom Plastic Extrusion

Whether you want flexible or rigid tubes or profiles, we can extrude or co-extrude a wide range of materials and colours, from the simple to the more complex. Our extrusion lines can handle rigid and flexible plastic rods from 1mm diameter and plastic tubes in a range of shapes from 2mm to 160mm in diameter, with many combinations of wall thicknesses and in a variety of materials. Plastic profiles can be extruded in sizes up to 320mm in width and 100mm in depth and in virtually any thermoplastic material of your choice.

If you would like to discuss your next custom extrusion project, we would be delighted to work with you.

Design & Manufacturing

We can work from e-mail drawings in many formats including solidworks, proE, .DXF and .DWG files, or from samples of existing products.

At our modern 40,000 sq ft factory in Manchester, we have the ability to produce a wide range of plastic products to suit most applications

Injection Moulding

Our injection moulding machines and presses range from 30 to 350 tonnes locking pressure. We mould in ABS, EVA, HDPE, LDPE, Polycarbonate, PC/ABS, Polypropylene, Polystyrene, PVC, Nylon and a huge range of engineering plastics.

We also offer a wide range of in-cycle and post-production finishing, assembly and packing services.

Plastic Extrusion

We can also design and manufacture plastic tubing and pipe profiles to meet your specific requirements.

New plastic extrusion profiles are continually being added to our range.

Plastic Extrusion Tooling

The tool room at Tatra Rotalac is run by extremely experienced and highly skilled toolmakers. They work with the latest machines and CAD CAM software to produce precision tooling for a superior finished product.

Rapid Prototyping

We offer a full complement of rapid prototyping technologies including:

Rapid Prototyping Stereo lithography (SLA)

Rapid Prototyping Selective Laser Sintering (SLS)

Rapid Prototyping CNC machining

Rapid Prototyping Low volume aluminium tooling.

We’ll explain the benefits and disadvantages of each and help you decide which approach best meets your needs.

Secondary Finishing

From in-line printing and hot-laminating foil finishes to drilling, cutting or punching, we can provide cost-effective processes to deliver your products (whether shutters, plastics extrusions or plastic moulded products) for their final application or next stage of processing.

Box Handles

Our injection moulded handles offer a high carrying comfort through its profiled middle section and handles can be moulded in a range of rigid or flexible and colours to suit your application. Handles can also be moulded with your company or product logo.

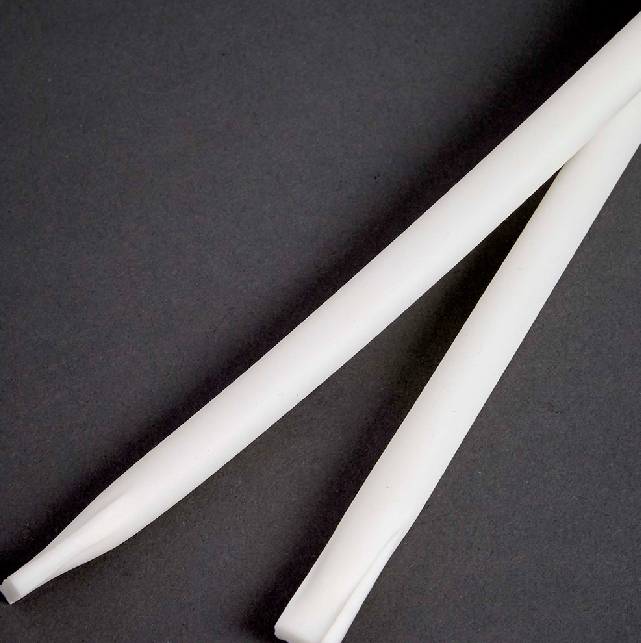

Cable Fillers & Separators

Cable fillers and separators can be extruded from a variety of materials including HDPE, LDPE, PVC, and PP in any colour and diameters ranging from 1mm upwards. Cable fillers and cable separators can be coiled onto reels in lengths to your requirements.

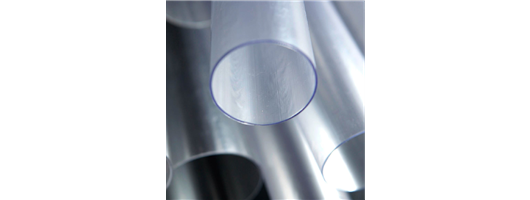

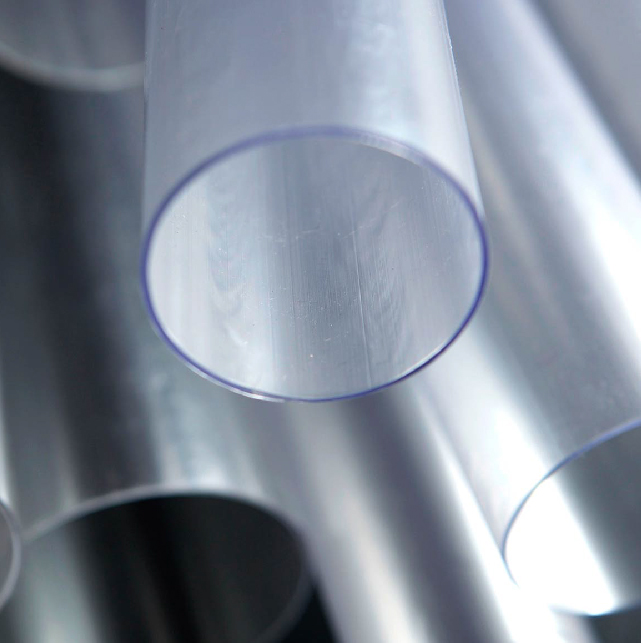

Core Liners

Here are some of the names used by the ground exploration and drilling sector to refer to core liners:

Window samplers

Clear sampling tubes

Core samplers

UV stable window samplers

Core barrels,

uPVC core liners

Hygienic Coving

Our hidden-fix coving is co-extruded from PVC and has flexible edges, doing away with the need for silicone seals, and provide a hygienic seal at wall-to-ceiling and wall-to-floor transitions.

Liquid Dispenser Tubes

These tubes can be irradiated or non-irradiated to suit your application, for example irradiated milk dispensing tubes. If required, we can also provide an assembly process of fitting the dispenser tubes to a cap.

Rail Products

We are accredited under the Network Rail Link Up Qualification scheme. Every year Network Rail take a survey of their suppliers and this survey includes procurement practices ensuring the Network Rail suppliers are always of the highest standard.

Network Rail Approval Certificate No. : PA05/870

Link-Up Qualification Scheme : Supplier No: 2268 − Certificate Number: 41223-2668/20364

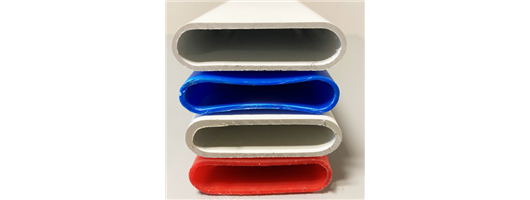

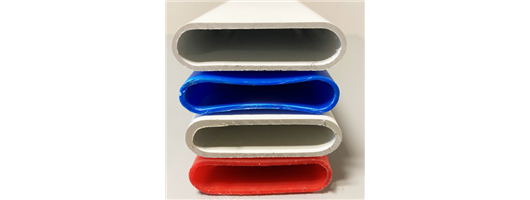

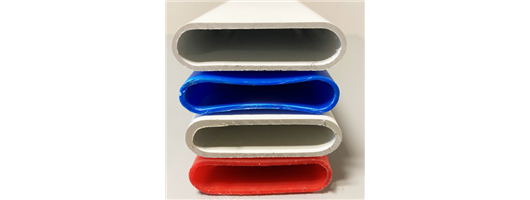

Oval Plastic Tubing

tube width

tube height

wall thickness

material required

quantity

lengths

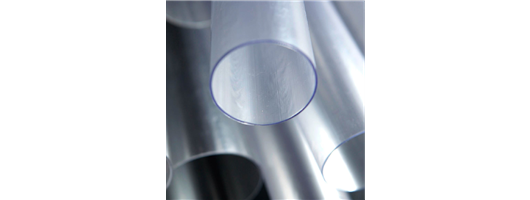

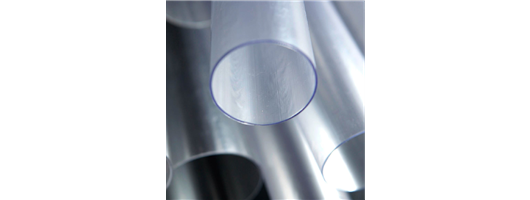

Round Plastic Tubing

outside diameter

inside diameter (or wall thickness)

material required

lengths

quantity

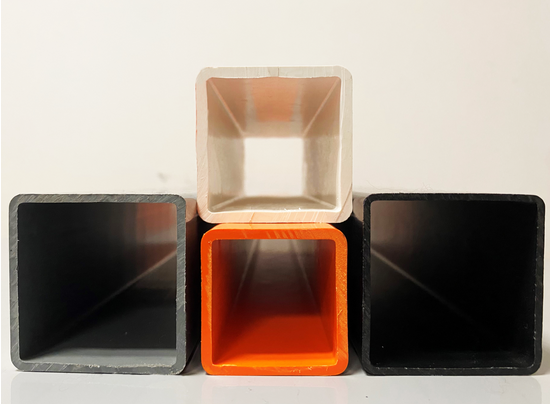

Square Plastic Tubing Specifications

Most of the products below can have any specified wall thickness between 0.6mm and 3mm, subject to confirmation and agreement on corner radii.

If you require plastic tube that is not square or rectangular, we extrude various other profiles, such as round, oval and more.

If you cannot see the exact dimensions you are looking for listed on this site, we will be able to make tooling for you, so contact us for Plastic Tube tooling details.

PVC Planking & Fencing

We also have a full range of PVC end caps and 85mm square posts also with caps.

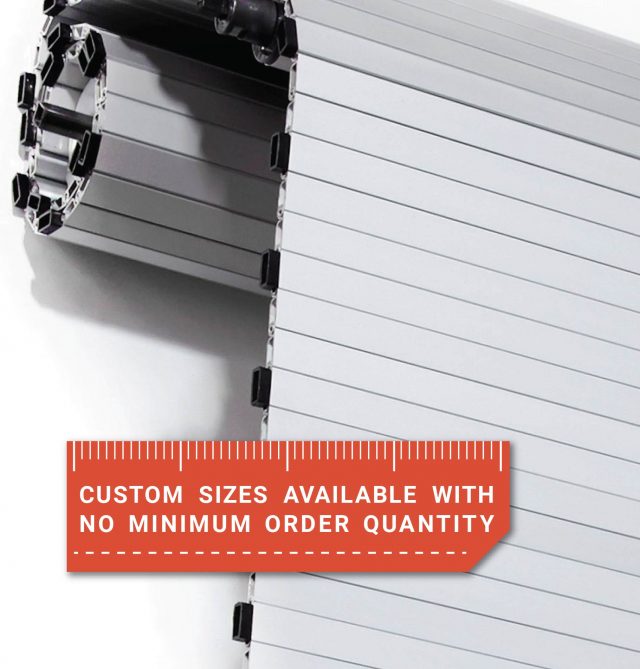

Vertical Opening Shutter Systems

Side Opening Shutter Systems

The range is available in plastic (Ecoslat™), aluminium and steel.

The Ecoslat™ side opening tambour system, made from PVC slats, has been developed by Tatra Rotalac to provide a smoother and quieter operation ideally suited for side tambours. Innovative construction ensures the Ecoslat™ shutter forms a perfectly flat rigid surface, without the zigzagging effect of multiple strand shutters. The slats are available in either a sawtooth or smooth finish.

Cable Sleeves (Dome Closures)

Complete assembly used for joints up to 50 pairs in Cables PET and PET armour

072123 (ABT0121 − 20)

SLEEVE 30A BASE

Includes insert

073147 (WBT0210)

SLEEVE 30A CLAMP

Hinged clamping collar

073011 (WBT1400)

SLEEVE 30A GASKET

‘O’ ring type gasket for sealing the cap to the base

073012 (CSL001)

SLEEVE 30D

Complete assembly, incorporating re-usable ports using heat shrink tubing. Used for radial distribution joints up to fifty pairs in Cable PET and Pet armour

073002 (ABT0911 − 20)

Connection Boxes & Block Terminals

Vented enclosure capable of accepting up to 20 modules, 4 incoming cables, an earth connection and 20 dropwires. Click here for the product sheet. 074855 (ABT1451 − 10)

BOX CONNECTION 19A

Vented enclosure capable of accepting up to 20 modules, 4 incoming cables, an earth connection and 20 dropwires. Click here for the product sheet. 074855 (ABT1451 − 10)

BLOCK TERMINAL 66B

For terminating two pair and five pair PE Cable Conductors. Click here to see product brochure. 072256 (ABT0361 − 20)

SLEEVE DROP WIRE PROTECTION 2A

A 30mm long PVC sleeve which is placed over the folded back strength members of Cable Dropwiring 10. The sleeve protects the conductors from possible damage caused by the sharp ends of the strength members 016330 (ABT1711 − 50)

FTTX Products

INTERNAL CUSTOMER LEAD IN KIT (CLI)

This is used to cover, control and protect the fibre optic cable where it emerges inside the premises. This would typically be used where the customer box is either outside the premises or not directly opposite where the cable comes through the wall from outside.

The kit consists of:

1 x CLI with 15mm Bend Radius

1 x Internal Cover (White)

1 x 300mm Conduit

1 x CSP Connector

Split Duct & Repair Kits

Thick wall rigid PVC in 3 metre lengths: each length comprises two halves. To be used with Duct Repair Kit 3A

095039 (FTE0051 − 3)

DUCT 56 SPLIT

Rigid PVC in three metre lengths, for repairing Duct 56

095086 (FTE0061 − 3)

DUCT 57 SPLIT

Thick wall rigid PVC in three metre lengths. To be used with Duct Repair kit 4A

095087 (FTE0071 − 3)

DUCT 59A SPLIT

Thick wall rigid PVC in three metre length. To be used with Duct Repair Kit 2A

095088 (FTE0081 − 3)

About us

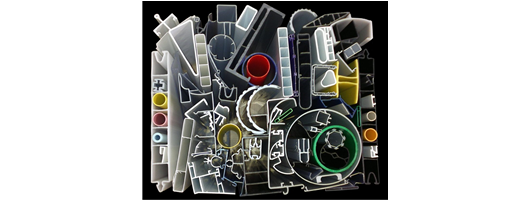

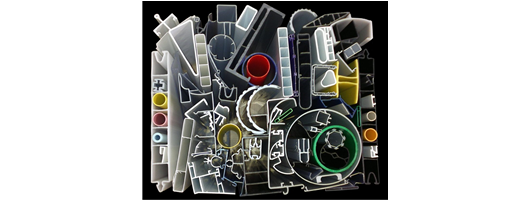

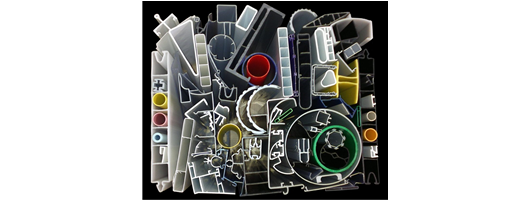

Tatra Rotalac Ltd: Leading UK Manufacturer of Custom Plastic Extrusions and Injection Moulding Solutions

With over 80 years of expertise in plastic manufacturing, Tatra Rotalac Ltd is one of the UK’s leading manufacturers of standard and bespoke plastic extrusions, as well as precision injection moulding services. Our long-standing commitment to quality, innovation and customer satisfaction has established us as a trusted partner across a wide range of sectors.

Comprehensive Plastic Manufacturing Services

At Tatra Rotalac, we offer an extensive suite of services to meet the diverse needs of our customers:

• Custom Plastic Extrusion – We specialise in creating custom plastic profiles, tubing and components tailored precisely to your requirements. We extrude both rigid and flexible materials, including PVC, ABS, HDPE, Polypropylene and more.

• Injection Moulding – Our advanced moulding facilities allow us to manufacture high-precision plastic parts in materials such as ABS, Polycarbonate, Nylon and PVC. We support the full lifecycle from concept and prototyping through to volume production.

• Rapid Prototyping – Using modern prototyping techniques, we bring your designs to life quickly and cost-effectively, helping you accelerate development cycles and refine product performance early.

• Secondary Finishing – Our in-house finishing capabilities include in-line printing, punching, cutting and hot-laminating foil finishes, ensuring your products are functional, aesthetically pleasing and ready for market.

• Design and Tooling – We offer full design support, including CAD development, prototyping, tooling and sampling. Our approach helps reduce time to market while maintaining cost-efficiency and product accuracy.

Industries We Serve

We work across a broad range of sectors, providing tailored plastic solutions that meet specific technical and regulatory requirements:

• Telecommunications – Supplying protective tubing and cable management components.• Construction – Producing durable profiles and building materials.• Rail and Aerospace – Manufacturing lightweight, high-impact-resistant parts.• Retail and Catering – Creating bespoke display elements and hygienic storage solutions.• Medical and Leisure – Delivering precision-engineered, easy-to-clean components.

Whatever your industry, we manufacture to your specifications with quality and efficiency.

Commitment to Sustainability

Tatra Rotalac is committed to sustainability and environmentally responsible manufacturing. We actively incorporate recycled materials into our processes and design products for end-of-life recyclability. By minimising waste and promoting reuse, we support a circular economy and contribute to a more sustainable future.

BRC Accreditation and ISO Certification

Tatra Rotalac is proud to be BRC accredited and ISO certified, underscoring our commitment to quality management and safety standards. These certifications ensure that we consistently meet the highest industry standards in manufacturing, hygiene, and product traceability. Our dedication to compliance helps ensure your products are not only of superior quality but also meet all necessary regulatory requirements.

Global Reach, Local Expertise

Based in our modern 40,000 sq ft facility in Wythenshawe, Manchester, we serve clients across the UK and internationally. As a BT and Network Rail approved supplier, we are recognised for our consistency, quality and reliability in critical applications.

Partner with Tatra Rotalac

Whether you need custom extrusions, injection moulding, rapid prototyping or high-quality finishing services, Tatra Rotalac is your trusted partner in plastic manufacturing. Our experienced team works closely with you to understand your requirements and deliver results that exceed expectations.

Let’s Talk

Get in touch today to discuss your next plastics project. Discover how Tatra Rotalac can bring your ideas to life with precision, speed and technical excellence.

Images