Company details for:

Bray Plastics Ltd

Quick Links:

Products / Services

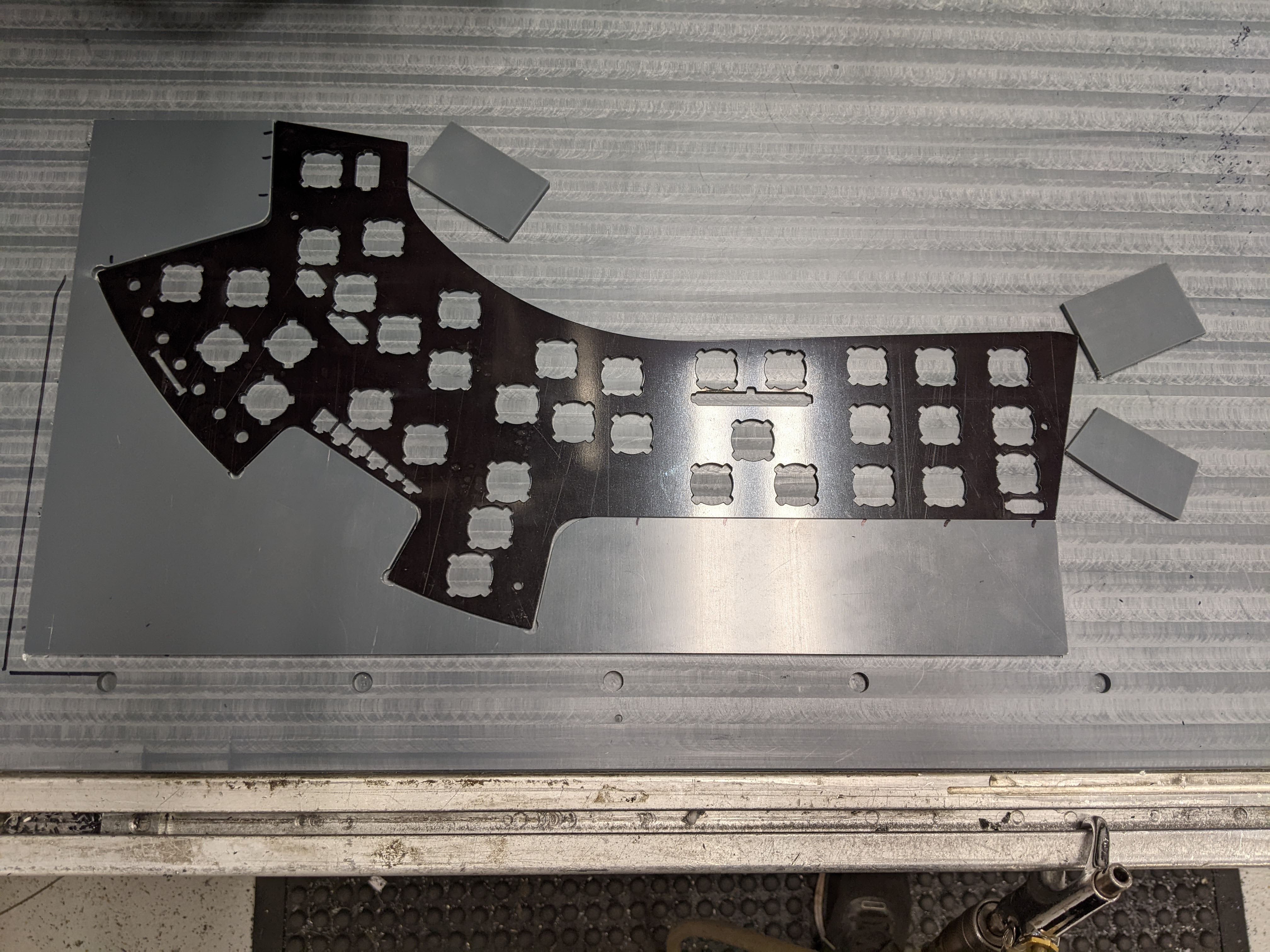

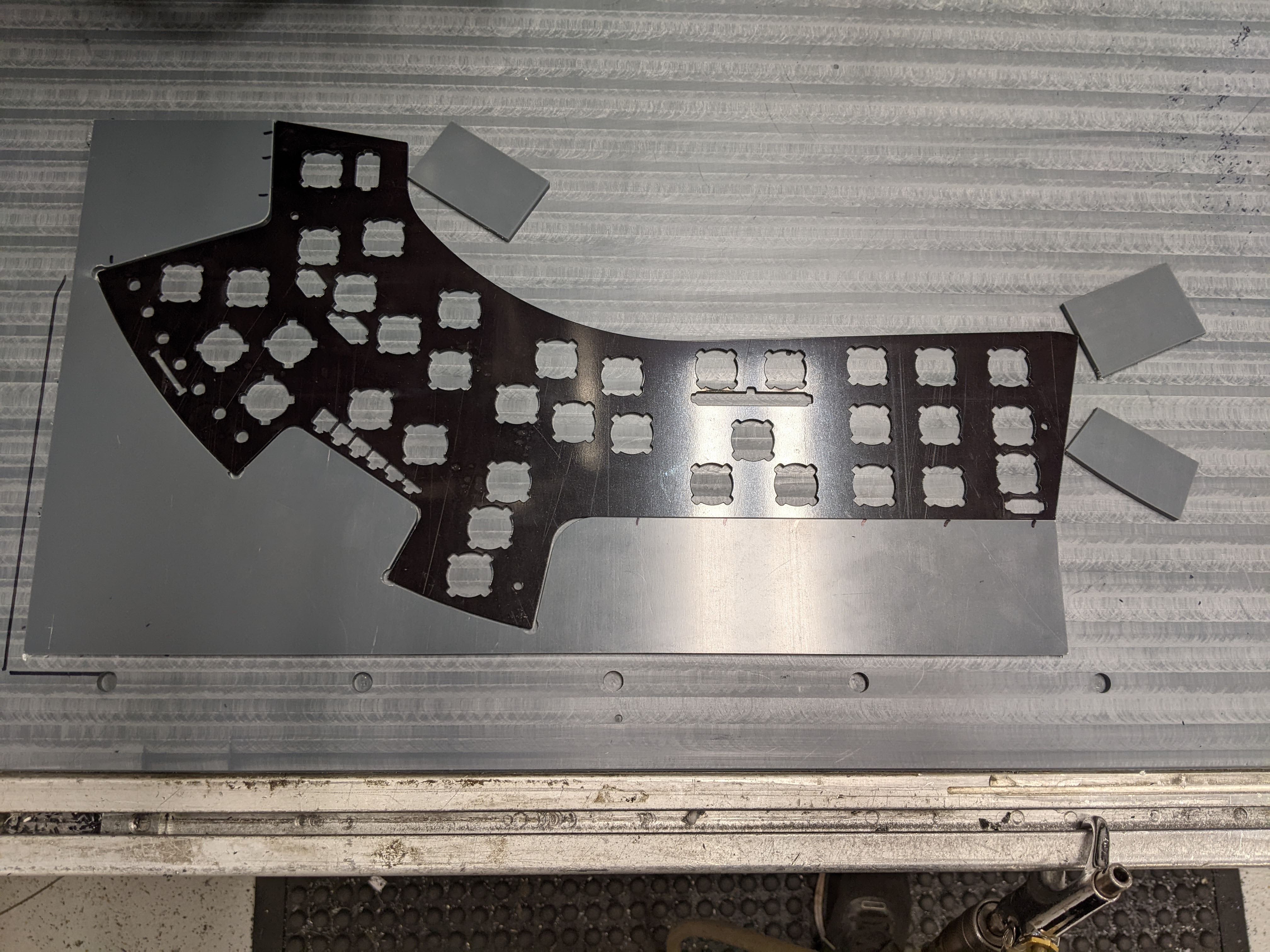

CNC Milling & Routing

CNC milling and routing is perfect for producing high quality and extremely accurate parts for either prototypes or the complete production parts. It is also perfect for adding details such as holes, cutouts and recesses to vacuum formings and laser cut parts.

We have 3 CNC routers and have the ability to machine up to 3000x1500x100mm as well as being able to machine “off-bed”.

CNC Turning

Plastic Fabrication

Plastics can be formed, welded and bent in much the same way as steels. These fabricating techniques allow designers to take advantage of plastic’s properties of corrosive resistance, finish, weight, Wi-Fi compatibility strength and clarity. We can also flame polish or buff suitable materials to enhance surface finish.

When it comes to joining plastic parts together, we can either use:-

Chemical bond − This provides excellent mechanical strength by “melting” the surfaces being bonded to create one cohesive part. MEK or methylene chloride are some of the more common chemicals used for bonding in this process. Ideal for clear materials such as acrylic and polycarbonate as well as ABS and HIPS

Structural bond − This process is often undertaken using a 2 part adhesive. Structural adhesive come in many different types for specific uses, enabling the bonding of many different plastics.

Welding − Welding uses a filler rod, similar to metal welding. The heat then melts the filler rod into the 2 plastic surfaces to be joined. Ideal for PVC, polypropylene, and polyethylene.

Mechanical fixings − These can be metal or plastic off-the-shelf fastenings. These can be simple nuts and bolts or screws into metal inserts which provide greater thread strength

Our understanding of the vast array of qualities available in modern plastics and the different processing techniques allows us to provide invaluable advice and find the most suitable and cost effective technique for your project. We actively source suitable environmentally-friendly options using recycled and recyclable plastics where possible.

Vacuum Forming & Moulding

Vacuum forming of plastics can be an extremely cost effective way of overcoming a number of problems that face designers, with tooling for short runs easily justified. We produce our own tooling , which means our turnaround times are short, and we can supply prototypes to production runs in a variety of thermoplastic materials.

We can advise on materials and how this process may benefit your requirement from concept through to production.

We have the ability to form sizes from 100 x 100mm to 2m x 1.2m.

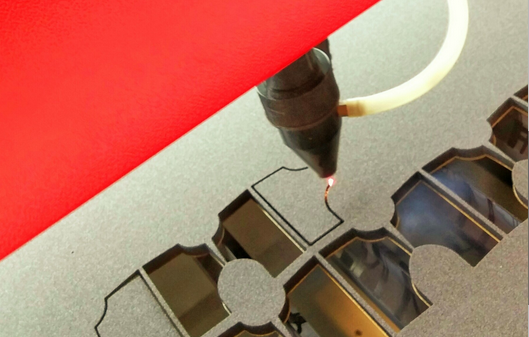

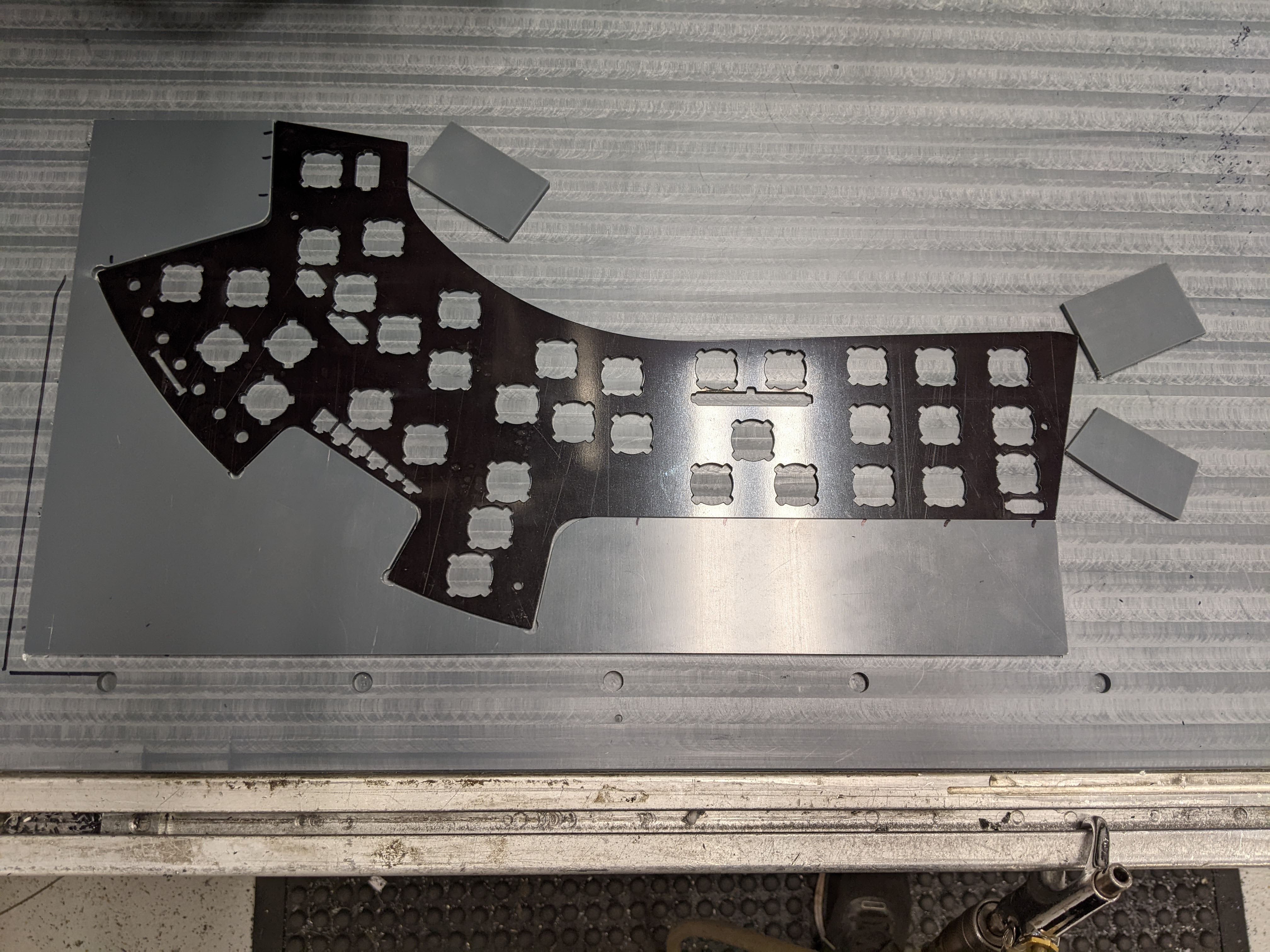

Laser Cutting

We have 2 150wattt CO2 lasers with the ability to cut up to 2500 x 1500mm sheets.

Prototyping & Tooling

3D Printing

Enclosures

About us

Bray Plastics Ltd is a team of skilled engineers specialising in custom plastic fabrication.

With over 30 years of experience in developing and manufacturing products and custom parts for a diverse range of clients, we offer a comprehensive and expert "turnkey" service. From design and prototyping to low-medium volume production and final assembly, we are equipped to deliver the ideal solution for your needs.

Our Services Include:

CNC Turning

Precision is assured. Our expertise enables us to successfully execute custom, complex projects for demanding environments. We have the ability to turn up to 300mm diameter x 1.5m long.

CNC Milling & Routing

Expertly engineered components in a variety of plastics and metals with quick turnaround times. We have 3 CNC routers and have the ability to machine up to 3000x1500x100mm as well as being able to machine “off-bed”.

Fabrication

Specialists in diverse plastic fabrication methods, including machining, routing, welding, with extensive expertise in material specifications, solvent and structural adhesives, and mechanical joining techniques.

Vacuum Forming

This cost-effective forming technique is suitable for both small and large components and is widely used across various industries. We have the ability to form sizes from 100 x 100mm to 2m x 1.2m.

Prototyping & Tooling

Our production equipment and expertise allow us to provide prototyping services ranging from single components to complete assemblies.

3D Printing

We have 3 print options; SLA (resin), MJF (Multi-jet fusion) or SLS (powder).

Laser Cutting

We have 2 150wattt CO2 lasers with the ability to cut up to 2500 x 1500mm sheets.

Enclosures

We machine both injection-moulded and cast aluminium enclosures, and also design, manufacture, source, and modify custom enclosures.

We provide a wide range of services, covering every stage of the production process. We offer bespoke machining and specialist plastic fabrications. Using our knowledge and expertise, working with you every step of the way, to find the best solutions.

We consistently assess the environmental impact of our projects by actively sourcing recycled and recyclable materials and promoting the circular economy.

Reach out to us today at 01525 219100 to discuss your project and discover how we can help you find the ideal solution!

Images

Videos

Articles / Press Releases

Reviews

Trade Associations