Company details for:

C&D (Sheet Metal) Engineering Ltd

Quick Links:

Products / Services

Powder coating

Products are finished in our automated powder coating paint plant where epoxy powder is applied to all surfaces to give a robust wear resistant finish. Our final assembly area is fully equipped to finish/pack the products/goods ready for despatch.

Metal Forming

The RAS bending centres produce a finished component automatically. These machines produce up, down, radius and partial bends all to the highest accuracy. With laser technology to measure each blank, the panels are produced with unerring constancy. Automatic tool changing enables us to provide a huge variation of bends to suit a multitude of applications. We have 10 CNC press brakes bending up to 3 metre long steel including the latest Amada HFE3i, 7 Axis machine.

Welding Services

We have a full range of welding facilities. These include TIG - MIG - Spot welding and cleaning and polishing in both mild and stainless steel, using jigs to maintain high accuracy. We have a Panasonic robot welding cell capable of producing high quality stainless steel enclosures which incorporates an automatic rotating table to speed up welding and loading times.

Sheetmetal Punching

CD Sheetmetal have the latest Amada punching cell capable of processing 6 ton of material automatically with load and unload (part stacking and scrap removal) with speeds of up to 860 hits per minute and this machine has a 58 station turret. We also have 3 CNC controlled “stand alone” punching machines.

Office Furniture

We design and manufacture an extensive range of quality office furniture, both standard and bespoke units, comprising of double door cupboards, side opening tambours, side filers and personal lockers. These products have been supplied to office dealers and blue chip companies throughout the UK.

All units are fully welded for a strong construction and have self levellers fitted, finished in epoxy paint for a strong durable finish.

These can all be supplied with a range of internal fitments.

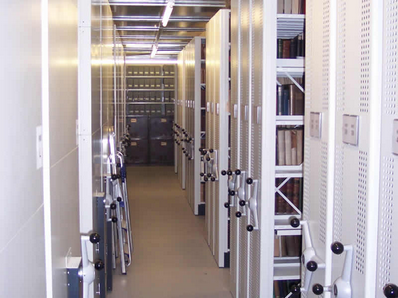

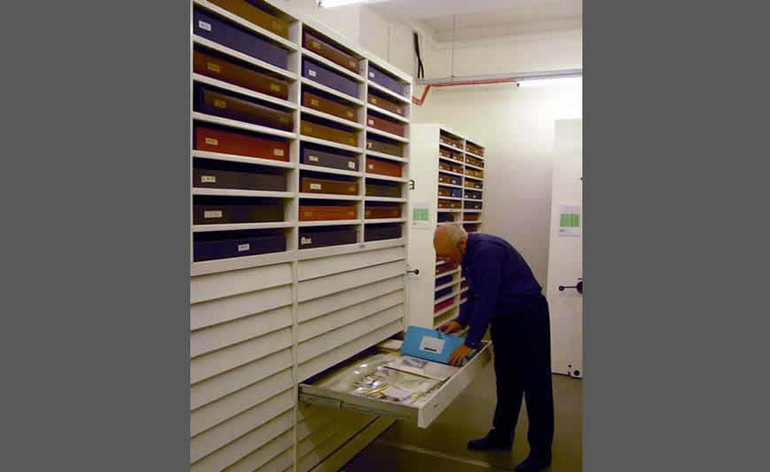

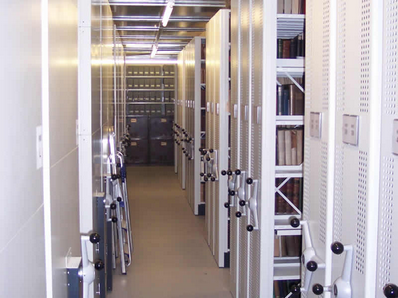

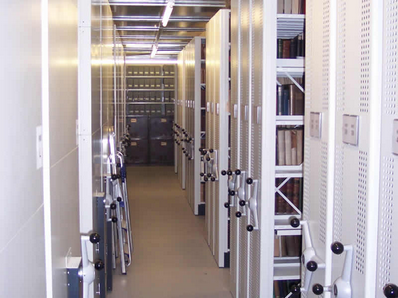

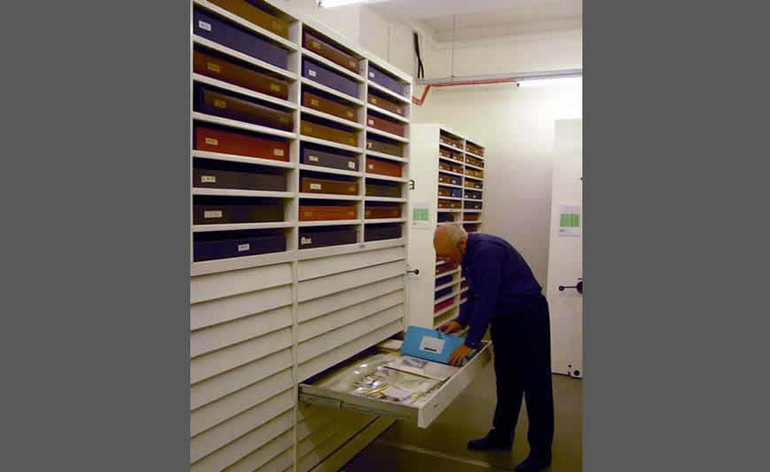

Museum Quality Cabinets & Storage Solutions

We produce a range of Museum quality cabinets and storage for all uses, including Herbarium, Entomology and Geology sample storage.

These comprise units which are fully welded and sealed against the ingress of dust and pests such as museum beetle, using inert seals such as plastizote, and finished in high quality epoxy powder paint.

We also design innovative bespoke storage solutions to meet our customer’s requirements.

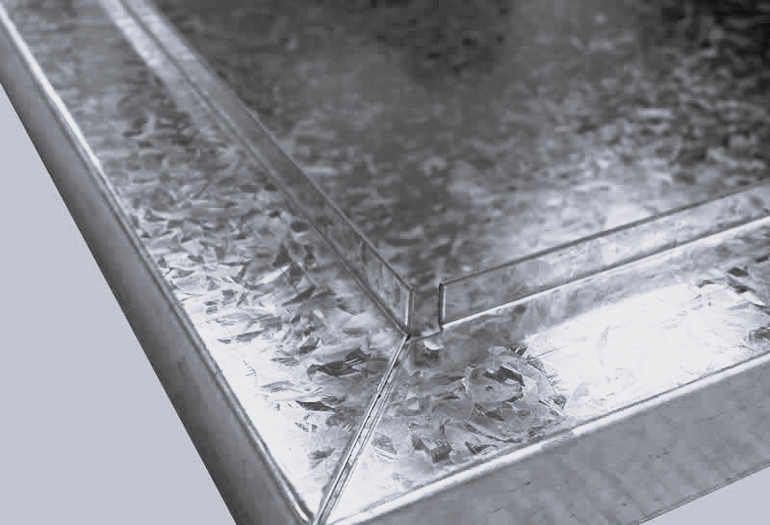

Deck Panels

With the flexible machinery we have, we can manufacture any size or style of deck panel very competitively.

With the wealth of experience in manufacturing racking solutions we will have a solution for you, this includes pallet support bars, dividers, rack protectors etc.

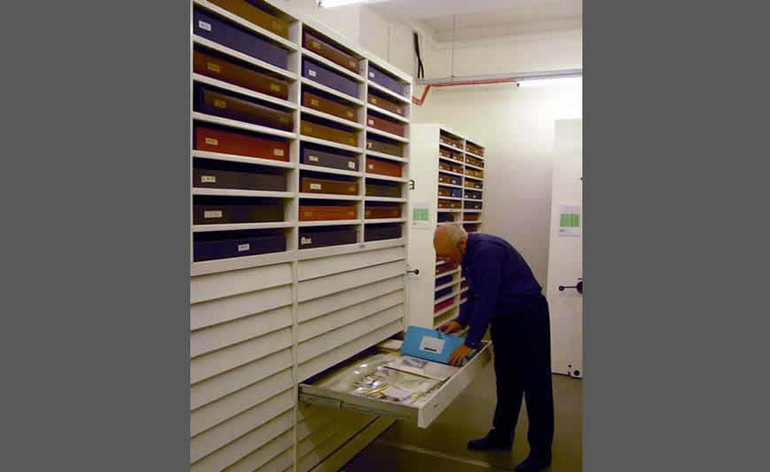

Plan Chests

We produce museum quality plan chests in various standard sizes, drawer configuration and styles. Special & bespoke units can be manufactured to order. Bespoke storage solutions can be designed & manufactured to incorporate shelves, drawers, doors etc. to suit our customer's individual requirements.

All units come with a range of different options including, deep rear hood and front flaps fitted to the drawer, this prevents drawing curl, anti-tilt and locking. We also offer a ‘drop-down’ front option of drawer, the drawer front easily rotates to just below horizontal enabling the fragile contents to be placed into the drawer without any damage to the item.

All planchest are robustly manufactured and an extended guarantee can be offered.

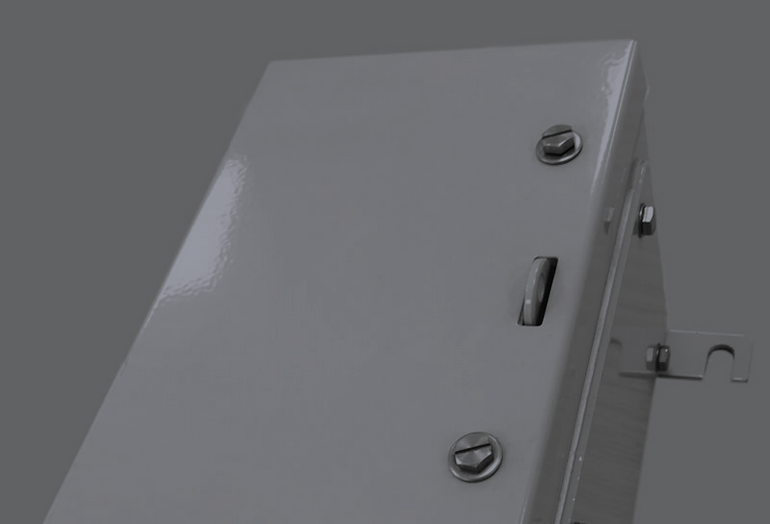

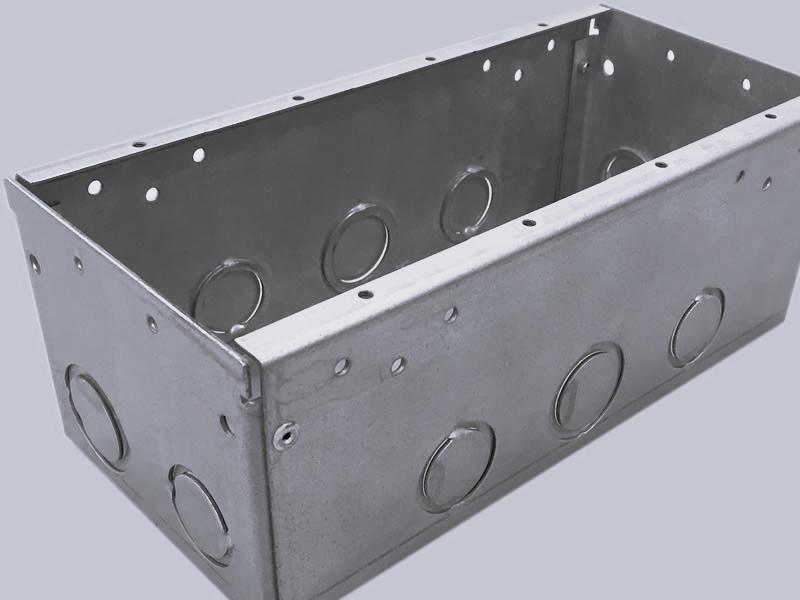

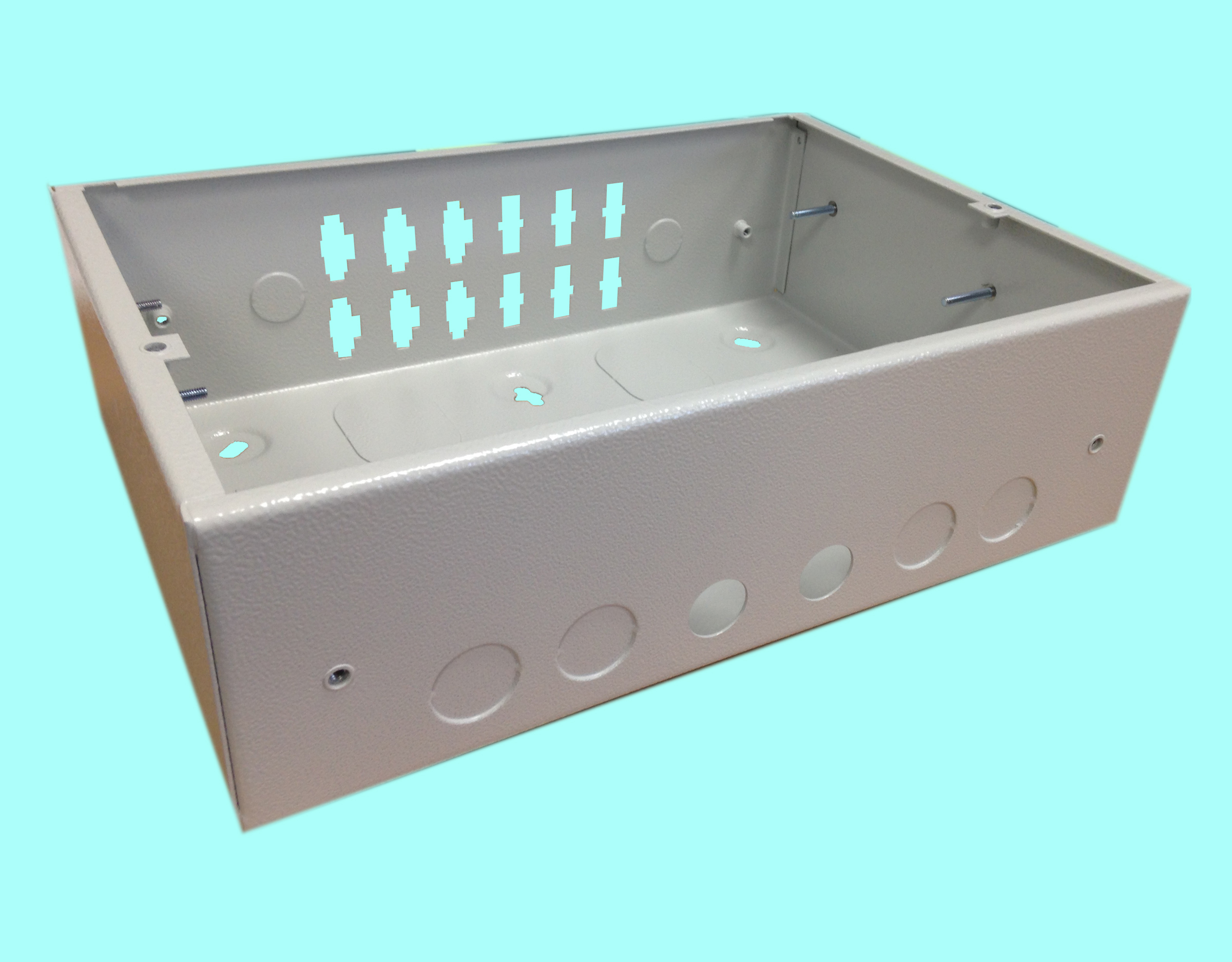

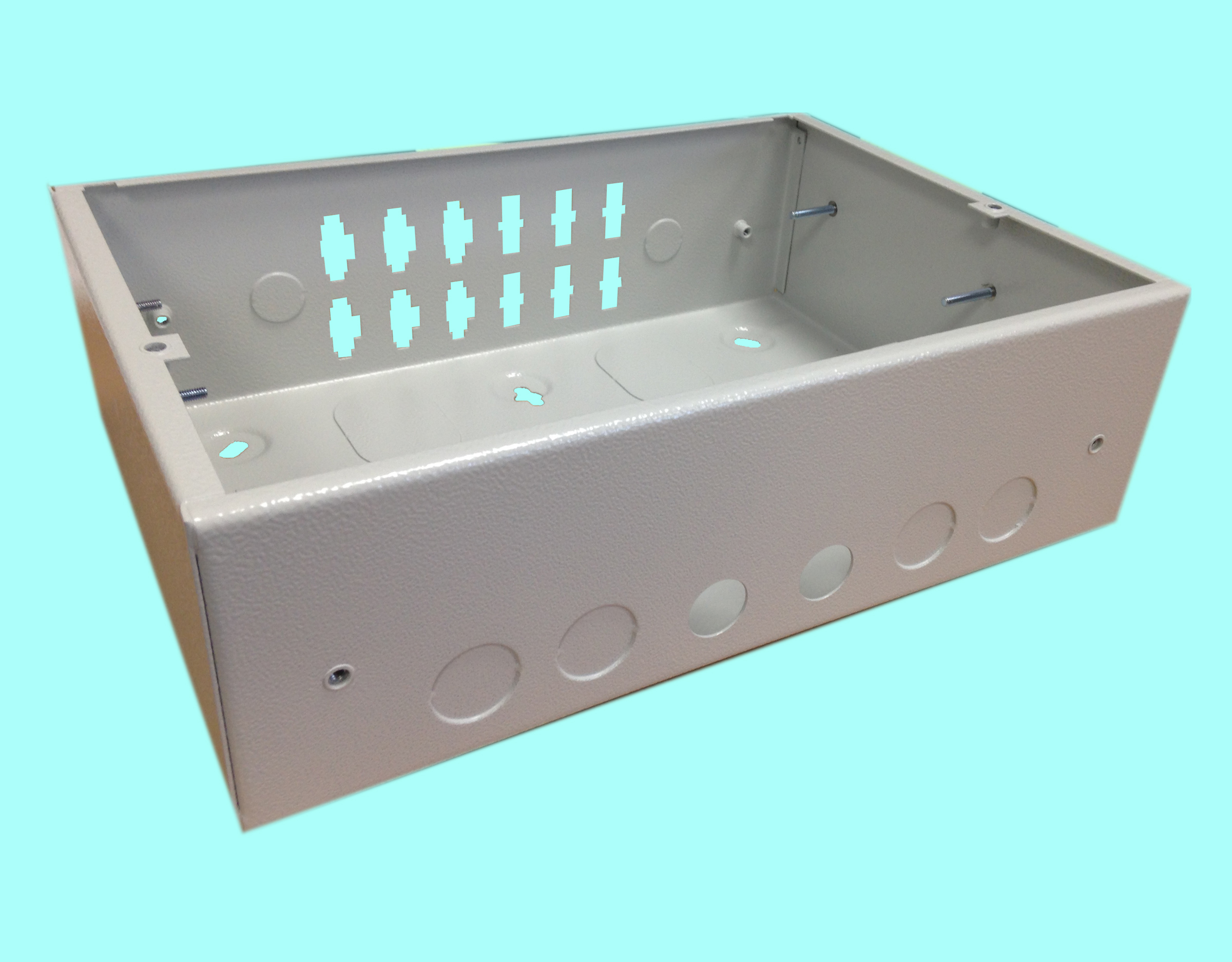

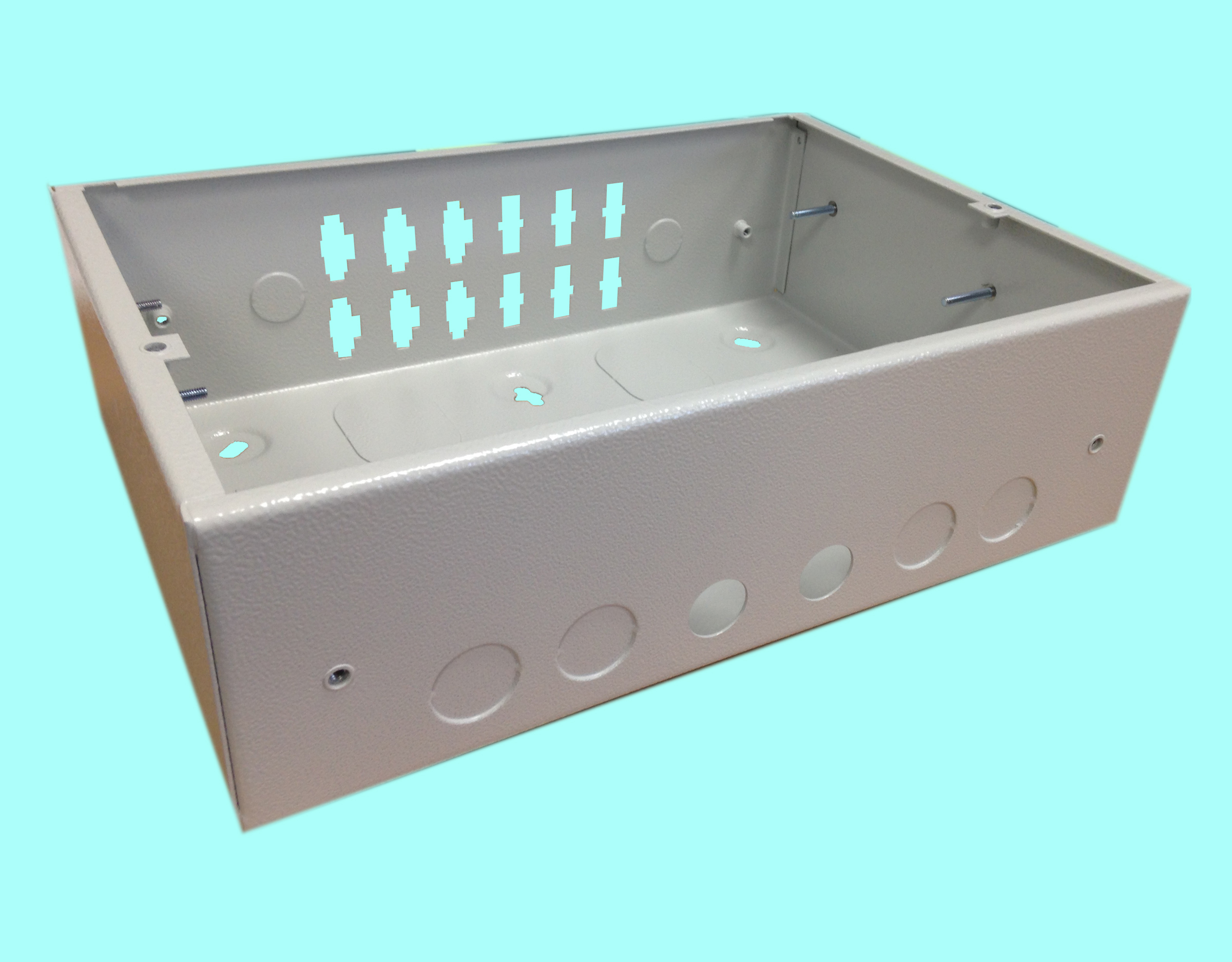

Electrical Enclosures

CDS manufacture many different styles of high quality electrical enclosures for various clients, these are used in many different applications and have a range of test levels to suit the customer requirements.

We have a wide range of tooling for a multitude of knockout sizes and special electrical inputs to suit any requirement, enclosures range in size from 114mm x 270mm x 80mm to upwards of 1800mm x 900mm x 200mm.

These are used in many industries such as Petrochemical, oil, domestic and industrial buildings.

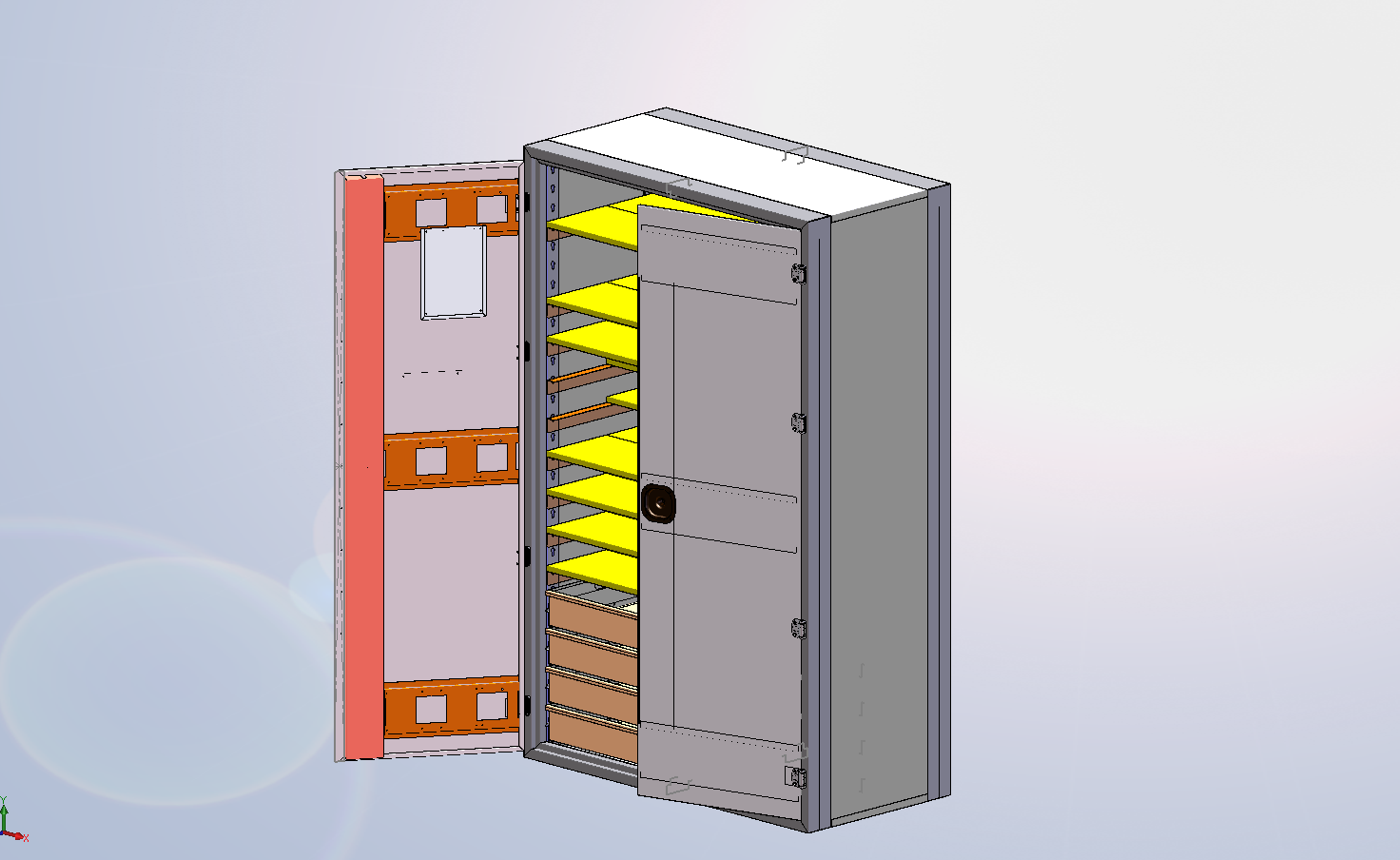

Computer aided prototyping

Computer-aided prototyping revolutionizes design by allowing us and our clients to visualize and improve on their ideas rapidly. Using software tools, our designers can build 3D models, create simulations, and test functionalities without huge material costs. This accelerates the innovation process, enabling our team to refine concepts and gather feedback, which ultimately leads to more effective and efficient solutions.

Metal work assembly

Metal work assembly refers to the process of assembling metal parts through various methods such as welding, riveting and bolting. The choice of assembly technique depends the design of the product, and the intended application.

Pressure tested stainless steel enclosures

Pressure tested stainless steel enclosures play a crucial role in protecting sensitive equipment in demanding environments. We design these enclosures to withstand extreme pressure, ensuring durability, safety, and reliability. The manufacturing process begins with high-quality stainless steel, chosen for its corrosion resistance and strength. Each enclosure undergoes rigorous pressure testing to verify its ability to resist leakage and structural failure under specified conditions.

In short, these enclosures combine robust materials with thorough quality checks, offering peace of mind for installations in harsh or hazardous settings. Their reliable performance helps keep valuable electronics safe while extending equipment lifespan.

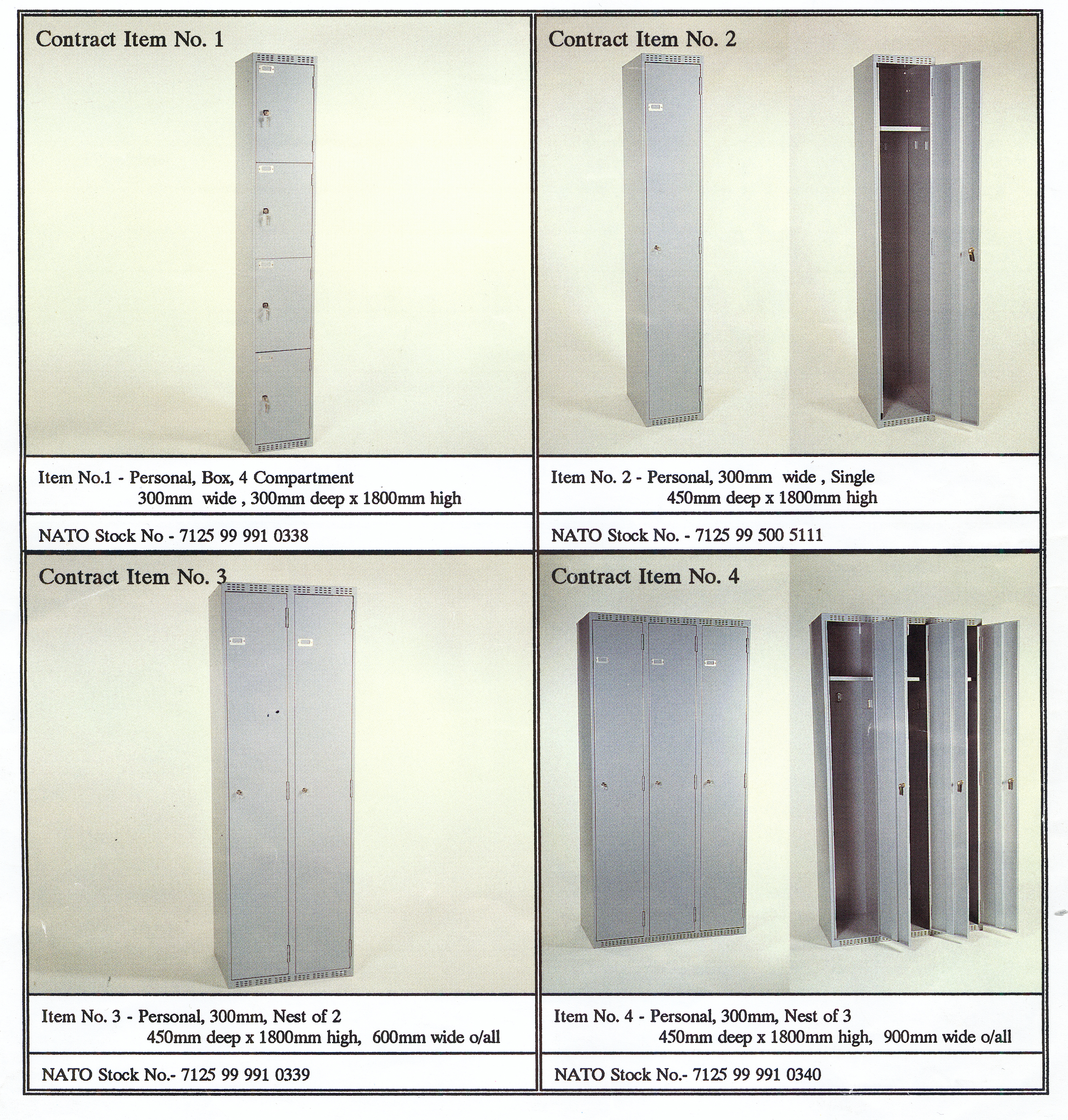

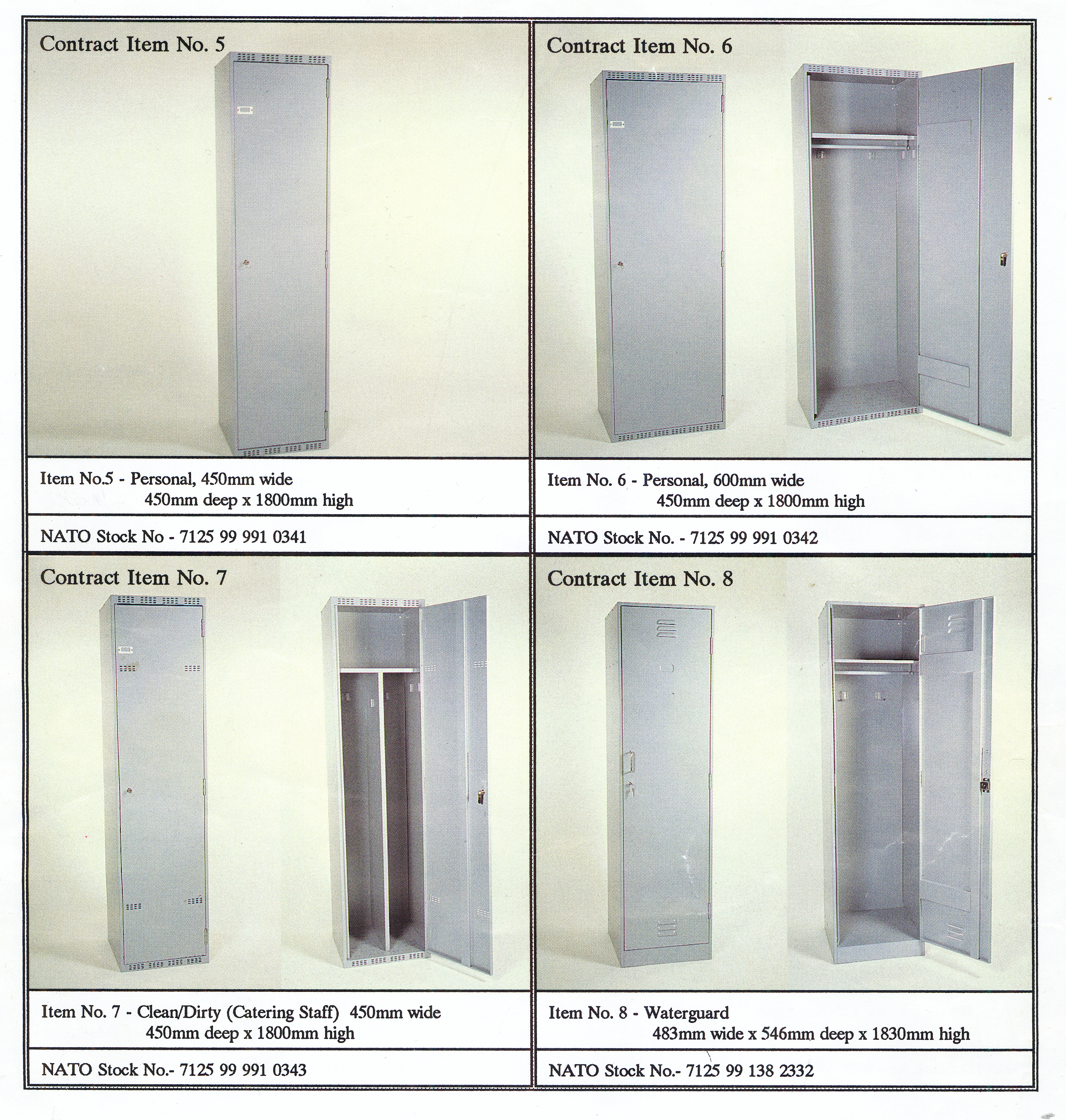

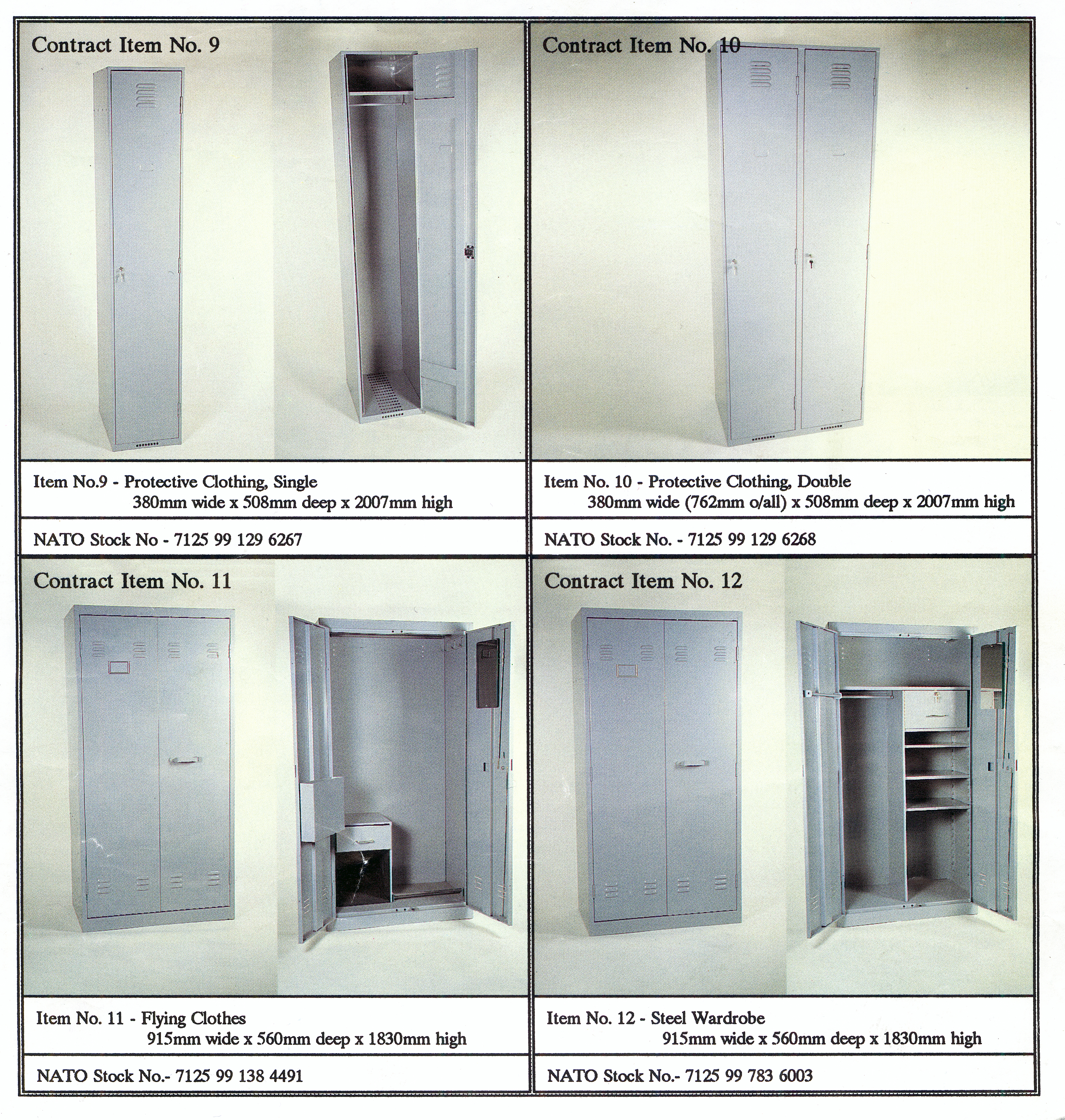

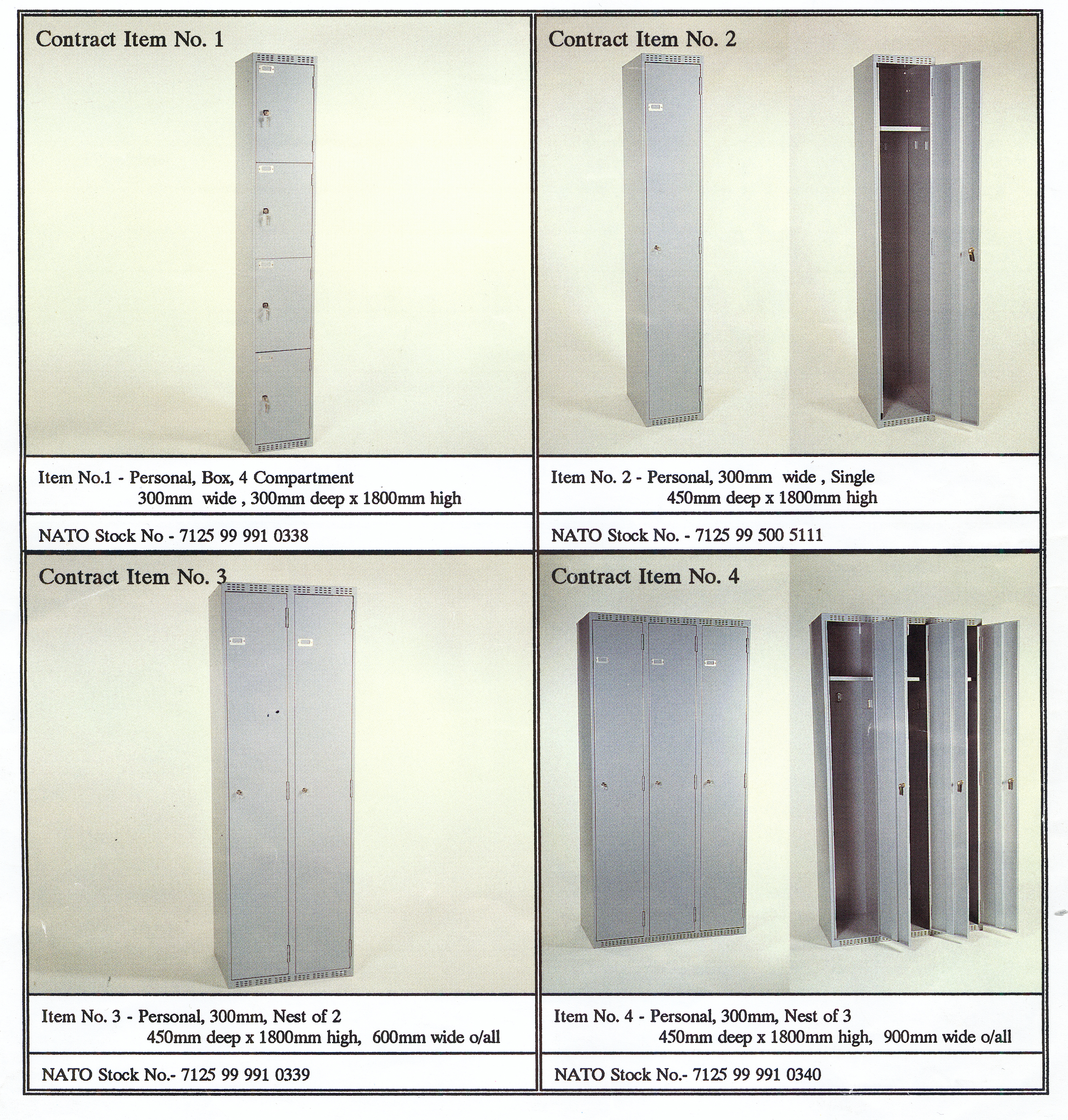

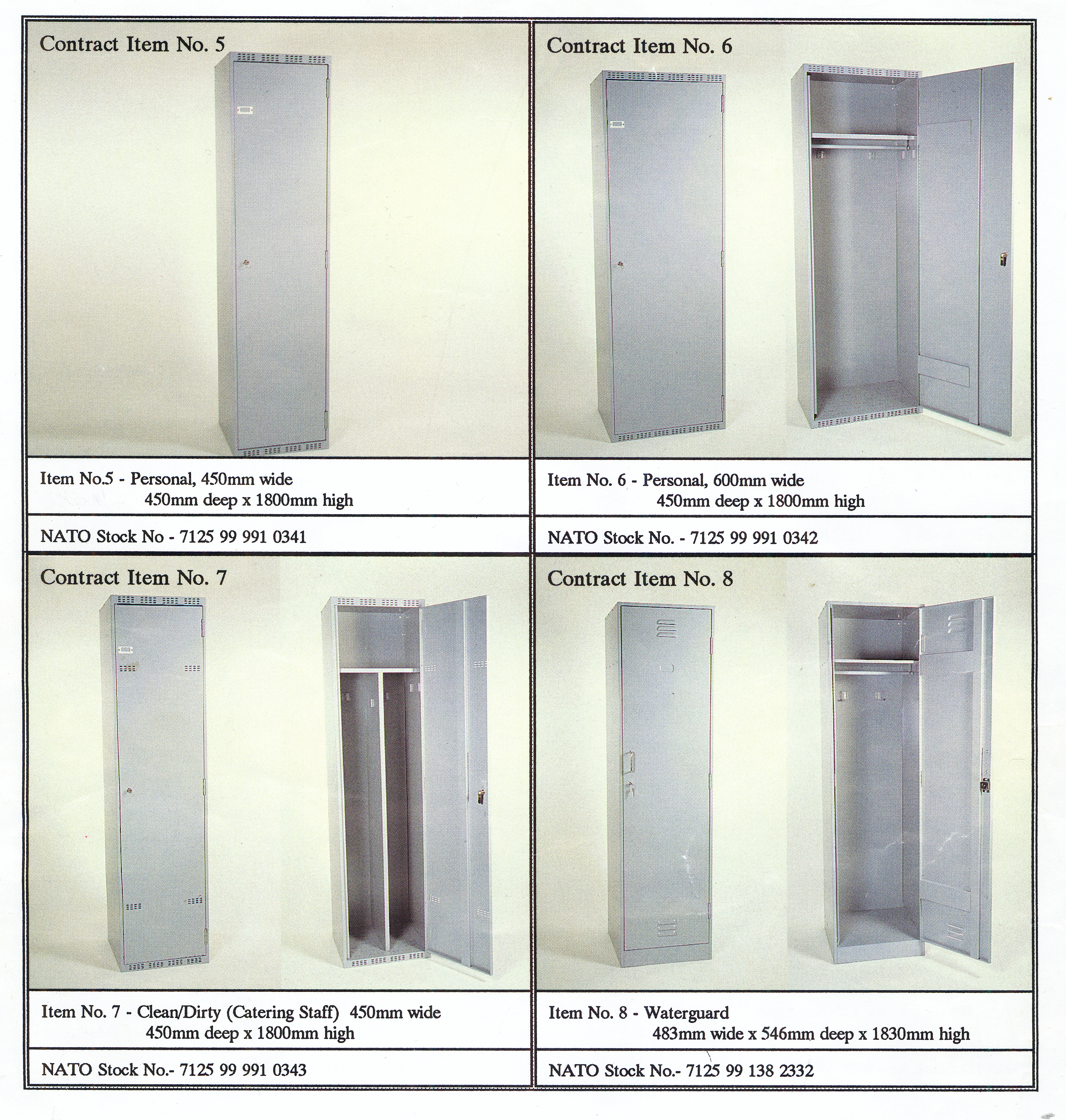

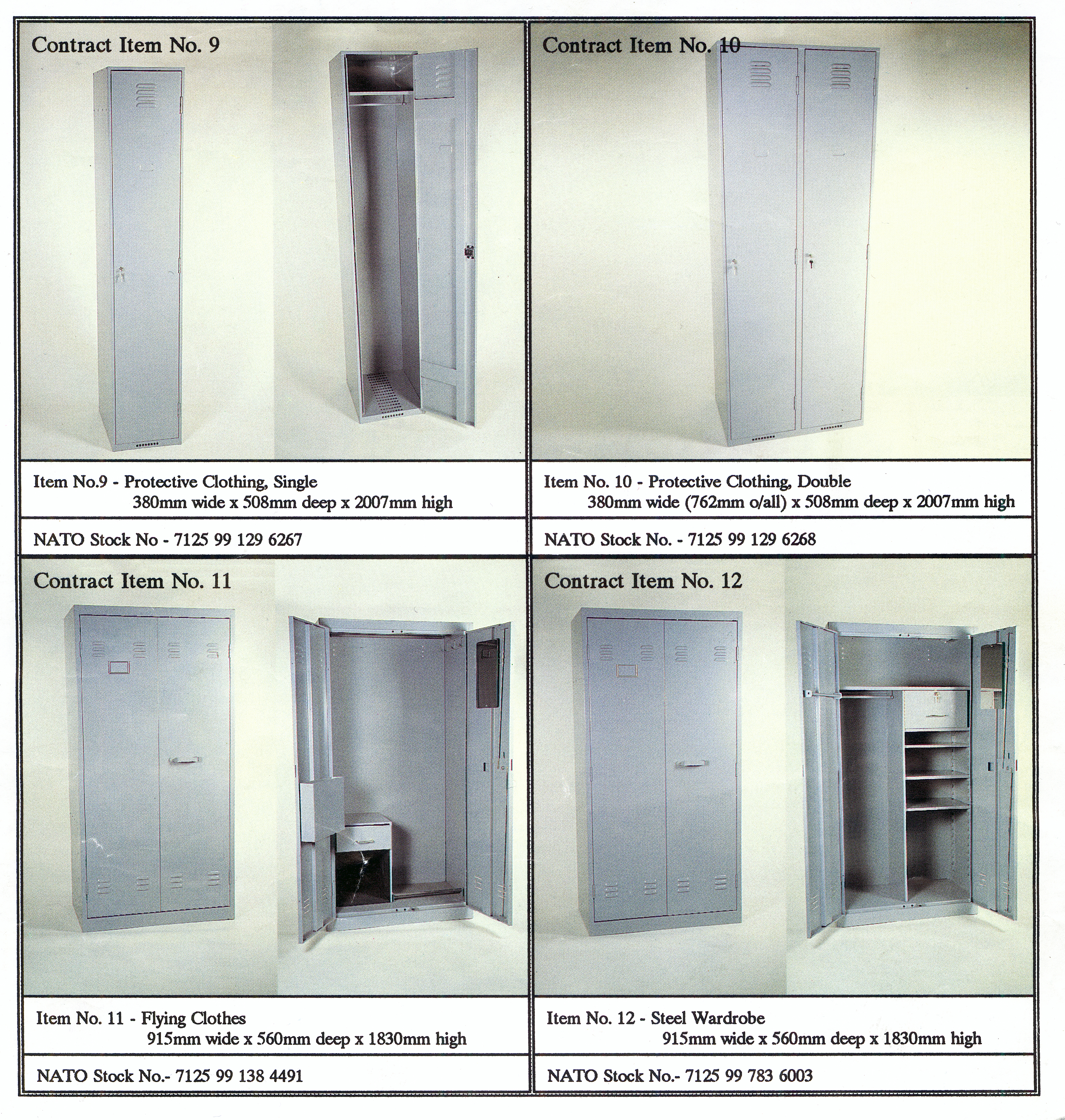

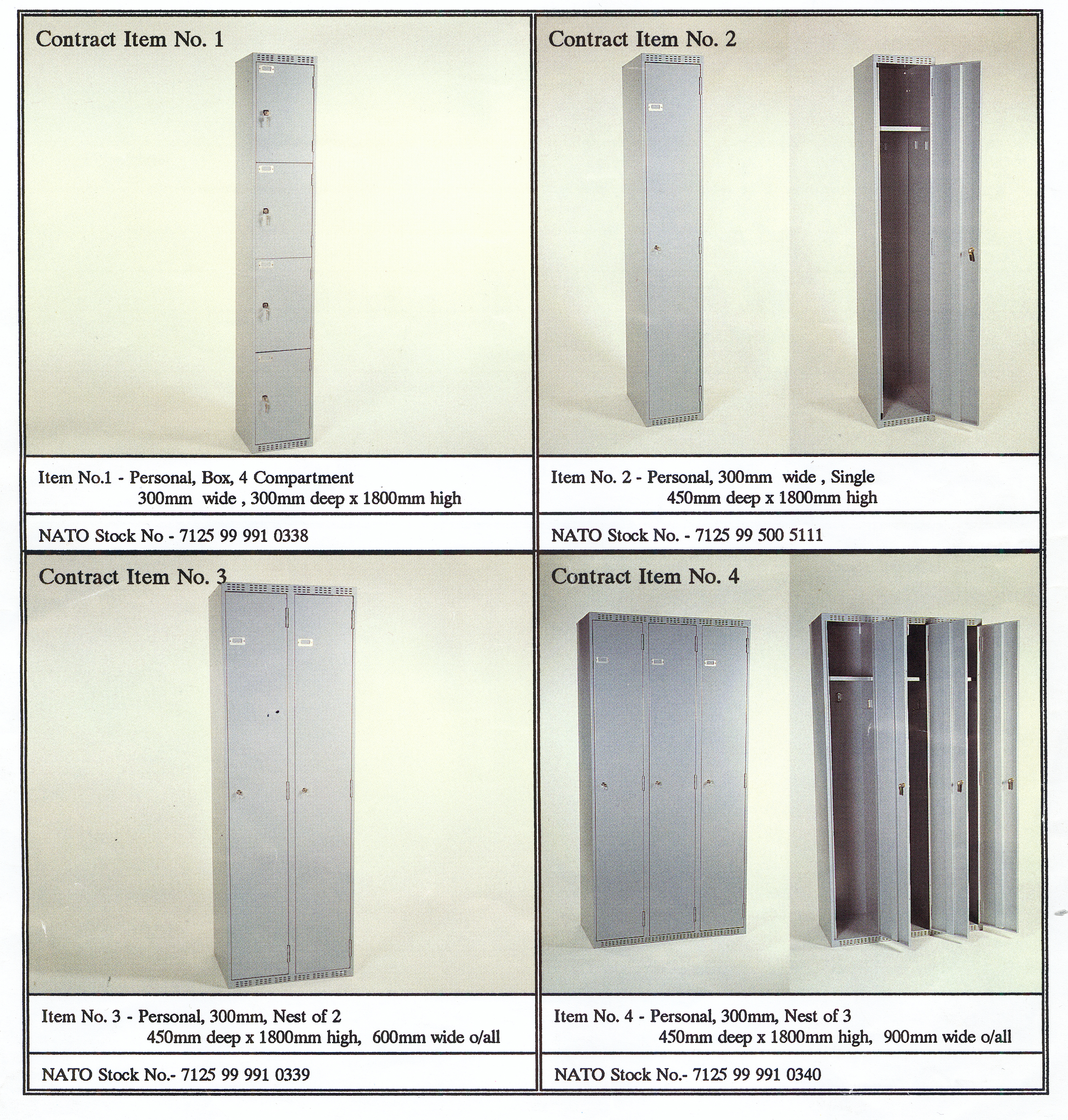

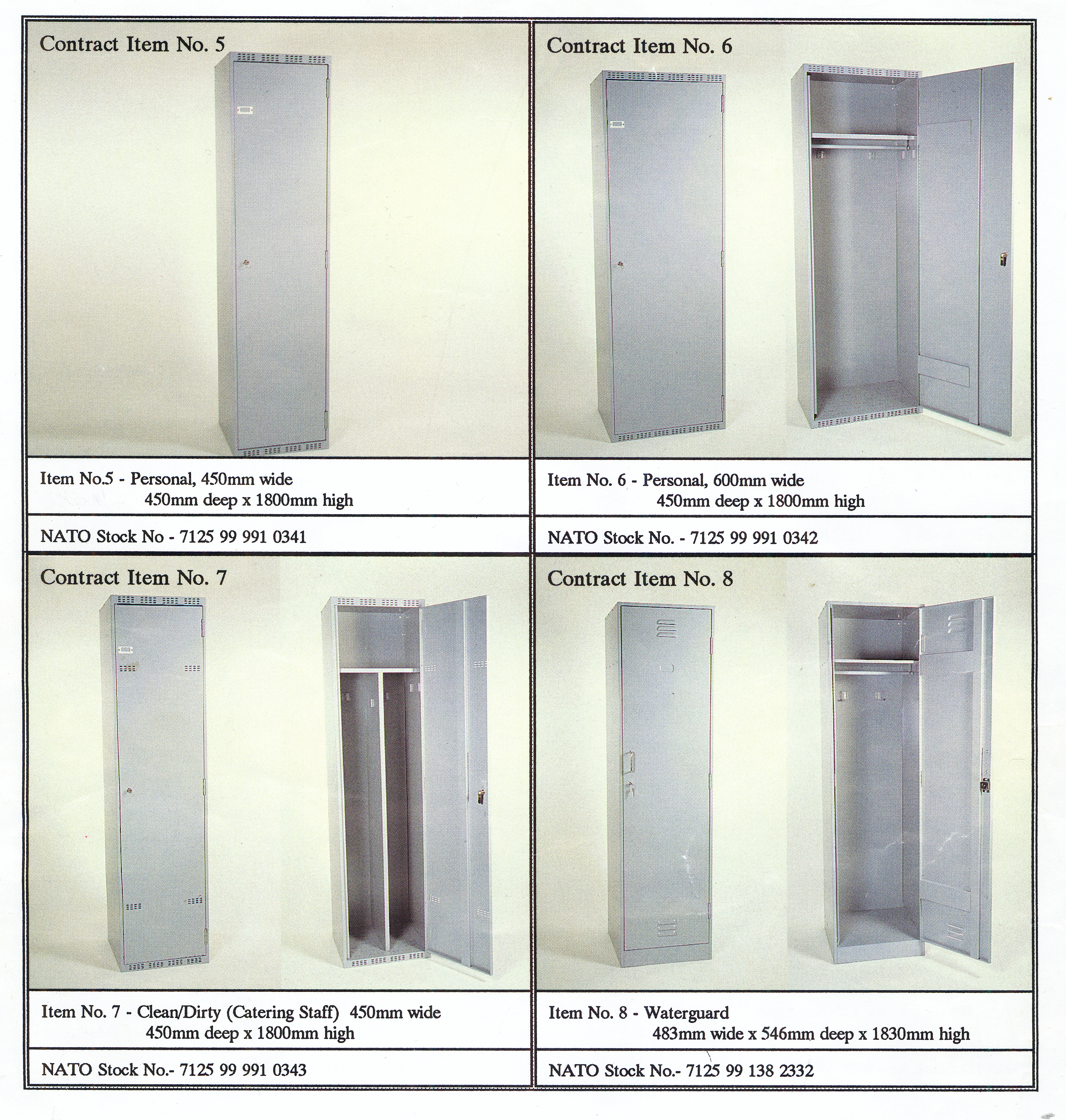

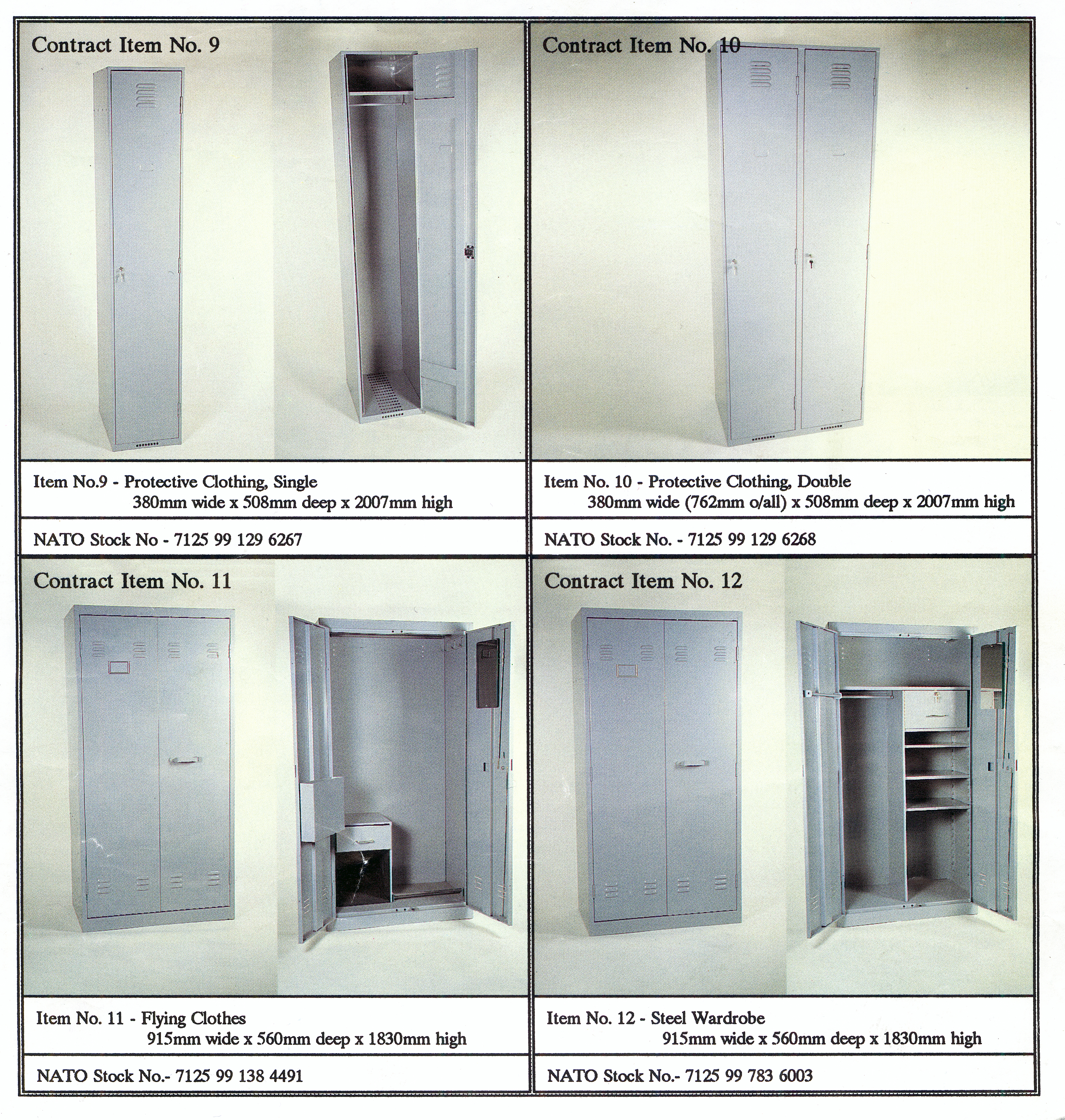

Bespoke locker solutions

We have a catalogue of bespoke lockers designed and tested, we are also able to cater these designs to your requirements, such as the shelving layout needed within.

Hand sanitiser station

Low maintenance – easy to clean

Key features: Suitable for Adults, Children and Disabled customers

50,000 shots of high-quality sanitiser fluid equating to 0.9ml per shot at 0.008p (cost).

Screen can display the message of your choice! Internet linked! Does not require mains when in Situ – 25 hours life on fully charged batteries – Mains overnight charge.

Call us on 020 8311 2056 for price and lead in time………

About us

Established in 1973 C&D (Sheet Metal) Engineering Ltd is a family-owned and operated business, with the family actively managing its daily operations.

Our company has earned a strong reputation for delivering innovative solutions tailored to customer needs, leveraging both advanced product design and a state-of-the-art manufacturing facility. A dedication to quality and punctual delivery remains central to its values.

At CDS we can manufacture any sheet metal project, including electrical components, shelving, fully assembled electrical enclosures, security cabinets, custom storage solutions for museums or bespoke office solutions.

Our Services Include:

Powder Coating Shop

Our automated powder coating plant applies epoxy powder to all surfaces, ensuring a durable, wear-resistant finish. The final assembly area is fully equipped to complete and package products, preparing them for dispatch.

Metal Forming

Our RAS bending centres automate component production with precision, executing up, down, radius, and partial bends with exceptional accuracy. Laser technology ensures consistency, while automatic tool changes allow for a wide range of bends see it in action at www.ras-online.de/en/products/bending/multibend-center/. We operate 10 CNC-controlled press brakes, including the advanced Amada HFE3i 7-Axis, capable of bending up to 3 metre material.

Welding Services

Our welding capabilities include TIG, MIG, and spot welding, along with cleaning and polishing for mild and stainless steel, ensuring precision with jig-based accuracy. We also utilise a Panasonic robotic welding cell with an automatic rotating table, enhancing efficiency and speeding up the welding and loading process.

Sheetmetal Punching

C&D (Sheet Metal) operates a state-of-the-art Amada punching cell, efficiently processing up to 6 tons of material with automated loading, unloading, part stacking, and scrap removal at speeds of up to 860 hits per minute. Additionally, we have three standalone CNC-controlled punching machines for enhanced precision and versatility.

Our 35,000-square-foot facility employs advanced technology and an integrated CAD/CAM system, enabling smooth production from start to finish. With a focus on quality and on-time delivery, we produce a wide variety of products, including racking, shelving, brackets, electrical enclosures, security cabinets, and custom storage solutions for museums and educational institutions.

Our mission at CDS is to define the sheet metal industry through innovation, precision, and unparalleled service. We are dedicated to providing superior quality products and solutions that exceed our clients' expectations, while fostering a collaborative and sustainable environment for our employees and the communities we serve.

We aim to be the trusted partner of choice for all your sheet metal fabrication and installation needs, continually pushing the boundaries of design, engineering, and manufacturing. We are committed to investing in our people, machinery and techniques, ensuring that our work is not only of exceptional quality but also cost-effective and environmentally responsible.

Our core values of integrity, teamwork, and customer satisfaction are reflected in every project we undertake. We strive to build lasting relationships with our clients by understanding their unique requirements and delivering tailored solutions that enhance their businesses and contribute to their success.

We are driven by a deep commitment to sustainable practices and our environmental responsibility. We are dedicated to minimising our ecological footprint and promoting the responsible use of resources in all aspects of our operations, from material selection to manufacturing processes and beyond.

At CDS, we are a team of passionate professionals dedicated to shaping the future of metal fabrication. Working hard at every stage of the manufacturing process for the best possible results.

If you have a project you'd like to discuss in detail, give us a call now!

Images

Videos

Articles / Press Releases

Brochures

Reviews

Trade Associations